CNC Routing & Lasering Custom Corian House Number Signs

I’ve covered a lot of different applications that we’ve used Corian for and making custom Corian house number signs is the one we’ll focus on today at CNCROi.com!

Having TOTAL design freedom isn’t something to be taken lightly, it’s an incredible opportunity for YOU, YOUR company and YOUR clients that CNCROi.com provides to you! With us, you are not stuck to doing things one way, we can go as crazy as your budget allows or as conservative as your clients wish. At least with us, this is an option!

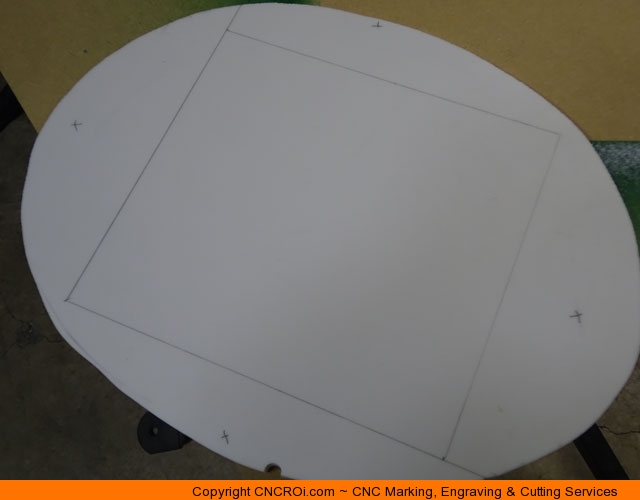

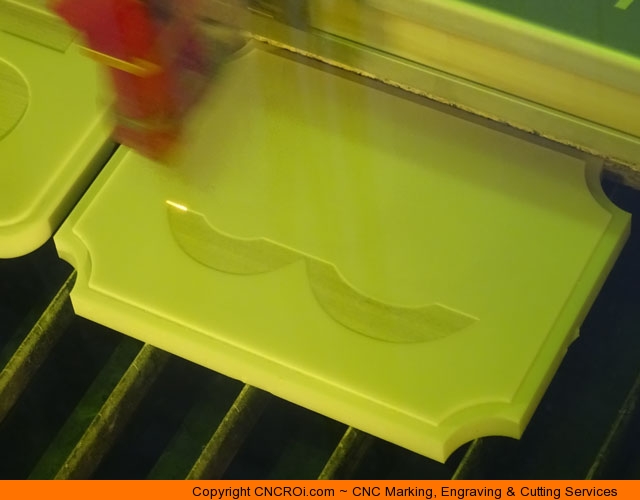

In this case, we used a scrap piece of white Corian and I outlined using a pencil (hard to see laser references on white using photography for this blog) where the two sets of custom Corian house numbers would be located.

This outline is important for two reasons, first, to make sure that we are using the most material possible (thus producing the least amount of scrap) from this piece of Corian and secondly, to make sure our X and Y are square for the CNC router. If it isn’t square, it means we may go over the edge or cut through something that isn’t intended.

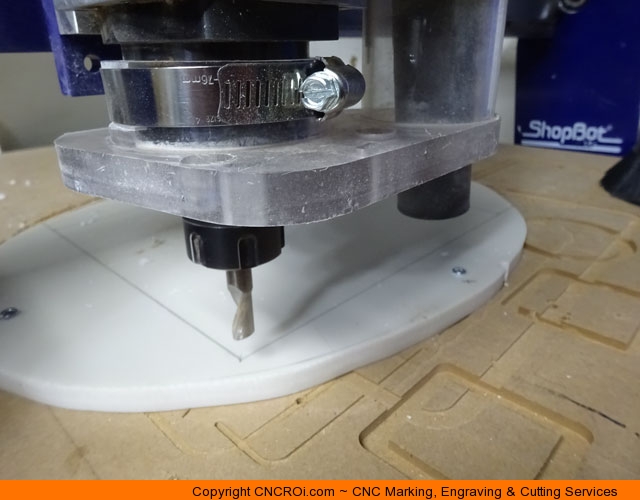

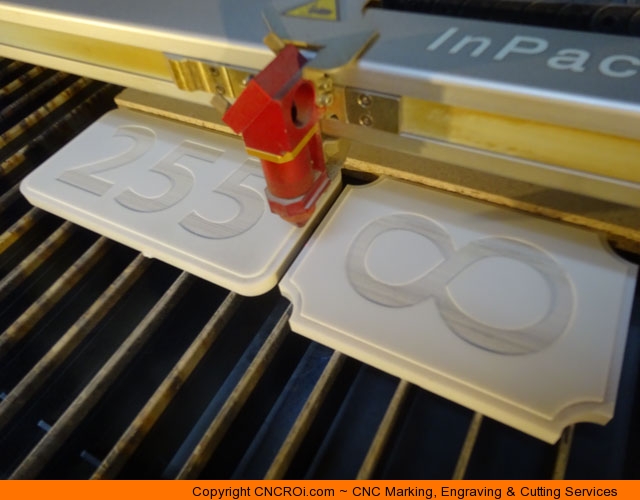

Our industrial CNC router does quick work of this white Corian, it’s a ShopBot Desktop and shortly, we will be expanding our CNC router capabilities as well with a full sheet machine. For now, this is more than fine for the tasks we do in our shop 90% of the time using Corian.

I wanted to introduce a slight “lip” along the top so with a little extra programming, this is created, it requires a 3 mm (1/8th) pass “on” the CNC router path and then a slight offset when cutting the entire piece out.

The process is seamless and although only one bit (the same) was used for these two custom-house number signs, it shows you the flexibility we can offer you. Of course, there are hundreds of different bit profiles to choose from, but we’ve found keeping things simple to be the most cost-effective and efficient way forward on Corian.

The tabs are in the Corian to prevent the piece from getting loose within the piece of scrap, this is important because if it gets loose, it will damage the surface and edge of the Corian. These tabs are sanded off after production using a variety of methods.

The process behind these custom-house numbers is almost identical to the one we use for custom Corian cutting boards, custom Corian signage of all kinds and custom Corian coasters. Having two sets of complimentary CNC machines (router and laser) allows us to produce the optimal result for your application in-house.

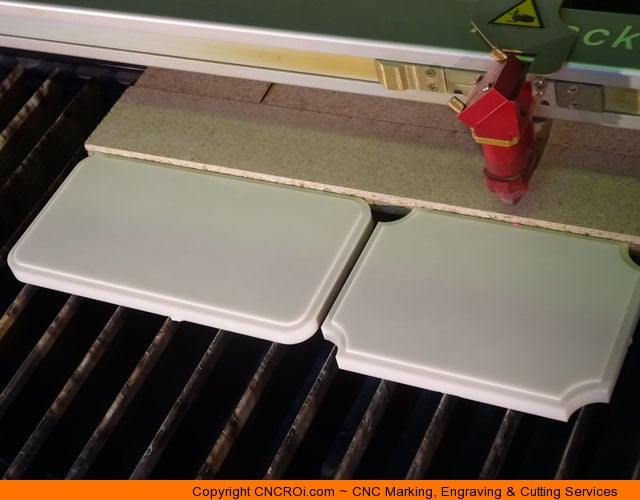

The two pieces of custom Corian cut by our industrial CNC router is now done, the next step is to break them out of their spaces, sand the edge and stick them in the laser to put the numbers on them.

Making these entirely in house has a number of advantages, the biggest, for our clients, is that we can honor NDAs which means we are the factory they don’t have so they can concentrate on offering incredibly different products to their clients without having to worry about supply and a drop in quality which often happens with overseas production.

CNCROi.com is also able to offer in-demand production and design services, which means your sales people can concentrate on sales and marketing without having to worry about quality control or being told “no, that isn’t possible”. For instance, if a customer says they want one of these signs done in Cherry instead of Corian or black Corian with white paint filling, that is no problem! That’s an incredible capability and freedom we offer!

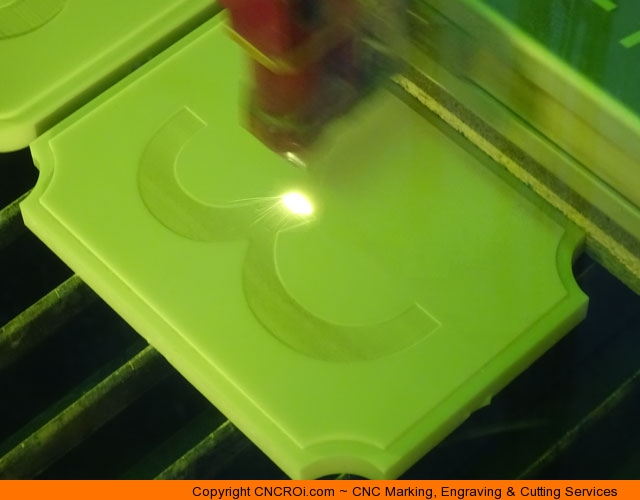

Our other industrial CNC laser, our Austrian wide-format Speedy 400 flexx, does quick work of engraving INTO the Corian. Although we could technically do the entire piece in the laser, its more efficient and produces better results to split the job across two machines. Yes, we could profile this using the laser but the CNC router is so much faster and produces a nice polished edge at the same time which means no sanding by us after production!

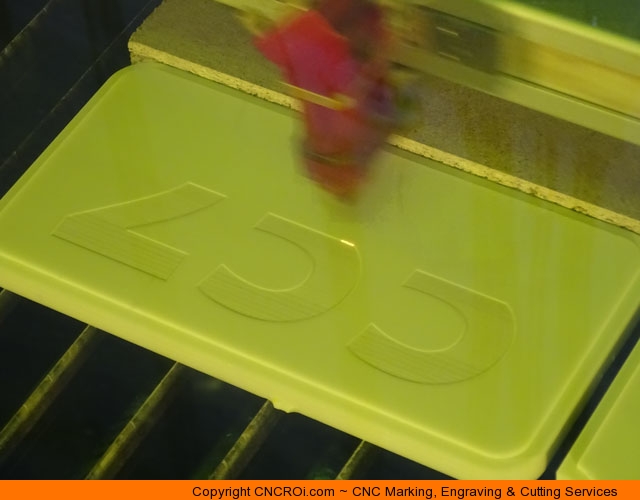

The depth we go into the Corian to produce these custom house numbers isn’t very much as it isn’t needed, they will be paint filled (black in this case) to provide the contrast after the laser is done engraving into the Corian.

The reason why we use our laser for the engraving instead of the router (in this case) is because we wanted sharp numbers and high-resolution. With a CNC router, you are limited by the size of your bit (which is round) so the sharp corners inside the “5” would be a little rounded. Some customers want this, others don’t… at least we can offer you the choice!

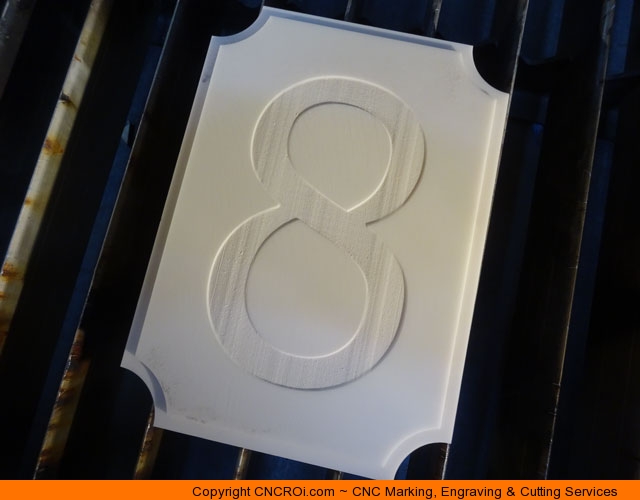

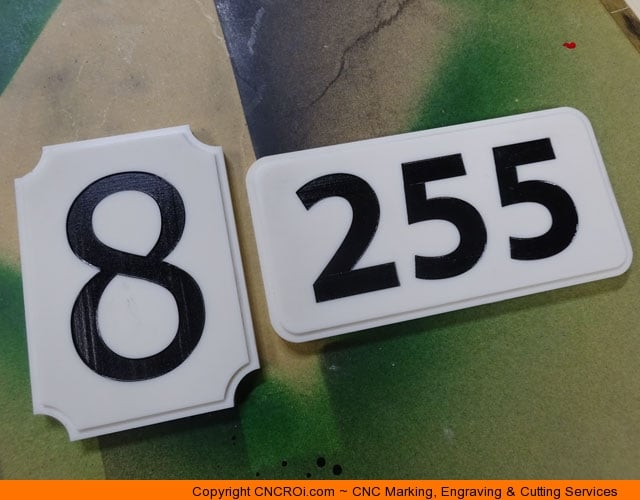

These are two very beautiful custom Corian house number signs, there are over 120 color options with the Corian alone and paint filling has even more! So, if you wanted the Corian to be RED and the paint filling yellow in the shape of a clown, yes, we can do that!

We are also able to do crazy things like wood inlays, so if you wanted the “2” to be red acrylic, that’s again, NO PROBLEM. Want a wood custom-house number with a V-carved profile? Yes, we can do that too. Basically, whatever you want, we can do.

Even without the paint filling these custom-house numbers look awesome, far better than what you can find in just about any store. Are they expensive? Well, they won’t ever rust, fade, crack (unless you drop it) or wear out so cost is relative. Basically, you put these on your house and they will outlast your house.

What’s especially nice about these custom paint filled Corian house numbers is that you can change the color of the paint filling as it is at depth, just spray paint another color, sand flush (rejuvenating the surface) and voila, the same sign matching an updated paint scheme for your home!

We’ve found that black paint filling with a white sign or the other way around provide the absolute best contrast when it comes to custom-house numbers. Taking things a bit further, we can apply the same approach to custom Corian cutting boards, coasters and anything else… so I hope you can see “beyond the number” when it comes to your application.

The texture is like fine sand paper, this is what makes the laser engraving so much nicer, it provides a really nice contrasting texture and color that’s tough to achieve any other way.

The “waves” you see in the Corian from the laser engraving are just slight variations in the Corian density, these are incredibly small so they really are of no concern. While the CNC router just cuts accurately across the Z axis (depth), the CNC laser works off material densities, more dense means less depth, less dense means more depth. These are a fraction of a mm so as mentioned, insignificant.

The two profiles look great! Again, these are custom to your application, and there can be as many ornamental steps as you want. CNCROi.com offers you complete creative freedom!

Looking for a passionate company that brings CUSTOM options to match your creativity? Contact CNCROi.com today!