It’s all about CNC size and clearance

Why did CNCROi.com invest in such a massive bed with huge clearance potential when, for most projects, we could have “gotten away” with something far smaller? Easy, ROI.

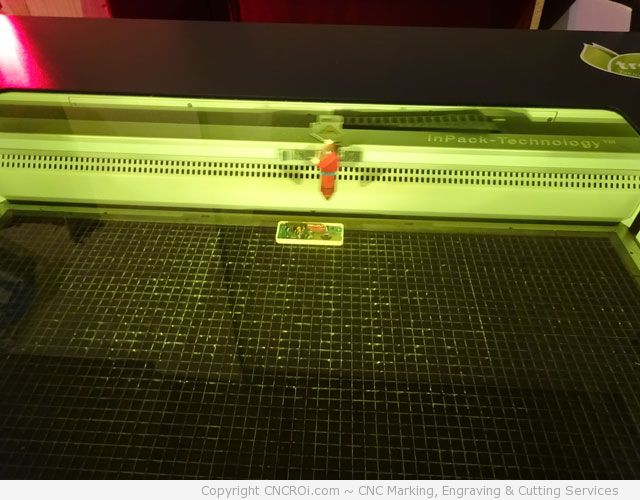

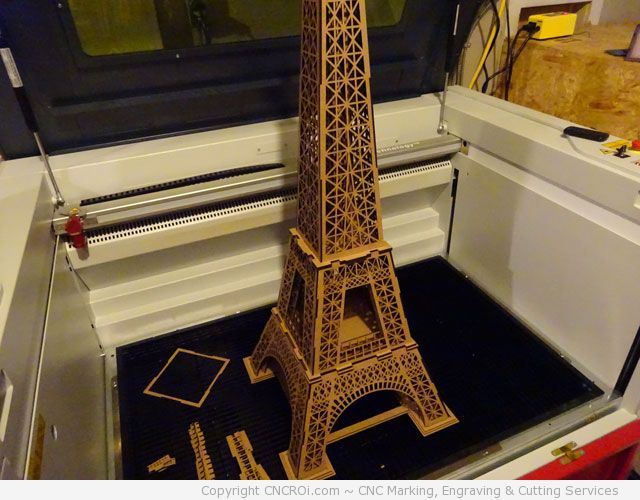

Yeah I know, the above picture seems to demonstrate a complete lack of ROI potential but it’s a great way of demonstrating just how BIG our CNC laser table actually is… and that’s not all, we can open the front and back to slide in far larger pieces… so imagine a piece that’s a meter wide and 5 meters long… no problem for us!

But bed size is only a small part of the potential we offer customers with large and awkward parts, take for instance vertical clearance.

We are nowhere near this part with the head but we are able to engrave INSIDE of it (video below). Because we invested in high quality lenses in addition to a great machine, we can take on projects that are sometimes simply impossible to accomplish any other way. Let’s say you wanted to engrave an entire car rim with the tire intact for a semi-trailer… yep, we can do that! Having a large bed size is nice, having vertical clearance is yet another bonus… but it goes even further than that!

We can drop our bed too! I met-up with a customer a few days back and they showed me their current CNC laser machine they use to make engraving, it did a good job but the reason why I was there was because they had a contract to do a part that simply didn’t fit in their machine. I literally told them that I can put their CNC laser inside of my machine and engrave the lid if they wanted me too. CNCROi.com closed the deal shortly thereafter!

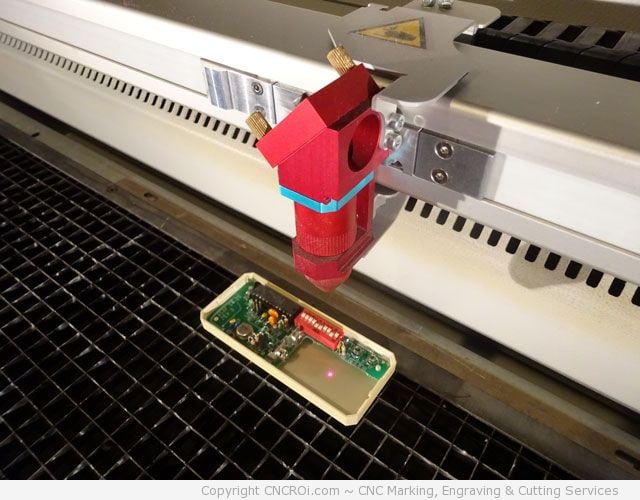

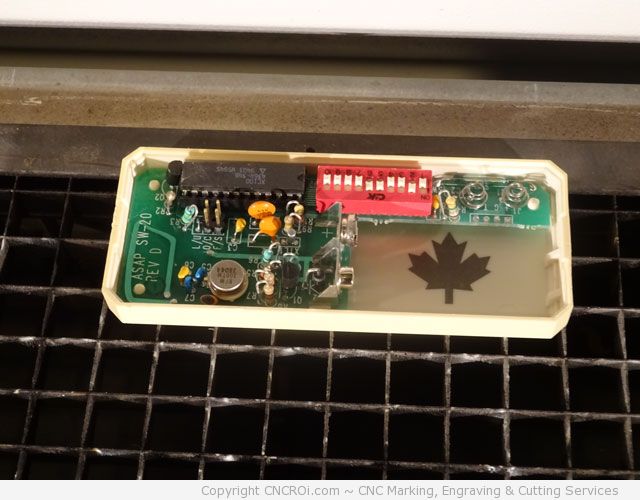

Let’s go back to the small widget we used our fiber beam (we have CO2 and Fiber laser sources in the same machine) to mark a permanent maple leaf inside of.

Imagine that circuit board was about 10x bigger and higher but the “base” where the marking had to occur was just as deep as seen in the photo above, if we didn’t have a long lens, it simply wouldn’t be possible as the CNC laser head would smash into the part that needed engraving.

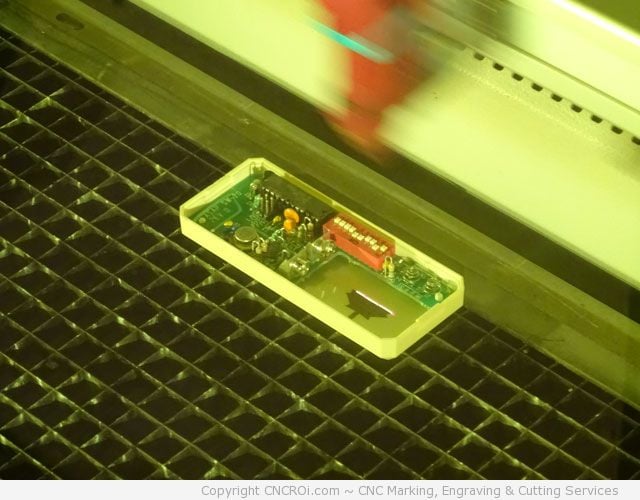

Look at how fast that head moves in the video and above picture, it smashes into anything and we end-up with a big bill and a broken machine, having the confidence to do our work inside and around parts without fear of damaging our equipment is a major plus. In this case, the results look amazing!

And from another angle… this is just random plastic that’s about 30 years old, we still got a solid black color change and it wasn’t cleaned or pre/post processed in any way.

Generally engraving is performed on our flat vacuum bed but we have supports under our grid table to keep it just as level and this demonstration was done in between two other jobs, one CNC laser engraving some great looking Corian and another making some wooden coasters… switching tables just wasn’t needed in this case. Having a wide range of tolerance on our fiber lens has lots of advantages… we got a consistent color change out of plastic even though it wasn’t completely flat. Impressive in its own right!

HUGE PRODUCTION RUNS!

I almost forgot, another huge advantage of having such a massive table with huge clearances to boot is that we can make huge jigs and massive production runs… there is an incredible ROI potential when you are able to engrave, anneal, mark or etch more than one part or assembly at once instead of one at a time.

For instance, I believe in the above job we CNC laser engraved and cut over 150 mirrored acrylic samples in one shot! On a smaller bed, maybe we can only do a quarter of that “per run” which means a lot more moving things in and out of the machine which wastes time and produces more waste. We’ve done the same with annealing stainless steel tags to engraving wood for clients, give us the opportunity to do the same for YOU!

Looking for a CNC laser company that can handle projects big and small, weird and normal… and get it done on budget and on time? CNCROi.com… contact us!