CNCROi.com 316 Stainless Steel Logo

CNCROi.com 316 stainless steel logo is now finally reality after thinking about doing something along these lines since I first developed our official logo over a year ago.

This was part of a larger custom 316 stainless steel plate job and there was a bit of room on the metal sheet so sticking it on allowed me to start the new year with a great looking logo to begin my 2019 videos with.

Making a CNCROi.com custom CNC waterjet cut and then fiber etched 316 stainless steel logo was a lot of fun, our typical steel jobs are nowhere near as intricate so its a nice break for the CNC machines to do something a bit out of the ordinary to showcase what’s really possible.

Below is our typical stainless steel work, in this case, it’s 304 stainless steel which is totally fine for the interior application these valve tags will be used for.

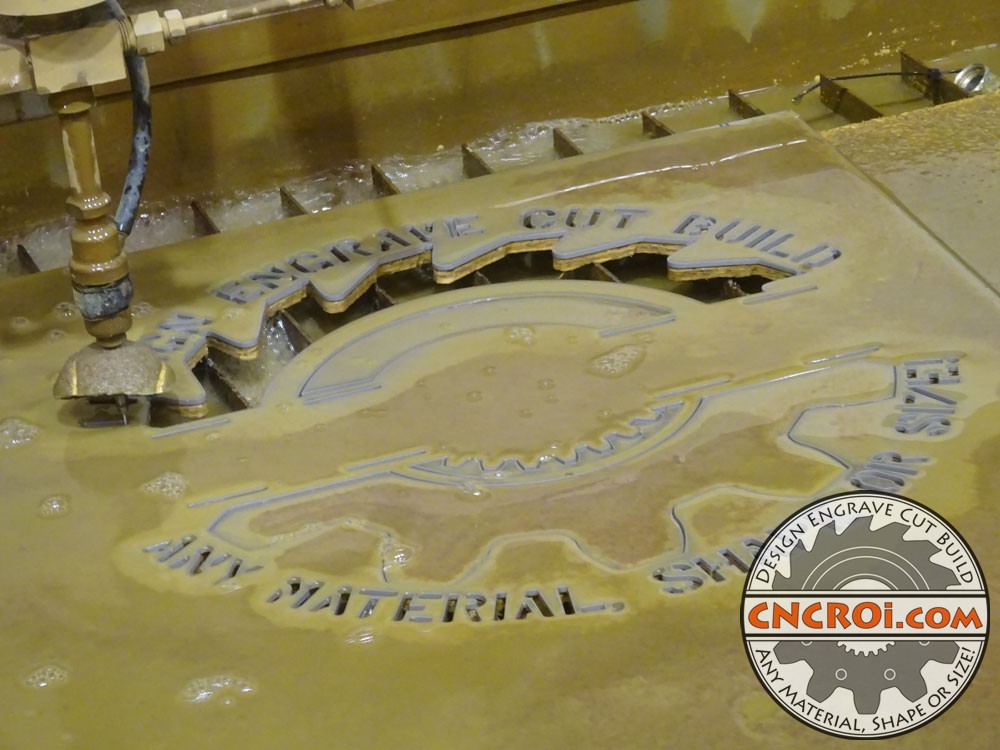

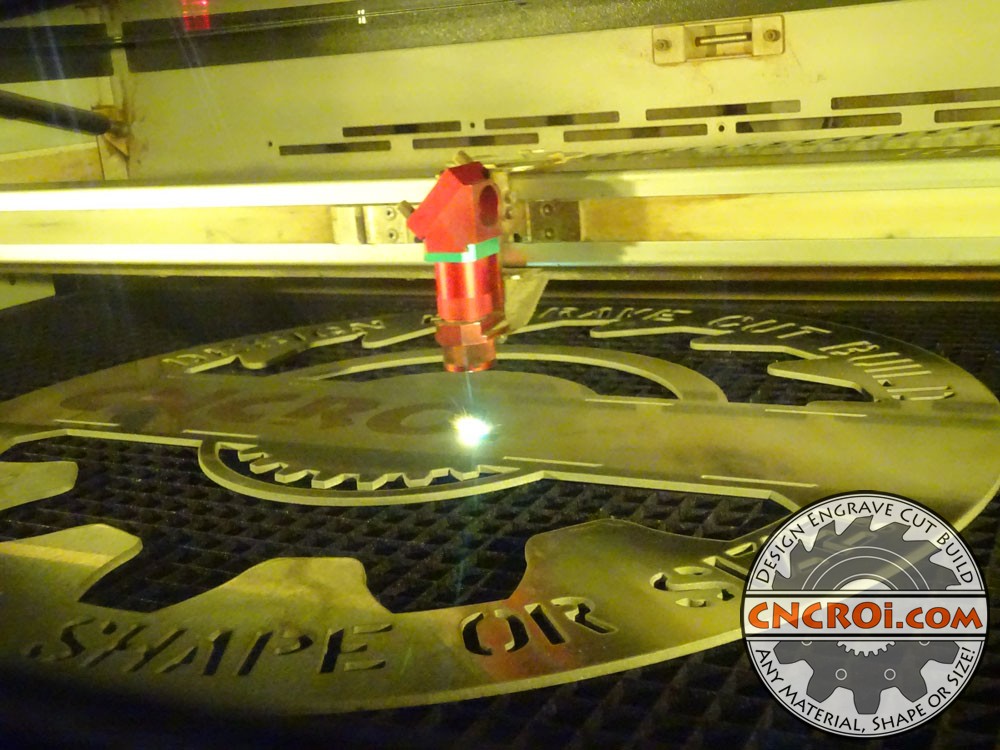

To contrast from the super shiny sheet of 316 stainless steel in the top image, you can see how CNC waterjet cutting is a muddy process, but this is a good thing as unlike CNC laser or plasma cutting this logo, I don’t have to deal with heat affected warping and zones as everything cools as it’s being cut.

You can start to see the formation of the CNCROi.com custom stainless steel logo coming out of the sheet of 316 steel already, the cut-outs for the logo wording Design, Engrave, Cut, Build along with the bottom being cut next any material, shape or size.

Steel logo signage can be painted of course, it looks just as good, but in this case, there wasn’t any point with going along the premium that stainless steel commands and deserves, the paint acts as a barrier between the steel and the outside environment.

The thickness of this soon to be stainless steel logo is 1/8″, 3 mm or 11 gauge which is perfect for metal plates and for this CNCROi.com logo as it will last a lifetime so the premium of going to 316SS over 304SS over that period of time is close to nothing and well worth the investment.

Unlike what many may think, 316 stainless steel isn’t corrosion proof, it’s just more corrosion resistant than 304 stainless steel which itself is far more corrosion resistant than regular steel but I still generally put a coating on the work that I do just for a bit of extra protection.

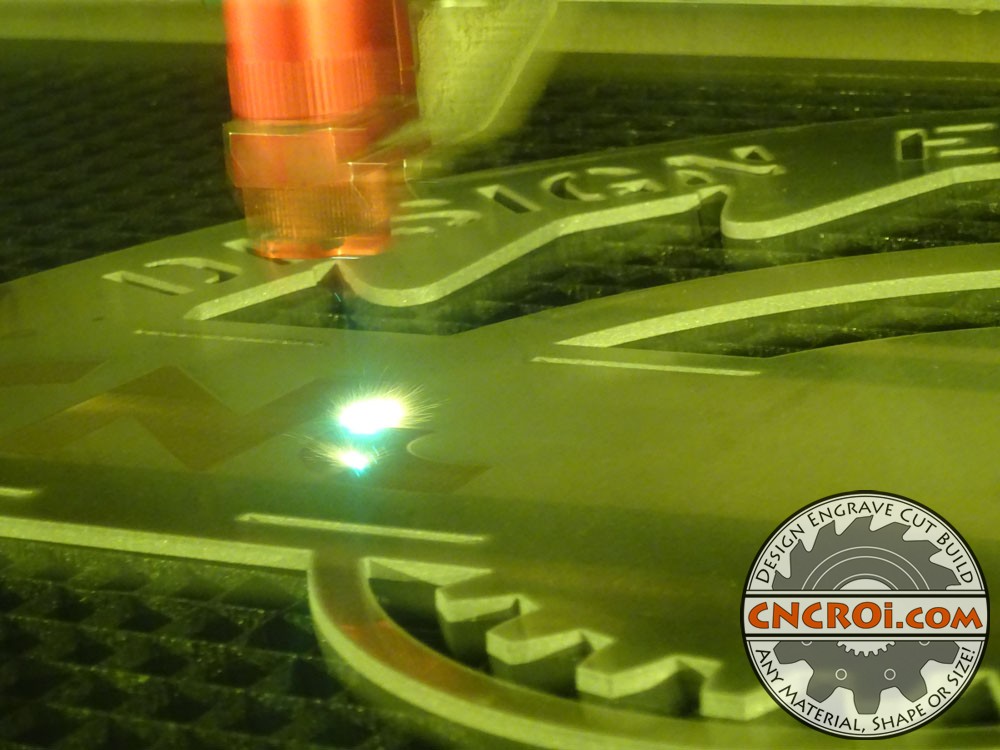

Etching vs annealing, they are two very different processes but the vast majority of our work now is etching, it has a wider angle of visibility and etching into the plate gives you a really nice tactile feel too.

It’s really amazing to see my CNCROi.com 316 stainless steel logo come to life after having it virtually for so many years, bringing it from pixels to real life which I can hold and feel the weight of is just an amazing way to start 2019.

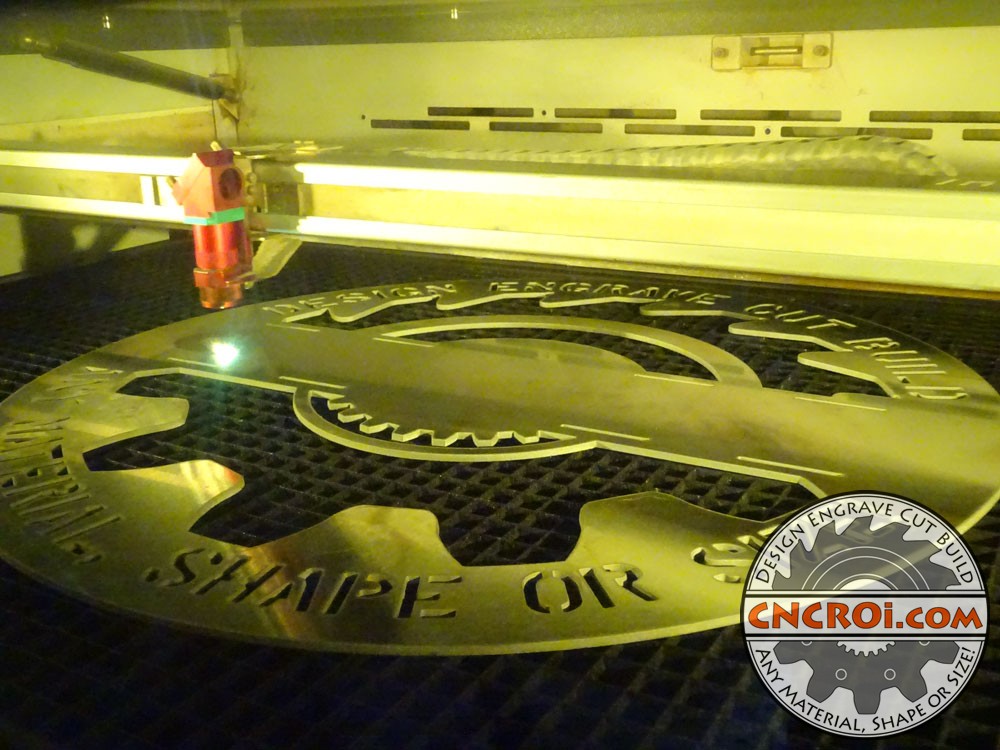

After washing the surface with just regular water, you can see the wonderful shine that only stainless steel gives, as this won’t be tumbled, this will remain the finish that I want for my logo in the background of future videos.

The steel aspect of CNCROi.com‘s business started years ago with custom welding tags, we’ve expanded greatly across the board in our offerings since then and it’s just so much fun to see how much we are capable of producing versus our initial beginnings.

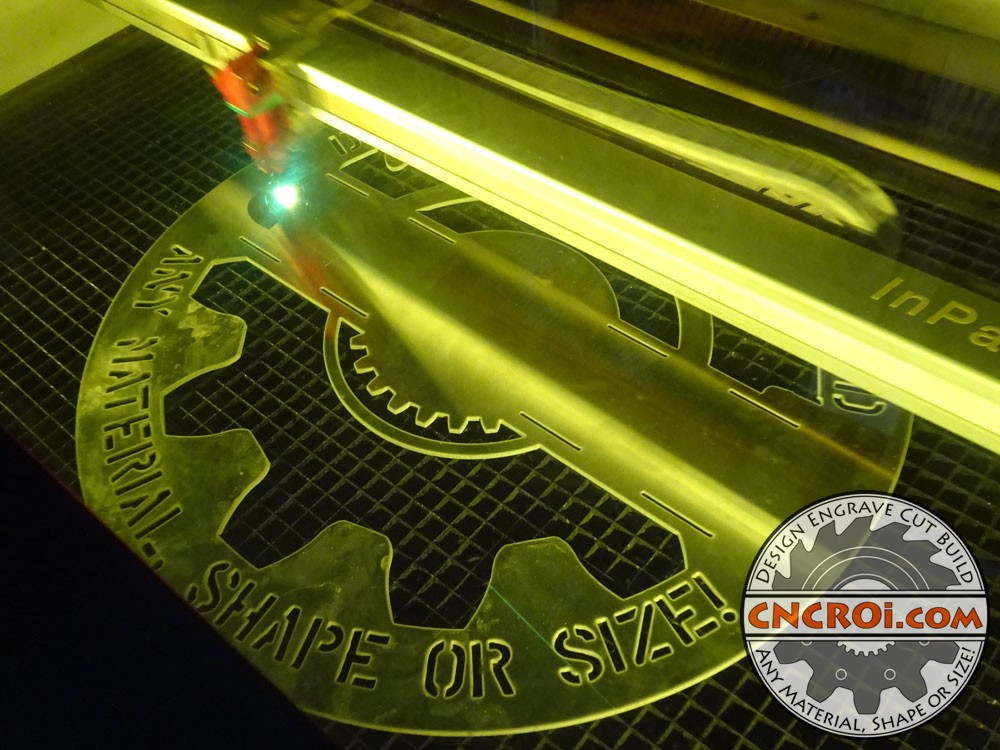

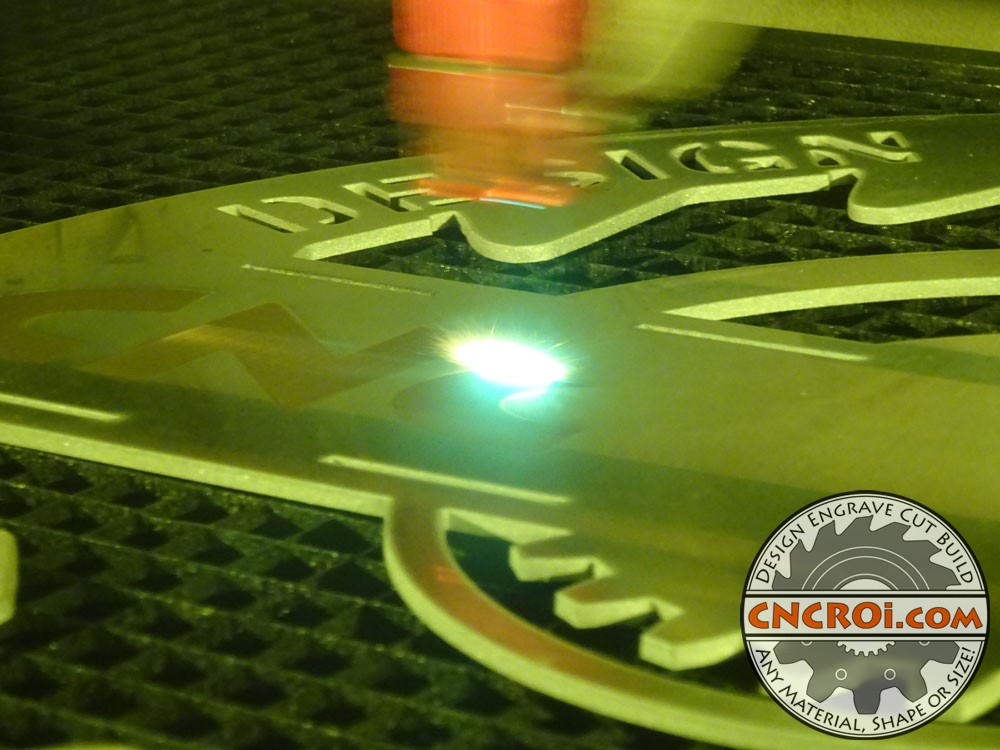

After cleaning-up the 316 stainless steel logo, it’s time to dump it into the CNC laser to begin the slow process of fiber etching the surface with CNCROi.com.

Fiber laser etching is a process that goes into the metal and also darkens it which is a completely permanent process which will never fade, crack, peel or come off EVER and with the industrial coating for extra protection, the etching looks black instead of dark brown.

CNCROi.com has mixed steel with wood before, here’s a project I did over the holidays showcasing the beauty that’s possible by mixing different materials together to produce something truly amazing.

There is something mesmerizing about fiber etching metal, whether it’s aluminium or steel, regardless of grade or gauge, just the process of creating images, text and logos permanently on and in them without having to use ink or dyes of any kind is just plain cool.

There are endless applications where CNCROi.com‘s custom metal capabilities can come in handy for businesses, from industrial machine tags to deep underground way finding to the top of mountains to deep below the ocean – WE CAN MAKE WHAT YOU NEED!

The CNCROi.com custom stencil capabilities are really fantastic too, having multiple machines allows us to better match design and materials to the applications our customers come-up with.

I do a huge variety of custom jobs at CNCROi.com for customers across the globe but it’s the metal ones that I really enjoy seeing the customer’s reaction to the most as generally, it’s an industrial application and wow do they love the work we do and aren’t shy of showing it!

Look at the image below, do you see the beam going from the right of the head down through the lens? Nope, it’s invisible, you can only see the result of the laser etching into this stainless steel logo.

Over a year ago, I actually made a far smaller CNCROi.com sign using just regular thin gauge steel, this was a lot of fun but you can see it has nowhere near the presence that the 316 stainless steel logo version I made in this blog post.

CNCROi.com‘s absolute flexibility when it comes to your custom requirements are endless, we could have made this logo solid or filled with holes as you see, thicker or thinner and even integrated other materials into the design such as wood and plastics.

Additionally, as all our work is vectors, the logo could have been scaled up or down to suit any dimensions you can think of, want a huge stainless steel logo outside your business and a smaller one in your store? CNCROi.com can do that!

If you want to compare different capabilities we have using the same design, this video will showcase some of them, of course, we’ve since acquired a full sheet CNC router so they are even more extensive now.

Before any washing, you can see the CNCROi.com steel logo below after being fiber etched, it’s a brown color but it will become black after we are done with it.

Steel logos never really get old, they have the same wow factor whether they are cut through or just etched on a typical steel plate but the look is just amazing regardless.

This was among my first annealing projects I did at CNCROi.com, you can really see how far we’ve come since those early beginnings but I just really love this quote.

This steel logo will easily last several lifetimes, I look forward to showcasing it for years to come, inside and out as CNCROi.com grows and expands.

Throughout the process of creating this 316 stainless steel logo, I couldn’t help but feel a great amount of gratitude to our suppliers and customers who make what I do for a living, running a custom fabrication shop, a reality.

Happy new year to all those who make my dreams a reality, it’s just so much fun to do what I do and being able to share it with others around the world.

Here’s to a great 2019 for everybody!