CNCROi.com for Medical Device Manufacturers

CNCROi.com is offering a host of custom CNC laser services across a host of industries, in this blog post, we’ll concentrate on our unique offerings that we provide to our medical device manufacturers.

NDA (Non-Disclosure Agreements)

Do you know how many blog posts CNCROi.com has? 224 including this one. Do you know how many client projects are featured in that? Two. One from a public school we work with (name not given) and the other from my cousin who has a welding business. The point is, we not only honor NDAs, we assume all the work we do is NDA by default.

We’ve completed projects for military applications, aerospace, oil and gas and the list goes on… some of these companies we’ve signed NDAs with, others we have not but that has made no difference. You can count on us to keep the work we do with our CNC lasers on your behalf confidential. Our blog posts are loaded with photographs, videos and content, when we work with our client projects, all that equipment is off and stored.

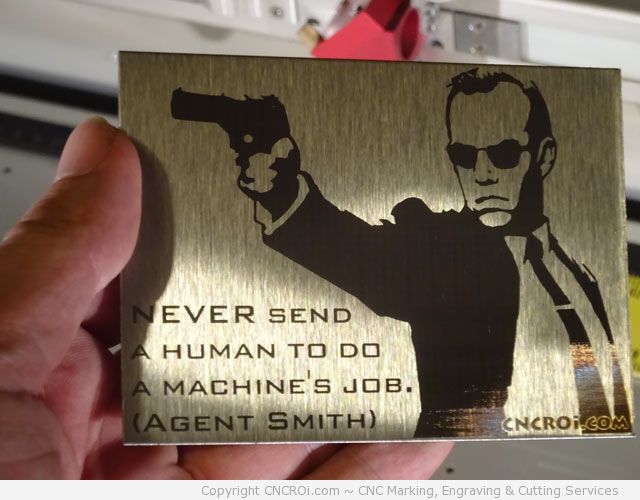

annealed 304 stainless steel

Power of dual-sourced CNC laser

The fact that we have a dual-sourced (CO2 and Fiber) laser tube in our CNC laser is vitally important. It means when we anneal stainless steel, we are ANNEALING IT PERMANENTLY, not having to apply a toxic ceramic paste that will fade, chip and come off over time. Our fiber laser work is food safe as we aren’t introducing chemicals to darken the steel, we are just heating the surface till it becomes black PERMANENTLY.

Surgical and general medical instruments can be permanently marked for easy re-ordering, polycarbonate stints can be permanently labeled and cut in one process and tooling can be scribed so that even after multiple stints in the autoclave or harsh environments where cleaning with bleach is necessary on a daily basis, nothing comes off.

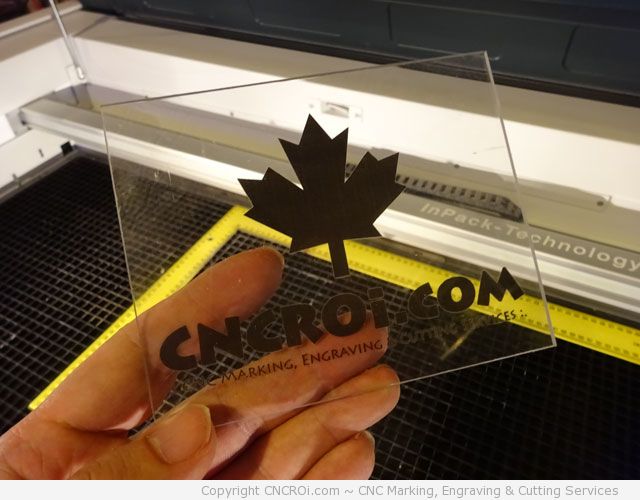

Our CO2 laser source (in the same machine) is mostly focused on engraving and cutting, if you need a custom test tube holder or entire acrylic gantry holder, we can easily produce one or thousands for you.

Our CNC laser machine is no-contact, meaning there are no vibrations and the heating is focused on the upper surface of the material we are working with. Cuts are smooth, flame polished and identical.

Some medical products have two different heights needing engraved and materials, you need a company that can mark both.

Reverse CNC fiber laser color changed polycarbonate.

Absolute Repeatable Precision

Where does our industrial wide format CNC laser come from? Austria. We invested heavily in acquiring a machine that has absolute repeatable precision. How precise?