CNCROi.com: Lean & Clean(ish)

Keeping a shop clean, organized and LEAN is a constant struggle given the nature of the materials we use and work with but it’s probably the most important thing we do IN the shop for both us and our customers.

Keeping the shop CLEAN(ish)

It goes without saying that when you have a CNC router, CNC laser, sand blaster, lots of hand and power tools working across wood through acrylics, things can get dirty FAST. As long as things are working, you’d think that pile of dust or those smoke or resin stains or that bunch of offcuts in the corner aren’t causing any problems by affecting production. THEY ARE!

I’m lucky enough to be able to visit shops all across North America and have visited factories as far as China and Australia to realize one thing after talking to company owners and directors. A clean shop is a PRODUCTIVE and EFFICIENT one!

It’s pretty much impossible to have a totally dust free and clean shop given what we do here at CNCROi.com but putting tools back where they were, optimizing tool placement, putting recyclables together or boxing what is still good but just laying around is an ongoing process before, during and after production runs.

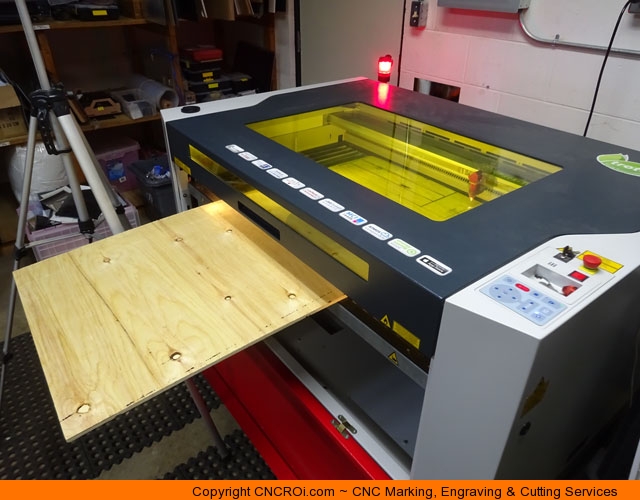

It does take time to clean things, for instance, I spent almost two hours cleaning just our industrial wide-format industrial laser, it has LAYERS of grime from a few jobs we did this week, it now looks like a new machine, optics are clean, hoses and everything else are in beautiful condition.

Imagine having a complex BBQ with moving parts with the equivalent of years of grime on it, that’s what a laser ends-up being in very short order – and yes, we use BBQ cleaner on it! Will it stay clean and WHITE like it is right now? NOPE!

Keeping the shop organized

I write about this a lot because I think it’s vitally important. Lots of time is wasted looking for XYZ if you have everything in piles, costing time which is money at the end of the day for both you and your customers. We have some jobs that require us to use half a dozen manual and power tools to “finish” after something has been processed by the sand blaster, router or laser and each time, they MUST be put back where they were taken from.

Why is this important? Well, we generally have several ongoing projects going and within a few days, the entire shop can easily be an absolute mess if ongoing organization wasn’t taken. For instance, we use to have our sanding equipment in several places in the shop before a custom designed and cut downdraft table was made.

Since then, sanding and finishing has been incredibly efficient, all the tools are in ONE SPOT inside the tool made to keep dust to an absolute minimum in the shop.

Keeping the shop LEAN

Part of keeping things clean and organized is keeping them lean. It’s extremely easy for CNCROi.com to go on buying binges to fill the entire shop with inventory to “speed things up” but what that actually does is increase costs and gives us less room to work in! We always buy extra material when we do buy material but it’s a constant balance to not go overboard. Our materials are kept RAW as long as possible, once we cut, engrave or otherwise mark it, the possibility of using the same material for another client decreases. Our scrap bin is just that, a small bin! The rest goes to the fire pit (wood) or recycling.

Lean is also about keeping things organized. There is always a more efficient method of doing SOMETHING, whether it’s storage, ordering or machine accessories. The faster you can move from A to B without tripping over something, without having to SEARCH for it nor having to even think about placement of things, the more efficient the entire process is.

For instance, most of the tools in the shop are actually on wheels, not because we like to have races with them in the parking lot but because it makes moving things around EASY and EFFICIENT. For instance, our industrial laser is 350 kg, if it wasn’t on wheels, you’d need a forklift to clean the dirt under it or when a long project several meters long needs engraving (which we can do using pass-through), it’s doable by one person instead of a team.

Challenges of a custom CNC shop

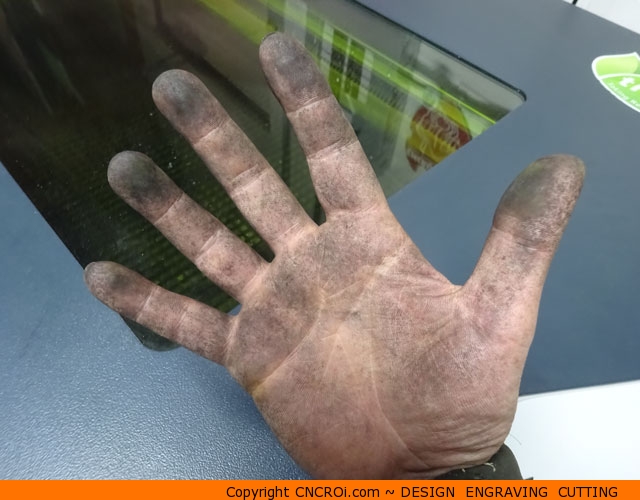

I hope this gives you a bit of insight as to what we do here at CNCROi.com when the cameras are off and a production run is done, if you think my hand is dirty in the above picture, imagine the equipment! That’s why keeping things clean, organized and clean is vitally important.

There is NOTHING worse than having a client visit the shop in a white suit and leave in a black one, I’ve visited shops that were an absolute write-off in my opinion and that reflects incredibly negatively on the business. Nobody wants to work in a shop where you need to swim through the dust to get at your station or having to dig for things to get to what you want.

CNCROi.com isn’t a hobby, it’s a business, and that means taking things like this seriously even if we aren’t a massive manufacturing company (yet). It benefits both us and our clients!