CNCROi.com for Manufacturing

A few days ago we looked at how CNCROi.com can help the millworking industry, today we’ll look at manufacturing. It’s pretty impressive how many verticals a high quality Austrian large format CNC laser can serve! Our machines aren’t just top of the line, they are industry leaders and we throw-in all the bells and whistles to assure you get the absolute best result each and every time!

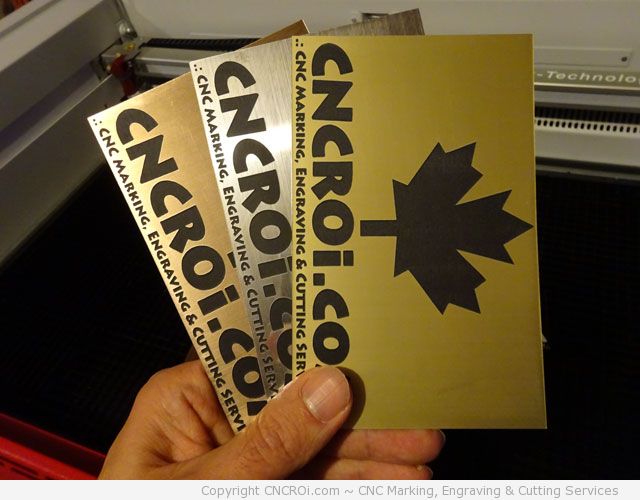

CNC Laser Marking

Due to the fact that our Trotec laser has a fiber tube right in it (along with a CO2 btw), we are able to laser mark a wide variety of metals and plastics directly without any need for pre or post production.

For instance, if your company is manufacturing injection molded parts, if you use a CO2 laser to engrave details, you tend to melt the plastic, not the kind of “marking” you’d want. Our fiber laser will not melt the plastic, it will mark it and in come cases, color change it for even better contrast.

If your manufacturing company is making aerospace parts, you deal with everything from cast aluminium to high-grade stainless steel and other exotic metals, again, CNCROi.com can help! With our fiber laser source, we can engrave, mark or anneal batch, part #s or even corporate details (logos, contact information etc.) in very fine point sizes directly onto the part quickly and competitively.

CNC Laser Annealing

One step up from laser marking is laser annealing, basically, we heat the metal so hot that it becomes black where the laser is focused on it. The process isn’t fast but it’s just as permanent except it’s BLACK. Laser marking, metal depending, tends to gray or brown the areas it’s touched.

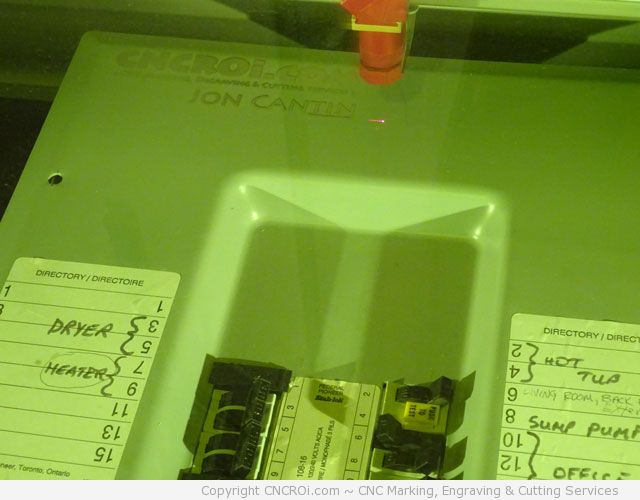

So, if you need something with a higher visibility such as electrical panel instructions or certification plates, we can do them for you precisely, quickly and at a very high standard of quality.

Annealing on the left, marking on the right.

CNC Lasers for Manufacturing

Some companies use materials whose composition might be best suited to CO2 laser engraving, an example would be cast aluminium where you want to actually remove and go into the material. An example would be a crank shaft or cylinder where you want identification or tracking numbers to be both permanent and just about impossible to remove. Laser marking and annealing are permanent but only on the surface (still bloody hard to remove though!), engraving goes deep into the material.

Not just widgets…

I’ve visited manufacturers all around the world, they don’t all produce widgets, sometimes they are focused on assembly of parts from various manufacturers to produce a final complete model. Here as well, CNCROi.com can be of service!

For an electrical part, you need to put in stickers that verify that they meet CSA and various other standards depending on the internals, why not make their job easier by contracting us to laser mark the wiring! Yep, we can do that too… and forget using those stickers that keep falling off or fade with time on the back of your model, we can use the laser for something that’s permanent and shows-off the high quality of your finished piece such as a logo on the front that won’t chip or peel.

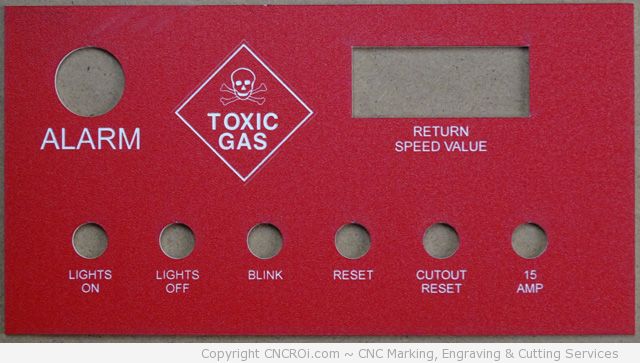

Laminates and beyond!

For machine manufacturers, we can also cut and engrave/mark industrial grade laminates of pretty much any size, color and density. Whether you have something high-end and want a titanium panel annealed with your logo and controls or plastics for your bargain basement line… CNCROi.com can help you out!

A trusted partner for manufacturers

Let’s face it, manufacturing is a volume business, you get metal/plastics in and ship them out ASAP. You need a reliable partner that will get the work done right the first time! You are sub contracting to us in order to save yourself headaches and increase production – you want to deal with a company that is more than a subcontractor but a partner in your supply chain. Look no further, give me a call!