CNCROI.com for the Millworking Industry

The reason why you see so many mill work companies using CNC is pretty obvious, nothing beats the ROI you get out of it! What use to take cabinet makers weeks if not months on more complex and sizeable projects can now be done in hours given the right scale and machinery. CNCs are so popular that even IKEA is able to produce some of its furniture in only a few minutes, including packaging and instructions being thrown in by robots!

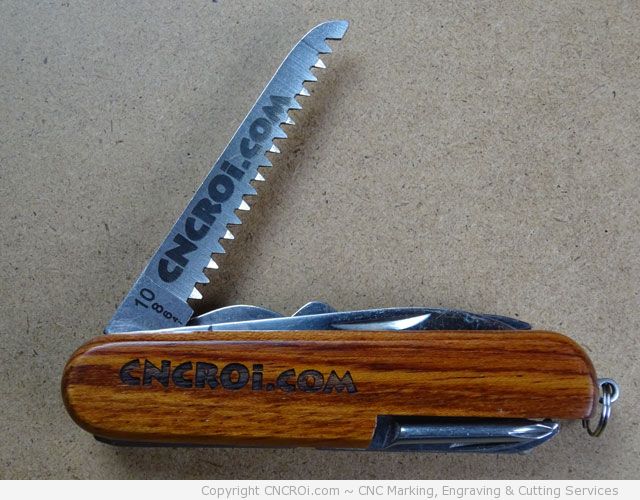

Generally, the first thing that comes to people’s minds when I say I do laser engraving and cutting is “trophy shop”. This isn’t a good or bad thing but it’s not what CNCROi.com is focused on. I see my company as a value added partner with industries of all kinds, including the millworking one.

How can your mill work company benefit from CNCROi.com’s offerings?

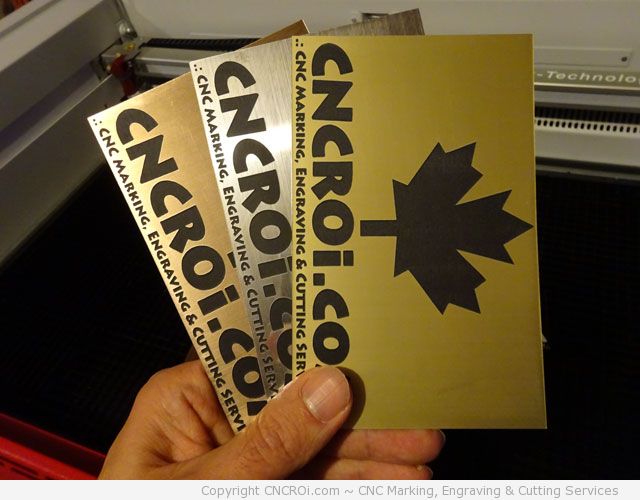

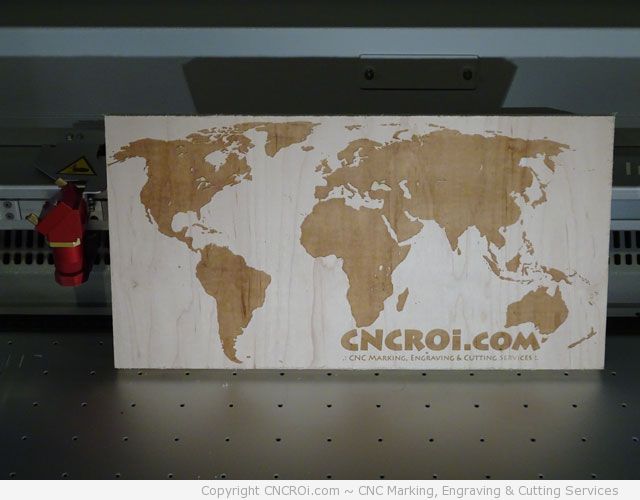

Sure, you see laser engraved pumpkins on this site and some small metal tags being annealed but that’s there to show ideas of what our Trotec Speedy 400 flexx can do!

We are the only company in Canada with a dual source laser that’s capable of laser cutting, etching, annealing, marking and engraving multiple distinctive materials in one production cycle. What does that mean? Well, an extreme example would be a very high-end mirror. We can laser engrave the wooden frame, the mirror FACE UP and using our fiber laser source, anneal personalized details on the metal brackets that support it in ONE production cycle even if they are all found at different heights! No post-processing, no loss of precision from moving things around and no headaches for YOU (or us)!

For kitchens, you may have a chair where the outside rim is wood with a few interior steel inlays… we can engrave/mark across those different materials which means you can have the Canadian Maple Leaf look great across multiple materials but still look like one consistent engraving/marking across the surface. Everything will be dead-on! No dirty and damaging post-processing!

Design experience

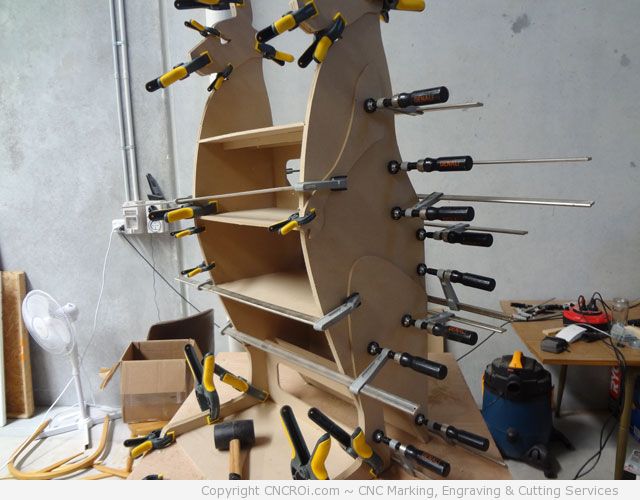

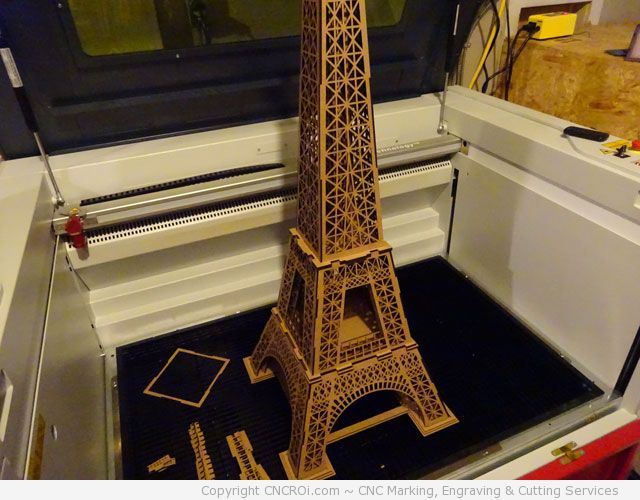

Our large format CNC laser is only a small part of the whole solutions portfolio we can offer your millworking company. We also have custom design capabilities – our sister company CNCKing.com has designed projects for CNC machines around the world.

So, let’s say your customer wants a custom designed dinosaur that’s 20 ft tall and has a wagging tail, we can design it and send you the files to cut it out on your Thermwood CNC Router… then you can give it back to us to laser engrave details about it on the various parts or to add additional detailing that’s tough to do with a round router bit. Oh yeah, if you have a Mitsubishi EX laser, don’t worry, you can cut that some dinosaur out of brushed metal and we can anneal or mark the same details we would have done on wood.

If you really want to get crazy and you owned both a Thermwood and a Mitsubishi cutting center, we can even design that dinosaur to have outlines out of stainless steel with wooden inlays… we can engrave/anneal both in one production cycle.

We can then laser cut a semi-transparent outer “skin” using acrylic that’s made-up of different colours to represent whatever you want!

Mill working Industry

Mill workers use a variety of materials for their projects, from 3/4 inch laminates (yes, we can cut that and you get to keep the same wood grain pattern minus a 1/16th outline that’s vaporized) to hardwoods and softwood of all kinds including manmade ones like formica, Corian and the list goes on. Basically, any material that you need something done to, CNCROi.com is your solutions provider!

Laser Engraving the World on Dupont Corean®

What’s the next step?

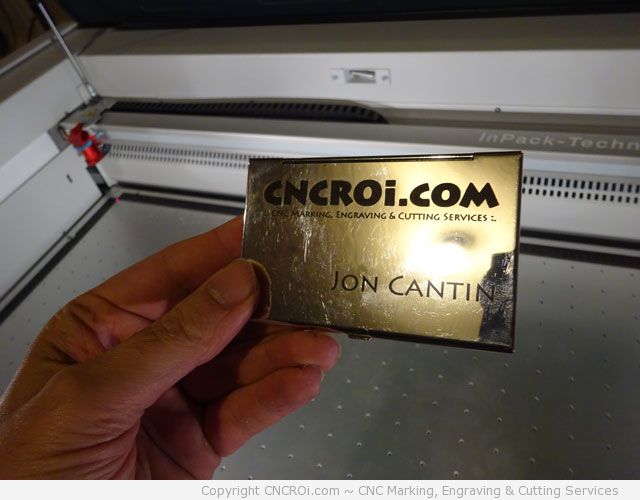

Now that I’ve opened your eyes to just a glimpse of how our services can augment yours and by extension, your client’s… what’s next? Well, send us an e-mail or call us with the project details and timelines involved. If you require us to sign an NDA and non-comp, that’s no problem, its common practice among our clients. Here’s my card, annealed on 304 Stainless Steel!