Common Custom FAQs Answered

Considering the incredible custom capabilities of CNCROi.com across a wide variety of business verticals and personal desires, it’s surprising how much of the advice I give as the owner regarding getting something custom done is the same.

Why Black & White is Best

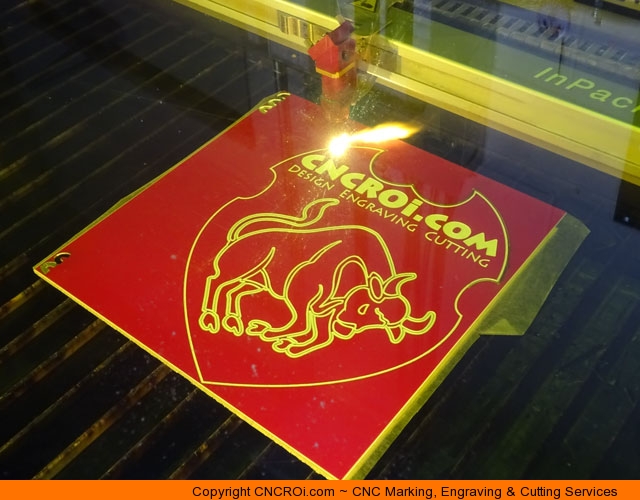

Although our laser and router and sand blaster etc. can make incredible work in a variety of colors, the FILES that end-up coming the best across 304 stainless steel engraving to stamps, laminates to woods are those that have been converted to lack and white.

There is something strangely beautiful about just having “two colors” or “two shades” to something that seems to go away the more complex something becomes. Here’s a great case in point, a picture of me with a quote done “grayscale” quality (varying depths of engraving) with the next being just straight black and white (engraving and not engraving. Which looks best?

VS

Just try to imagine if they were done using the same laminate, and either way, you’d agree I have a face for radio and the of Mohammed bin Rashid Al Maktoum has the most gravitas. This generally holds true across a variety of applications, custom veneer business cards to general signage and promotional items.

Custom is EASY and STRAIGHT FORWARD!

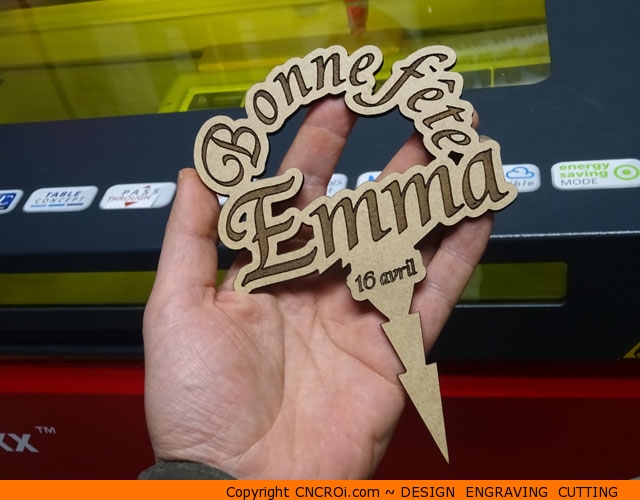

It’s surprising how complex our stuff can end-up being production wise but in the eyes of the customer who may feel overwhelmed, rather easy and straight forward. Basically, we try to make something complex as painless as possible for YOU so you don’t have to deal with the endless issues that come about in the custom world.

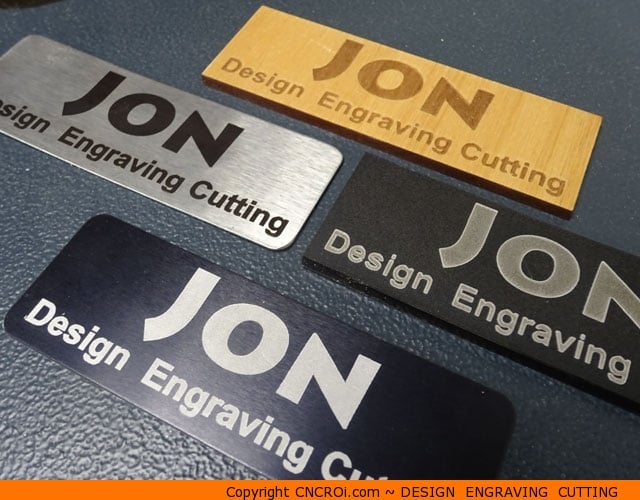

For instance, if you wanted some custom name badges with names and titles across your whole department, the questions aren’t anything off-putting or overly onerous. For instance:

- Send us a database of all the names (first name one column, title second)

- What color combination do you want or material preference do you have?

- What is your timeline and your shipping address?

THREE SIMPLE QUESTIONS and quite literally, production an begin right away! We send you a digital proof of the design so you don’t need CAD, if you want something a bit more complex, a sketch is fine and we’ll convert that to something we can make in the shop and the biggest issue you’ll have is who opens-up the package once it gets delivered to your office!

Resolutions are GENERALLY 500-600 DPI

For the vast majority of the materials we work with, engraving is done between 500 and 600 DPI. This is, by the way, above the “traditional” resolution of CNC laser shops due to the extra time involved but our demographic doesn’t mind paying a little more for something that’s substantially more attractive close-up.

About the only material we work with at 333 DPI which is the industry standard, is glass because it looks best at that level, just about everything else, metal through ceramics, is at a higher resolution if the material can handle and show the difference properly.

Material Durability

There is an exponential sliding scale when it comes to material durability, at the top of the scale are our metal offerings, both 304 stainless steel and anodized aluminium and a step down, you have your woods and acrylics and a step lower, laminates then stamps (due to their application with repeated pressure and cleaning).

At the end of the day though, ultimate durability depends on how well you take care of things at your end. We can make a fantastic annealed stainless steel sign but if part of your daily routine is to throw a rock at it, it won’t be something to pass onto the next generation by the time you are buried in the back yard.

We do work hard thought to make sure what we make lasts though, for instance, we don’t HAVE TO apply a clear acrylic seal on the back of our custom mirrors but we do, because it makes a huge difference by adding an additional shield to reduce the back reflective material from being removed. We don’t HAVE TO apply multiple layers of clear acrylic (we use this stuff a lot in the shop) for your anniversary wooden log but we do because it will last longer that way.

Rush Order are to be AVOIDED

Generally, a heads-up goes a very long way when it comes to custom, it gives suppliers time to ship things normally instead of by private helicopter (which gets passed to you via the bill), give time for things to settle before moving onto the next production run and just gives everybody involved a lot less stress and breathing room.

Wanting something YESTERDAY ASAP that would typically take a week start to finish isn’t a good start, it’s best avoided all around. Some things are well-known, everybody reading this has an incredibly predictable birthday coming-up… so why wait till it’s only a day or two away to order your custom cake topper that’s useless if it’s late?

You are getting married in 3 months from now, what is the point of waiting two and a half months before STARTING to think about something custom for your wedding? The earlier CNCROi.com is involved with your custom plans, the better everything will be all around. Ideas are fleshed out, materials and production are taken care of in an orderly fashion and it will save you money too!

“I don’t know, we’ll have to do some material testing”

Generally with our more industrial or manufacturing customers, my answer to them will first be “wow, I didn’t think of that” followed by “I don’t know, we’ll have to do some material testing and you get back to us with the results of our production.”

We are a custom CNC services shop, sometimes our customers have brilliant ideas using novel materials that I have nothing to gain by saying “yes, it will work” when I really have no clue! Honesty is the best policy, material testing is part of the game and we are all the better for it when it comes to optimal production and receivables.

How do you…

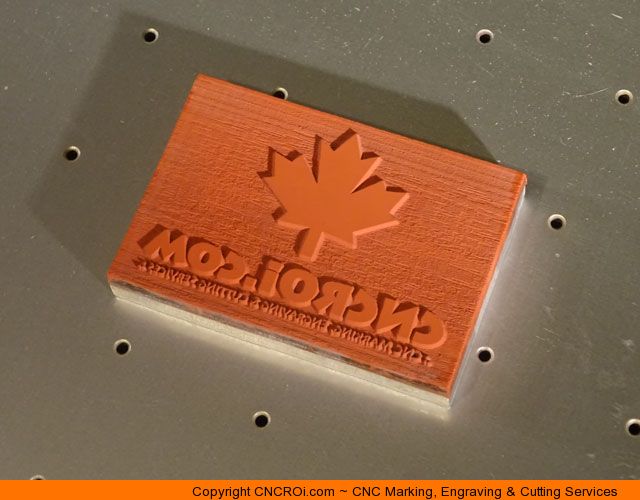

One of my many goals here at CNCROi.com was to show people how we do what we do, it’s not rocket science but does take some time to figure-out so if you are wondering how stamps are made, here’s a video to help you understand the absolute basics!

There are over 300 blog posts alone on CNCROi.com going through various projects, hundreds of videos and even books that I wrote available at our e-commerce store. Basically, if you have curiosity, we want to be your resource to not only gain some insight into how your custom project came into being but what to do to make sure you get the best results!

Client List

We’ve had potential customers ask of often for a list of current customers, unless it’s something extremely specific, the general answer is NO. We work as part of a cog in a bigger wheel with wholesalers, distributors, manufacturers and the like and those are covered by NDAs.

In fact, NDAs are so regular in the business we are in that even if we don’t sign one, we assume there is one just to make things easy. That’s why RARELY will you see anything “client specific” we made for our customers on our site. Yes, we make lots of rubber stamps, but our showcase is of OUR STAMPS, not our clients.

Any other questions, ask away!

We certainly don’t know everything here at CNCROi.com so we don’t expect our customers to know everything either. If you have a question, feel free to contact us and ask!