Making Custom Acrylic Animal Stickers

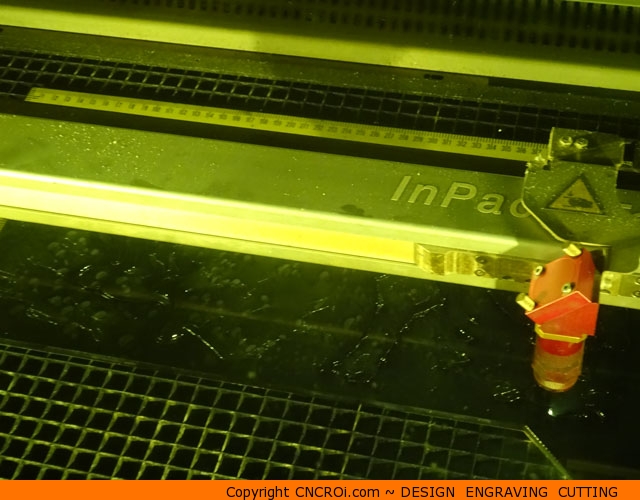

Let’s make some custom acrylic animal stickers! Not only can CNCROi.com make custom shapes of pretty much anything, but we can also turn them into stickers using any material as well!

In this case, it’s quarter-inch or 6 mm thick acrylic with a double-sided self-industrial-adhesive, making these incredibly strong stickers that can stick to pretty much anything.

If you want to see other ideas for custom shapes, check out our growing SHAPES LIBRARY.

In this case, we are using a scrap piece of acrylic and applied double-sided industrial tape on the back, turning it into a sticker.

This acrylic can be had in lots of different colors and thicknesses, so there is a lot of production possibilities when it comes to making custom acrylic animal stickers.

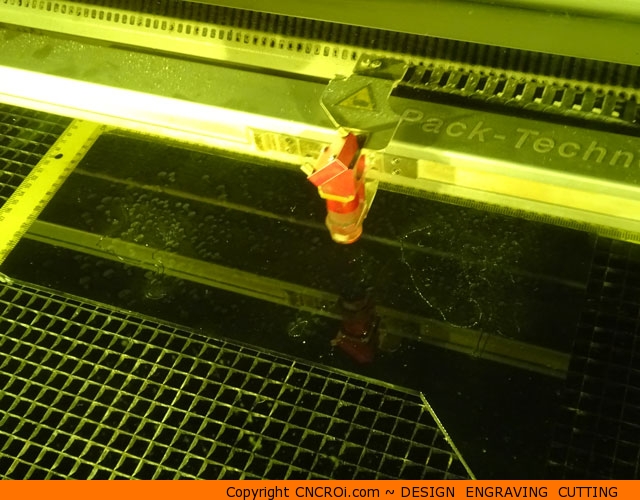

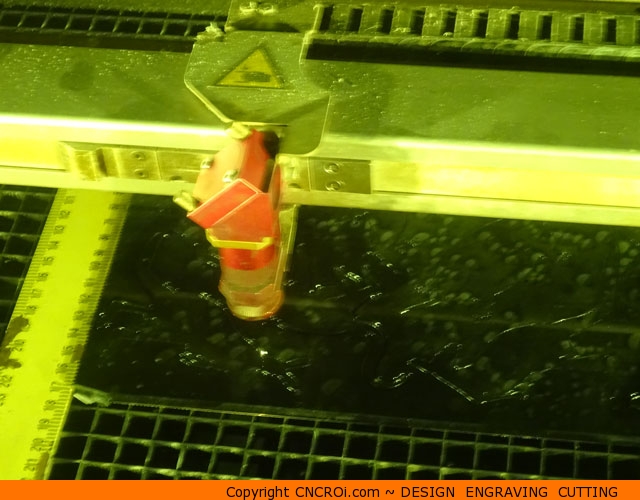

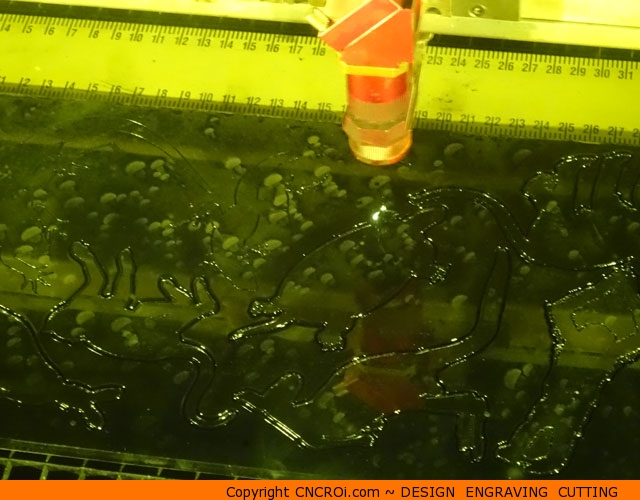

Like our previous videos showing custom shape library releases which you can view at BUY ONLINE in the top heading, these custom acrylic animal stickers also have an exterior outline so more detail can be added inside, though in this case, you don’t see it very well.

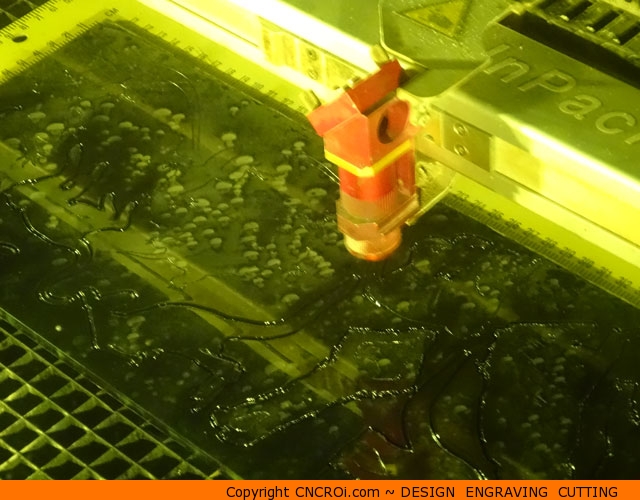

There is some dust build-up on the surface of the acrylic due to static but don’t worry, that comes right off and is actually an advantage during filming as the jet black color of this acrylic makes filming focus difficult.

Laser engraving out each shape before cutting out the final silhouette can also double as a score line, if you had a project that.

For instance, required the custom to “break” parts or have tabs in your acrylic or any other material, we can just as easily integrate that design feature using our Austrian CNC laser as we can with our ShopBot CNC router.

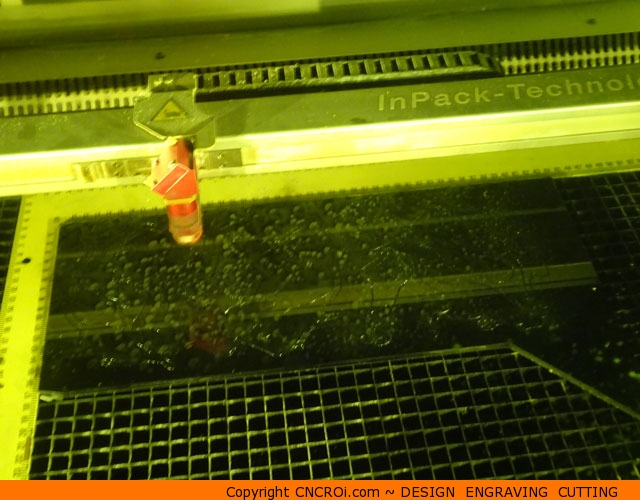

Adding additional details to these custom acrylic animal stickers does two things, it provides more character and visual appeal to them, which isn’t immediately noticeable using black acrylic.

Secondly, it protects small parts from breaking off such as tails and nails which, are generally so thin, that they just snag and break.

There are thousands if not millions of different animals all across the planet, our goal here at CNCROi.com is to get at least a small fraction of the more commonly known ones in our shapes library for you to enjoy the work we can do with them.

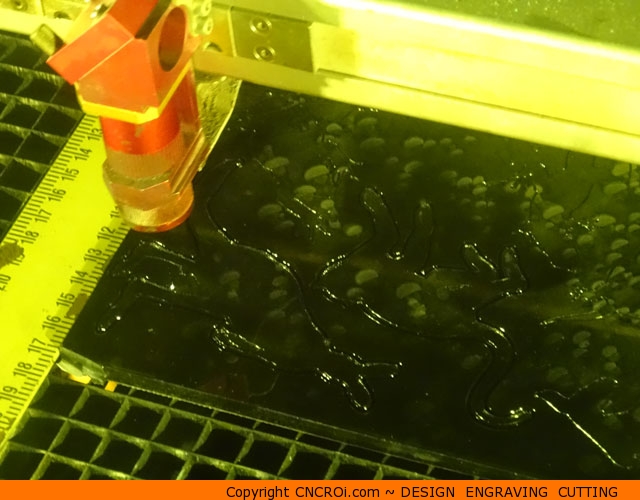

There is no need to mask acrylic like we did with the plywood and MDF custom animal shapes earlier due to the fact that the smoke or vapor is just a very fine dust without any “stickiness” to it which is easily wiped off.

CNC laser engraving can be one of two ways, the first, as you see in this video and photos, is essentially a cut line that doesn’t have enough power to actually cut THROUGH the material.

The second is the traditional left to right movement, they both achieve the same result but the most efficient process is dependent on the design and parameters at hand for custom acrylic animals stickers.

This is where having a CNC operator (me!) who has years of experiences comes in handy as I’m to the point there I can just look at a design and decide right away which process is the most cost-effective for the given material at hand.

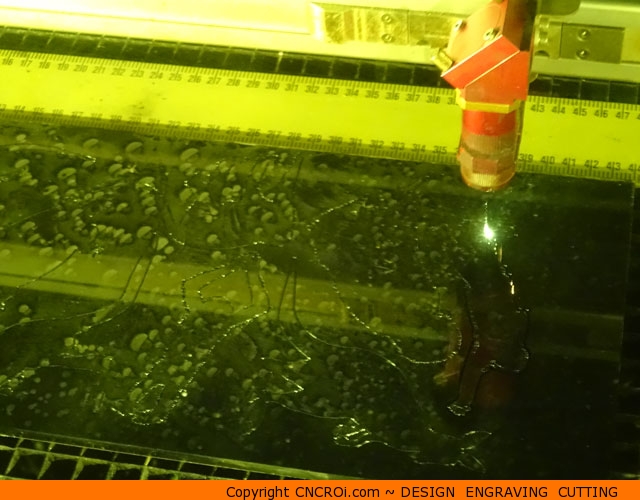

Now that we are done the engraving process, time to cut the custom acrylic animal stickers out of their acrylic plastic binds!

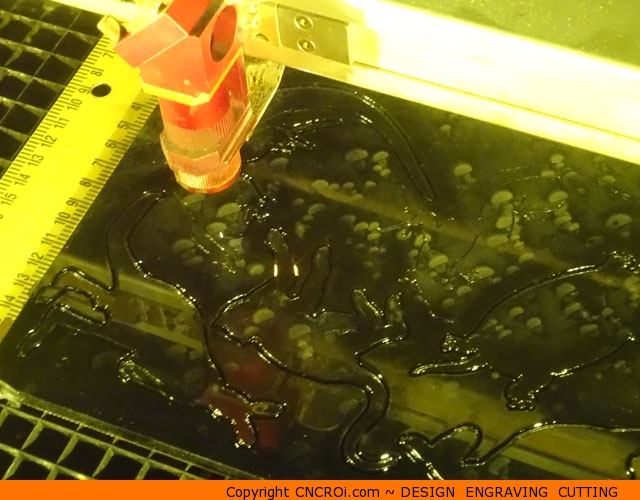

It goes without saying that cutting takes longer than engraving for the same amount of “lineage” and with the power required to cut through this quarter-inch or 6 mm acrylic, there is some serious fire shooting DOWN.

Fire in a CNC laser is a given, but you want the fire going DOWN instead of UP as it’s relatively safe then, otherwise, the fire and related combustion goes up into the head, cracks lenses and can literally burn the whole machine up if not taken care of IMMEDIATELY.

We have a powerful extraction system so there is no chance for the fumes and vapors to ignite anywhere near the machine during the making of these custom acrylic animals stickers.

That’s only helped by dual extraction thanks to a vacuum table and back vents so we can do tons of acrylic and foams, which are generally trouble, without any.

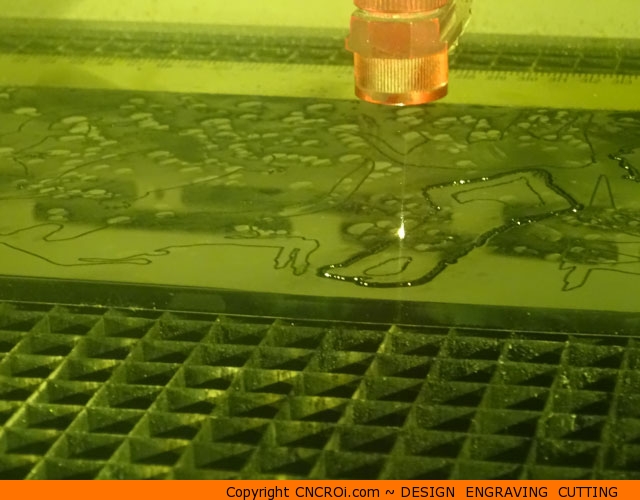

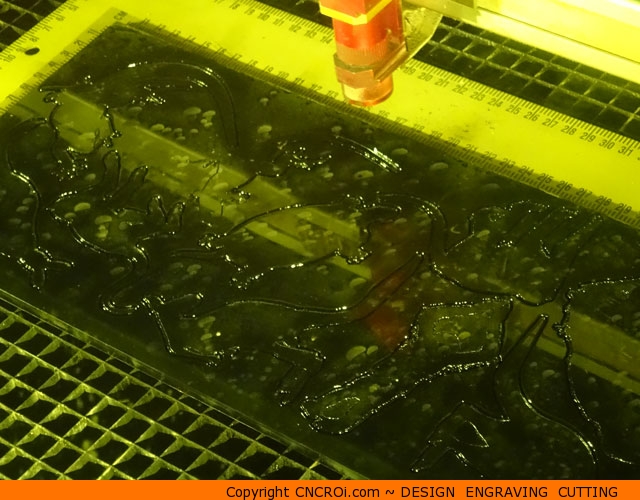

As our industrial wide-format laser cuts away at this acrylic, keep in mind that this is special acrylic because it has double-sided tape on the back.

The double-sided tape is being cut at the same time as the silhouette of the custom acrylic animal stickers, which means that the adhesion is PERFECT across the ENTIRE SURFACE of the shape.

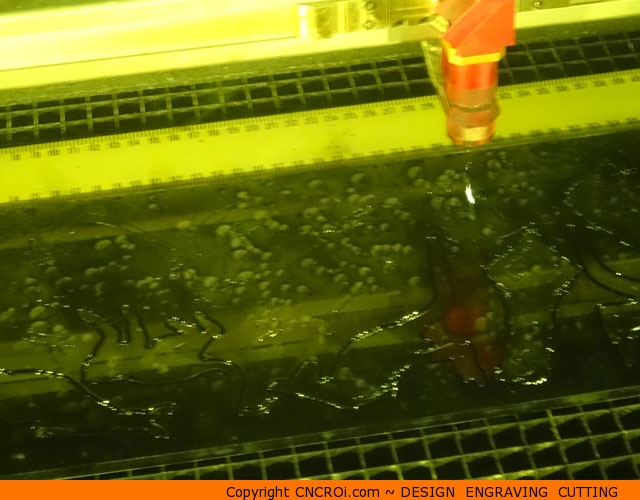

Although I could have technically put these shapes right next to one another, I wasn’t sure what material I was cutting these shapes out, they are all from scrap.

If this would have been wood, the spacing would have been fine but for acrylic, a tighter fit is possible. It depends on the thickness and silhouette of the final shape.

If you look closely at the image below, you’ll see the flame shooting int he bottom that lights-up between two earlier cut lines for the monkey custom acrylic animal stickers.

Having pieces too close together sometimes causes them to “weld” back together, hence at least some spacing being required.

This is the final CNC laser cut before these custom acrylic animal stickers are all done.

Depending on the light, you can see how the additional detail comes out, so this extra is highly dependent on the material that we are cutting and engraving as to whether this is worth it or not.

Keep in mind that we do lots of material testing, if there is any doubt, we do a test to show you the results before going into production.

The custom acrylic animal stickers came out great, you can find these and many more right now in our SHAPES LIBRARY, check it out!

Do you need a custom silhouette or shape for a custom cutting board, coaster, house number sign or anything you can think of, even life-size 3D puzzle? Contact CNCROi.com and we’ll make it for you!