Custom Acrylic Coasters: Smoky VS Clear CNC Laser Engraved & Cut

Custom acrylic coasters are always fun to make, they are pretty durable (I’ve had mine outdoors through 4 seasons for a few years) and can be endlessly customized, from thickness to transparency and design options are pretty much unlimited!

If you are a long time reader of CNCROi.com‘s blog, you may remember that smoky acrylic from a long time ago when I was just starting the company, in that case, I made a relatively simple custom acrylic coaster.

It just shows you how much acrylic can be customized for just about any application, from simple and traditional to wacky and 3D with edge lighting, literally anything can be made out of acrylic.

Just keep that in mind when you contact CNCROi.com with a custom project, these are only ideas that I’m sharing through these demonstrations, not finished product lines.

As I tell all my customers, your product is whatever we come-up with, it’s made custom from raw material for ultimate control of branding and messaging.

If this design looks familiar, it’s our logo that you see plastered but here’s the exact same design applied to my custom wooden name badge.

Now, onto the fun of first, clear glass looking acrylic before jumping into the smokey acrylic coaster production.

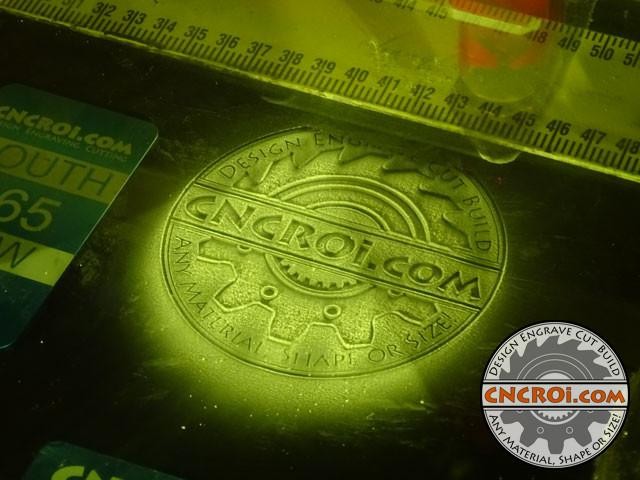

Both designs are identical in this CNCROi.com demonstration, the only difference is the acrylic “color” and “transparency” along with focus.

Focus plays a key role in end-results, for instance, if you want (or your design lends to) having lots of lines which is great for back lighting or edge LEDs, then this clear acrylic is a great way to add a lot more depth to a design rather than the pretty much matte finish of the engraved custom smoky acrylic coaster.

This is where operator skill (mine) comes in handy, I’ve done projects over endless materials for applications far and wide and as a result, most likely what you are after is something I’ve done.

This experience is gained through thousands of hours at the laser and other equipment, to me, laser engraving and cutting is like driving a bike and the settings to achieve a particular result are intuitive at this point.

The reason that I’m showing you two different engraving results on the same acrylic base is that I want to show you different finishing options possible.

The same concept and ideas can be just as easily applied to custom acrylic jewelry as well.

There is also a lot of passion behind CNCROi.com, you don’t get to this level of CNC enjoyment if it’s a job, I work everyday with my laser and other equipment in the shop and I really enjoy showing you what we can do while keeping 99% of our customer projects secret.

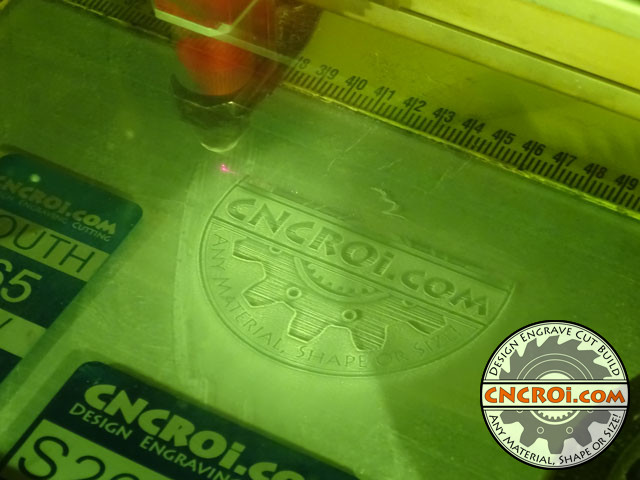

This clear acrylic was engraved at 600 DPI but dead-on focused which is why you see the strong laser lines across the engraved area, to get rid of those, I just run our Austrian wide-format industrial laser out of focus to make the beam tip thicker, thus melting more plastic in the surroundings.

All the dust you see around and on the coaster comes from the vaporized plastic produced by the heat of the laser, it’s so in focus that it doesn’t just melt the plastic, it turns it into powder instantly!

This is how we make snow in July!

The lighting in our Trotec laser also exaggerates the lines in the base, as does the dust, after a quick clean-up, you will see their prevalence diminish.

And yes, we do have frosty acrylic that we can use to create the same effect as you see below, check out the video of the corporate award above to see how we did that for the F16.

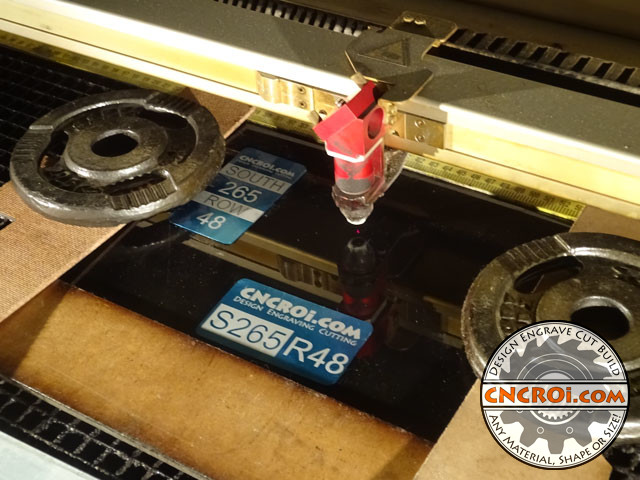

Now that the clear acrylic custom acrylic coaster is done, it’s time to cut the same design out of the smoky acrylic.

The weights you see are used to hold the acrylic down, engraving the surface of acrylic (heating) causes it to bend upwards, a few kilograms of weight solves that, don’t worry, it solidifies back flat after cooling.

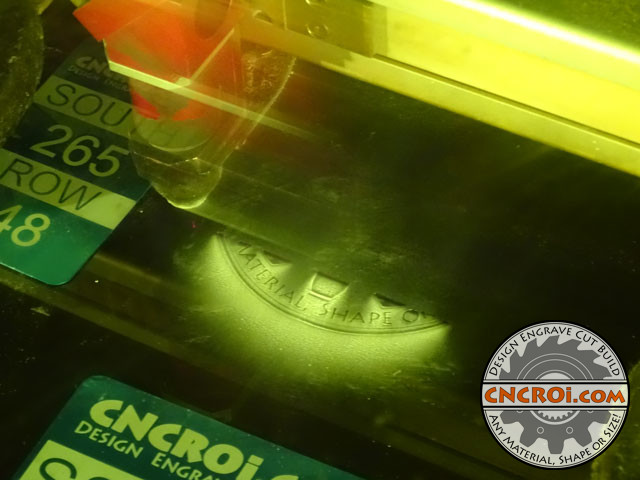

The nice thing about smoky acrylic is that you can really see the dust being produced over the glass looking acrylic above.

CNCROi.com has made endless custom acrylic coasters, we are able to handle production runs from the dozens to the thousands, all the same or different designs or materials.

It’s always amazing to look at a laser do its high precision work using materials you’d think would just burn right up from the heat.

The same design below is the same one as above, except above is paper (flammable too) and you can begin to get an appreciation for what CNCROi.com can make and custom do for our company or organization.

CNCROi.com performs the engraving first, then the cutting, this maintains everything to spec as we want to keep the full sheet of acrylic on the bed in one spot and together for as long as possible.

We don’t only engrave or cut acrylic, we can also color change it!

As soon as you cut out the acrylic (or any other material), there is a dramatically higher chance of it warping, burning and being off-centered due to a much smaller surface area getting hit with lots of laser heat.

The cutting of custom acrylic coasters is always fun, especially when it’s somewhat transparent, as it’s one of the few times you actually get to see the laser go through material, top to bed.

The beautiful flame polish of the acrylic from the heat is also a bonus, it’s smooth to the touch and reflects light amazingly, hence being great for LED installations.

Like the clear glass acrylic above, you can really see lots of vaporized dust but notice the engraving, there aren’t as strong lines going across the base.

Out of focus, wider beam, more melting area at depth.

If you are wondering what edge lighting on acrylic looks like, watch this amazing CNCROi.com video!

Here they are side by side, before cleaning, each has their own visual esthetic.

Here’s the smoky custom acrylic coaster, you can clearly read all the information on there, the lines are perfect, no missing steps and what needs to be sharp, is, and what needs to be rounded, is.

Now for the clear custom acrylic coaster, both it and the one above still have their protective masking behind them, this just keeps them from getting scratched.

And now you can really see how amazing the smoky custom acrylic coaster looks like, it’s consistently beautiful and incredible sharp and will last several years!

And compare that to the aggressive lines on the clear acrylic coaster below, each has their place in a design, and yes, we can mix and match them quite easily with CNCROi.com equipment.

Personally, I’m fine with either custom acrylic coaster effect, visuals aren’t always smooth and perfect and maybe it’s due to my background in 3D animation, but things that are too perfect just don’t seem natural to me.

Here they are together, amazing acrylic coasters, made to order, to your spec, however you like them!

And a close-up of both coasters, just so you can see how totally amazing our laser is at making custom acrylic coasters or using it to make just about anything else under the Sun.

Need something custom? Contact us right now!

That’s not all CNCROi.com can make out of acrylic, check out this video below!