Custom Acrylic Jig: CNC Laser Cutting 1/4″ (6 mm) Acrylic

Making a custom acrylic jig is pretty straight forward but there are issues that you need to be aware of in order to have the best result for your application.

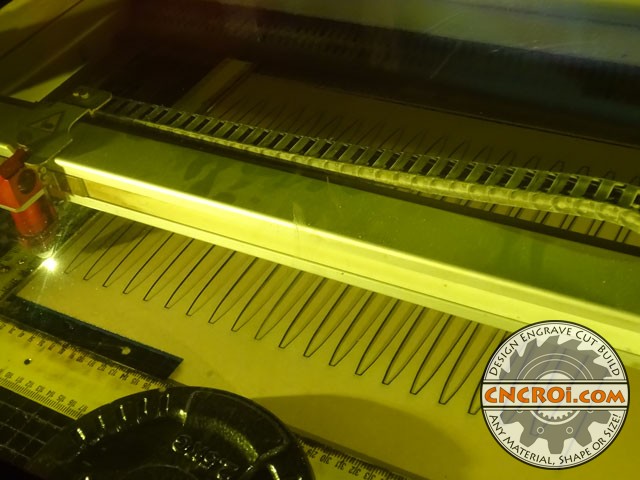

One of the first things to realize is that acrylic is plastic and as such, it is affected by heat so if you have a jig LOADED with holes then it’s dramatically more prone to warping during production.

As such, the easiest way to lessen warping possibilities with a custom acrylic jig made by CNCROi.com is to space things out a bit more.

Additionally, the thicker the acrylic we use for your jig, the more dwell time there is in any particular area, what that means is that the laser head is moving slower and thus, the flame underneath is there longer thus increasing the warping.

Easiest solution to that, is to go with a thinner acrylic, this lessens the amount of dwell time exponentially and thus, dramatically decreases the chance of warping.

Another way around warping issue due to heat is to have the jig made-up of multiple layers, so a flat layer not heat affected, thicker the better, followed by the one that is heat affected, bonding the two together creates enough weight that everything goes flat.

Of course, most jigs go flat and under their own weight, flatten out and can be secured easily with double-sided tape as well, so a little warping has never been an issue at the CNCROi.com shop.

Acrylic is a wonderful material for lots of jigs, it’s available in a huge variety of colors and can be easily combined to make signage or really neat and overly complex jigs.

For our Canadian customers, I made this sign.

While to represent our American customers another.

Acrylic is available in a variety of thicknesses as well and we have experience cutting both big and small things using a variety of equipment we have here in the shop.

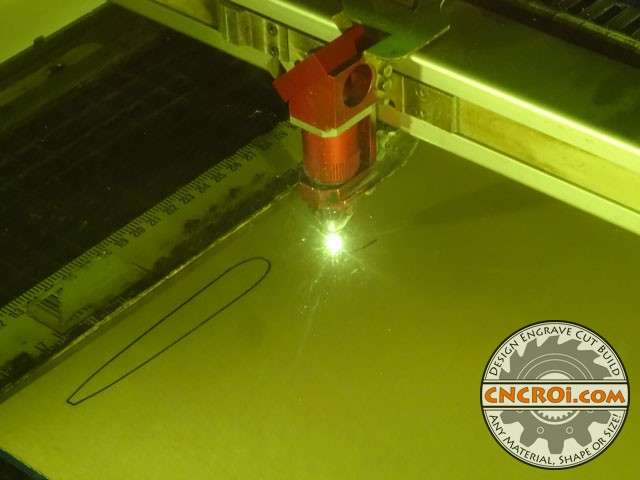

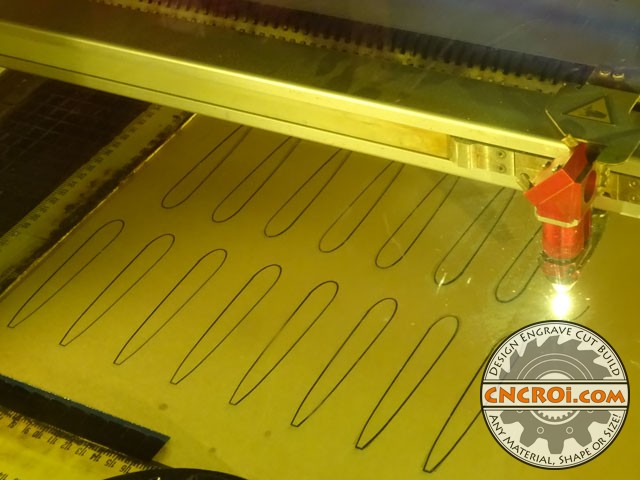

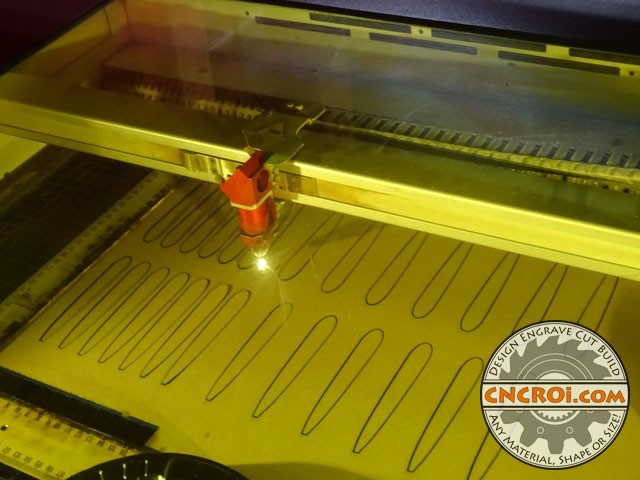

The reason you don’t see much fire happening around the acrylic is due to the fact that we have compressed air shooting down and a vacuum table quickly sucking out the combustible gases that are released when the acrylic is vaporized by our Austrian Trotec laser.

If you are wondering what the fire looks like underneath this sheet of acrylic, behold.

This material would be very dangerous to cut if it wasn’t for the laser that we have and the precautions we built-into the laser to avoid having a fire that could burn the shop down on any lesser set-up.

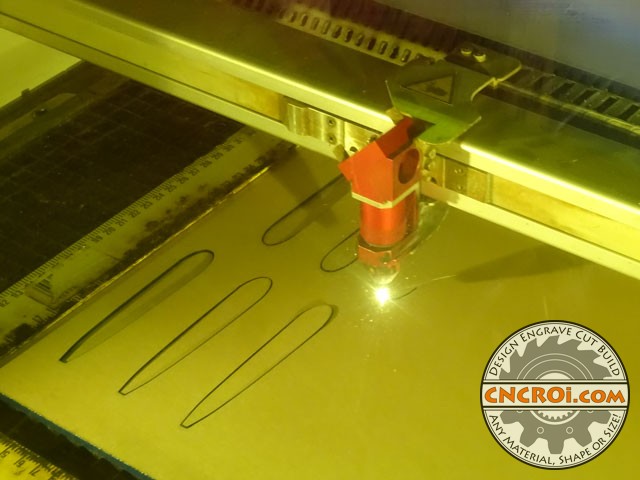

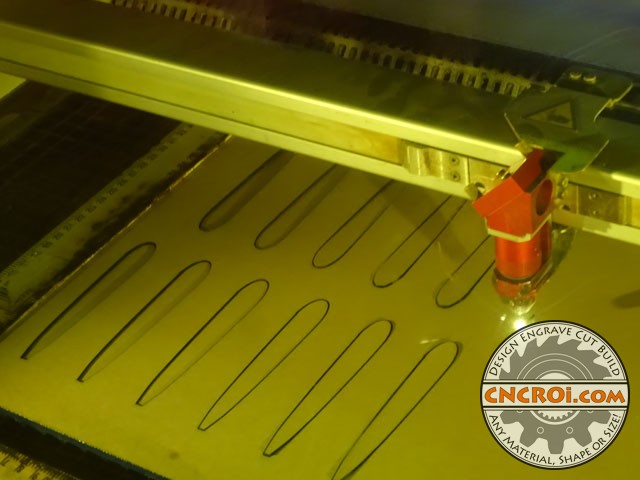

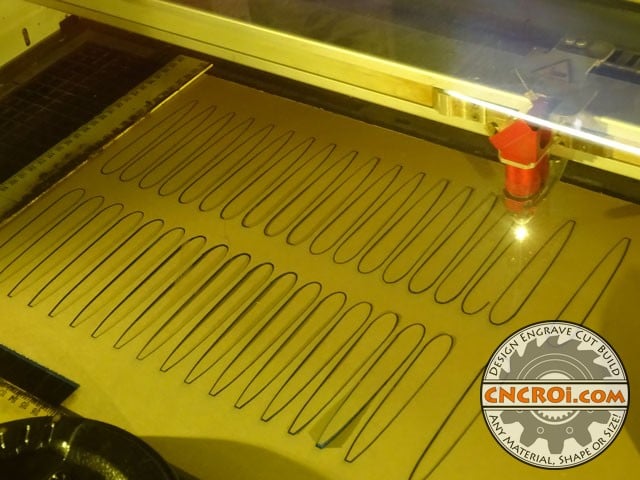

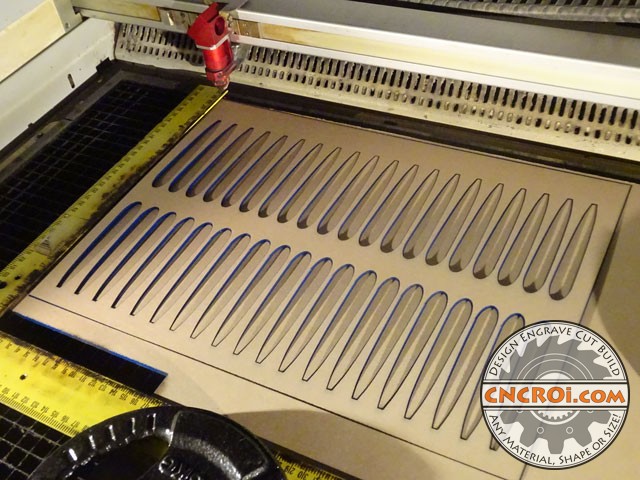

This custom acrylic jig is just about done, just need to cut it out of the sheet we layed onto the laser bed.

As it’s cutting around, the laser is producing a nice flame polish which allows for a very nice edge finish on the acrylic, something you wouldn’t get if we did this with CNCROi.com‘s CNC router or with a waterjet.

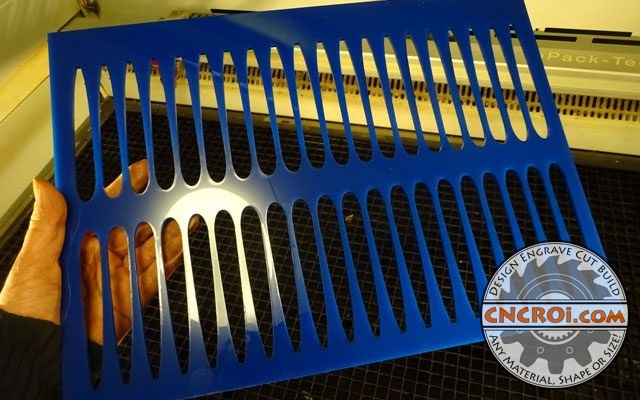

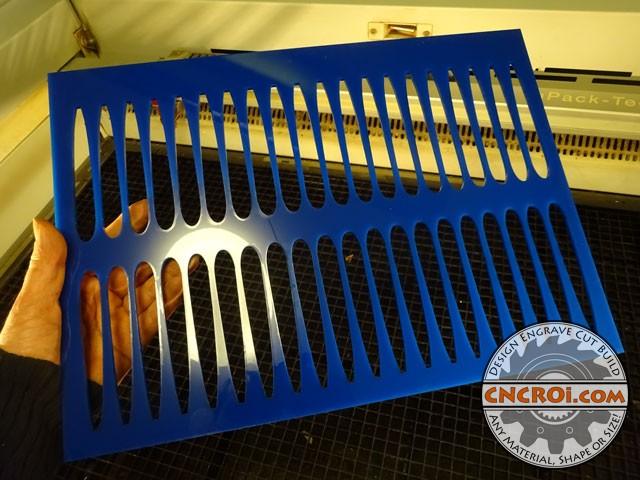

The custom acrylic jig is now completely cut out of the sheet, and ready for use.

Removing the protective masking shows you the results of our CNCROi.com laser cutting out all the shapes and forms from it.

We also make a lot of other products using acrylic, from custom coasters…

to animal silhouettes both existing and long extinct…

molds for pottery or imprint…

jewelry at all different price points and material options…

cake toppers for birthdays and anniversaries…

keychains of all sizes, shapes and colors…

amazing corporate and personal achievement plaques…

and a mix and match of other things.

So if you are looking for something to be made out of acrylic, be sure to contact CNCROi.com and we’ll make it for you.