Custom Acrylic Router Guides: 1/4″ Plastic

These custom acrylic router guides will last the customer for many units as they are using it to make furniture parts for their business, hence using 1/4″ thickness.

Custom acrylic router guides can be made using anything from 1/8″ through 1″ acrylic, if you wanted them to be even more durable, consider steel or less durable, MDF, it really all depends on how many times you plan on using it as each material has their plus and minus when it comes to this specific application.

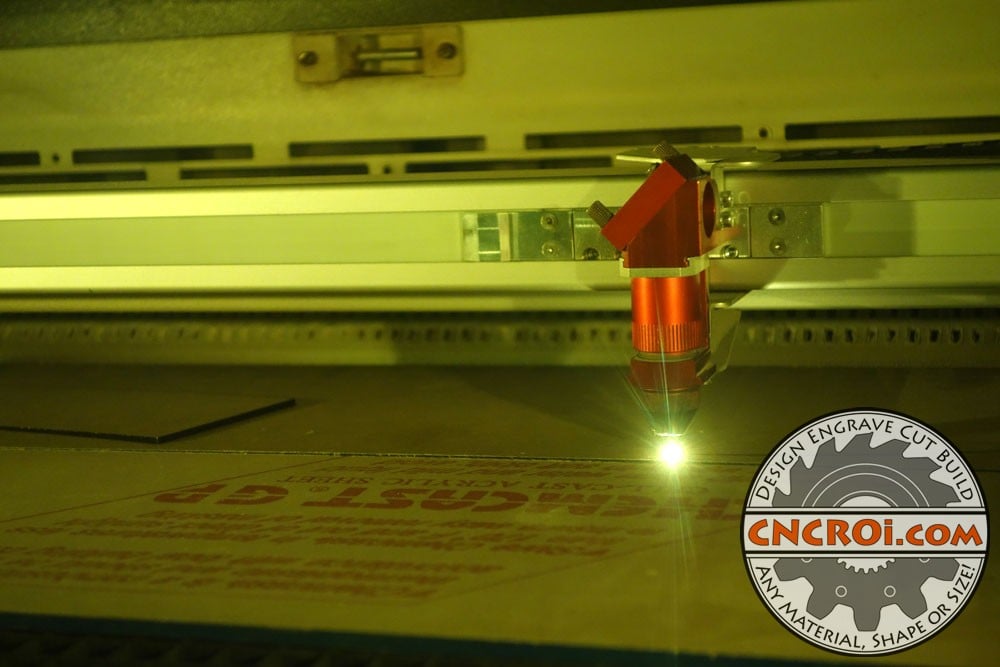

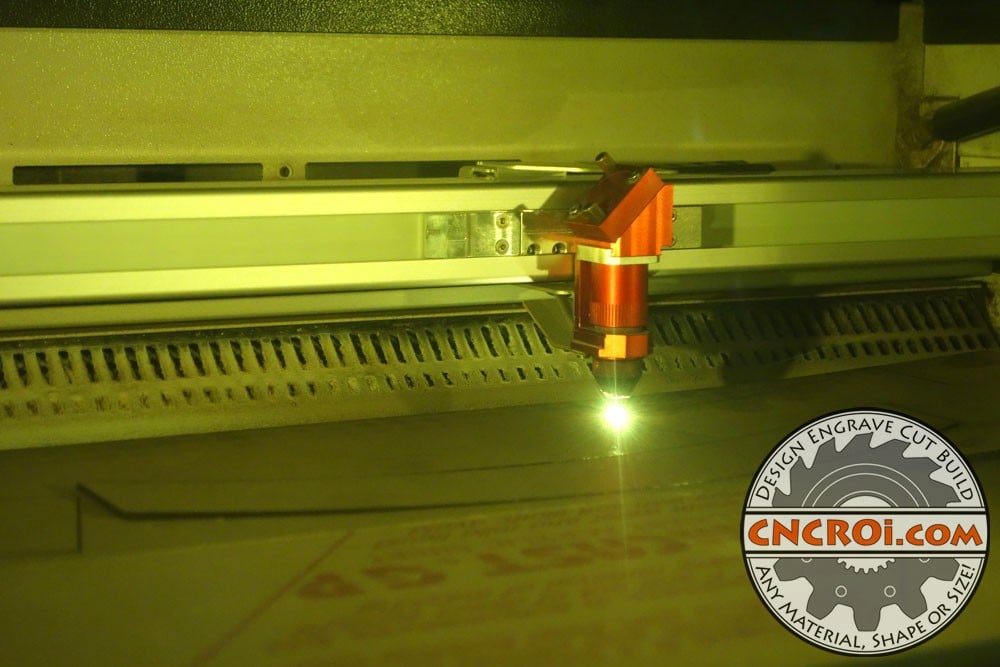

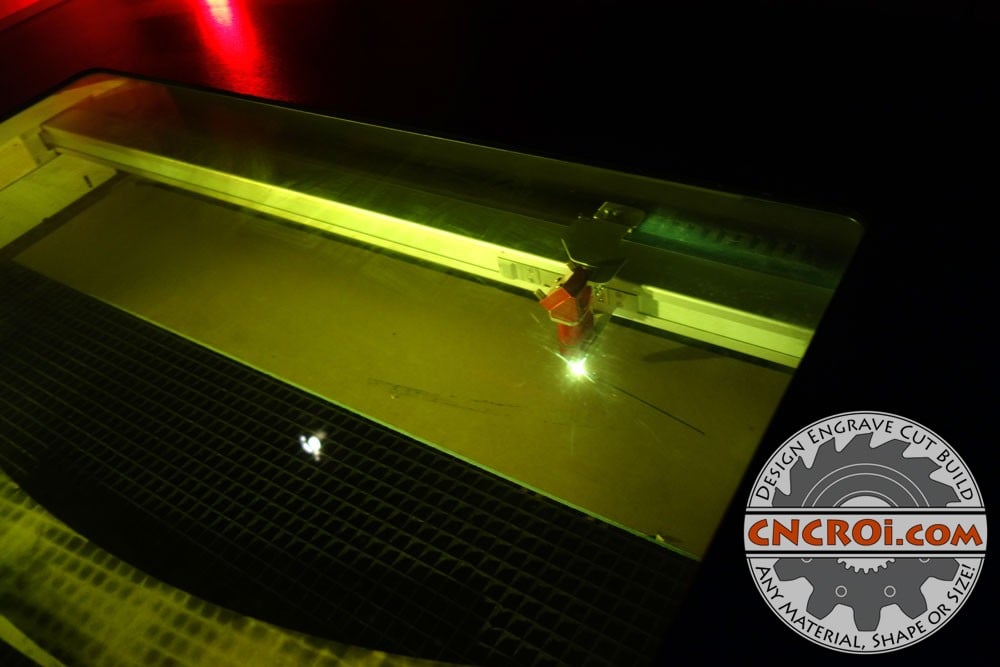

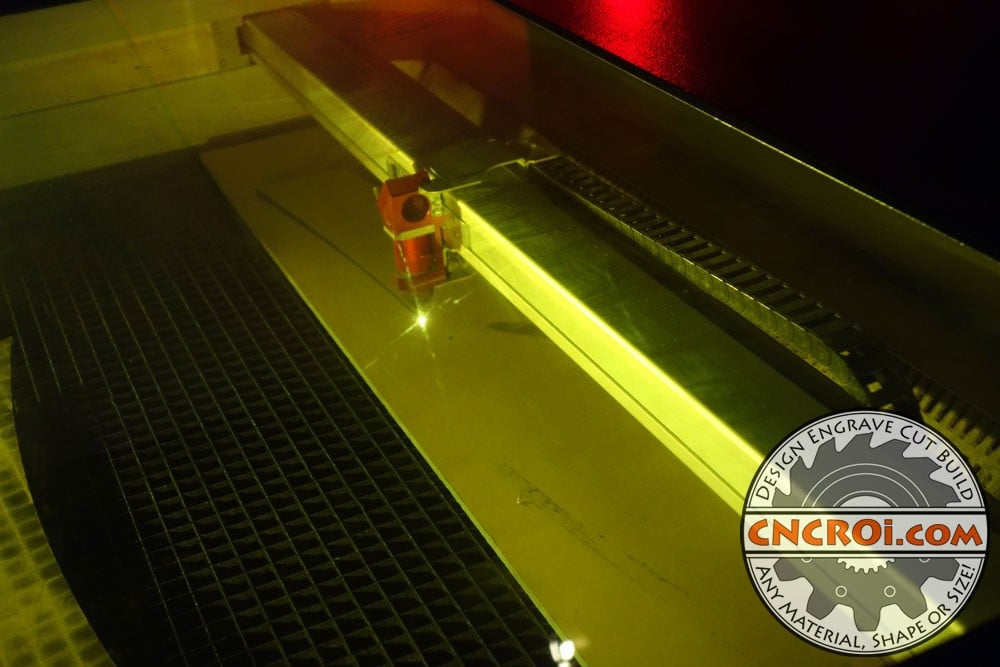

For the best cut quality that the customer required for their project, I cut these custom acrylic router guides at CNCROi.com using our CNC laser.

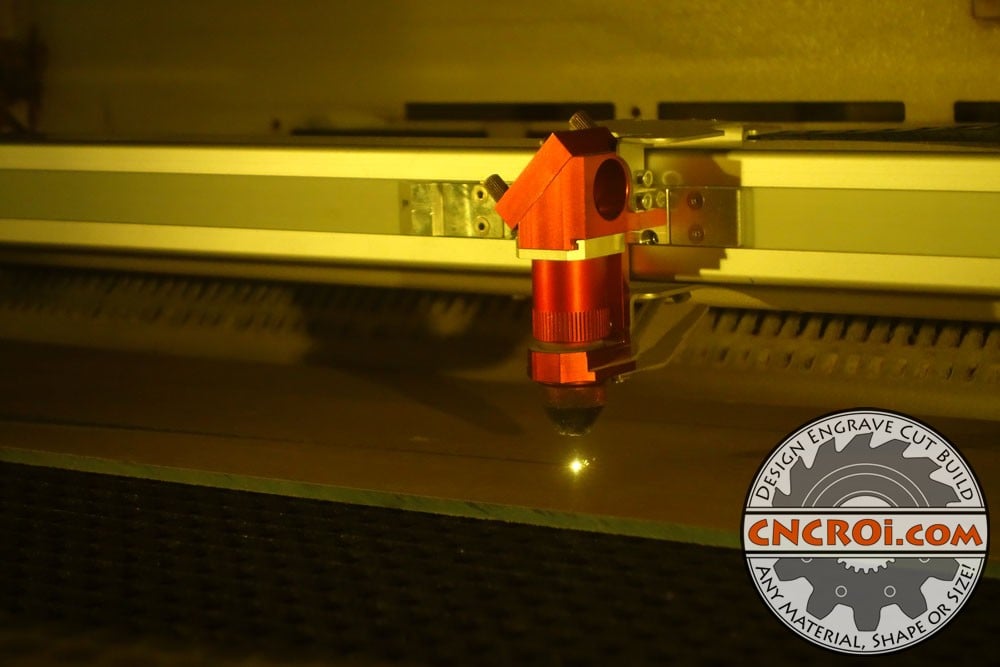

Unlike our CNC router, which we can also use for this application, the edge is a smooth flame polish, with the router, it’s a little rougher but like material options, machine output options also have a cost and benefit associated with the production of the part.

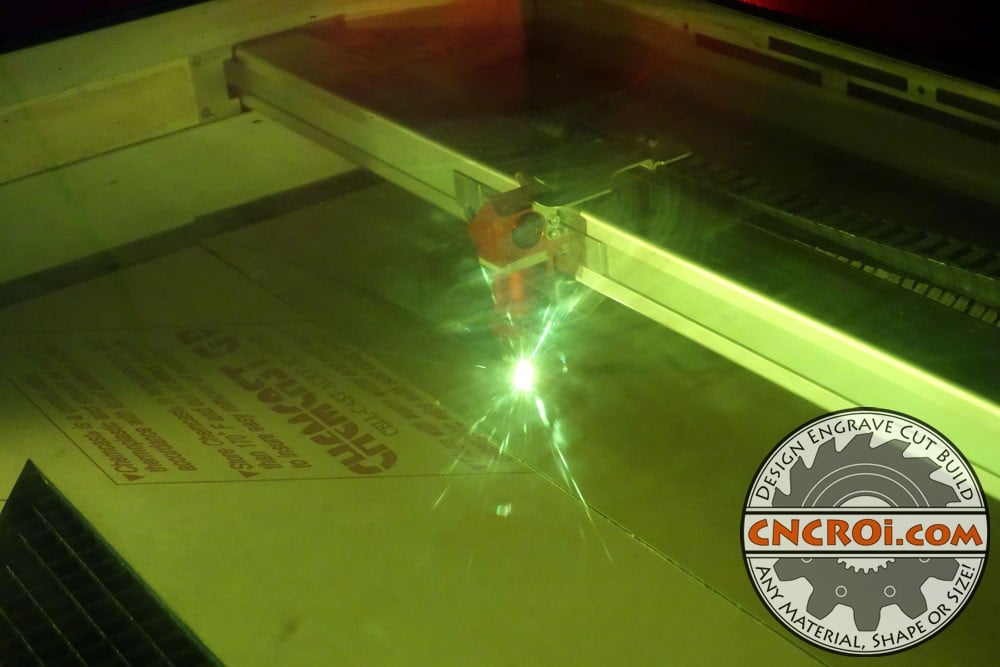

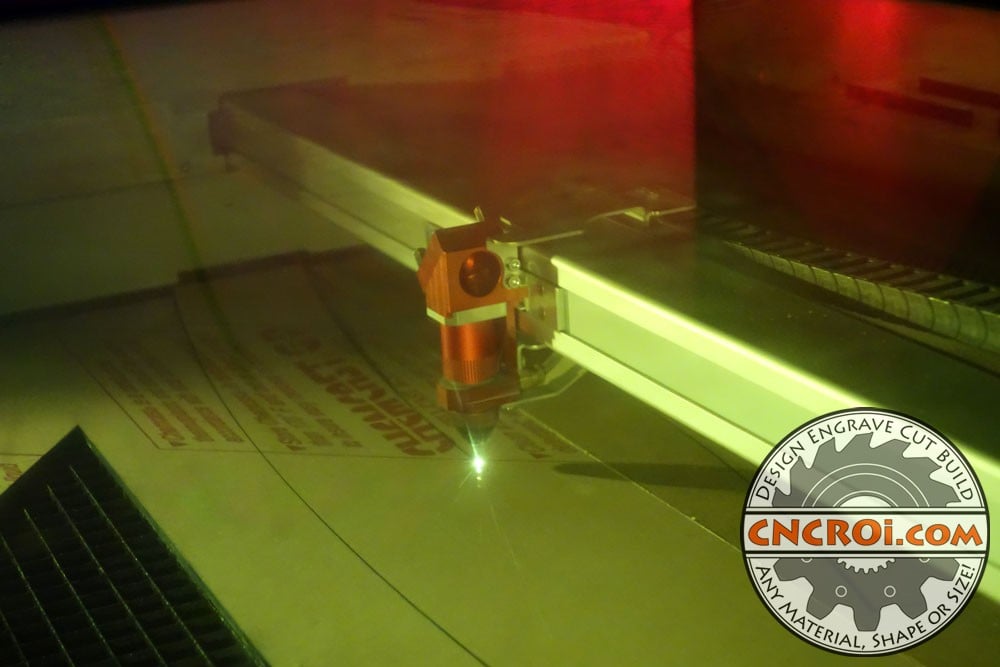

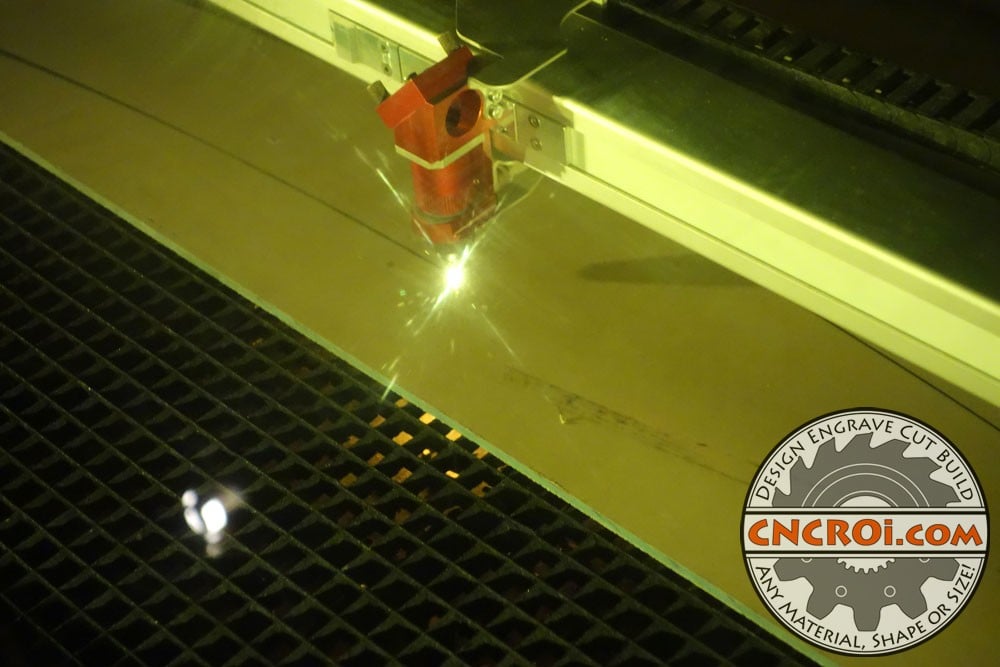

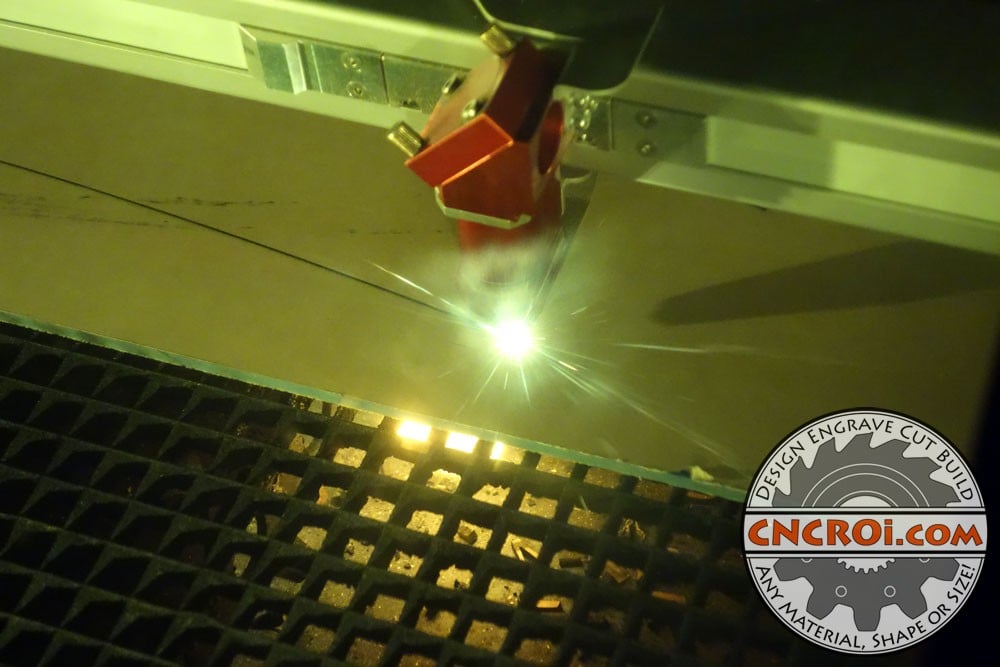

You have to keep in mind that with lasers, acrylic is basically solid gas, so there is always a fire risk cutting it, but we’ve taken a number of steps that might not be evident, that greatly reduces the risk of the shop burning down.

There’s always more than one way to cut metal at CNCROi.com.

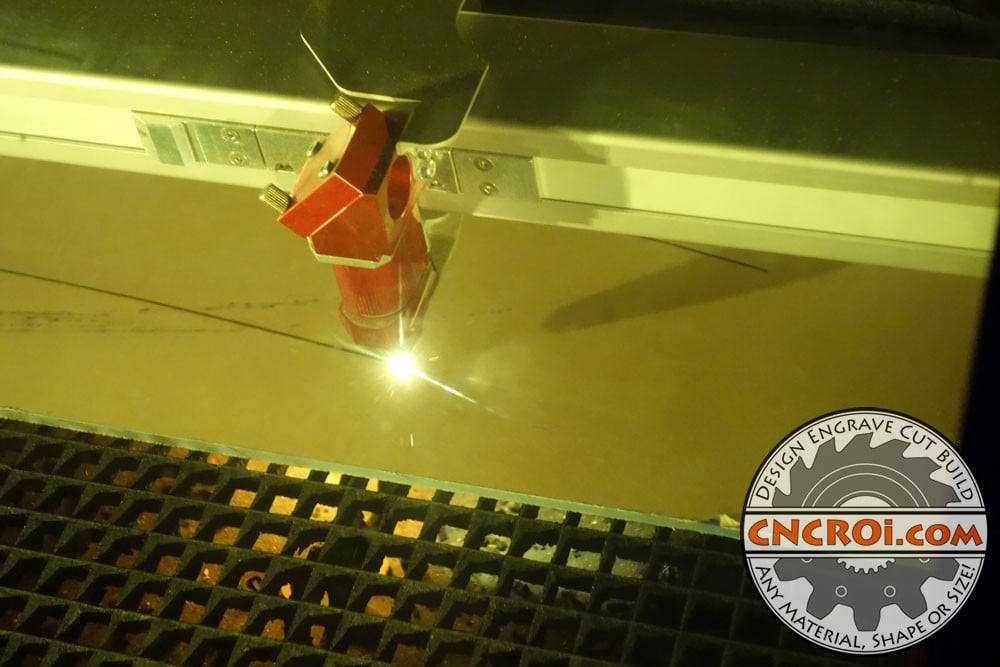

The really nice plus in the laser department when it comes to cutting custom acrylic router guides is that the machine never touches the material, as such, no hold-down is required in order to cut the parts at CNCROi.com.

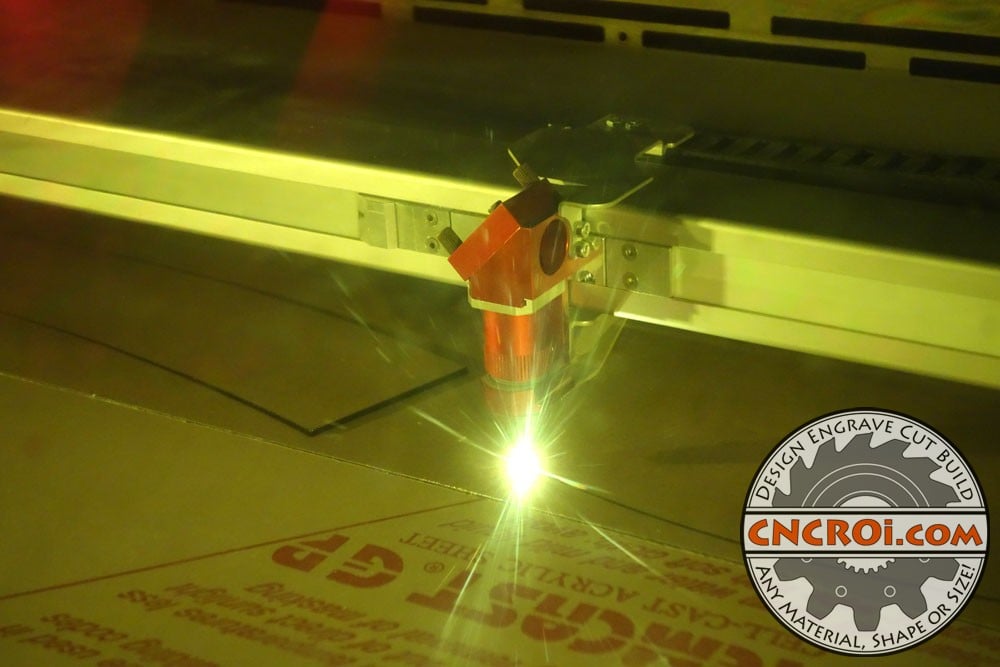

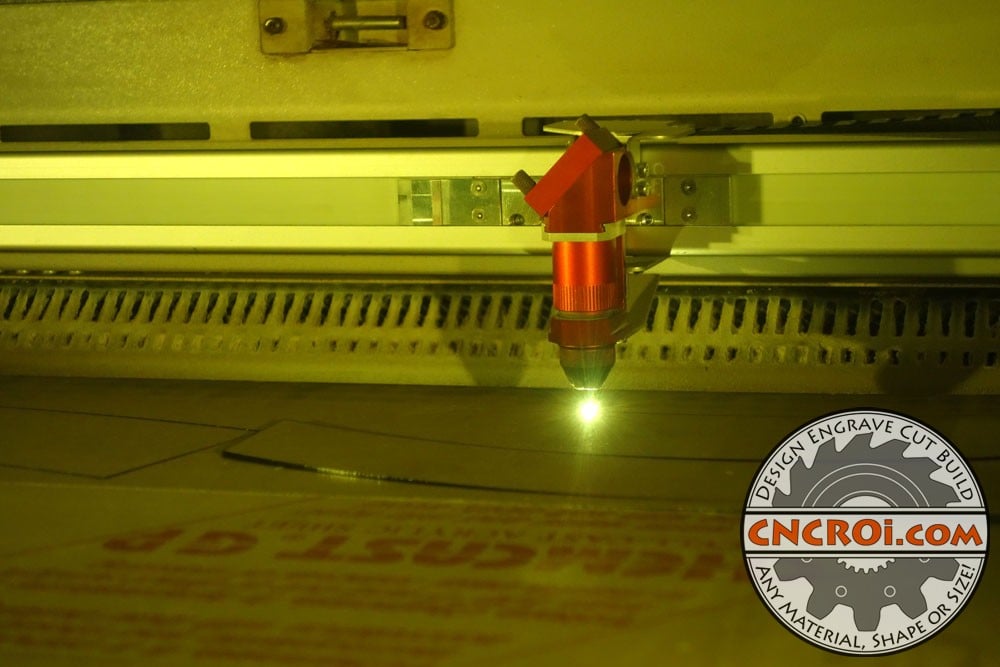

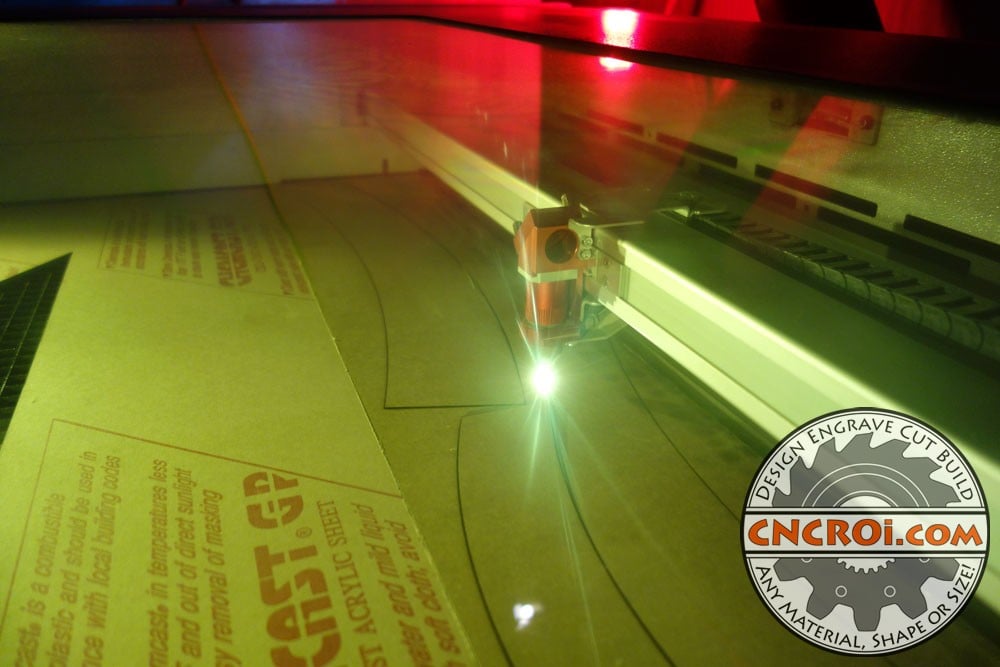

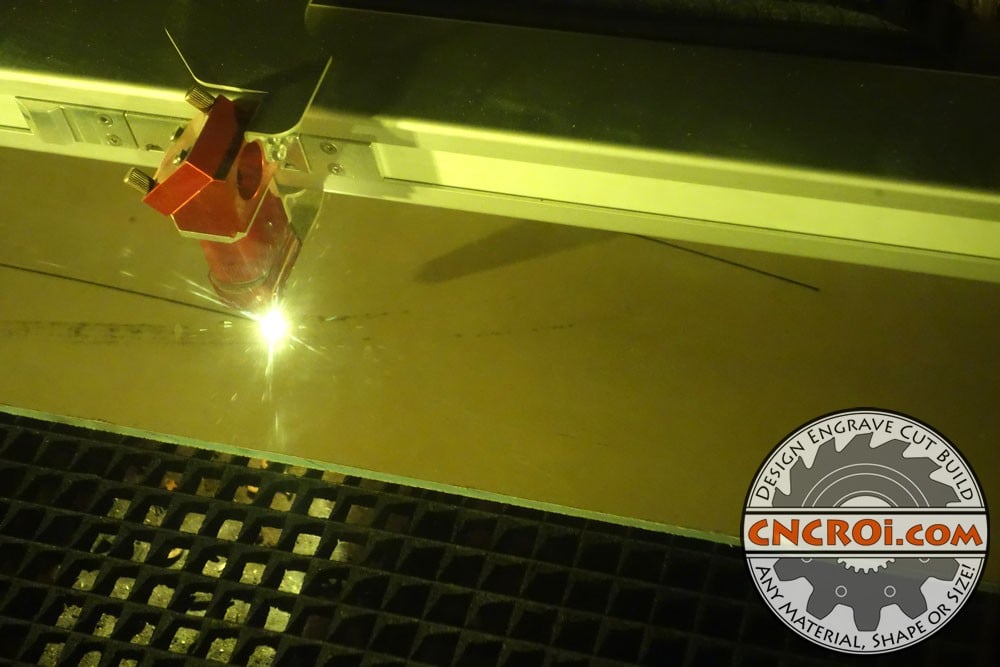

The reason why you don’t see the actual acrylic in these photos and videos that will become custom acrylic router guides is because they are covered by a protective masking on both sides, this keeps the surface of the acrylic clean, especially the backside, which has a lot of soot built-up from the flame shooting back up.

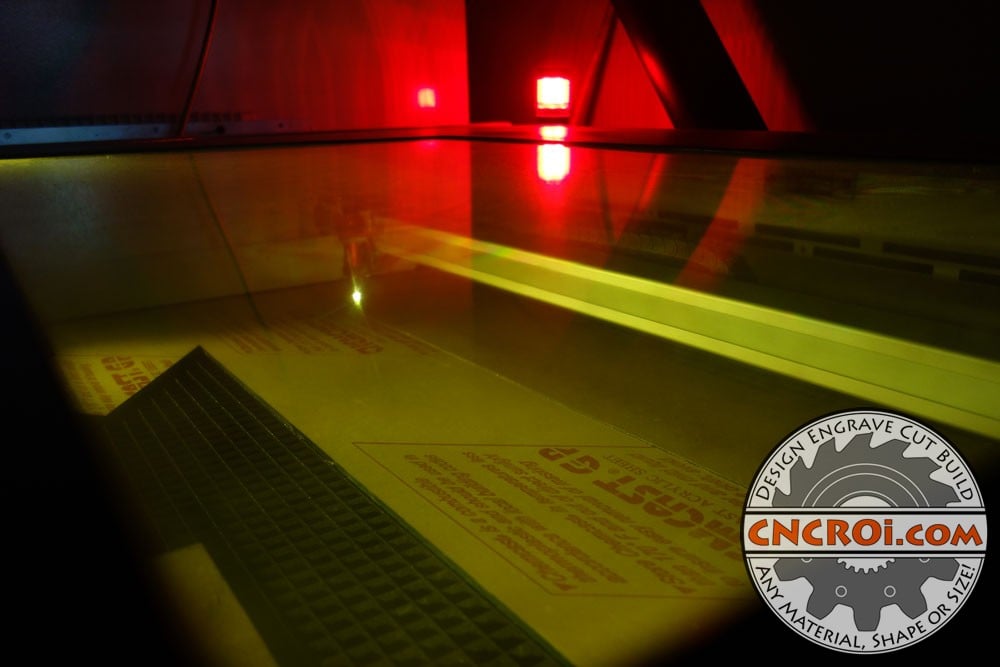

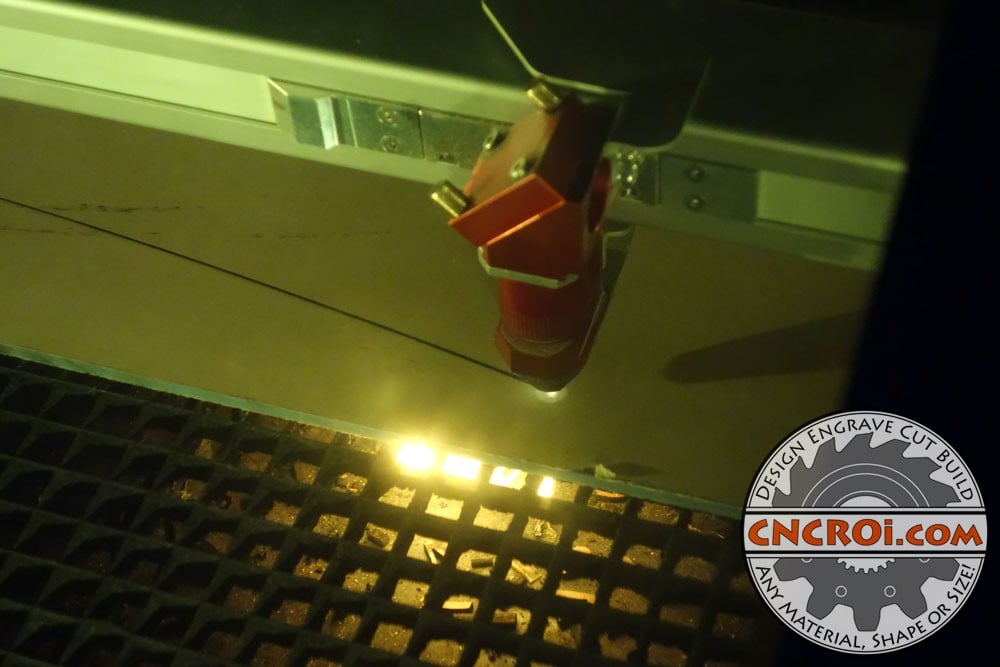

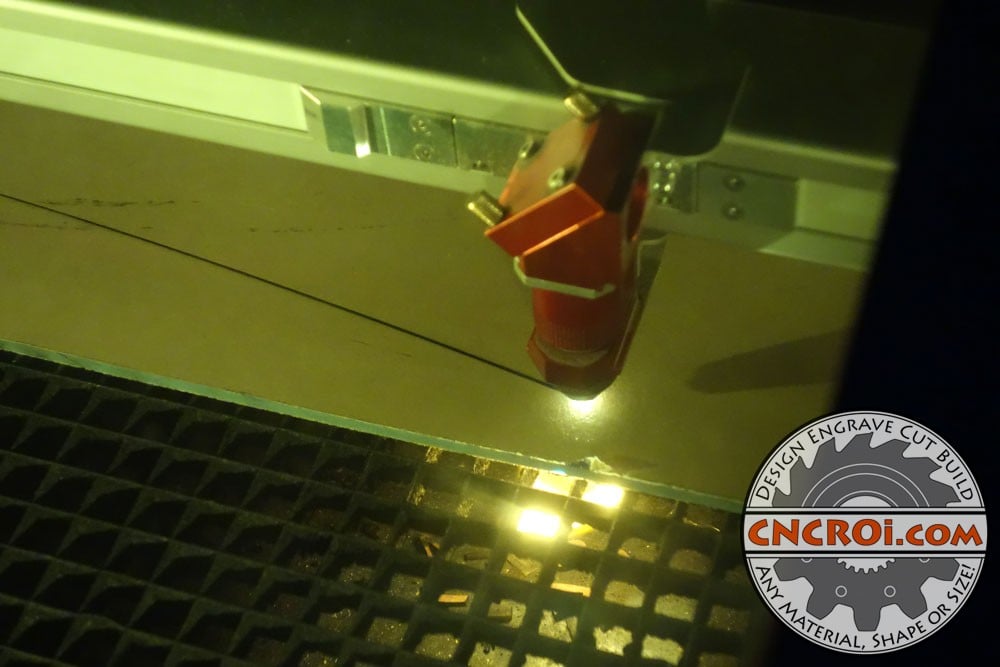

The reason you don’t see a flame on the top of the acrylic sheet at CNCROi.com is because there is compressed air shooting down where the cutting is occuring, this extinguishes the flame and pushes it through and under the material.

Just to give you an idea of what’s possible using a CNC laser.

There is certainly some heat generated during the cutting of the custom acrylic router guides, that’s why you see it temporarily lifting in the above photo, once it cools back down, this goes back to flat but if this becomes an issue, CNCROi.com can just cut it out of thicker material or use our CNC router.

When cutting acrylic with a laser, the major advantage over a router other than not having to hold it down during production is the tighter cutting area we can achieve, as there isn’t a spinning bit involved, so the parts can essentially be one next to the other.

For this custom acrylic router guides project, the parts that make it up fit just perfectly on some scrap I had in the shop, so I had wonderful use of material and anything left over was there anyways so it isn’t much of a loss, it gets recycled or thrown into the fire pit.

Of course, I also have some fun with my routers at CNCROi.com.

Once one set of custom acrylic router guides is cut at CNCROi.com, the next one is set-up and ready to go until all of them are ready for the customer to use with their manual router.

It’s nice to be able to throw a piece of acrylic on a bed and just cut it out without having to be concerned about holding it down, spacing for a router bit or making sure everything is flat, but it does come at a potential risk, this stuff is highly flammable.

Metal is a wonderful choice for guides if you have something you want to use a lot of.

When it comes to acrylic, it’s a very durable material but keep in mind that it does shatter if you throw it on the ground, so it isn’t bullet proof, if you wanted that, we can also make these using polycarbonate which is even more durable and literally, bullet proof.

The fun part about cutting acrylic is how clean an edge we achieve at CNCROi.com thanks to the flame polishing effect of the laser built-in.

The bright light you see in all these photos and video aren’t the laser, they are the affect of the laser on the cutting of the custom acrylic router guides, you never actually see the laser anywhere.

When it comes to material choices, generally they are down to three, MDF, acrylic and the more durable steel.

The thickness of the kerf, or cut area line, is less than that of a human hair, as a result, nesting of shapes is fantastic, unlike our router, where we can’t use a CNC bit of this small a diameter without it instantly breaking from the pressures put upon it pushing and pulling through the material.

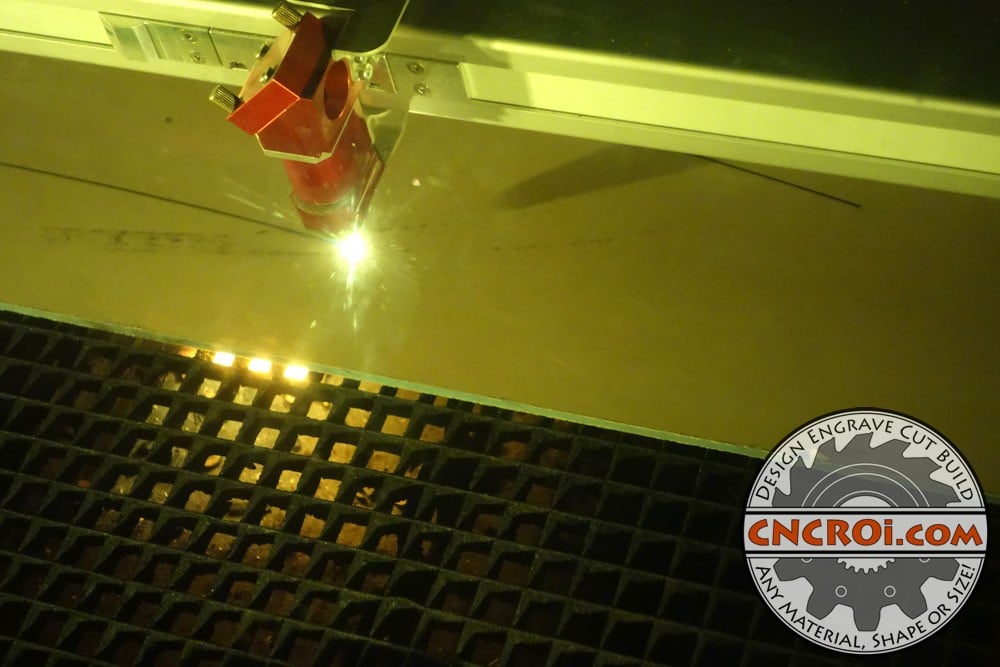

I’ve found the grid table to be the best table for cutting acrylic in our shop, we can change the table to a solid one or even magnetic, but this works wonders and does a fantastic job making sure everything is safely done in our shop.

Curves, squares, straight lines or sketched-out shapes, all work totally fine with our laser and by extention, our router as well when it comes to making custom acrylic router guides.

Suffice it to say, I do a lot of custom guides for guitars and other instruments.

The reason you don’t see any build-up of combustible gases or smoke is because CNCROi.com has a powerful extraction system that quickly throws it all away from inside our CNC laser.

You’ll notice the flame underneath in the above picture, that’s quite dangerous because if the acrylic catches on fire, it burns hot and fast!

Need custom acrylic router guides? Contact CNCROi.com right now!