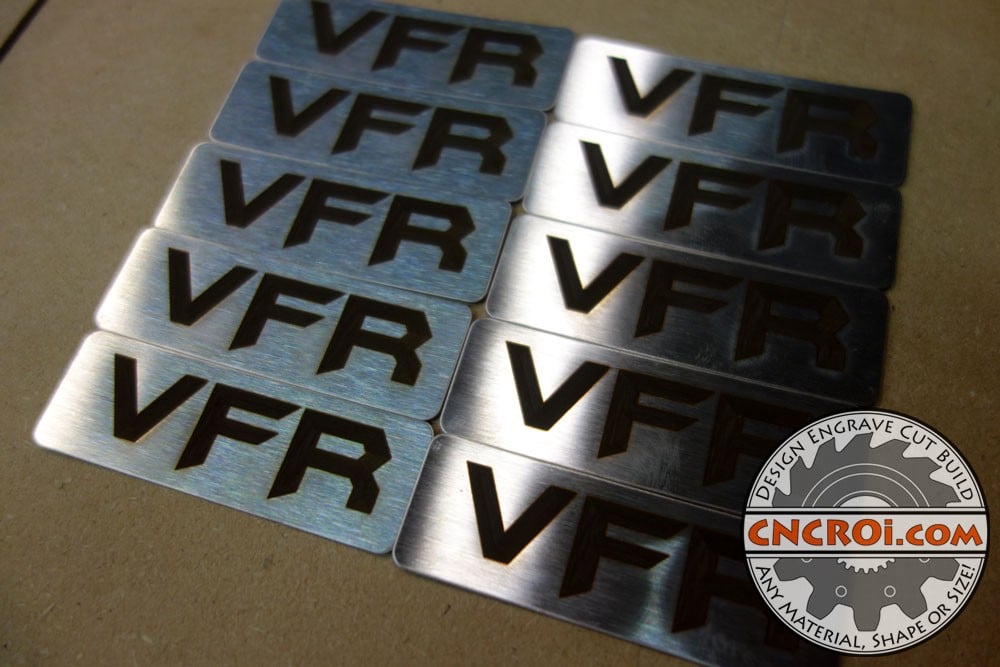

Custom Automotive Tags: 304 Stainless Steel

Custom automotive tags can be made to any spec you can imagine, and CNCROi.com offers a host of blank options as well if you are in a rush to benefit from them ASAP!

Stainless steel is a wonderful material for custom automotive tags because you can weld it directly to the base metal of the same spec, so you don’t have to worry about galvanic corrosion.

CNCROi.com has several different ways of etching stainless steel, but for some applications, cutting through is more advantageous and of course, we can do that as well.

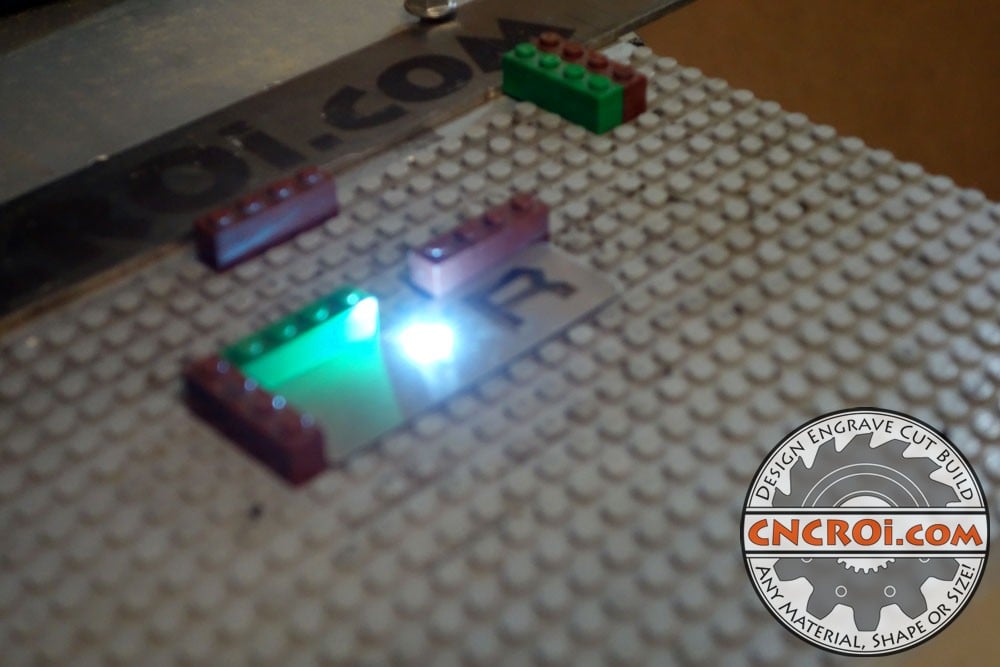

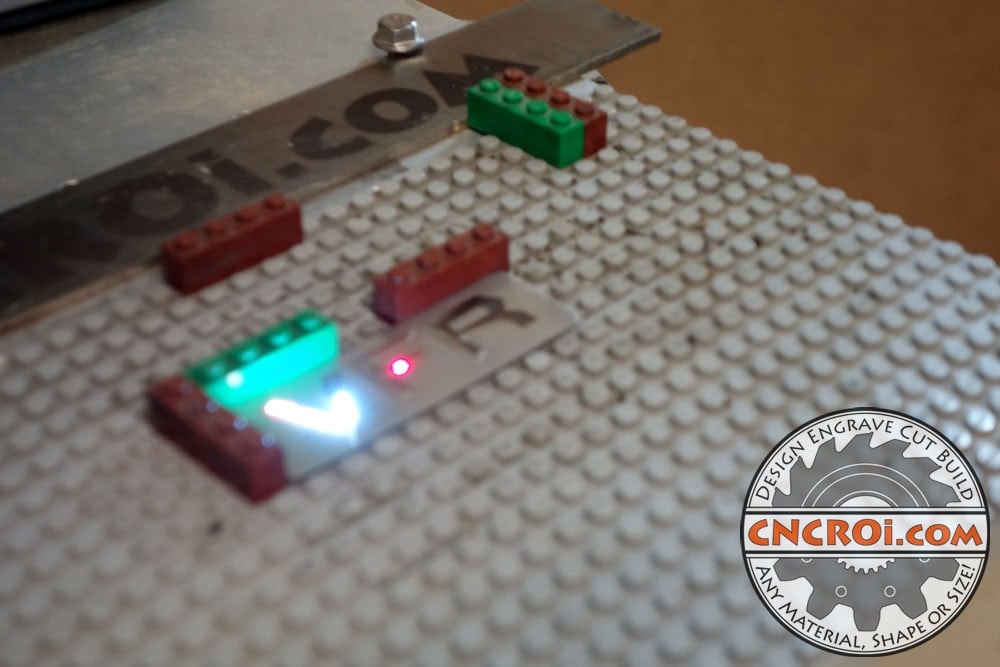

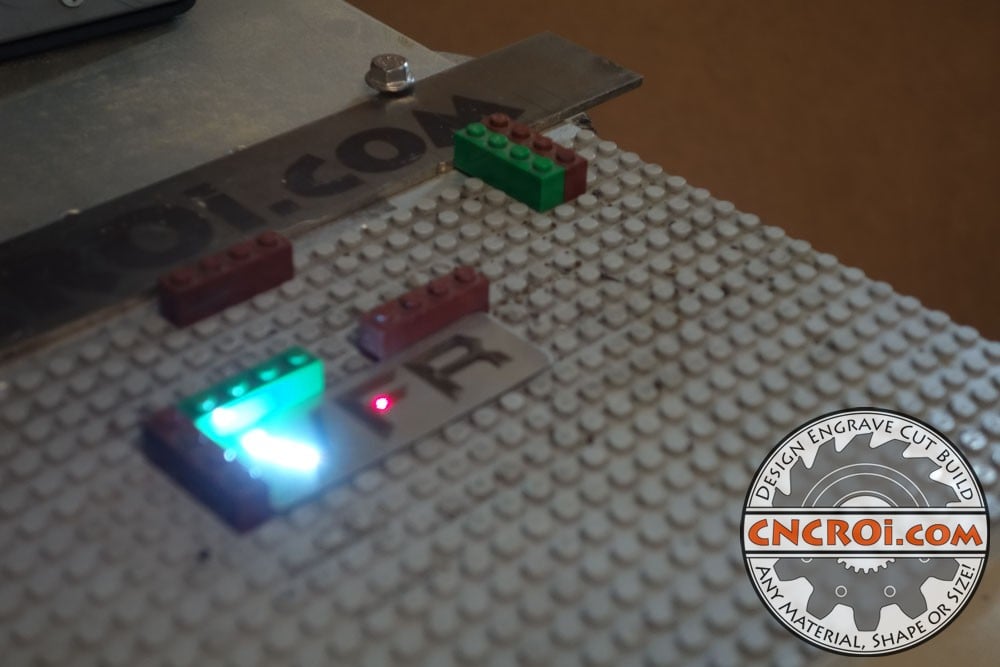

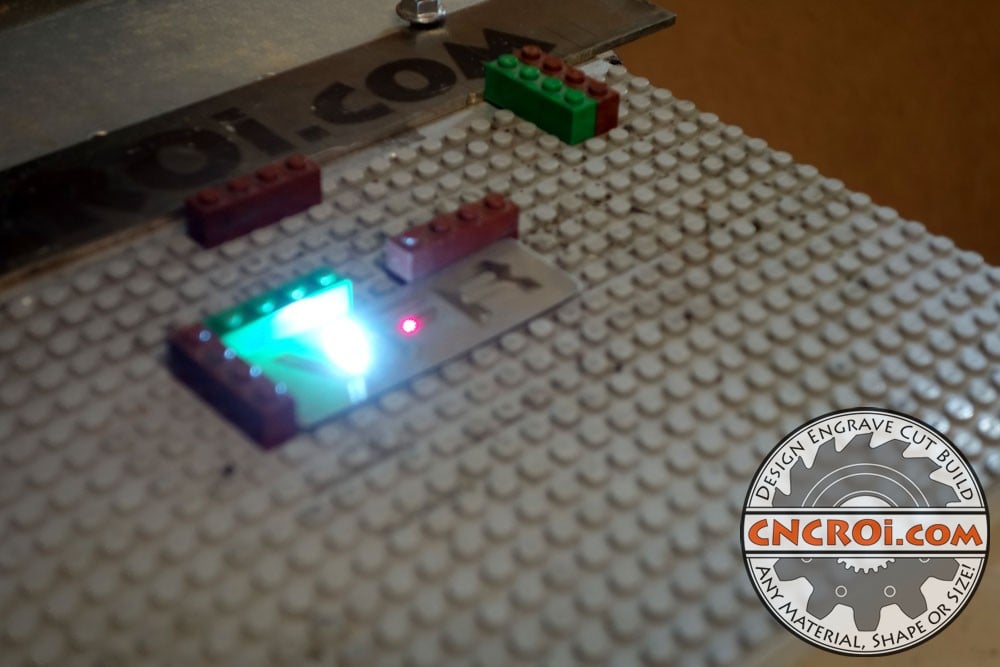

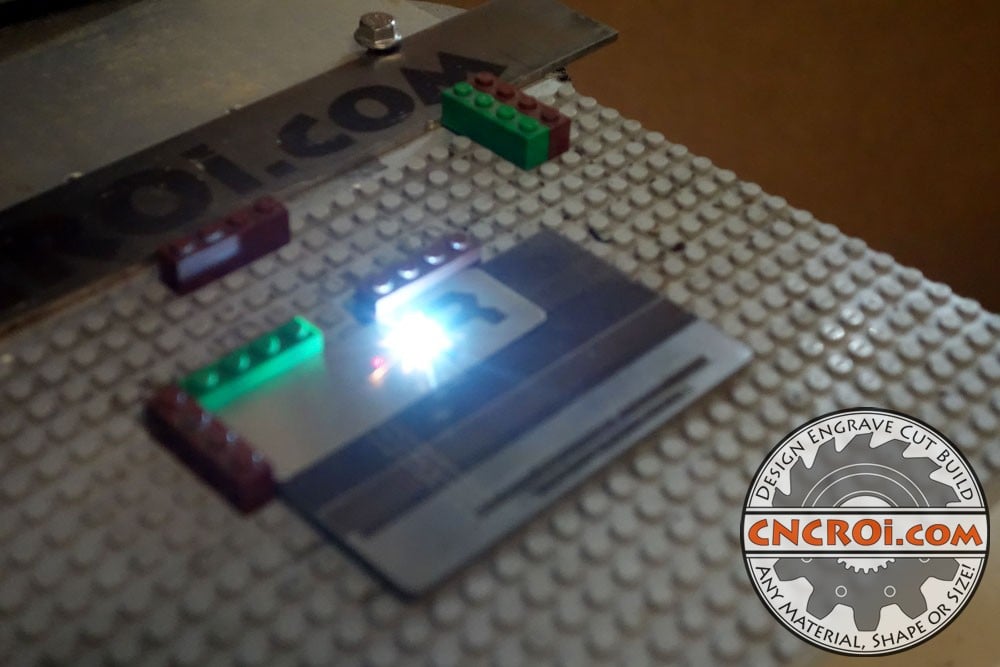

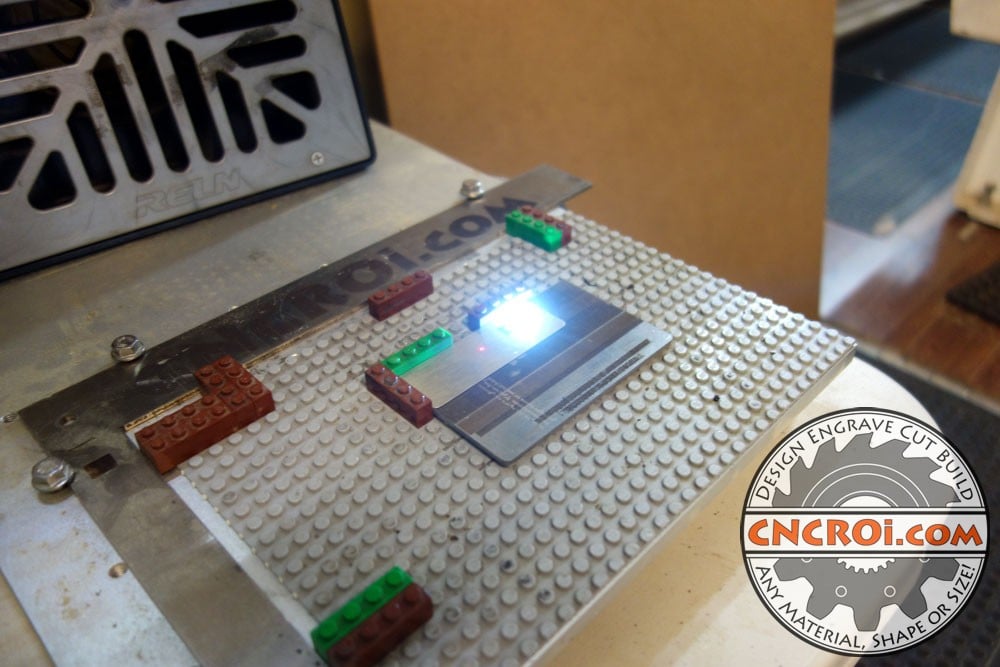

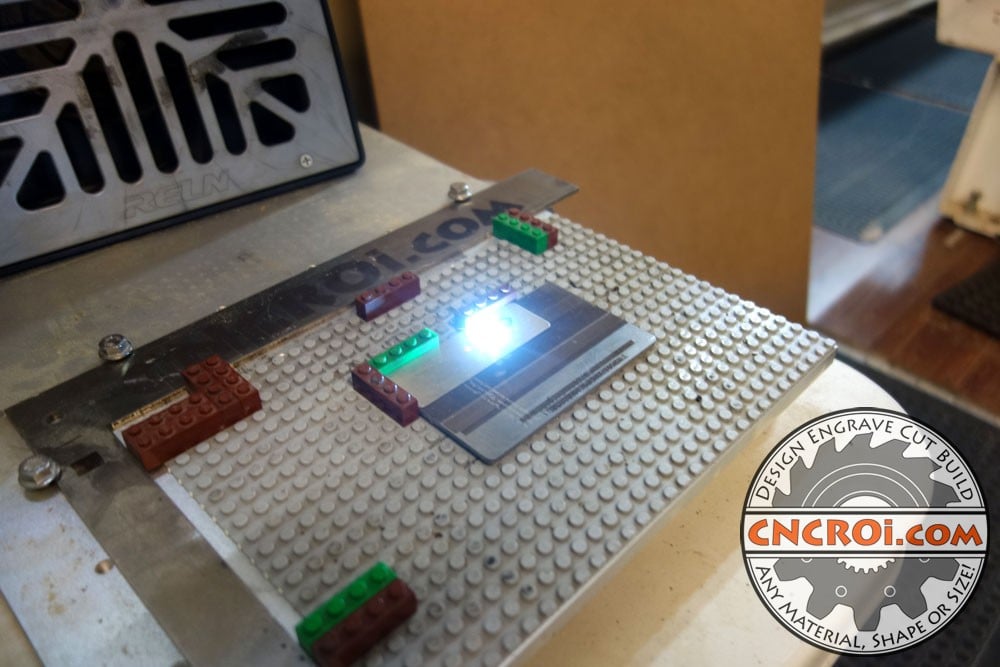

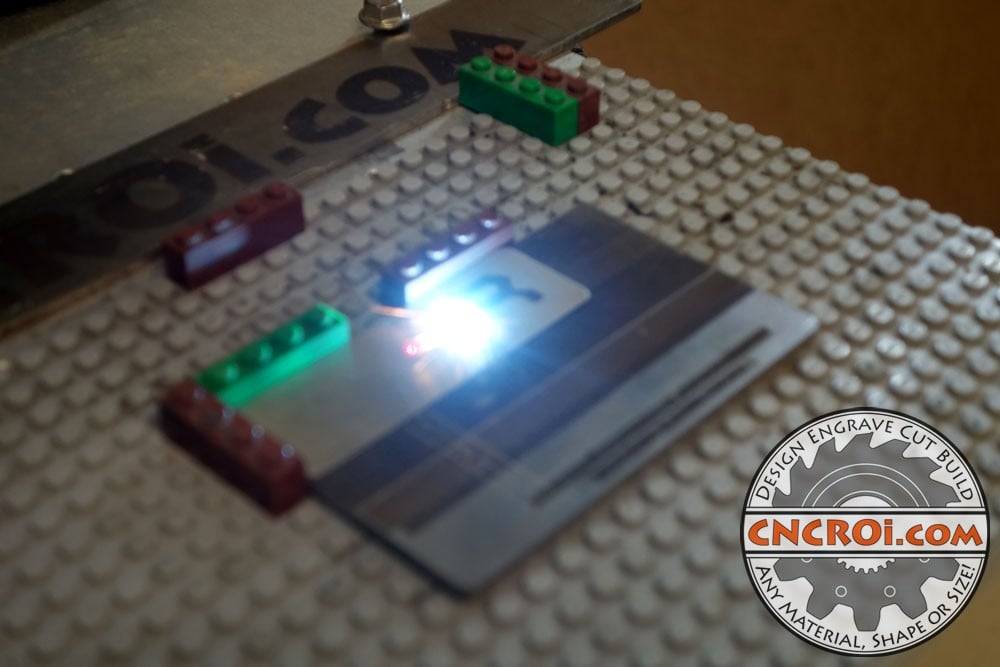

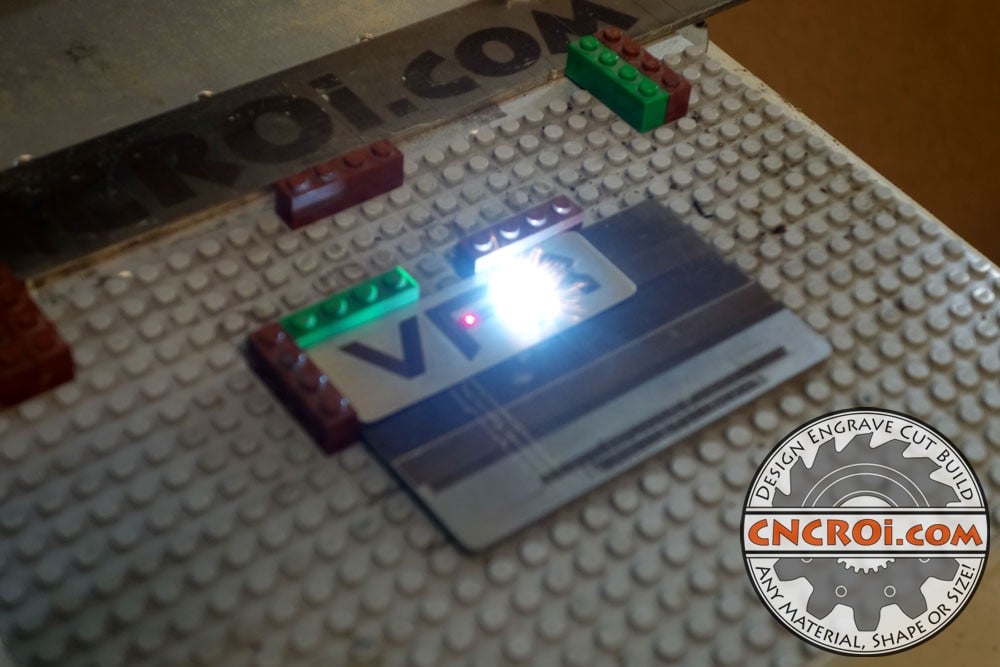

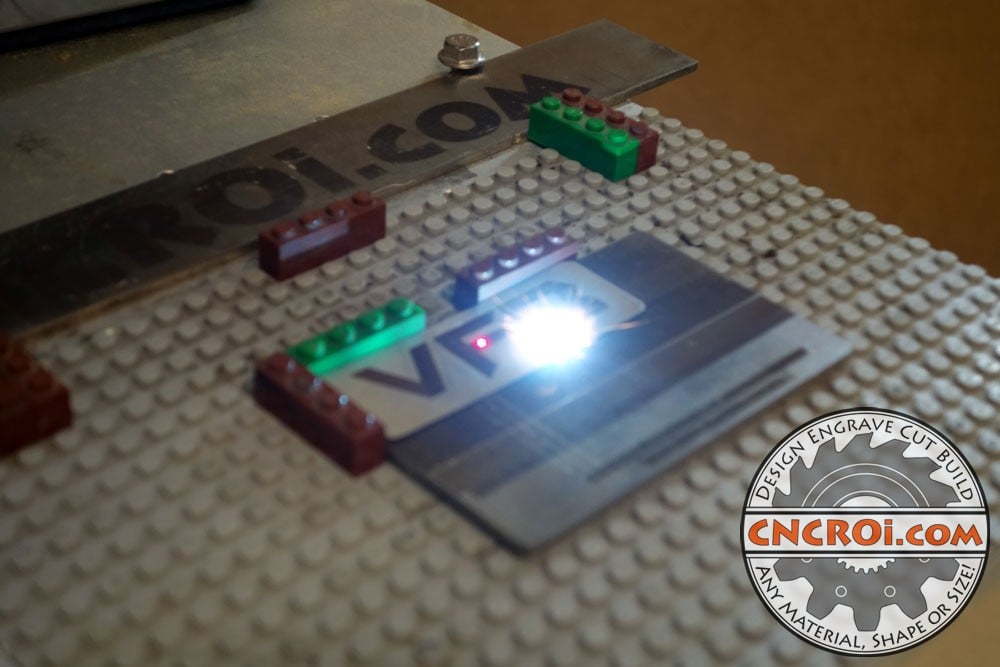

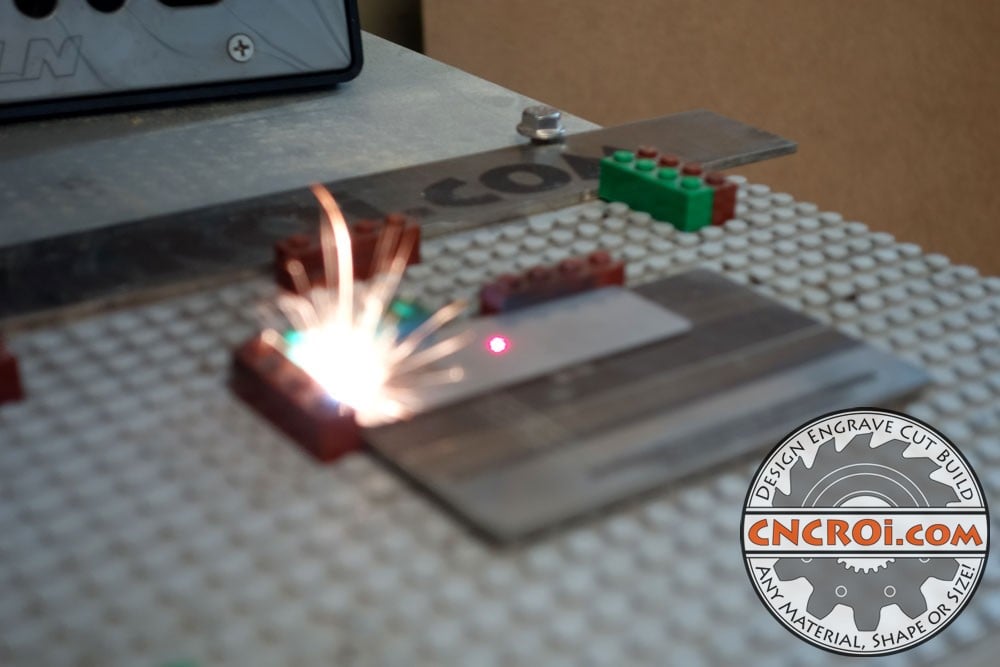

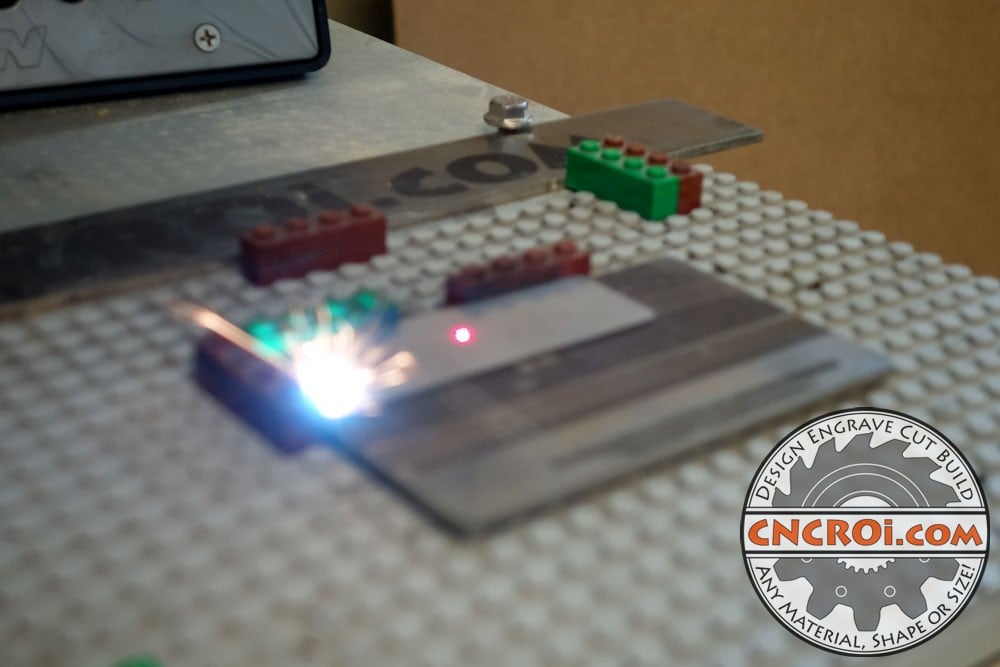

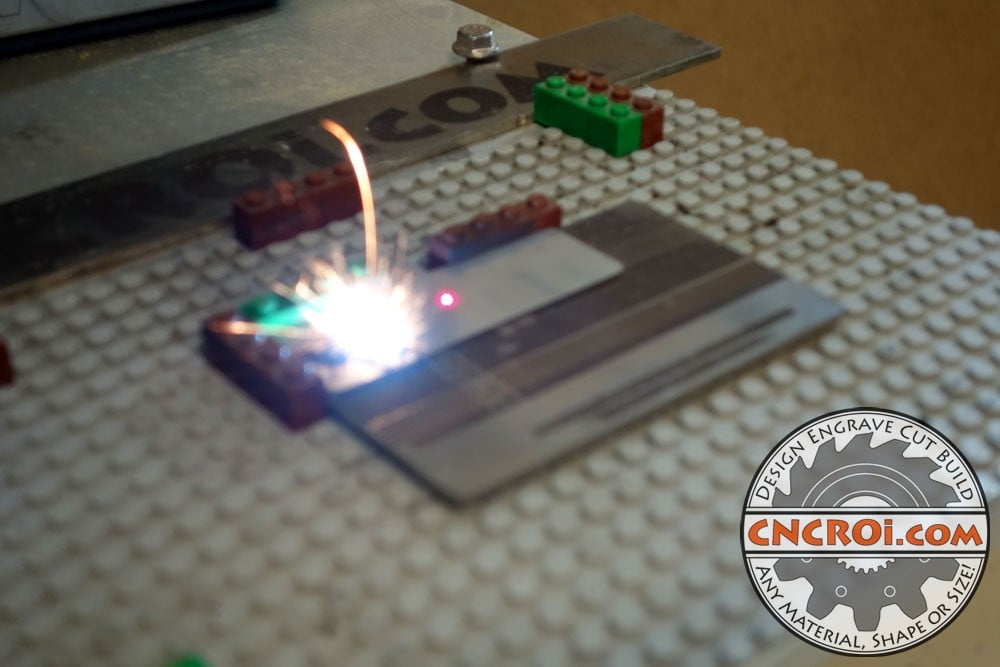

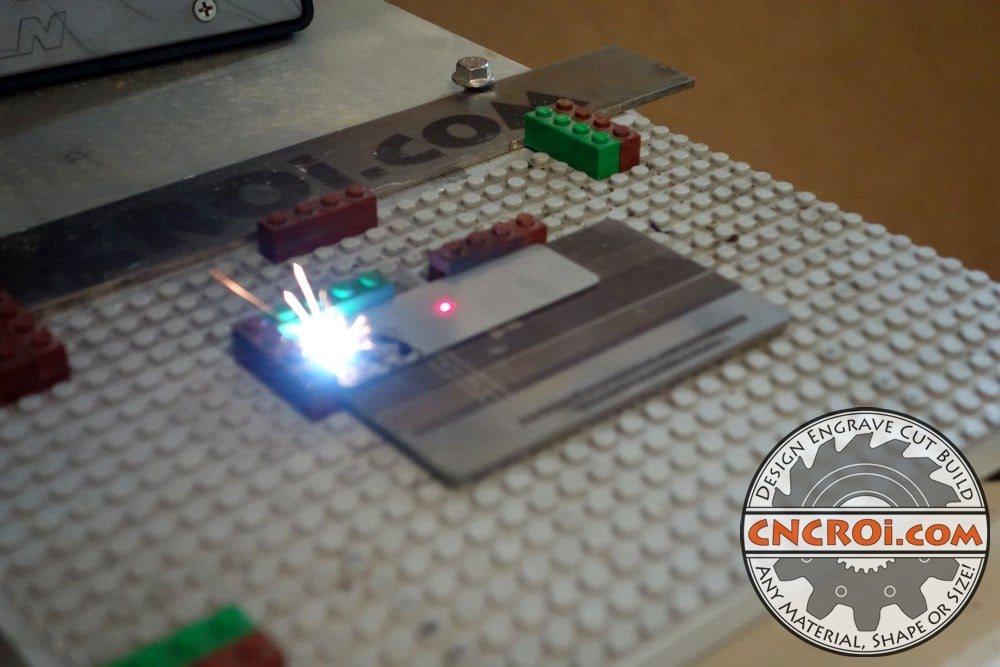

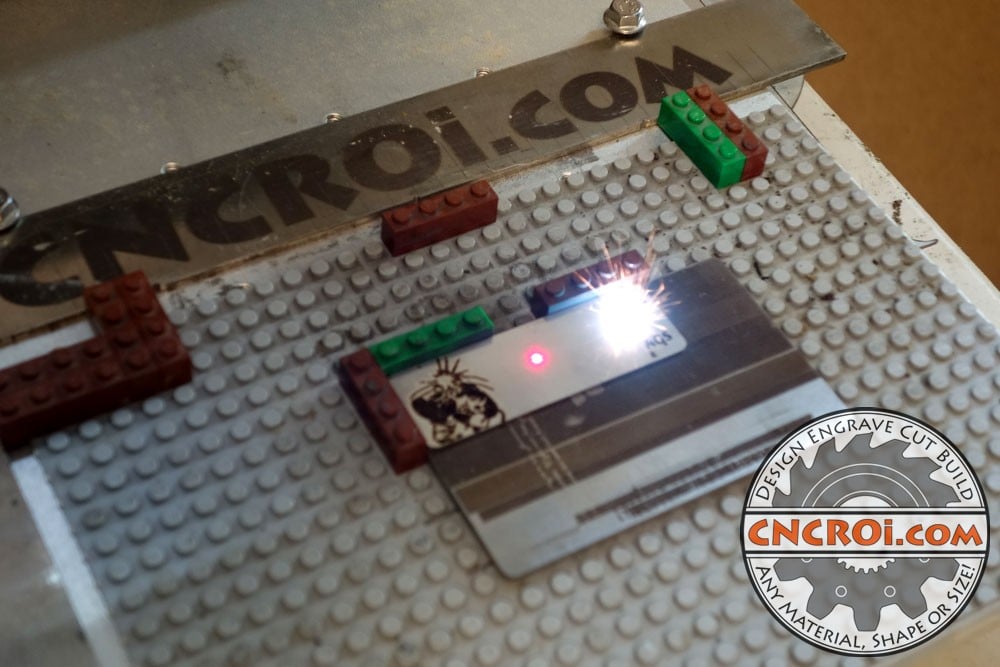

It’s very hard to get proper focus when you have a bright light so that’s why most of these pictures that I took with my camera are so out of focus when I was making these custom automotive tags with my fiber laser source.

Etching is done at such a fine resolution using lasers that pretty much any design works great, so feel free to mix and match fonts, images and even sketches together but keep in mind, it can only etch black.

If you wanted to see what deep etching is like application wise, the above link is a prime example, painting a surface covers the etching but if it’s deep… the paint go inside and not over, thus, you still see the etching.

Although we make a lot of custom automotive tags at CNCROi.com, most of the time, the customer wants holes on one or both sides so they also have the added flexibility of riveting them to their projects.

Keep in mind that the durability of stainless steel fiber etched tags is second to none, these will be fine in just about any environment.

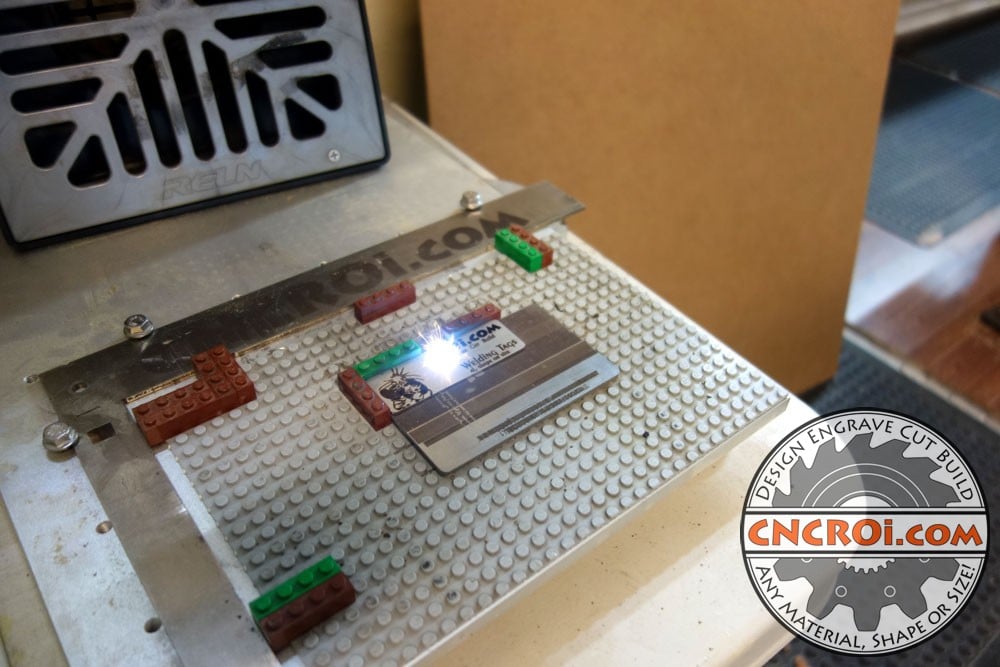

As the fiber laser etching happening on these custom automotive tags is a hot process, I was actually starting to melt the Lego sheet underneath, so I put a piece of thick stainless steel inbetween the tag and the sheet to prevent this from happening.

When it comes to etching, the deeper you go, the more of a shoulder you get, this is because the laser isn’t shooting straight down but at an angle due to the orientation of the mirror.

I have a fraction of an inch to play with my fiber galvo laser, so even if things aren’t dead flat, the etching will be the same on all these custom automotive tags.

When it comes to custom tags, CNCROi.com makes them at any spec, but I make tons of large production runs of our most popular tagging options so I can offer them in very quick turnaround and cost effectiveness.

The reason it’s tough to get good photos of the galvo laser doing its work is because the light it produces on the finished media is unfiltered, meaning, there is nothing inbetween the light and the shop itself, like a screen, as such, the intense light produced overwhelms the camera and focusing system.

The vast majority of our etching at CNCROi.com is actually on 11 ga 304 stainless steel, as you see in the above video.

The sparks run off in any random direction they want during production, but they don’t get far and are not hot enough to melt the Lego plastic jig underneath, as such, this set-up is fine for thousands of tags well into the future.

Do keep in mind that with custom automotive tags, I generally advise customers to have two holes as well for riveting, this allows ultimate flexibility when it comes to adhesion as those holes can also be used for tack welding them in place.

What happens if I did more than one pass on these custom automotive tags? The etching would just get deeper, though true depth will take quite a while and at this thickness, it will start to bend quite a bit in the process.

CNCROi.com has years of custom metal fabrication experience, so if you wanted this to be part of a larger project, we can totally make it for you and ship it right to your door!

We have several different technologies when it comes to producing custom plates, from laser to waterjet to plasma, each has their plus and minus.

Just for fun, I decided to make a new tag for myself, this is thicker 0.05″ thick stainless steel rather than 0.02″ thick for the previous tags because I like to brand photos that I take when I post stuff on instagram with my welds so they aren’t copied and the base metal from those can be quite hot, thus more prone to warping a thin tag over a thick one.

Regardless of what’s being etched, it’s basically the same settings and the same process though I did etch mine a little deeper with repeated passes because, it is thicker, so it can widstand the extra heat.

Fiber laser etching is fun, I’ve been doing custom fabrication now for decades and etching for over a decade and it just never gets boring.

Here at the tags from another angle so you can see just how much light affects the look and texture of these custom automotive tags.

Need custom custom automotive tags? Contact CNCROi.com right now!