Custom Cedar Trays

Making custom Cedar trays is a good way to test out design options available to CNCROi.com customers who want just about anything made out of Cedar, after making these items, my design process and parameters are pretty much all sorted and ready for production!

I really enjoy working with Cedar in the shop, it smells great, machines quick and is very easy on the machinery… and there are limitless design possibilities with it!

I had a few pieces of scrap left over from a job I did so I decided to use that to further hone my Cedar specific design and production skills making various custom Cedar trays to give to friends and family.

Cedar is a very dry wood, incredibly durable “out in nature” and resists mold and rot pretty well, so if you left it outside during a rainstorm, you won’t have it become instant scrap as if it was made out of MDF or a laminate.

Cedar is a wonderful material for a variety of purposes, including custom Cedar house number signs made by CNCROi.com!

What I really enjoy about custom Cedar trays is that the shapes, sizes and uses can be just about anything, so my goal with making these trays was to see just how extreme some designs can be made out of Cedar and what further I can do to optimized and speed-up my production cycles without any deadline to have to meet.

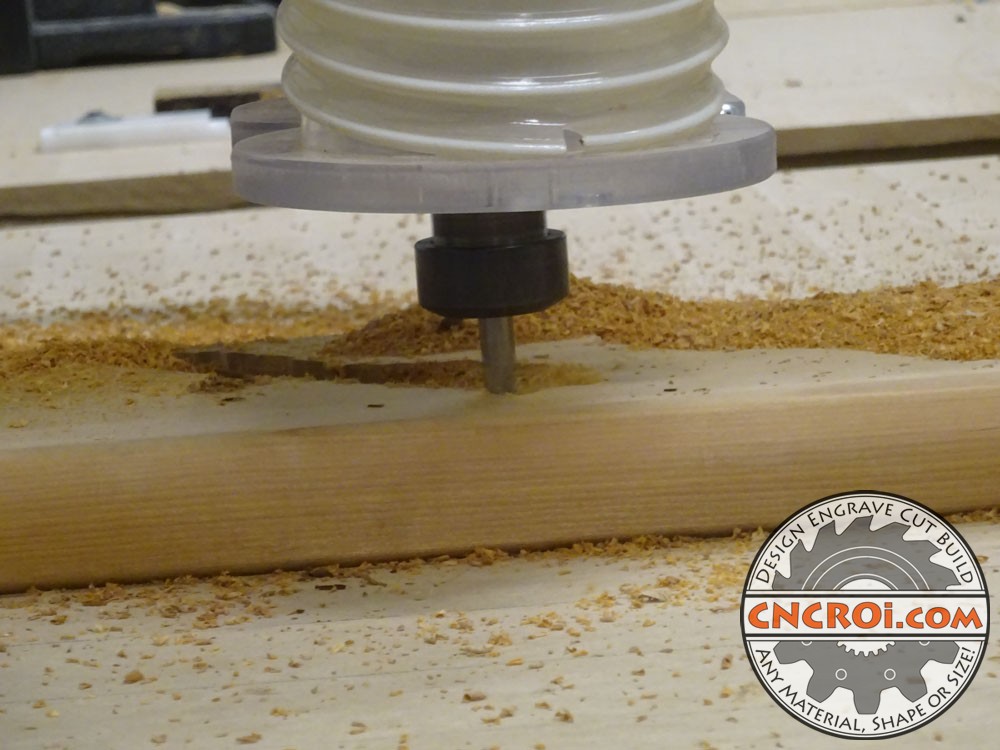

As I was filming and photographing this project, I kept the dust shoe off the ShopBot PRSAlpha on purpose, otherwise you don’t see any of the action but you do pay with that with Cedar dust all over the bed, good thing custom Cedar trays smell great during production to offset this!

To hold the pieces of scrap Cedar I had, I used various hold-down techniques, the easiest and most effective is actually just driving bolts right through the material onto the bed, even the Hulk couldn’t lift this off the table without chipping a nail!

Cedar can also be easily paint filled, so if you want some extra color and contrast, that’s available to you by CNCROi.com.

With the dust shoe, all this dust which smells great would be picked right up, and it’s the typical set-up I use when doing custom work with my CNC ShopBot router.

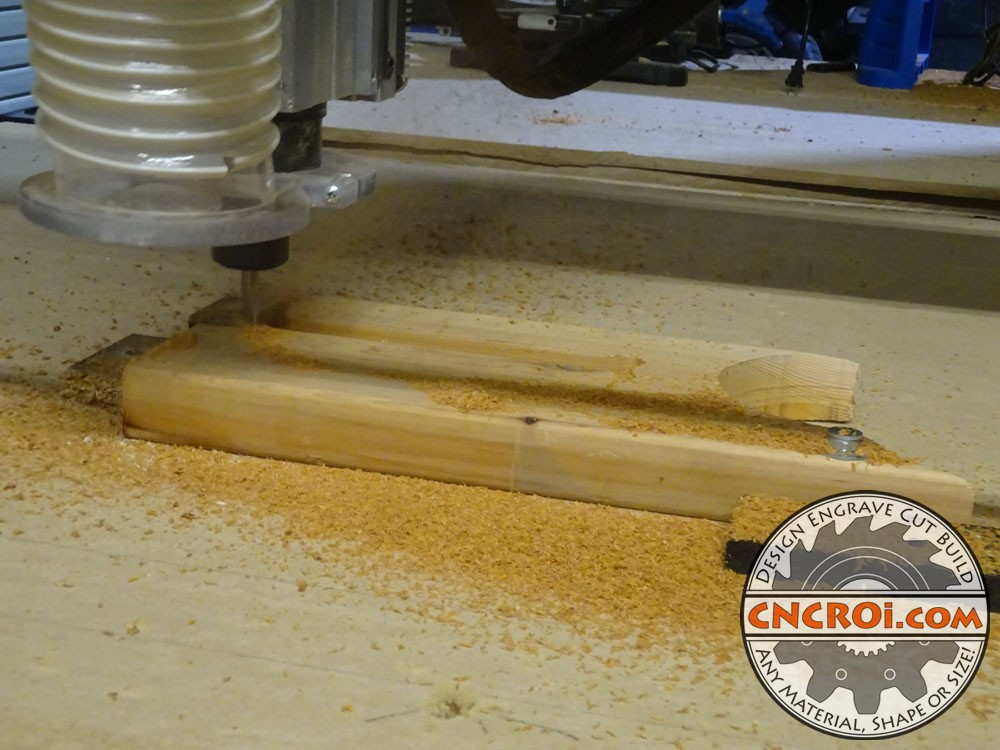

These two peanut trays, even with a huge knot right on the edge, came out absolutely amazing, I did sand them a bit but not too much, you learn from looking at rough work over finished pieces as all the “issues” are far more evident.

After all that testing and having fun, it was time to make a custom Cigar ash tray that will be totally sanded and cleaned-up just to show you how beautiful custom Cedar trays can be when they are being made for actual real world use.

Custom Cedar corporate awards, plaques and other personalized motivational items can also be manufactured for you by CNCROi.com.

As with all the other custom Cedar trays, there is some serious saw dust being manufactured at CNCROi.com and as you can see from the piece, it’s obviously a piece of scrap but we’ll turn this rock into a diamond!

I’ve never made a monogrammed custom Cigar ashtray so this was my opportunity to see how everything can come together and I was beyond impressed by the finished results after optimizing all my production settings with the earlier custom Cedar trays.

After almost a decade with a ShopBot Desktop, I’m continually impressed at just how fast this new machine at CNCROi.com really is, it really blows me away at just how smooth it is at the speeds I’m able to achieve cutting big chunks of wood out to form a design I want to make.

Of course, custom Cedar cigar ashtrays can be made out to any size or shape as well by CNCROi.com.

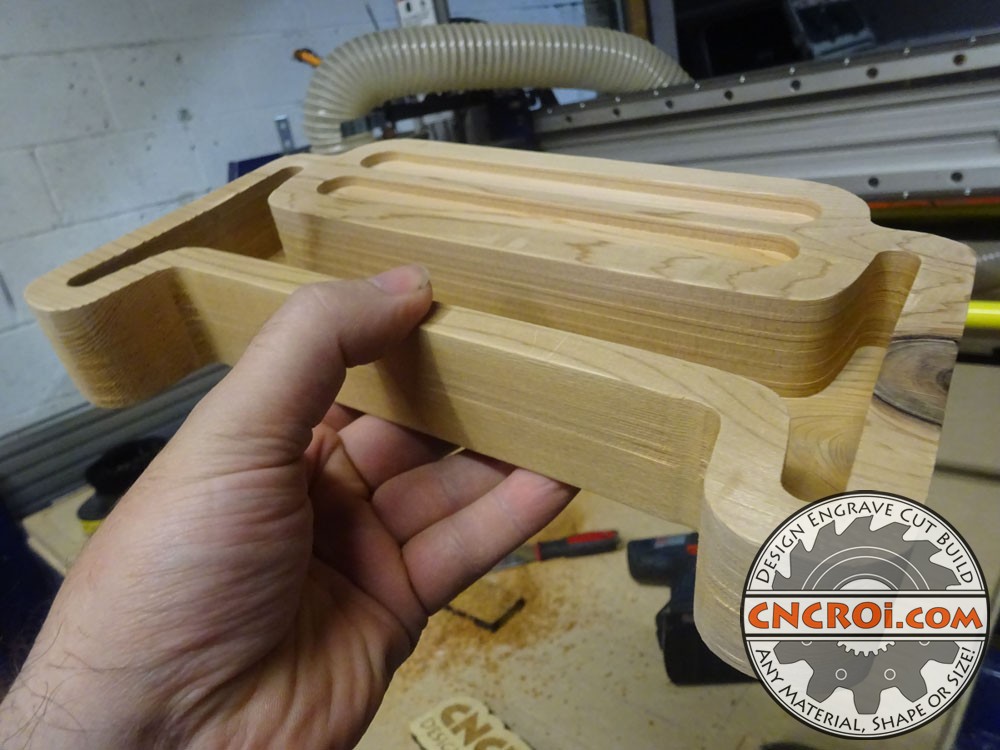

Right off the ShopBot’s bed, you can see that the time I spent optimizing bit to material really has paid-off, the finish is already a lot smoother, I’m cutting way faster and this custom Cedar cigar ash tray will require a lot less sanding and finishing than the earlier custom Cedar trays would have.

Notice the knot at the end of the “I”, generally knots are nothing but trouble but for this, it makes no difference, it’s as if this huge difference in material density wasn’t even there, if this was done with my laser, I’d have a very different result making a production run of custom Cedar trays.

Cedar can be laser engraved by CNCROi.com too, rough or finished form.

You can see the edges need a bit of sanding and in the inside as well, but this being Cedar, it’s incredibly quickly done at CNCROi.com with a full wood shop of tooling.

And here are the finished results after some sanding, there are always going to be a few things I’d like to optimize for all these custom Cedar trays but this exercise was incredibly fruitful so that the next production run of Cedar goes a lot quicker and is more cost-effective with less finishing required.

After making this, there are already a few more items I want to make out of Cedar, these custom Cedar trays are great because when they no longer suit their purpose or get broken, they can be thrown right in to the fireplace to keep you warm and you can contact CNCROi.com to make a fresh one for you!

Looking for custom Cedar trays?

Contact CNCROi.com right now!