Custom CNC in 3 Easy Steps

After years (decades?) of designing and working with completely custom CNC projects across a variety of industries, I tend to forget how formidable to some people the possibility of doing anything they can imagine really is.

Most things in life are “pick one” whether it’s coffee at the store or filters for the car. For CNCROi.com, it’s “tell us what you want and we’ll make it”, so let’s try to simplify our capabilities with your ideas in 3 easy steps.

Regardless of application, these steps are the same, whether you need some wedding invitations made out of high quality specialized paper or industrial CNC laser cut, bent and welded 316 stainless steel lighting boxes.

1: Budget, Volume and Timeline

You must have an idea of budget or at the very least, a range you want this project completed it with associated volume (price per unit?) and timeline. Budget will help us cut through the noise in a split second.

If you want, let’s say, 20 custom corporate awards, each unique to the personality of the person they are being given to with a 200$ to get this all done including materials and designing, we aren’t the company for you.

2: Design

There are several ways of getting a design done, the easiest is you sending us an EPS file telling us EXACTLY what you want, short of that, a sketch is good, CNCROi.com can take things from there. If you have no idea what you want done design wise, send us pictures of what you LOVE and what you HATE and we’ll put those together and present a few designs.

During the design process, material options will be suggested that fit within your budget, as a general rule, the more processes are required for the completed piece, the higher the cost while overall volume decreases price per unit.

3: Production

Depending on the budget and timeline, we’ll either produce a 3D render, animation or physical proof of the project at hand. If it’s large, we’ll do a scaled down version that we need signed-off before real production begins.

Payment Terms

Generally, due to the nature of our work, we require a 50% deposit to begin working on your project with new clients and the rest required upon delivery. Your physical location is of little consequence by the way, if you are located in Australia or Africa, Asia or South America, we have a network of custom shops that can locally cut, assemble and deliver a project to you. We generally ship direct within Canada, USA and Europe.

Contact us today!

.

,

How it was made!

Want to see how the sign in this post was made here at CNCROi.com?

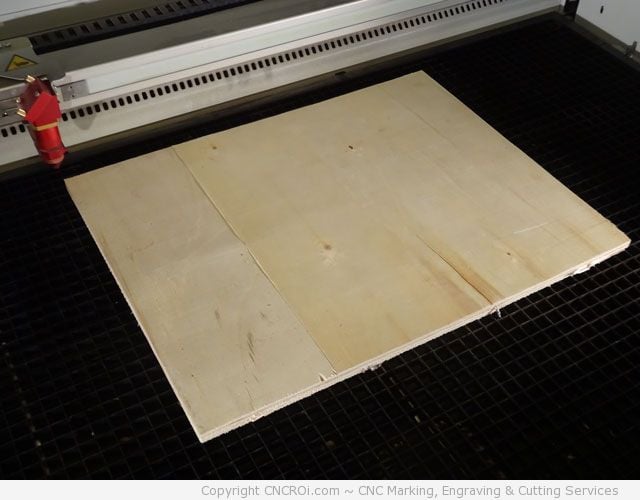

We got some new equipment in the shop and of course, it came in a box, it’s 1/4″ plywood of dubious quality so it’s perfect for another test in the shop regarding custom signage.

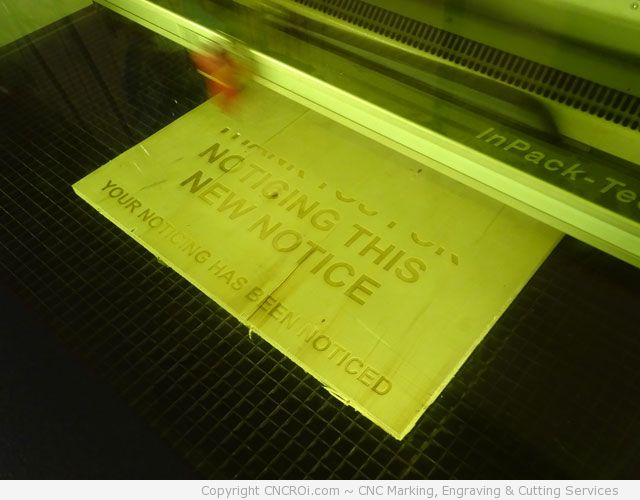

First step was laser engraving the wood, this produces the initial “darkness” so that the letters stand out.

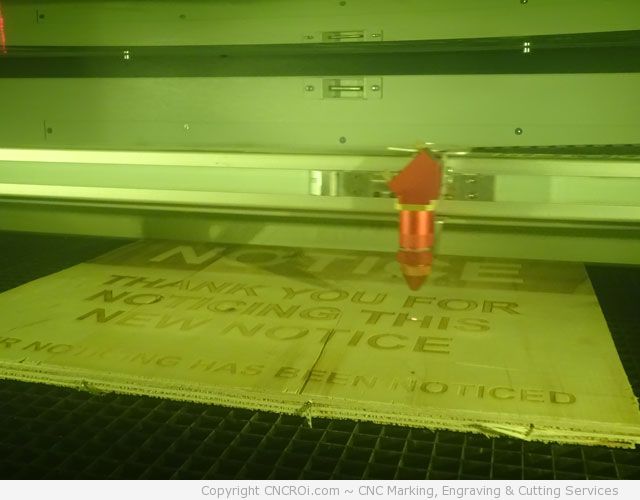

I designed the NOTICE to be a reverse engraving, instead of engraving the letters, our Austrian CNC laser engraved the area around the letters for more impact.

Afterwards, doing a secondary pass on each letter to improve contrast.

This adds laser time but it’s worth it as it makes everything POP.

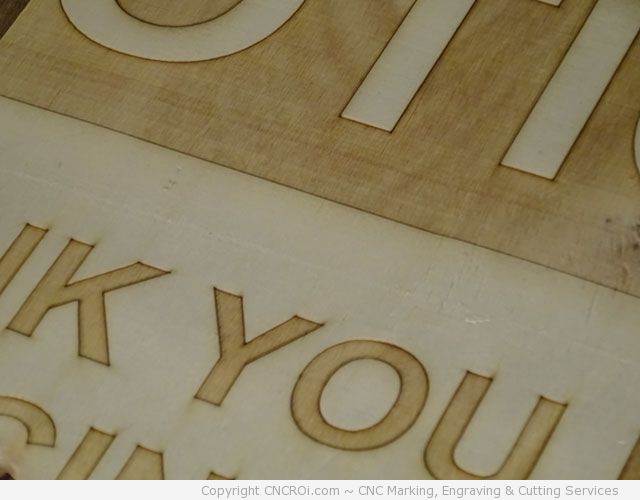

The finished sign looks good, the smoke damage is minimal due to our strong extraction and gas kit pushing air onto the project as it was engraving.

If you look very closely at this “sign”, you will notice some slight residue from the resins in the wood around the letters, the simplest method to resolve this before it happens is to use masking, in this case, it wasn’t necessary as it’s just a fun sign for in the shop.

Here is a video of this being made by our Trotec Laser.