Custom CNC Laser Annealing Brass Valve Tags

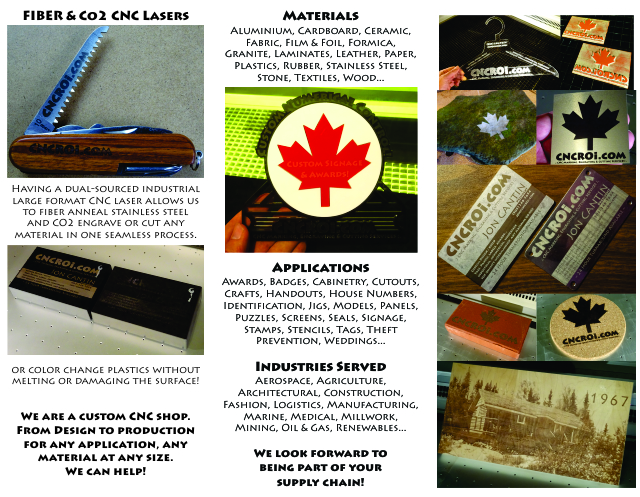

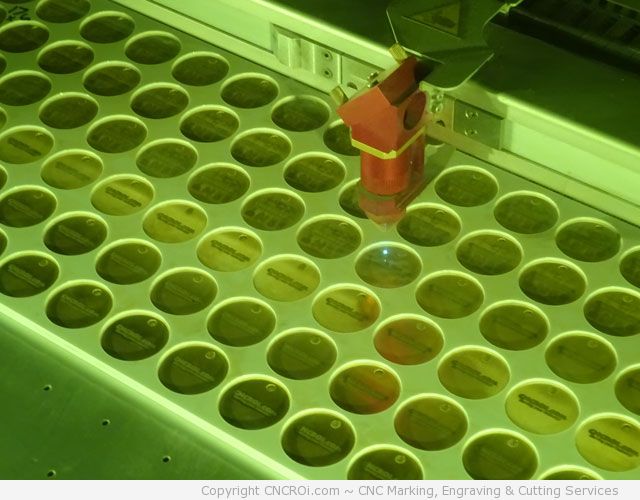

CNCROi.com processes a lot of metal, from annealing brass and stainless steel to metal forming and cutting it. Today, we’ll take a look at custom CNC laser annealing brass valve tags, on both sides.

As an ever-increasing challenge to remain competitive in such a competitive field where we work with manufacturers, mines and hydro-electric installations to provide them with top quality brass and stainless steel valve tags… we keep on playing with processes to increase daily production capacity which saves our customers money and us time.

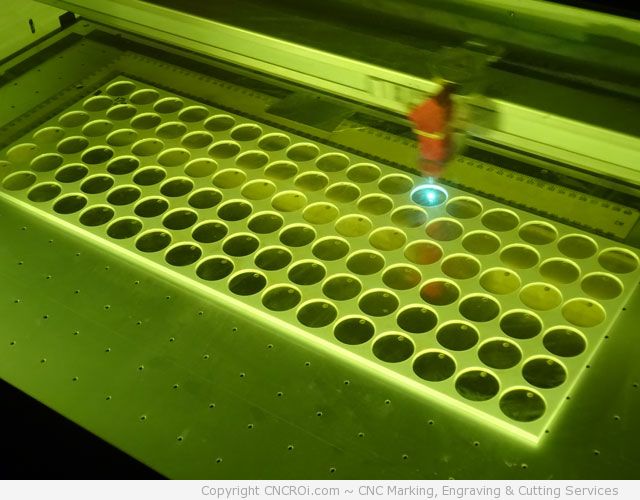

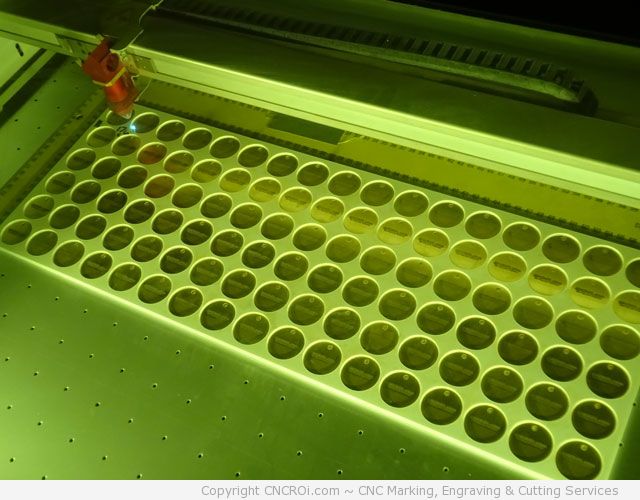

One massive time savings for us is using database integration within our production cycle, what that means is that we aren’t retyping custom alpha-numerical information one at a time, all we do is “feed” it to the laser seamlessly.

What this means is that there is no room for error from retyping information, production is dramatically sped-up and our customers get their tags, generally, within 24 hours, even if it’s hundreds at a time. We can also do runs of several thousand stock and process dependent for those ultra-rush needs.

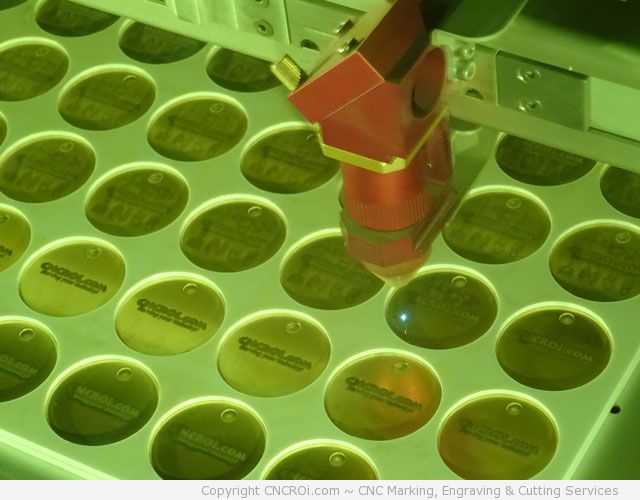

Here, we are doing two processes, CNC laser engraving the first pass of our CNCROi.com logo and then fiber cutting other information. Sometimes, depending on what needs to be done, one process is significantly faster than the other, producing similar results.

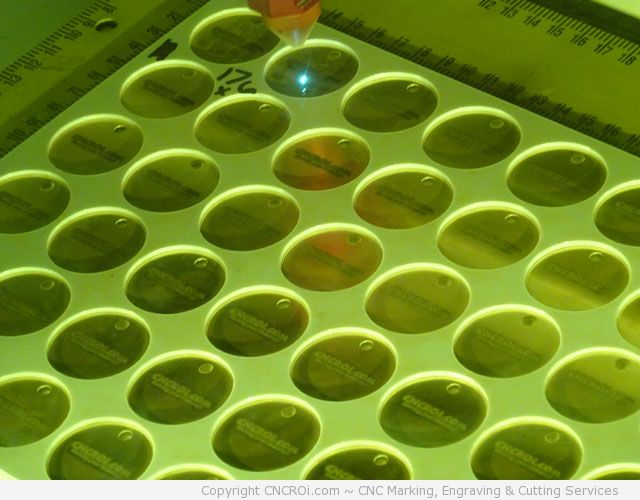

This is why it’s very important for us to understand the intended application for our custom stamped or cut metal tags… in some circumstances, brass is a better fit than stainless steel, polycarbonate over laminate and so forth.

You can see our fiber laser etching via cut path, all the little details added to our sample valve tags. This process is fast but care must be taken as to not move too fast to avoid head lag from having too many G-forces going in various directions… the cost of not getting things right is jagged results.

Depending on the laser power settings (and application), overpowering to produce a texture that can be felt across the tag is preferable to a smooth annealed finish.

After the process is done, the brass tags are dirty from production so instead of cleaning them all one at a time, we put them into our ultrasonic cleaner. We are starting to use this process of cleaning more and more across materials as it allows us to dramatically increase production capacity and speed to customers.

CNCROi.com invests heavily in experimentation and process engineering, it allows us to remain one step ahead of our customers. If they have a specific price point they wish to hit for a particular application, having working and recent knowledge to give insightful and resourceful answers helps us tremendously and gives our customers confidence in our ability to meet them on budget and time.

This production run involved several hundred brass valve tags, annealing them on both sides – easily done within one day in-between several other projects we were working on. These tags are for our customers, but we have plenty more in stock for them too.

Looking for an awesome company for all your CNC laser cutting, annealing, marking and even tag stamping? You’ve found CNCROi.com! Contact us today!