Custom Anodized Aluminium and Stainless Steel Coasters

CNCROi.com does lots of custom projects for promotional use by our clients, some of which are awesome custom coasters. In this blog post, we’ll review some of the coasters we’ve done in the past, and will be doing well into the future.

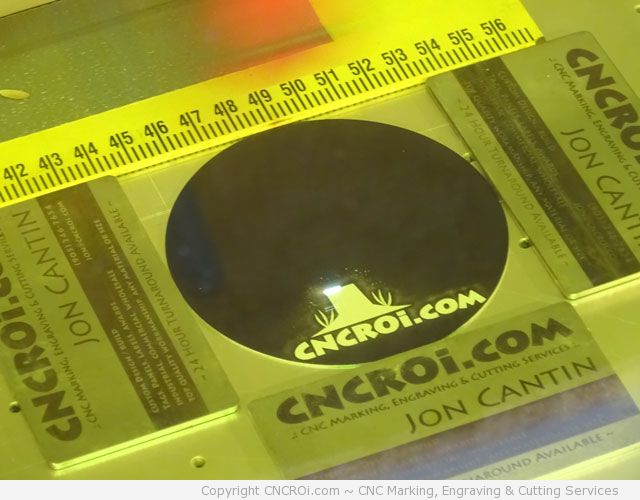

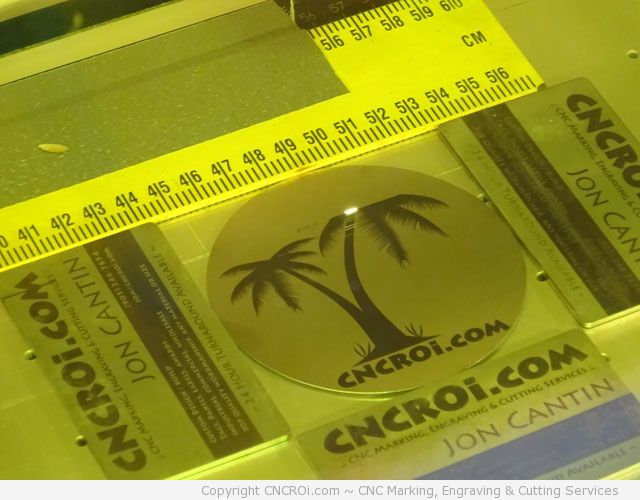

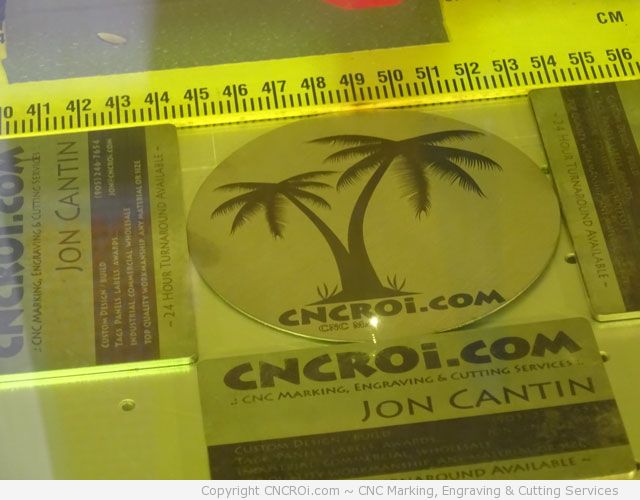

Generally we do assemblies when it comes to coasters, so these 3.5″ round stainless steel and anodized aluminium are generally inserted on-top or inserted into acrylic wood wooden bases.

The reason why we prefer to use stainless steel or anodized aluminium inside of coasters is because unlike wood, they don’t absorb water, don’t stain and are exceptionally easy to clean.

As for anodized aluminium, it’s less expensive to fiber mark it rather than anneal stainless steel but unlike stainless steel, anodized aluminium is available in a variety of colors.

We also use a lot of acrylic inside of our coasters as well, the advantage is the same as metal as they don’t absorb water and like anodized aluminium, available in a variety of colors and opacities to match just about any logo out there.

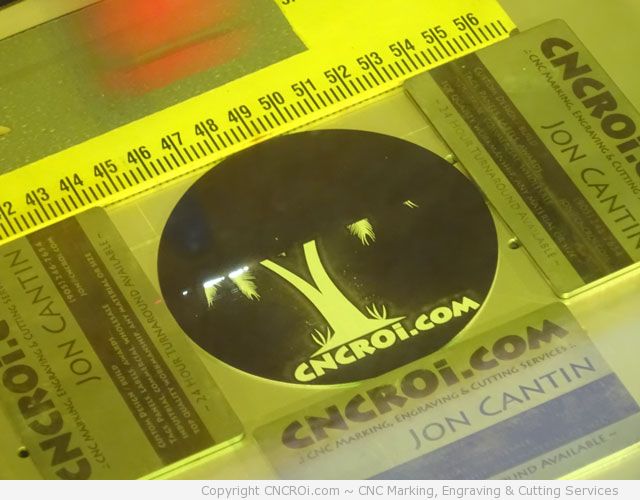

The custom stamped black anodized aluminium coasters look fantastic in any light, black provides the ultimate contrast with the permanent results from our fiber marking process.

With our industrial Austrian CNC wide-format laser, we are able to handle large production quantities, within exact specs and on time and budget. Generally, we do this work using jigs but for one-offs such as this, holding it place using some scrap stainless steel tags.

Anodized aluminium is very lightweight compared to stainless steel, but either fiber marking this or annealing stainless provide permanent results.

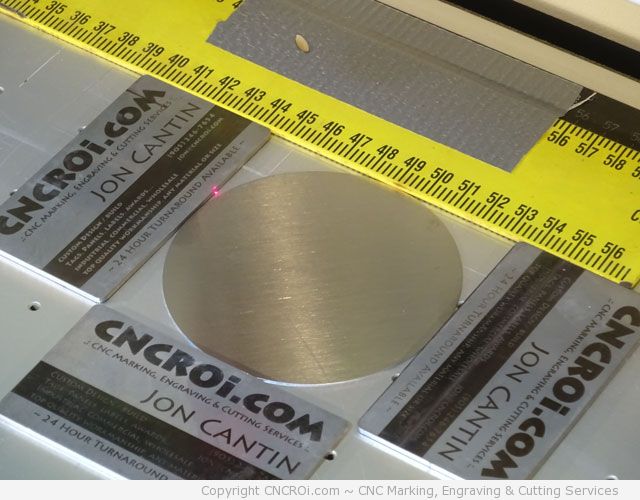

Next up, we’ll put the exact same design onto stainless steel, again, custom stamped to the same specs as the anodized aluminium above.

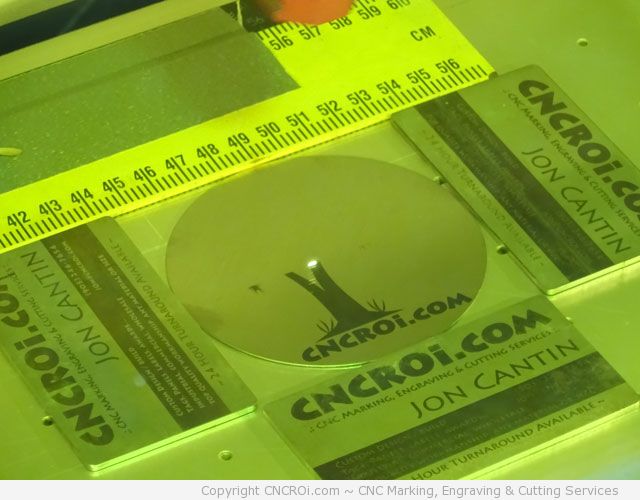

We used out fiber tube for both the off-white marking on the black anodized aluminium and annealing the stainless steel coasters in this blog post. Same tube, different power and speed settings. Annealing is dramatically slower than marking.

We use REAL annealing for our stainless steel, not ceramic bonding. The reason for this is that we invested heavily into a fiber laser source, which means we can permanently anneal stainless steel directly instead of using a toxic ceramic paste which produces non-permanent results.

Having the right equipment is only half of the story, the other, being able to meet the very tight tolerances involved with annealing stainless steel with our fiber laser tube.

We have a fiber specific lens, which allows us a lot more tolerances than normal when it comes to annealing, this allows us to have a precise result over a wider range of focus points.

Regardless of the size, color, shape and thickness of the custom coasters you may have a need for, contact us and we’ll turn your ideas into physical reality.

The ruler you see in these pictures is in mm but to help give you another idea of scale, I also put my thumb so you can see how precise the fiber annealing of the letters is.

We’ve done a lot of work using stainless steel and anodized aluminium across a wide variety of applications and industries. Need something custom? Contact CNCROi.com.