Custom Corian Coasters with Custom Various Inserts

CNCROi.com makes lots of custom coasters using a whole mix of materials, sizes and shapes. In this blog post, we’ll review some more custom options we can offer to you!

I’ve done lots of videos of CNCROi.com cutting out custom coasters out of wood and Corian but this time around, we’ll make shallow dish ones so that the insert sticks out a bit rather than recedes into the bottom.

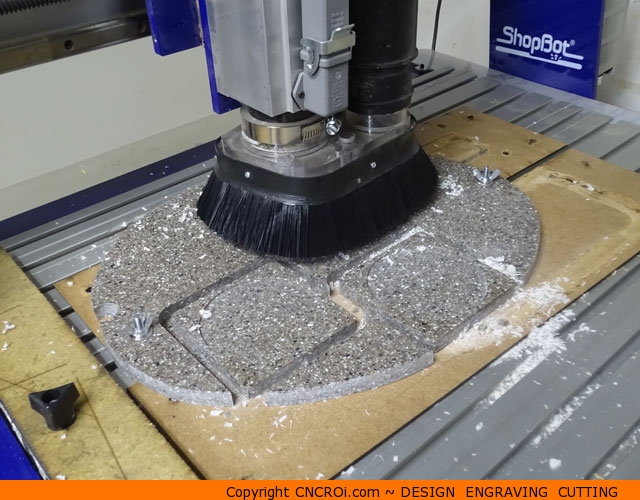

For demonstrative purposes, I grabbed a scrap piece of high-quality Corian from our demo inventory and affixed it using bolts to the CNC router. Sometimes we use screws, sometimes bolts, it depends on the material we are cutting through and what needs to be done in what volume.

We have an industrial spindle on our ShopBot CNC router which is plenty powerful enough to easily cut out coasters all day if needed and other custom promotional items.

We also use a specialized Corian router bit with our work that helps us produce a nice finish which lessens the amount of sanding required after production.

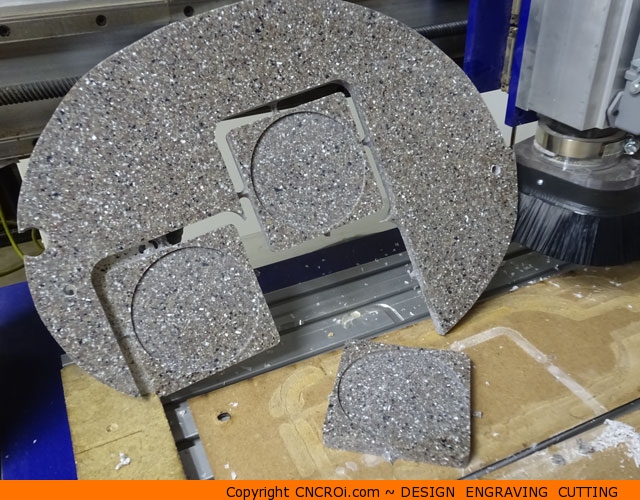

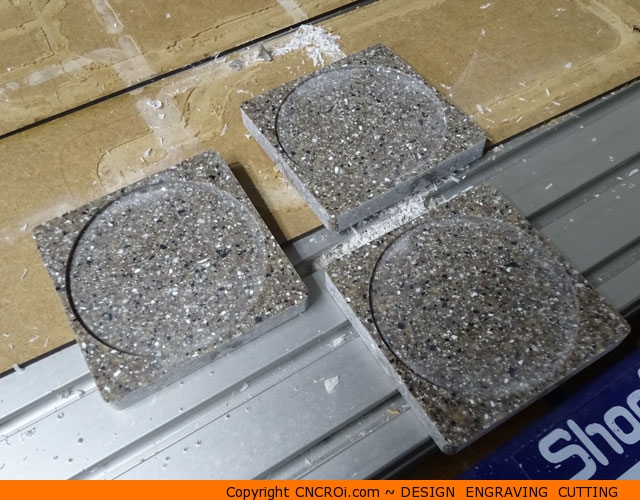

In this case, the scrap will produce 3 identical coasters, as we are an on-demand shop, we could have made 3 different ones just as easily, it makes no difference to the machine or production time given big enough volumes.

The small Corian flakes you see building-up around the workpiece are what was once part of the scrap Corian, the vast majority of it is sucked-up by our industrial vacuum system but some still manage to escape.

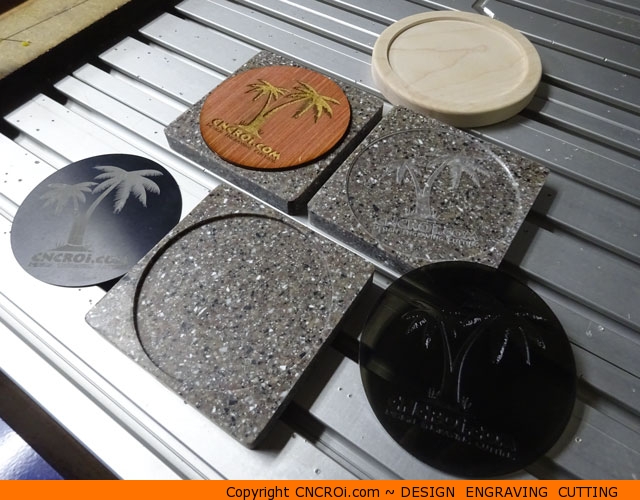

What’s really nice about making custom coasters for CNCROi.com are the endless possibilities we can offer our customers. The same can be easily extended to custom signage, cutting boards and a lot of other options.

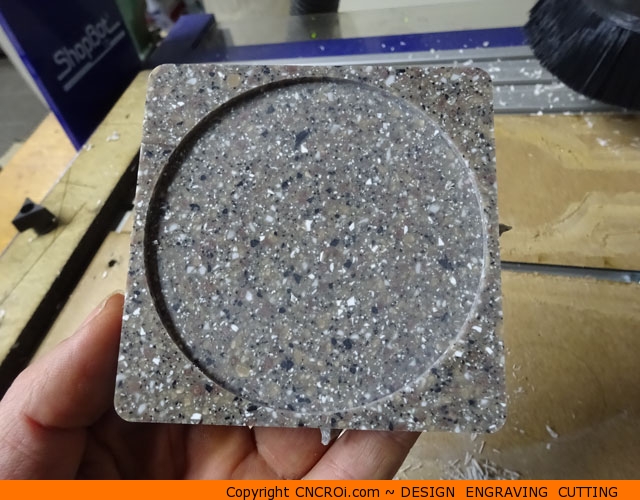

The tabs you see in these custom coasters out of Corian are sanded off after the work is done, the reason they are there is to prevent them from moving during production. Unlike our industrial Austrian CNC laser, a spinning router bit produces pushing and pulling forces on the workpiece so holding it down is essential to high quality production.

The coasters are almost done, we are now cutting out the third. The “scrap” from this scrap will be kept as it can still be used for other smaller applications such as custom Corian name badges and stakes to kill vampires.

These custom coasters out of Corian are square with rounded edges but if you wanted round ones or any shape, we can make them just as easily.

These three custom coasters are now finished. The nice thing about round coasters is that you can make more of them per unit of scrap than square ones but for production where we get a whole sheet, the square ones are more efficient to produce as they take-up a whole row in one shot leaving no scrap behind.

The purpose of the tabs on these custom coasters is to just hold them in place DURING production, they are meant to be easily broken off once the work is done by hand.

There you have it, another new custom coaster is born to the world!

Even without custom inserts going into the custom coaster, we can make some awesome stuff with these. For instance, we can laser engrave right into the Corian and paint fill it with a logo or message…

or produced something with 3D carvings.

But for this blog post, the focus is on showing you start to finish, a custom coaster being made along with custom inserts so we’ll continue down that path.

These haven’t been cleaned yet but are a little dull looking from a layer of dust all over the coaster produced from the sanding of the tabs off each side of these custom coasters.

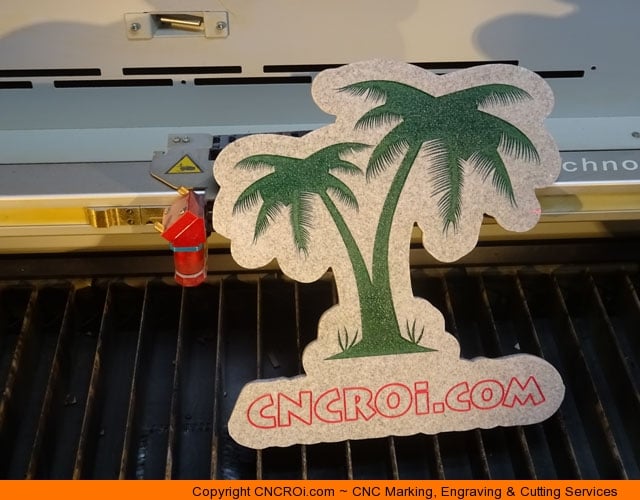

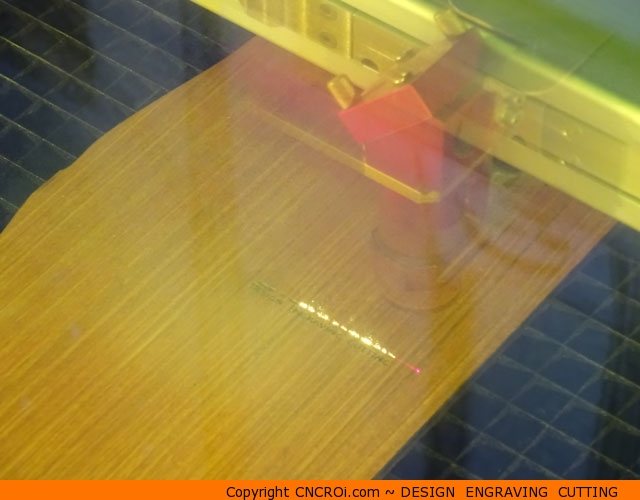

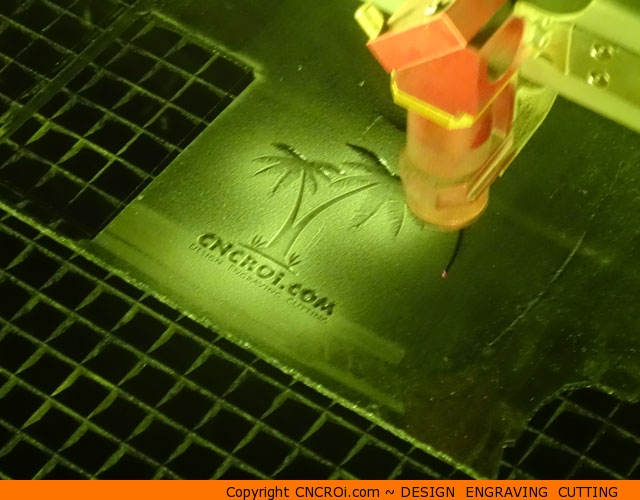

Now its time to migrate to our other industrial machine and cut out some inserts in this plywood. We could have made these with our industrial router but due to the fine engraving detail required, the laser is a better choice.

Like the Corian, this is a scrap piece of plywood from the CNCROi.com shop. We run a lean shop and I try to waste as little material as possible, if there is something that could be reused for another client or project or for these demonstrations, that’s what I use over new material.

As you can see, our industrial laser never touches the plywood, it vaporizes off a layer from the plywood without introducing any push or pull so no need to build in tabs or hold it down in any way.

In this case, the custom coaster insert is being done in wood but the process would be identical if it was Corian, acrylic or any other material including laminates and rubbers.

Our industrial laser is powerful, it’s able to cut through 3/4 inch (18 mm) wood without any trouble so this quarter-inch (6 mm) plywood is nowhere near a challenge for this Austrian machine!

One coaster down, and another two were made afterwards.

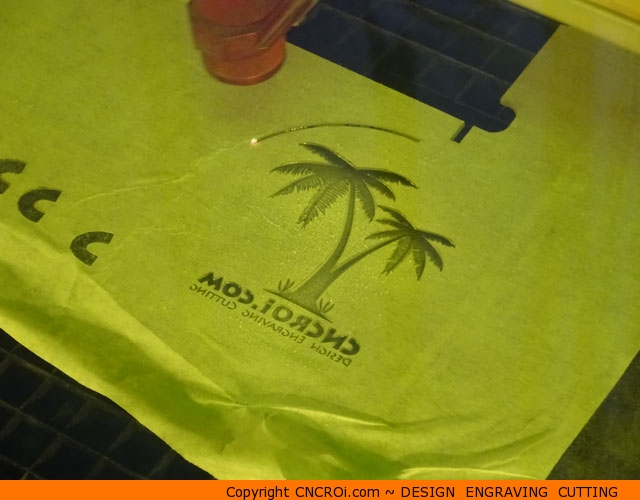

Generally we mask work but in this demonstration, i wanted the edge to have a bit more contrast so letting the resins settle around the edges of the custom coaster insert worked in my favor so I let it be.

Three identical custom coasters out of Corian, three identical custom coaster inserts made out of plywood.

Generally we’d apply a varnish or seal onto the insert to make the colors stand out more but we are now doing to make the same custom coaster insert out of other materials to show you just how much the look changes using different material options!

The design is a pretty simple one, let’s say you didn’t want a wood insert but something made out of acrylic or material that’s easier to clean, let’s do that next.

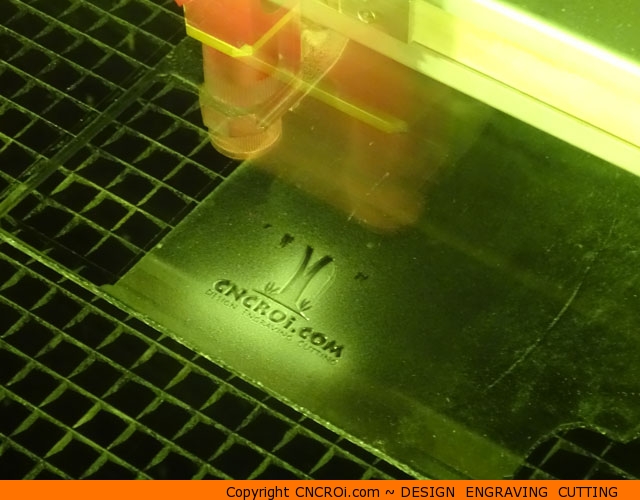

The exact same design file was used, just the settings were changed to produce another custom coaster insert but this time semi-transparent acrylic.

The process is the same, engrave out the design and then cut it so that nothing moves during the production process. I hope you can now realize how flexible we are production wise, if you wanted a thousand coasters to be each unique and different design along with matching inserts, it’s no problem for CNCROi.com!

The resolution we can achieve on wood and acrylics is over 600 dpi, so even if you have a complex design, bigger is always better, but you can still show fine details.

After engraving this custom coaster insert out of acrylic, it’s time to cut it out. What’s especially nice about the laser when it comes to acrylic is the nice flame-polished edge we achieve.

The dust you see on the surface of this custom coaster insert is easily wiped away, it doesn’t stick to the coaster insert surface at all.

There you have it, a very sharp-looking and highly detailed custom acrylic insert!

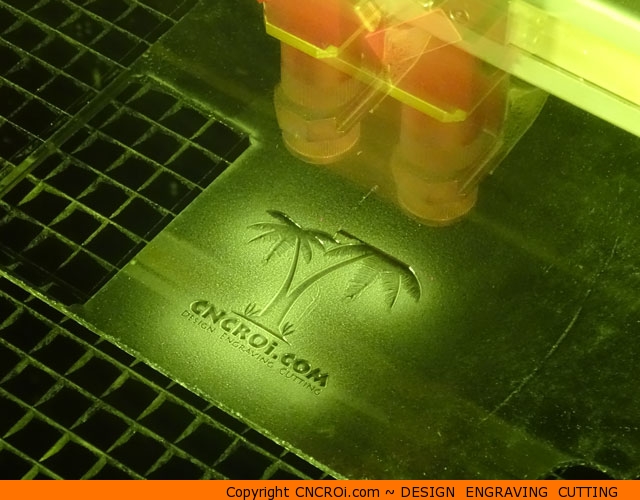

There are hundreds of options when it comes to acrylics so let’s cut out another one using our laser but this time, we’ll make it out of clear acrylic and reverse-engrave it as well. The reason being we want to see the engraving but not have it fill-up with liquids like coffee over time (though it is easy to clean).

We’ve now engraved more than half way through it, the masking is on the underside in order to protect it from the grid table underneath from heating-up during the laser cutting process and making grid patterns into the custom coaster insert.

Again, this is a piece of scrap that was used on previous projects and blog posts and there was enough room left on it to produce yet another thing from it.

Cutting out the custom coaster insert out of clear acrylic is just about done, after this, we’ll stick it into one of the custom Corian coasters we produced earlier and see what it looks like!

You can see the masking clearly now and the engraving we made, it’s reversed on purpose so that when it’s flipped into the custom coaster, it’s the right way up.

There you have it, a fantastic looking custom acrylic insert!

Like the earlier darker tinted acrylic, the clarity of the words and detail of the image is outstanding!

You can see how the laser doesn’t take away from the details either, everything is sharp and permanent, unlike something that’s printed. The engraving is part of the acrylic, not a layer on its surface.

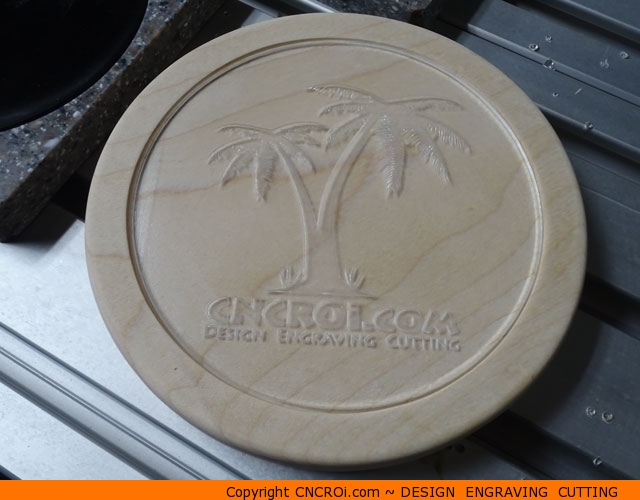

Here is another option, making custom wood coasters, again, low profile and this time with a custom anodized aluminium insert that’s been fiber engraved using our Austrian CNC laser.

Putting in our custom plywood coaster insert, you can see how drastically the look changes.

And the clear acrylic, again, we could have laser engraved into the wooden coaster and skipped the insert all together if you wanted us to. It’s completely your choice!

The tinted black custom Corian insert also looks fantastic! We didn’t reverse engrave this one because it would be hard to see on the underside.

As you can see, CNCROi.com‘s custom coasters are completely custom to your requirements, any shape, any size, any color AND any material. The same holds true for the insert as well!

Looking for some fantastic custom coasters for your corporate gifting, wedding, award show or any other use? CNCROi.com is here to help! Contact us right now!