Custom Corian Cutting Board Production

Custom cutting boards, wall plaques and even furniture can be made using Corian… all of which CNCROi.com can design and make for YOU!

What we do to use the maximum of space on this piece of scrap Corian is to actually draw out the layout with reference points on the Corian which will become a custom cutting board using our Austrian CNC laser. The extra space is kept there intentionally, we need a way to hold the piece down during CNC routing.

Once the design is marked with the absolute precision of our Trotec Laser, we then drill in support holes which will then be used to screw the piece to our sacrificial MDF board that’s on our ShopBot Desktop.

The screws prevent anything from moving while our big industrial bit powered by an industrial spindle power through this half-inch (12.7 mm) piece of solid Corian.

The first thing done is the indent into the board that will capture the juices during the cutting process – our custom Corian cutting boards by the way are sanded and polished on both sides so BOTH sides are usable.

We make these custom Corian cutting boards to spec, any shape, any size and whatever pattern you wish on the surface, we manufacture just for you. Quantity and volumes are no problem as we use industrial machinery for both precision and speed.

To make things easy in this case, we used the same bit to both cut out the Corian cutting board and the juice capturing indent but we can use as many different bits to produce differing results as you wish.

After the outline is done, it’s cut through using a few passes. The reason we use industrial CNC equipment to make these cuttings boards is the absolute precision they offer our customers. If they want a hundred custom Corian cutting boards using different materials all cut the same, we can do that. We can also cut these to any size across those hundred, so a hundred the same or hundred different, makes no difference to our process.

You will see some slight marking on the board left over, I decided to cut a little lower than I outlined on our CNC laser, this isn’t a big deal as this is sanded to a nice polish afterwards, these marks on only on the very top surface and assign a X and Y coordinate.

There are endless options for contours and profiles, from rounded to square (shown here) to angled V-carved. We can also engrave and paint fill this using either or AND our industrial CNC laser. It all depends on what you are after spec wise.

The chips you see on the board during production are what is left after our industrial bit has cut through the Corian. The lighter dust is sucked-up by our powerful vacuum system.

In this case, there were so many chips produced cutting such a large track through the Corian that it clogged-up the vacuum, again, not a problem, it’s quickly and easily unclogged after production for the next board.

Looking at the above picture, you can see the supports that were used to hold this custom Corian cutting board in place during production. These are broken off and sanded down after.

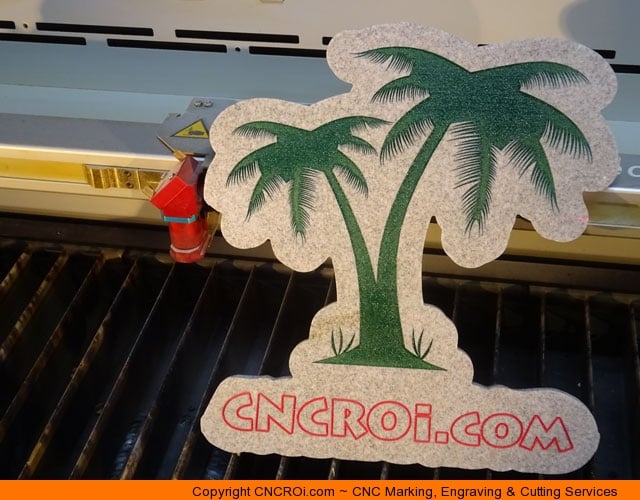

The board now looks awesome, it will go through a secondary process using our industrial laser to put the customer’s logo on it (not shown) before handing it to them as a gift. Here’s an idea of what’s possible using paint.

What’s nice is we can get Corian is over 120 different colors, which means that if you wanted this custom Corian cutting board in the shape of a heart using red Corian, we can do that for you!

The advantages of a custom Corian cutting board are many, from easy clean-up to longevity. There is no maintenance required, just cut what needs cutting and clean-up after.

Are you looking for custom Corian cutting boards, wall plaques or anything else made out of Corian and other materials? Contact CNCROi.com today!