Custom Corian Molds

Custom Corian molds are great for concrete or cement inlays because it doesn’t stick to it, meaning after the aggregate dries, you can take these molds out and voila, a perfect result with very little mess compared to using wood or other materials for this purpose.

https://www.youtube.com/watch?v=Yg9sRBrlRzI/

CNCROi.com has made lots of molds using other materials but this was the first time we were employed to do such work using Corian for use in a concrete job and the results worked out beautifully!

Corian has the consistency of very hard wood, so it’s no problem for our CNC router to cut it to shape and size as required by the customer.

As these custom Corian molds will be thrown-out after they served their purpose, we were able to use scraps of various colors, all half inch thick, which saved the customer a ton of money instead of working from sheet goods.

Carving Corian also looks fantastic, so you aren’t stuck with “flat” shapes and designs with CNCROi.com!

https://www.youtube.com/watch?v=QUHsKj-gHXc/

Corian is incredibly strong but very brittle, it’s made from compressed acrylic and is available in hundreds of colors, but for custom Corian mold production, none of that matters.

Most of the custom Corian jobs CNCROi.com does for customers is actually signage and coasters, so making a mold using this material was a nice change of pace and all the wonderful benefits of this material, being stable, being thick and being easily available really worked greatly in favor as the material of choice for this job.

Here’s a great example of paint filling a laser engrave custom Corian sign.

https://www.youtube.com/watch?v=l28w_NX_z1s/

Using the CNC router, hold-down is always an issue, so we used a down cut bit which means instead of pushing material out while cutting out the shape, the bit was pushing down on the material, there were two major benefits to this.

First, pushing down rather than up on material when cutting it means the forces are going into the table which keeps things DOWN rather than trying to lift off the table as the vacuum system is rather useless for such small pieces, hence you see the screws holding the custom Corian molds down during production.

Secondly, driving material downwards means there is equal pressure on all sides of the cut, which makes things less likely to move though CNCROi.com did employ tabs that were sanded off after the fact just to makes sure the cuts were all perfect on these custom Corian molds.

Corian also paints incredibly well, what’s even better is that it also sands very well, so I can spray paint it to fill then sand the surface flush and everything looks sharp!

https://www.youtube.com/watch?v=HFRpv16enq8/

As placement was put roughly in the middle and I was crossing my fingers that what I programmed would cut within the irregular pieces of Corian offcuts, I did get extremely close to one edge making these custom Corian molds as you can see in the image below.

I think I was within 1/32″ of having to redo that part because that piece would have been missing a top but as luck would have it, it just worked out so I didn’t have to cut another “og” at CNCROi.com.

You’ll notice on the picture below that the Corian is being pushed rather aggressively into the table, the consistency of Corian after it’s cut is like fine grit or sand, and some of it is pounded into the groves rather tightly, which means that the project didn’t even have a chance of moving during production.

Corian has been used at CNCROi.com for other custom purposes, probably my most useful invention are these custom Corian work holdings, you’ll see them in a lot of videos and blog posts.

https://www.youtube.com/watch?v=8qC5FNKLLTA/

The tabs that are part of the custom Corian molds are hard to see in the photos so below is what they look like, very thin and again, using a down cut bit makes extra sure that nothing moves regardless, so these tabs are just some built-in redundancy.

Corian laser engraves wonderfully and it also machines extremely well, which is why CNCROi.com keeps finding new uses for this material and always has some in stock to manage rush jobs such as this one.

If you are wondering about tool wear on Corian, it’s definitely not the best material for knives and thus, blades and bits, but with the right tools and experience behind them, the bit we used for this job was as sharp before as it was after this custom Corian molds job.

You may be wondering, why do we have Dog twice? Well, the customer wanted to do a test with it before doing the real thing so I suggested we just make some extra and they can do a small-scale test before doing the far larger and more expensive job.

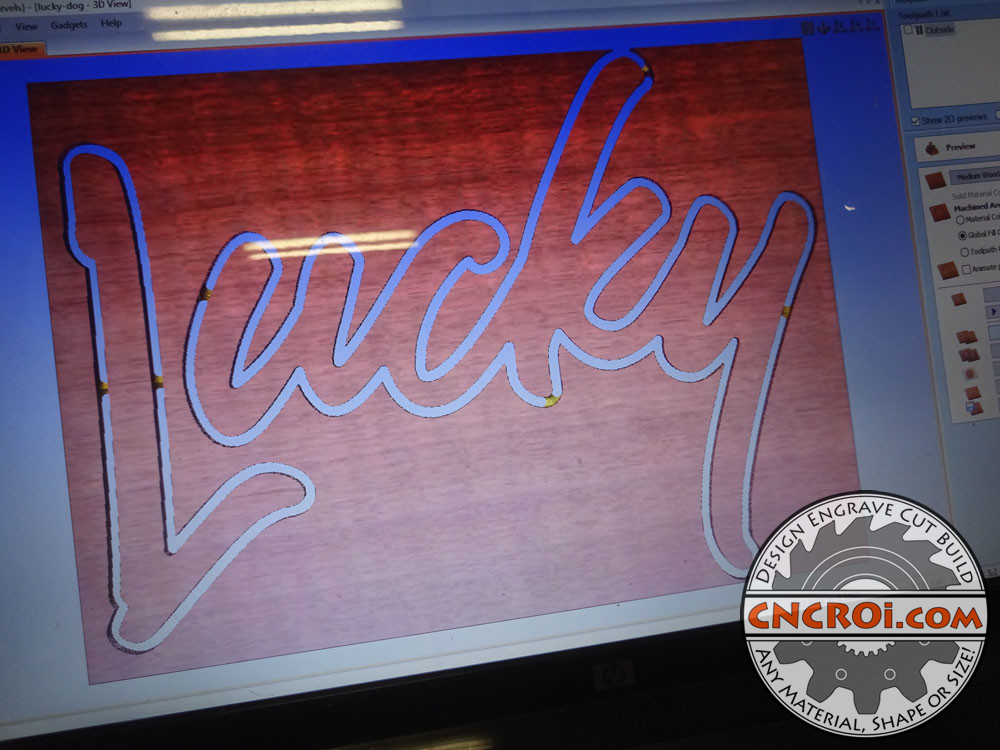

The absolute diversity of Corian color is amazing but what’s even better is that this follows all the way through the material, meaning it isn’t just the top layer that has the color and chips you see so pockets of material, like you see in the “y” above, continue.

https://www.youtube.com/watch?v=m7lYfxH6PmE/

Corian can also be very sharp after it has been machines, not as bad as Formica but pretty close, it’s a mix of hardness of the material and the sharpness of the bit, the edges can be like razor blades after production which is why in general for plaques, CNCROi.com breaks the edges.

With this custom Corian molds job coming to an end, it makes you realize just how diverse the uses of any given material really are beyond their initial intention, this stuff is used mostly for countertops… but CNCROi.com uses them for plaques and now molds!

If you look very closely at the image below, you can see the tabs from the screenshot above, they are very thin and not very high compared to the overall project but they hold just enough to easily break off after production but hard enough to not allow anything to move during production.

Here’s the finished custom Corian job in all it’s glory… amazing isn’t it?

Looking for custom molds? Contact CNCROi.com!

https://www.youtube.com/watch?v=jb-rQCDsIwM/