Custom Etched Machine Tags: CNC Fiber Lasering!

CNCROi.com produces custom etched machine tags for a number of companies, the results are permanent, sharp, precise and made to your specs!

Today we’ll focus on fiber laser etching into 16GA 304SS “custom-standard plates” we do in volume for customers needing them NOW which we can generally get out the door within 24 hours for their customers.

What makes CNCROi.com is that we hold inventories of our more common plate sizes across stainless steel to anodized aluminium AND can produce custom etched machine tags and plates at any size, gauge (thickness), shape or metal type for your own custom client requirements.

We also offer a host of other custom solutions as well, from stencils through to lamacoid and valve tags, that, just like our etched machine tags, are custom to your specs. Here’s a great video showing you the durability of just some of our solutions.

Like our other custom solutions, CNCROi.com works based on your requirements and specific needs across a host of materials, designs and sizes.

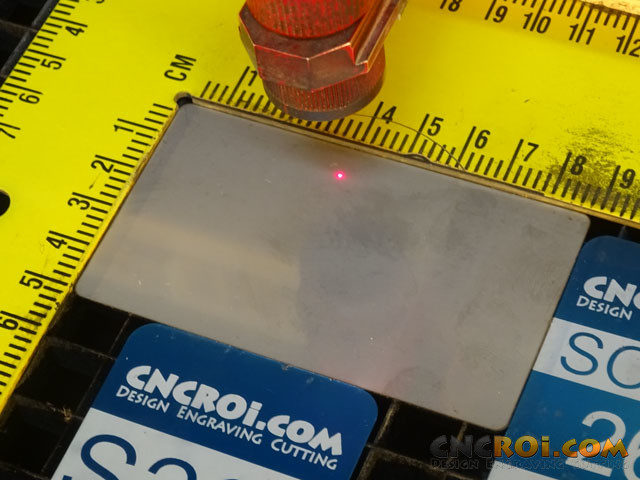

I’ve made lots of videos of my business card being made across many different materials, today I’ll make a new one from this 16 gauge 304 stainless steel custom business card sized plate.

We offer a lot of different “finishing options” from annealing to deep etching and sand blasting to cutting but regardless of you requirements, CNCROi.com can make it for you, budget and volume do play a factor.

If you want to see what etching onto a similar plate looks like, which is then cleaned using our industrial sand blaster, check out this video.

The difference between the above custom business card and the one we are reviewing on this CNCROi.com blog post is that it wasn’t cleaned-up using our industrial sandblaster, hence having a different surface finish.

The details we can achieve with metal across many grades, alloys and finishes is very accurate, just about any design works well as long as it’s black and white.

Having grayscale or colored “information” just muddies the result, straight contrasting comes out better.

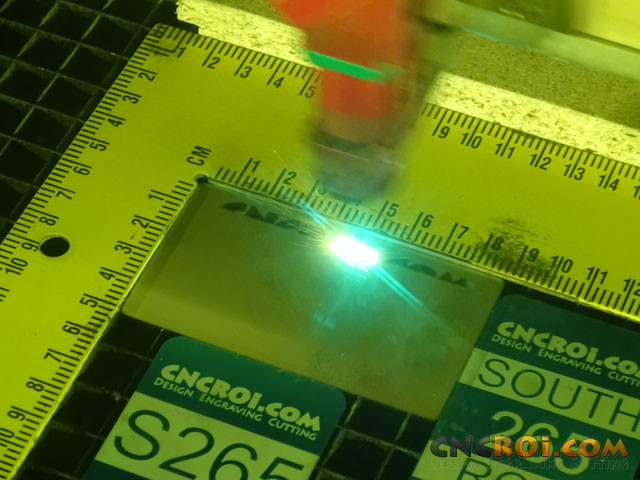

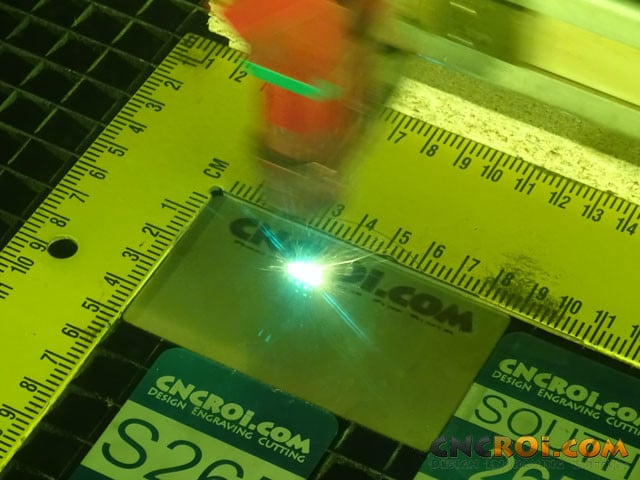

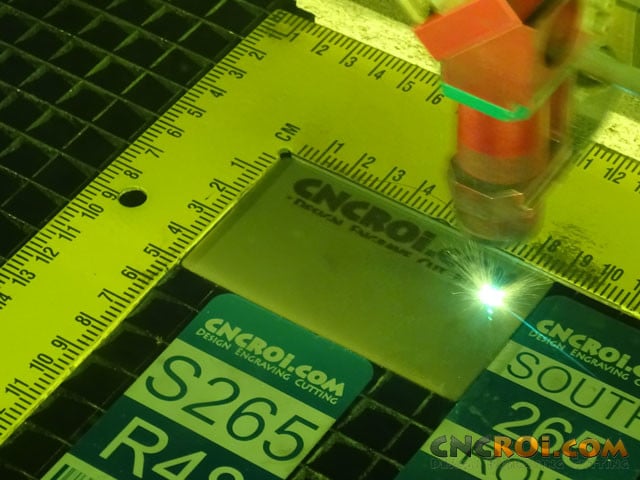

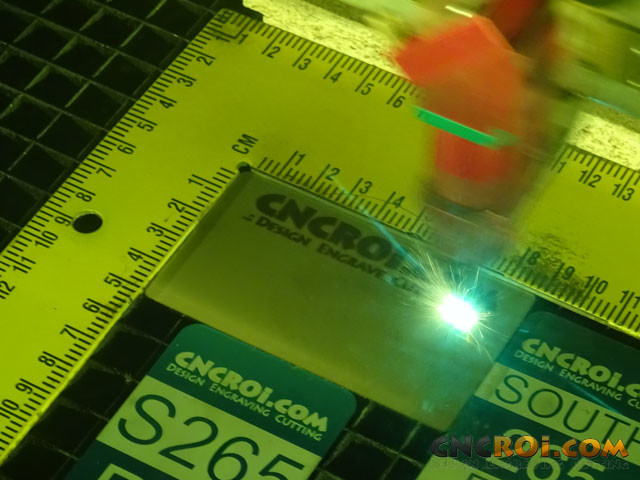

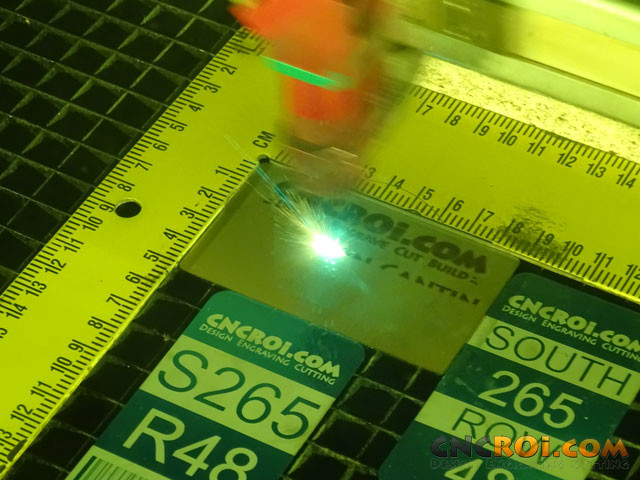

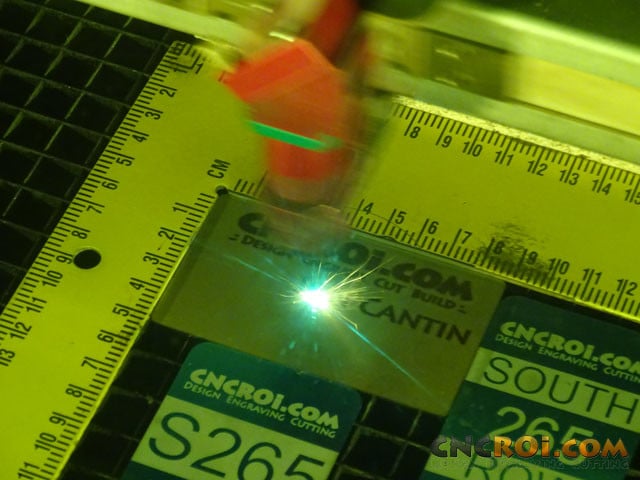

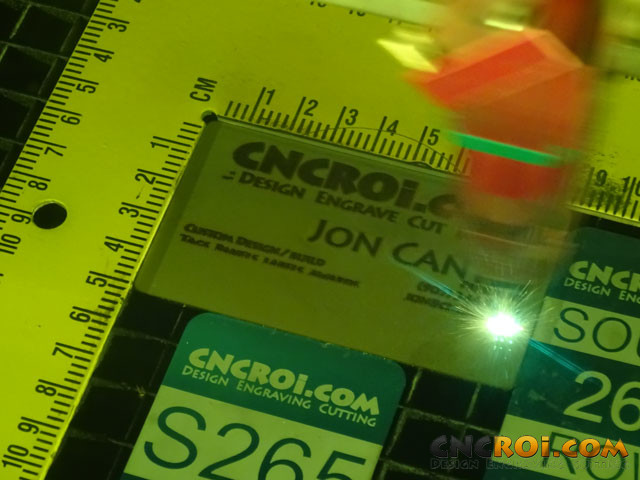

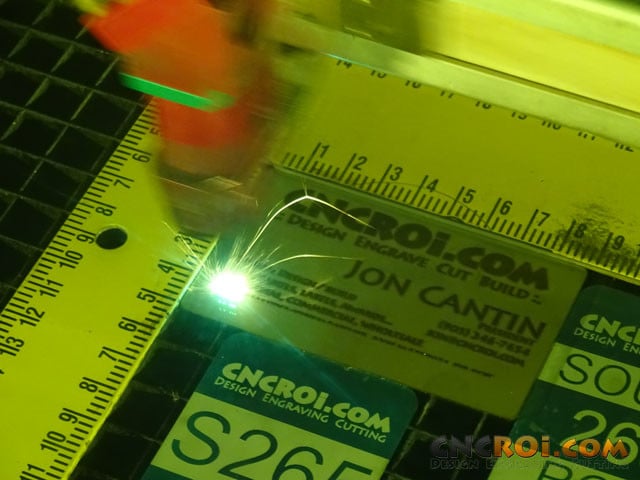

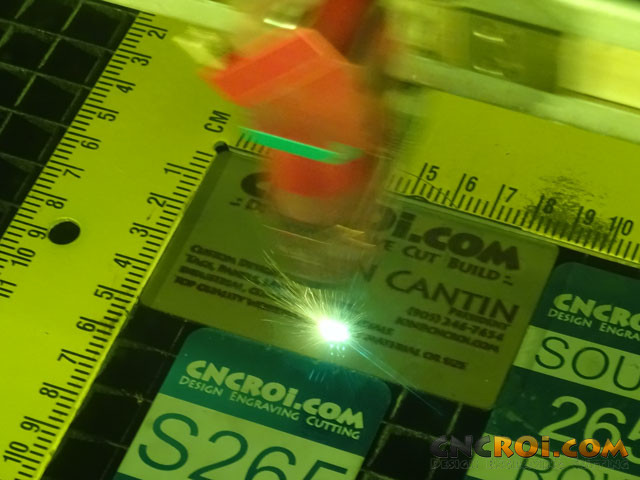

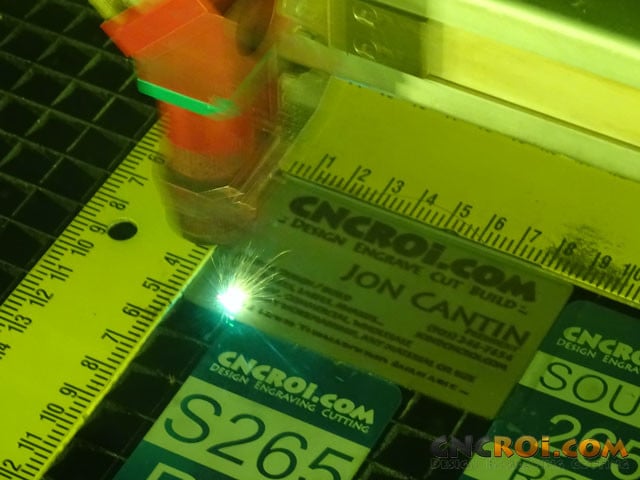

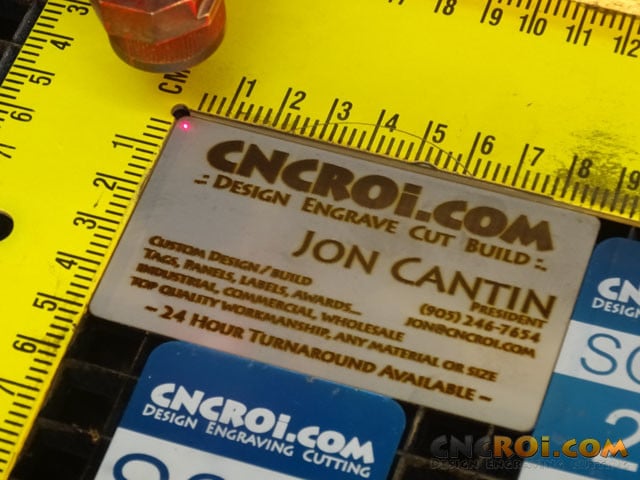

Notice how bright the fiber laser light is when it’s busy vaporizing metal where we are doing some custom etching, this business card is being done at 600 DPI and extra slow, just to make sure everything comes out clear.

We can go as low as 125 DPI or as high as a thousand, it all depends on the application this will be used for, low resolutions is fine for murals and BIG SCALE items while higher resolution for smaller details and designs (images and text).

Custom etched machine tags are generally “relatively” smaller in size and done at 500 through 600 DPI.

Custom etched machine tags are different from annealing machine tags, take a look at this video showing you that process of almost the same design.

If you are looking for extremely unique business cards, we make those too, but generally out of thinner gauge stainless steel, just for weight but again, we work on your specs.

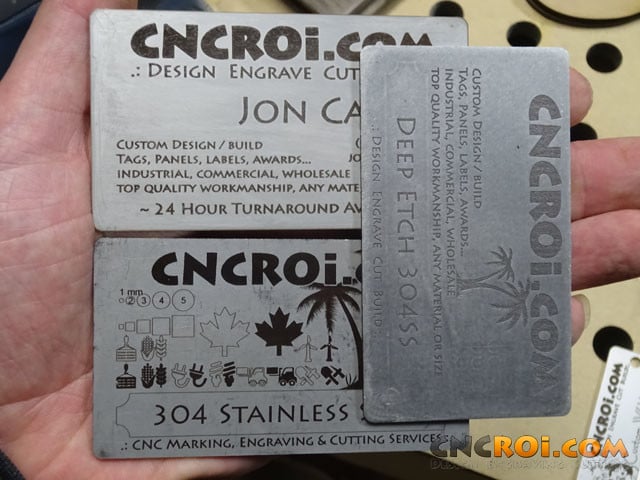

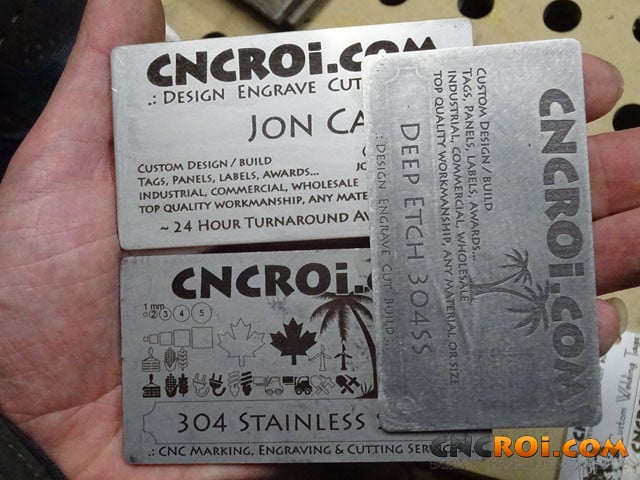

While both of these business cards are annealed, and stainless steel, the difference is surface finish and thickness (gauge).

The resolution is the same, so whether we etched machine tags or are producing custom metal business cards or valve tags, CNCROi.com can help you out with high quality products using our top of the line equipment and processes.

The sparks produced from etched machine tags are similar to those produced during welding, both are a heat process and add to the entertainment factor for our custom metal fabrication and branding exploits.

CNCROi.com doesn’t really have a volume minimum but the fewer units you get us to produce, the higher your per unit pricing will be, generally, if you are going totally custom, things start to make financial sense, depending on the design, around 50-100 units with pricing only getting better from then on.

Unlike custom stamping, CNCROi.com‘s unique approach to custom means that if your volume entails a variety of sizes and shapes (using the same gauge), it still counts as “volume count” so to get your metal volume quantity discounts.

You aren’t stuck getting all your machine plates and tags identical from etched details to size. Each etched machine tag can have different sizes and information etched onto them, makes no difference to us!

The more volume you have, the better the price per unit and some of our customers even bunch-up their orders with their customers to make a volume buy for ultimate value!

If you don’t need stainless steel, brass or other metals but want something bright for machine tags through business cards, anodized aluminium is also a wonderful option, due to the process though, if you want to go custom on that end, we have a bit less flexibility at low volume counts.

Regardless, etched machine tags is an endlessly creative task that CNCROi.com has specialized in for years and our customers have come to count on us to produce amazing results for their custom branding requirements.

Custom cut and etched machine tags for most of our customers wanting them made out of anodized aluminium is a seamless process, but for some reason, the two most popular colors are blue and black which both etch off-white.

Watch this video showing you custom laser engraved machine plates to get an idea of that process over this blog post concentrated on 16GA 304SS custom etched machine tags.

Just to give you an idea of flexibility CNCROi.com can offer your business, here’s the same custom fabricated and etched anodized aluminium on a smaller plate.

Generally, tags are smaller than plates in size and are thinner in gauge.

Etched machine tags takes longer than annealed ones, simply due to the fact that etching is a process requiring more power and heat to vaporize the metal while annealing is just a top surface process.

Regardless, both are incredibly durable and look amazing in any light for most applications.

The reason why some of our customers prefer etched machine tags over top surfaced annealed ones is that their application requires SUPER durability, nothing will fade, crack or peel regardless of which process you go with.

Etching just provides yet another level of durability as it’s into the tag instead of just on the surface, of course, we can also anneal the etched tag, but generally costs are too elevated for both processes onto a custom etched machine tag.

As for custom etched machine tag production, some of our customers give us a hand drawn shape with dimensional references while others give us CAD files precise down to the hundredth of an inch.

Due to the huge variety of customers we work with to make their custom dreams a vivid reality, CNCROi.com is use to a large diversity of ways of you getting your information across to us.

Crunched-up napkins with crayon sketches through electrons, we are fine either way!

You aren’t stuck with metal etched machine tags with CNCROi.com either, we also make them out of polycarbonate if you need something you can “see through” and further work with at your end.

Polycarbonate is bullet proof glass, we can work across a large variety of thicknesses as well, paper-thin through an inch thick, whatever your specs call for!

The reason for the two other blue anodized aluminum tags in these photos and video is for more precise clarity requirements, the light from fiber etching and annealing is incredibly bright and it plays havoc with their auto-focusing.

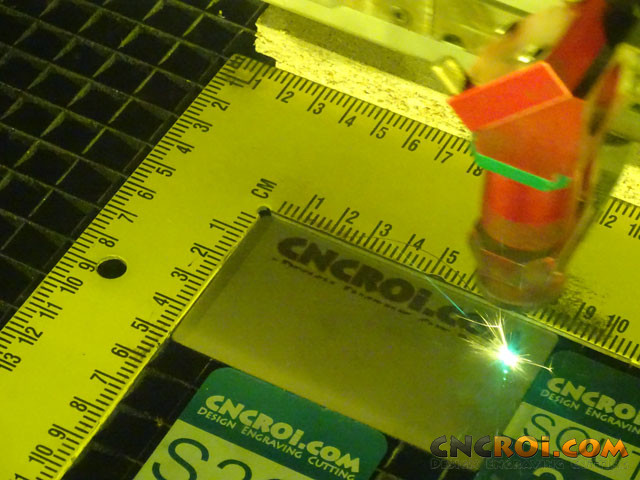

Now that the top of this custom etched machine tag is done, CNCROi.com DESIGN ENGRAVE CUT BUILD, it’s time to add my name, title and other information.

As this is business car sized anyhow, I just put a version of mine onto the custom 304SS 16GA tag.

The reason for having various text sizes is to show you the incredible clarity achieved during the etching process, this etched machine tag is as easy to read with small text as the larger text making-up my logo and website address.

CNCROi.com tests our processes and due to our custom work on a regular basis, that’s all we do really, we have experience producing the best results possible.

To help keep the custom etched machine tag cool during production, CNCROi.com blows air onto it to prevent it from warping too much.

There is always a light warping, that depends on the amount of surface that’s etched or annealed, so for some custom machine tags that require a lot of information.

We even move-up a gauge or two to account for the extra metal thickness required to counteract the extra heating applied onto the plate.

Another application we keep inventory for in the “custom-general” category are our welding tags, stainless steel through anodized aluminium.

CNCROi.com keeps inventory and produces bulk quantities of these to keep them affordable to our clients AND it allow us to maintain a 24 hour turnaround, something unheard of in the custom fiber etching and annealing of industrial quality plates and tags.

CNCROi.com takes great price in our work, metal through plastics, woods through leather. We are passionate and ambitious!

Being a custom shop, design through build, makes sure that no two days are the same and etched machine tags are no different.

The difference between fiber laser etched machine tags and diamond dragged or peen stamped are that the contrast is far better, the resolution dramatically higher and as it’s a non-contact method of production, we aren’t introducing surface stresses.

Heat does occur but it never stays hot long enough to cause additional tempering issues though on thinner gauges, some warping can occur (but it’s minor).

The nice thing about on-demand etched machine tag production is that we can make them as per your requirements when you need them, so you can order a large volume of plates from us and we ship them to you as your machines head out the door to their customers.

This means you can enjoy volume discounts even if the amount you get produced need to be customized for each machine over the course of a period of time, even if you don’t know what will go onto the tag months down the line.

CNCROi.com works within your production stream, not the other way around, that’s the advantage of custom fabrication through etching.

Now that this custom etched machine tag (or business card) is just about finished, you can see that the results don’t look as sharp as the other photos and videos shown in this blog post.

This is because of the slag and other metal debris that forms around the etched machine tag, this happens with annealing as well but not to the same extreme.

This is why it’s hard to photograph and videotape these processes, the results are blurry and there is an extremely bright light to boot!

Hence additional visual references being required for proper documentation.

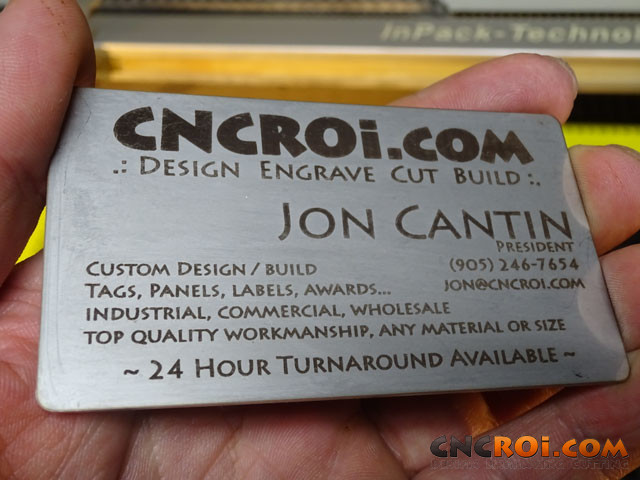

Before we jump into the cleaning-up processed on this custom etched machine tag, take a closer look at the information put into the 304 stainless steel plate.

If you are wondering, this could have also been a round plate as well, the size, shape and thickness plays no factor regarding capabilities.

Generally though, the bigger the size, higher the gauge (thickness) and the more customization required the higher the price.

Take a closer look at the card below, and compare that to…

The cleaned-up etched machine tag, quite a contrast isn’t it!

There is a bit of fuzzy fabric that’s rubbed off on the rough surface of the etched machine tag where it’s black and brown.

It isn’t a big deal as it comes off, but everything else stays in place.

Unlike annealing, where the surface where the fiber work is done is smooth and only slightly raised, the etching process is rough and into the metal.

Going back to our custom etched welding tags, you can compare the same process across a variety of designs and sizes.

The custom etched machine tag could have had holes, in any shape or size or quantity as well, every aspect of these plates can be customized to your requirements.

Let’s compare the deep etched 304SS that’s been sand blasted to the right with the top etched plate you saw being made in this CNCROi.com blog post and at the bottom, annealed 304SS.

All three plates are the same thickness, you can see that there is a bit of a bevel on the sand blasted one, that’s caused by the sanding process during the abrasion processes.

Need custom etched machine tags out of stainless steel or anodized aluminium, contact CNCROi.com right now!