Custom Fabrication Across Wood, Metal & Plastic

When I first began CNCROi.com I couldn’t have imagined that I’d be running a custom fabrication shop across so many materials and processes.

It began with a Trotec Speedy 400 flexx with both a CO2 and fiber laser source, from there, through the years, we’ve expanded dramatically in space, equipment and client base.

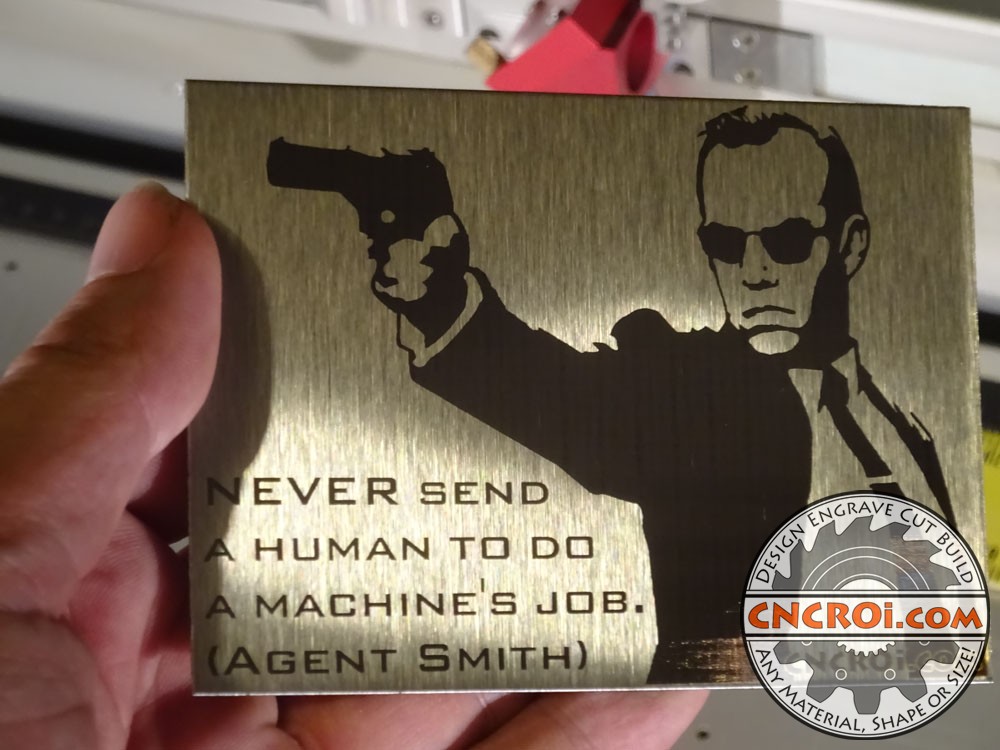

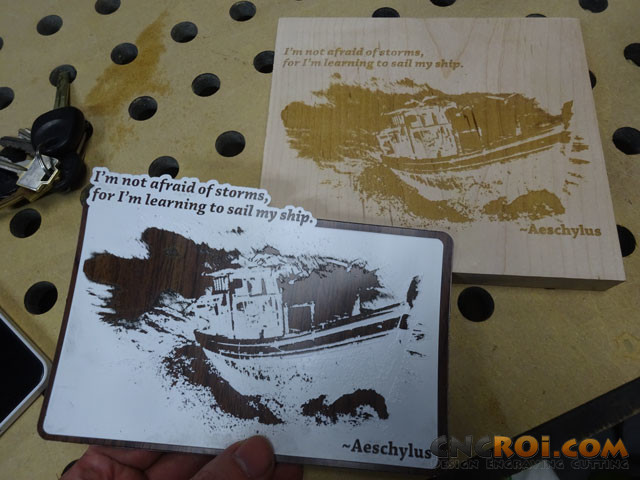

Although our machines and facilities have grown, our focus has never changed, that of being a custom fabrication shop across Wood, Metal and Plastic.

CNCROi.com does quite of bit of woodworking, whether it’s with our amazing ShopBot PRSAlpha or our laser or supporting equipment, they all play an important role towards bringing and completing projects for our customers.

There is an incredible synergy that’s developed through the years, as our customer base and project size grew, so did our expertise and ability to bring projects to reality for our customers.

Over the past year, things have changed quite a bit though, more and more businesses are coming to us with projects that others just don’t want to take-on, for us, we’ve been completely custom fabrication shop from day one, so material testing, getting specialized equipment and expanding our resources is just part of the game.

You might see a lot of CNC projects at CNCROi.com, but for us, it doesn’t just start and end there, we do a lot of projects that don’t involve any CNC work at all due to our capabilities across wood, metal and plastic.

Like Amazon, you order from CNCROi.com online where the details of your custom projects are sorted out then we ship it right to your door as per spec outlined, and through the years, most of our projects are actually started and shipped within 24 hours.

I’d say the biggest reason for our success as a custom fabrication shop is CNCROi.com‘s willingness experiment using the background that we’ve had on day-one doing custom work, we didn’t start with a product or specific project, we began as a service offering whatever you wanted.

It’s one thing to say CNCROi.com can make or build something, but quite another to actually do it, and that’s what we’ve been doing for years now.

When it comes to all the materials that we work with at the shop, each has their own unique characteristic that must be accounted for and when it comes to a specific design spec, some are better than others.

There is a lot of creativity that comes into what CNCROi.com does, some projects are very straight forward with very little room for changes or calibration mistakes while other projects are completely open to interpretation.

When it comes to custom production, a lot of things need to be sorted-out but CNCROi.com‘s approach for our customers who give us the flexibility is refrain from having them thinking about all that’s involved, to them, it’s a seamless process design through fabrication.

The seamlessness of our approach as a custom fabrication shop, where our customer are as much or little involved as they wish to be when it comes to custom fabrication for them.

Wood alone has hundreds of species while metal has thousands of types, same goes with plastics which are probably in the millions but with CNCROi.com, the decisions as to what is done and how are up to our customers.

If you have a project that requires custom fabrication, be sure to contact CNCROi.com, we are passionate eager to make whatever custom you may need.