Custom Hardwood Mould Making: Poplar

Today we’ll review a custom hardwood mould making using Poplar at CNCROi.com.

https://www.youtube.com/watch?v=daITxJpn3js/

I’ve been laminating hardwoods for a long time with my other business SandboxRanch.com so it comes in very handy having all that experience to apply towards these thermoforming moulds.

I laminated this Poplar a while back, and it has been immencely useful for a few things, so when it came time to try out a poplar version of a thermoforming mold, I was excited to give it a try and now that it has been used a few times, it has actually been a resounding success for the customer.

The major advantage of Poplar for custom hardwood mould making is that it’s very easy on machinery bits, our machine is incredibly powerful so it can easily power through even the hardest of woods, but the bits are another situation, the longer they last, the more I can make with them and hence, the more cost-effective these become for CNCROi.com customers.

Regardless of the hardwood we use to make custom hardwood moulds, the process is the same, laminate the kiln dried wood, chop it up and then carve out the design the customer needs.

When it comes to making custom moulds, CNCROi.com can make them out of acrylic, delrin… even aluminium, so any option you need, we can fabricate for you.

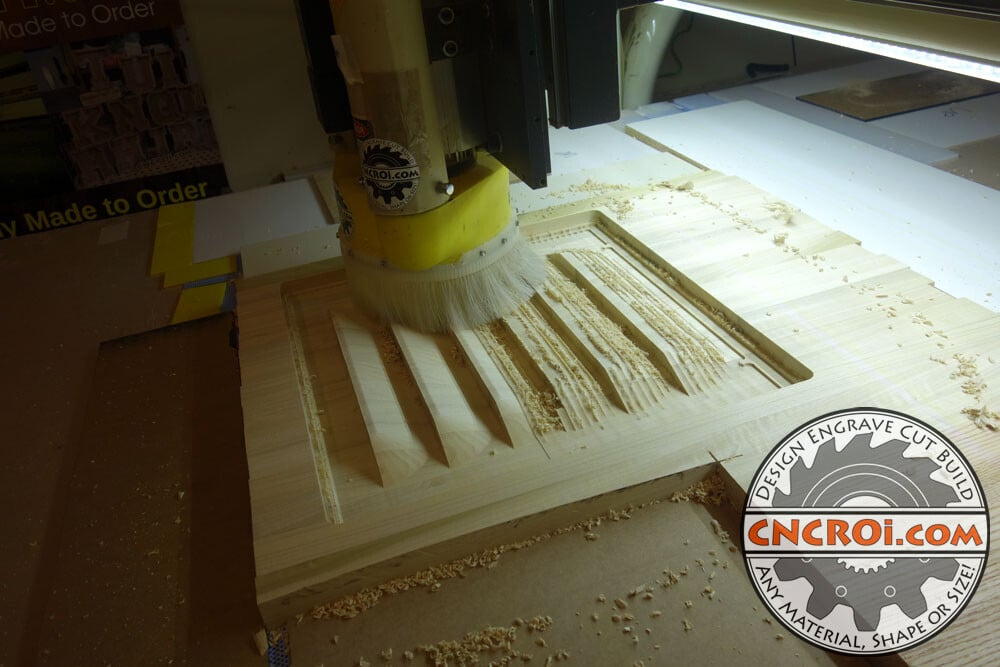

You can tell this is the rough pass as things look “rough” and happen a lot faster on the video accompanying this blog post, as a result, once clearing of material is complete, then it’s the very slow process of fine detailing.

Even with our roughing bit at CNCROi.com, you can still see how good the poplar is looking, the focus of the initial pass is material removal, as such, it’s a “rush” to lift and chip as much as possible, regardless of the finish, the finishing bit is what takes forever and will be making things nice and smooth.

That’s why you have all that lifting on the edges, that comes from the upcut bit lifting material, as Poplar is a relatively soft hardwood, you get a lot of this but again, it doesn’t matter for the initial pass when making a custom hardwood mould.

Of course, CNCROi.com also makes Corian parts for our customers to then use for their mould making requirements.

Keep in mind that Poplar is a softer hardwood, but still a hardwood, as such, much of the production care and speeds and feeds are actually identical to their harder cousins that have taken CNCROi.com a very long time to sort out, that’s because our machine is such a beast and the differences in hardness are almost irrelevant.

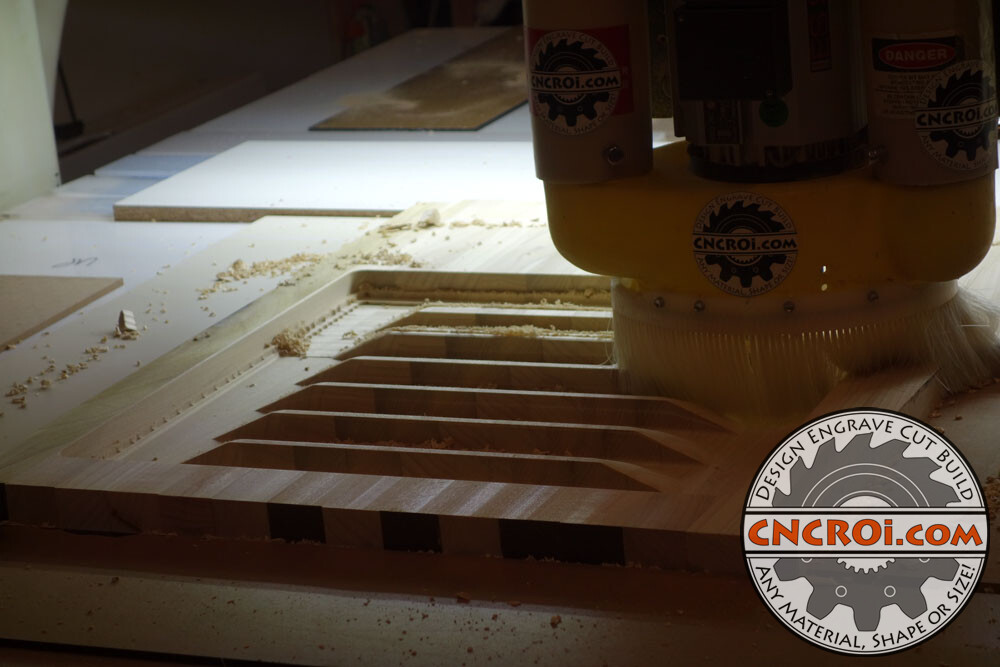

You can see the massive difference between the first and second pass below, custom hardwood mould making takes time, from laminating the wood to refining the initial pass, and this final clean-up pass is what takes by far the longest of the bunch to produce, but wow, does it produce a fantastic finish for our CNCROi.com customer.

Another advantage of Poplar is the weight, it weighs substantially less than Oak or Maple or even MDF, especially after the mold is produced, as a result, if you have employees who need to move these around constantly, having a Poplar custom hardwood mould is a no brainer to keep workers compensation at bay.

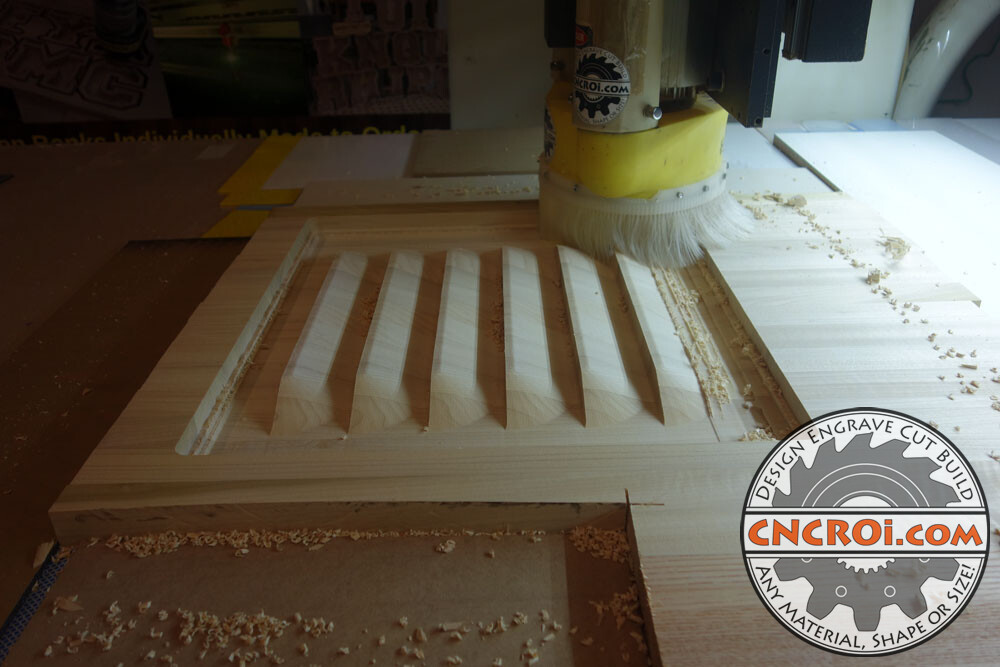

It always amazes me just how wonderful our Thermwood CNC router produces molds in the final pass, the lack of vibration and a wickedly overpowered spindle and ultra sharp bits produces a sanding-free finish that has taken me over a year to sort out with my banks which directly applies to these thermoforming molds as well.

When it comes to Oak, which of course is another hardwood option for custom mould making, the process is the same as you can see in the video above.

You’ll also notice with the initial pass, there is a lot of dust and chips produces that fly pretty much everywhere, with the second pass, we are removing at a minimum 0.01″ of material and on the edges or places the larger bit doesn’t get to, up to a quarter inch, this is why the cleaning-pass takes so long, the steps are so much tighter and the small amount of material removed is essentially dust after the initial chipping pass.

When it comes to making these custom hardwood moulds, the largest continuous mould that CNCROi.com can produce is 5ft x 10 ft, the size of our table, the lamination process yes, most certainly, can be done at that size.

You can see how the light I installed across the static gantry on our CNC router is really helping to show any faults in what we are producing, but as you can see, there aren’t any hidden knots, voids or chipouts across the custom hardwood mould.

CNCROi.com can of course produce both positive and negative moulds, they are basicaly the same side of a coin but for some customers, they prefer one over the other, so above is a video showing both “versions” of the same design.

Once cut out, fresh off the machine, you can see how clearly and sharp just about every detail of this custom hardwood mould are, a little dust and wood chips settle on there but nothing that can’t be extremly easily removed at CNCROi.com.

Even close-up in the image below, you can see how all the edges are dead-on sharp, you can actually see the “steps” the finishing router bit took to clean up the entire surface of the custom hardwood mould.

Notice how the lines are all straight, there isn’t any swerving, skipping or other issues that would be present using a machine that wasn’t so over-powered, right away, our customer can accept delivery of this, drill a bunch of holes and they are straight into using this for their thermoforming needs.

MDF is also a good option, probably best for resin filling so that, instead of having CNCROi.com make a solid resin version of your thermoforming mould, just have us make the much more cost-effective MDF version then fill it up with your resin, let cure, finish then you are ready to go!

What impressed me most when the customer showed me the finished results of their thermoforms is how close to this custom hardwood mould they were, it was pretty much an exact replica except their finished product didn’t have the drilled-out vacuum holes that they put into this to aid in sucking the plastic down when the heat is applied.

This is another small but really nicely finished mold to add to their inventory, many more to come and yes, we can do just about any shape, size and material requirements for your moult making needs at CNCROi.com.

Need a custom hardwood mould? Contact CNCROi.com right now!