Custom Jig and Fixtures: Laser Cut for Printers

Custom jig and fixtures are laser or CNC routed or waterjet cut for any make or model of printer, UV or flatbed alternatives.

By far the printer type we make the most custom jig and fixtures for at CNCROi.com are UV printers, they just have such a huge diversity of products that are printed upon that it keeps us pretty busy making all forms of shapes and sizes for customers across North America and the Caribbean.

The general shapes for our custom jig and fixtures are square and round, think golf balls and business card sized for everything from custom UV printed name badges to UV printed promotional merchandise.

The advantage of CNCROi.com for our custom jig and fixtures customers is our “general” 24 hour turnaround, which means they have an order coming through their door in the next week and they need a jig to do said work, we’re ready and able to help!

We have lots of experience making custom jigs of all shapes and sizes for use on endless materials for huge or small production runs.

There are a lot of ways to make custom jig and fixtures for UV printers, most of what we make for this industry are wood based, it’s cheap, lasts a long time and very easy to work with.

As most UV print shops are temperature controlled and the custom jig and fixtures are under no stress at all, there is no material warping and most of our customers in this field also have a vacuum table so what we make pays for itself easily on the first run and becomes a profit center from then on.

CNCROi.com can make custom jig and fixtures of any size, shape or pattern, if you have a project that calls for UV printing 10 000 acrylic elephant key chains, not only can we cut the key chains for you but we can also make the jig for you to then print onto them with!

There is also an endless variety of ways to make custom UV printer jigs and fixtures, whether you want them out of one layer or multiple, CNCROi.com can make them for you on-demand to your spec.

As for thickness, we can make “tops” for custom jig and fixtures as thin as 1/32″ up to as much as you want, so not only does CNCROi.com offer you the flexibility as to the shape but also the width, height and thickness of your overall jig.

Additionally, CNCROi.com offers you a custom shapes library and can work off your files thanks to the power of NDA so basically, we can cut the shapes you want and the related jig all in one shot for you to them print for your customer.

Whether you want parts or the custom jig and fixtures to be out of metal, wood, plastic or paper, CNCROi.com can cut them out for you in record time and on-budget.

CNCROi.com also makes custom jigs for internal use too, from custom key chains which we cut using waterjet, laser or router to dog tags and the like.

Just send us your digital files and through the magic of the internet and the postman, you’ll get them at your door within a week, if you need things “next day”, CNCROi.com can also do that but you’ll pay FedEX though the nose.

CNCROi.com can also make mixed-media custom jig and fixtures, meaning if you want to UV print a baseball bat, a few golf balls and a canoe paddle all on the same jig, we can cut it for you.

The advantage of CNCROi.com when it comes to custom jig and fixtures is endless, you are not locked into something that’s mass produced and already made, our approach is very different, on-demand production start to finish.

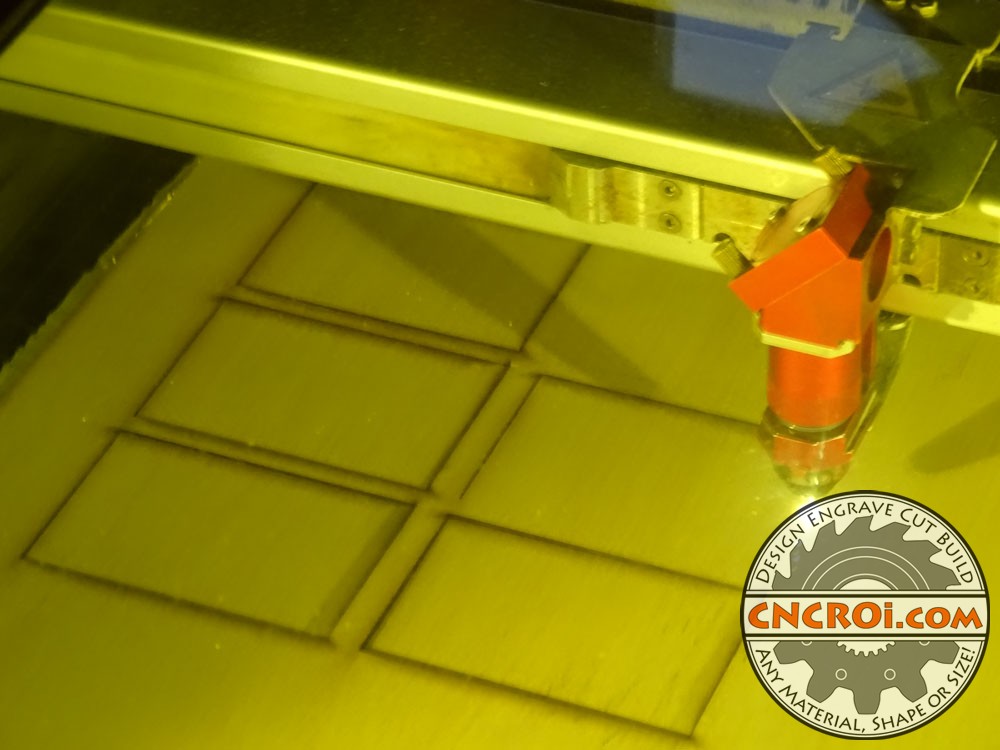

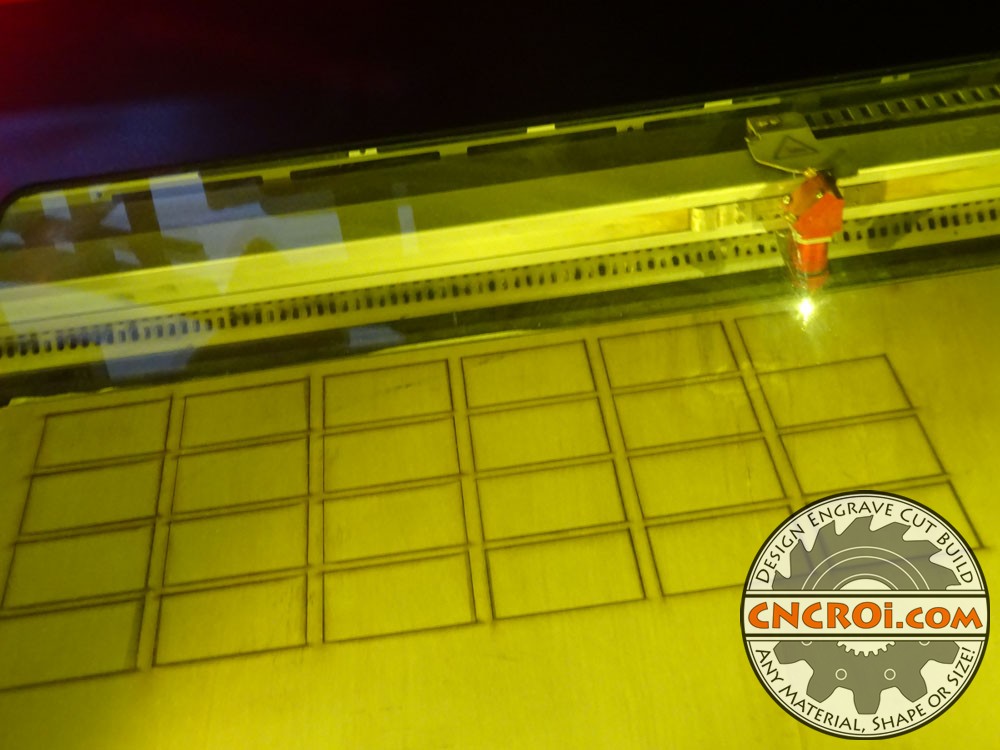

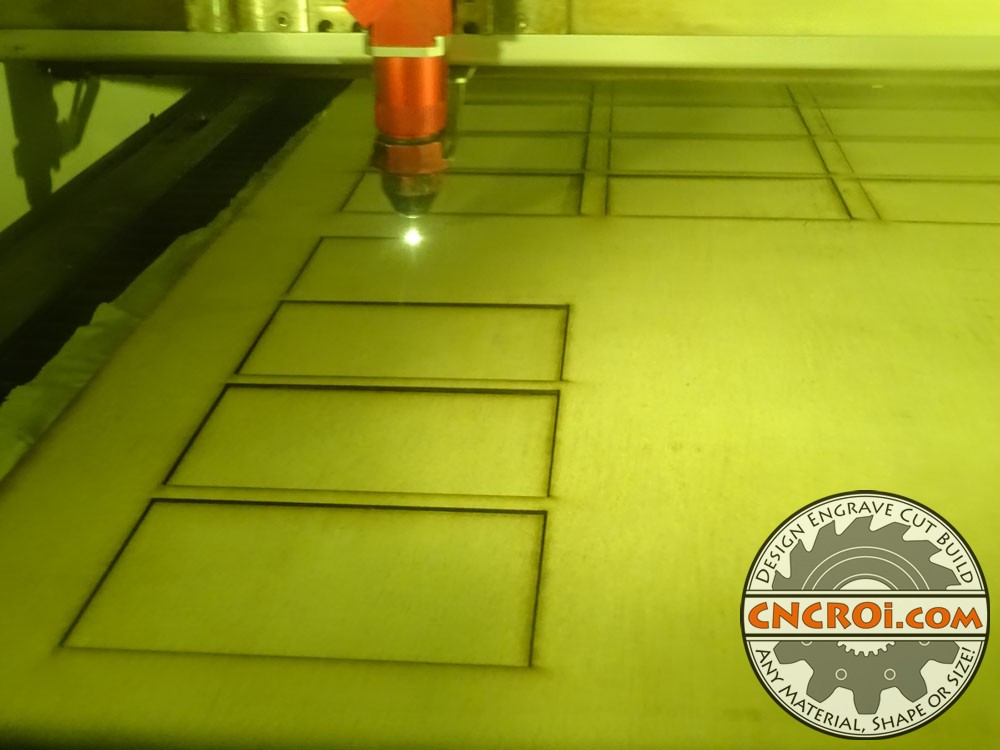

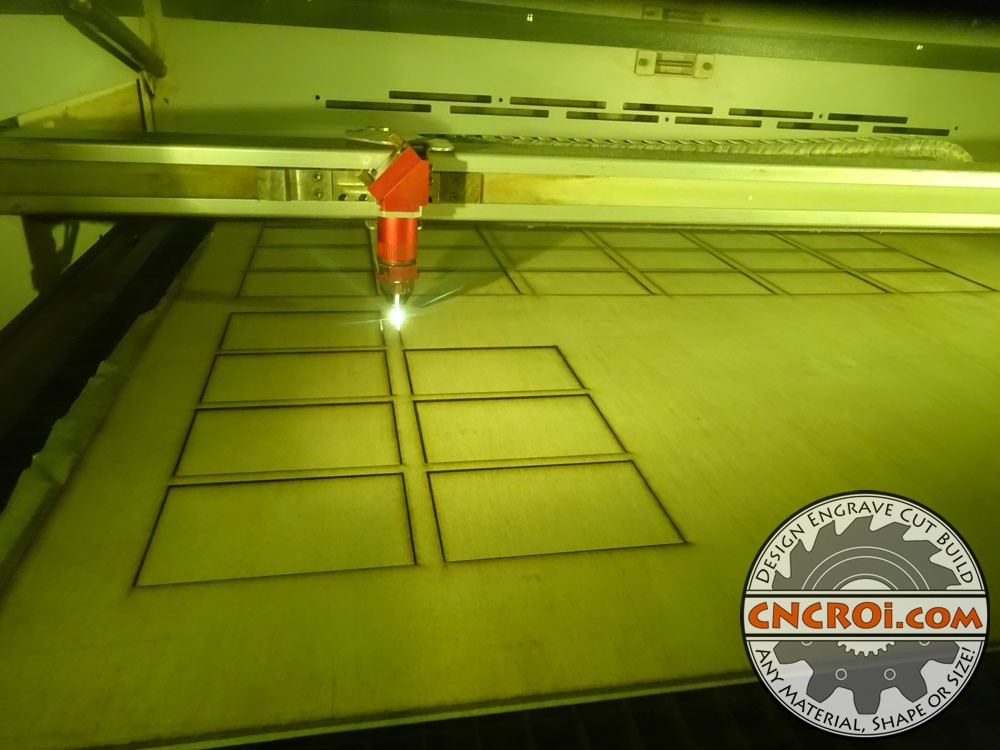

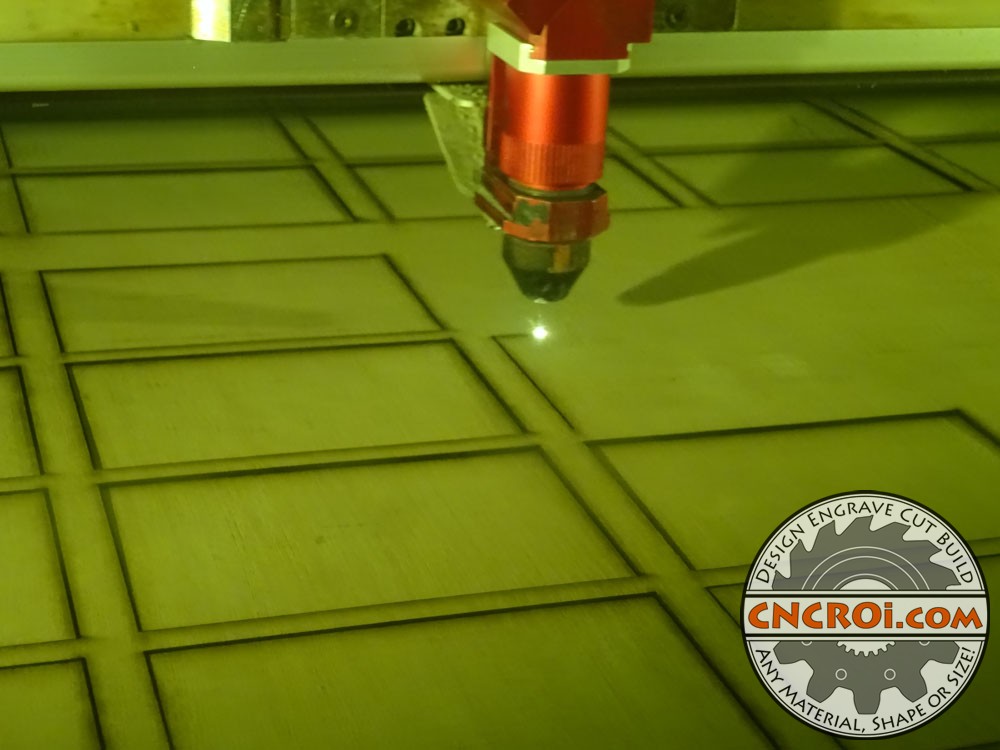

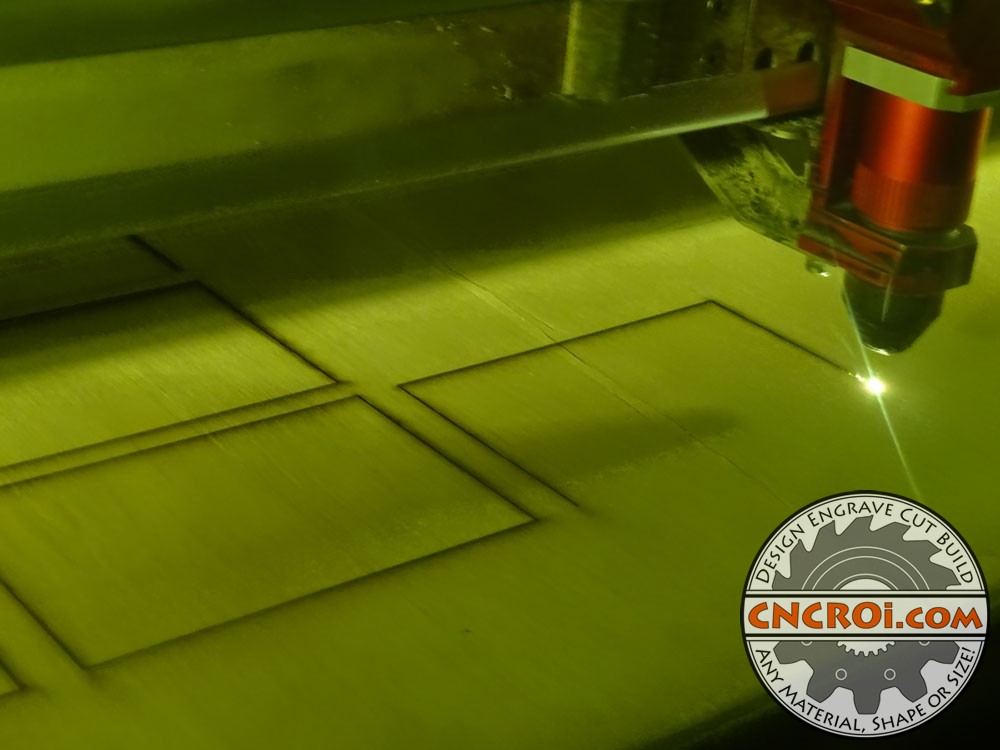

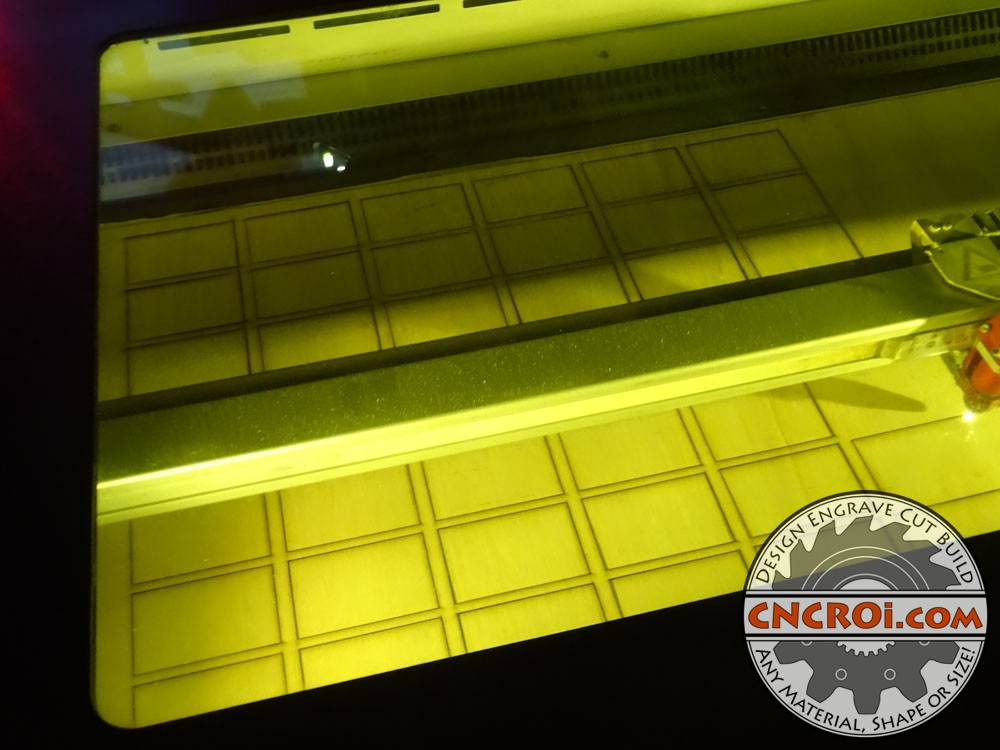

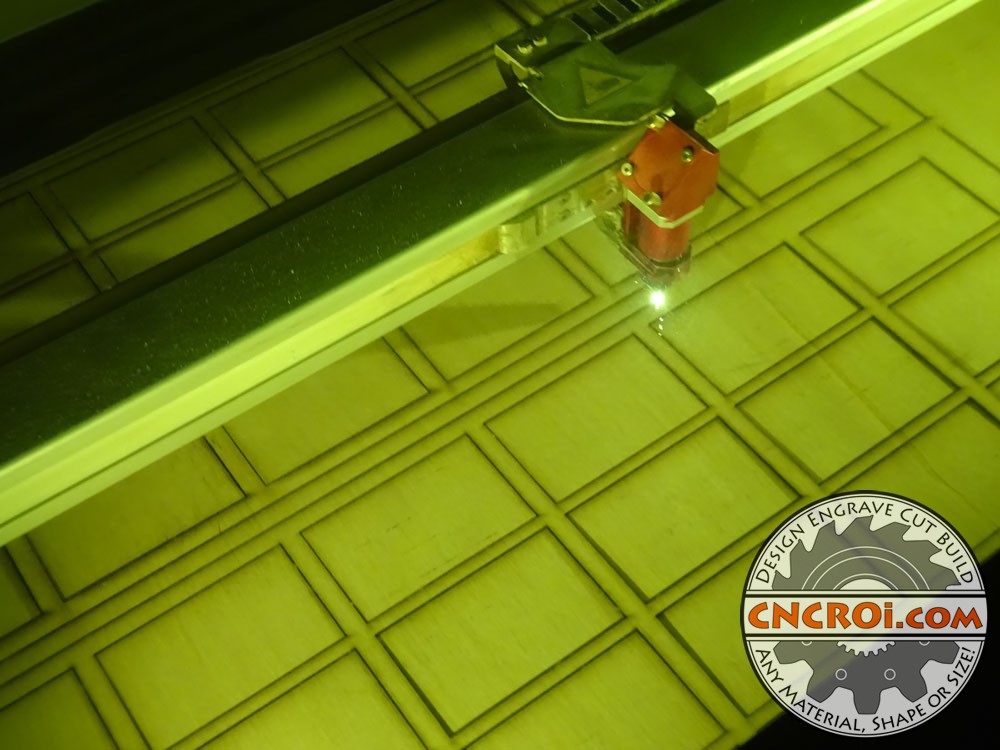

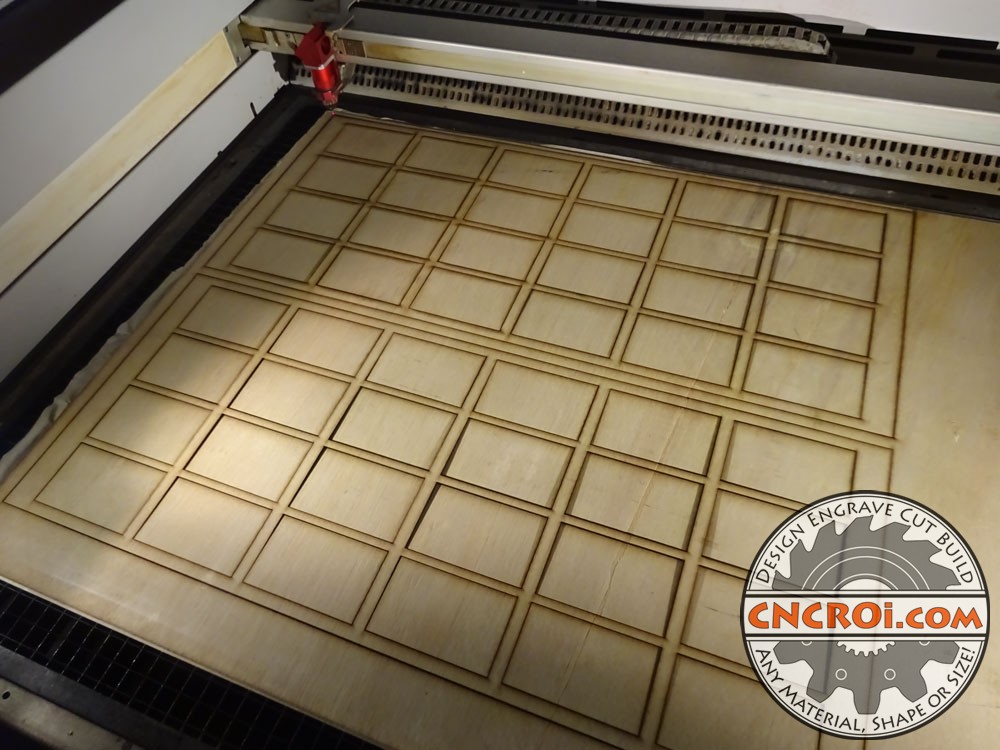

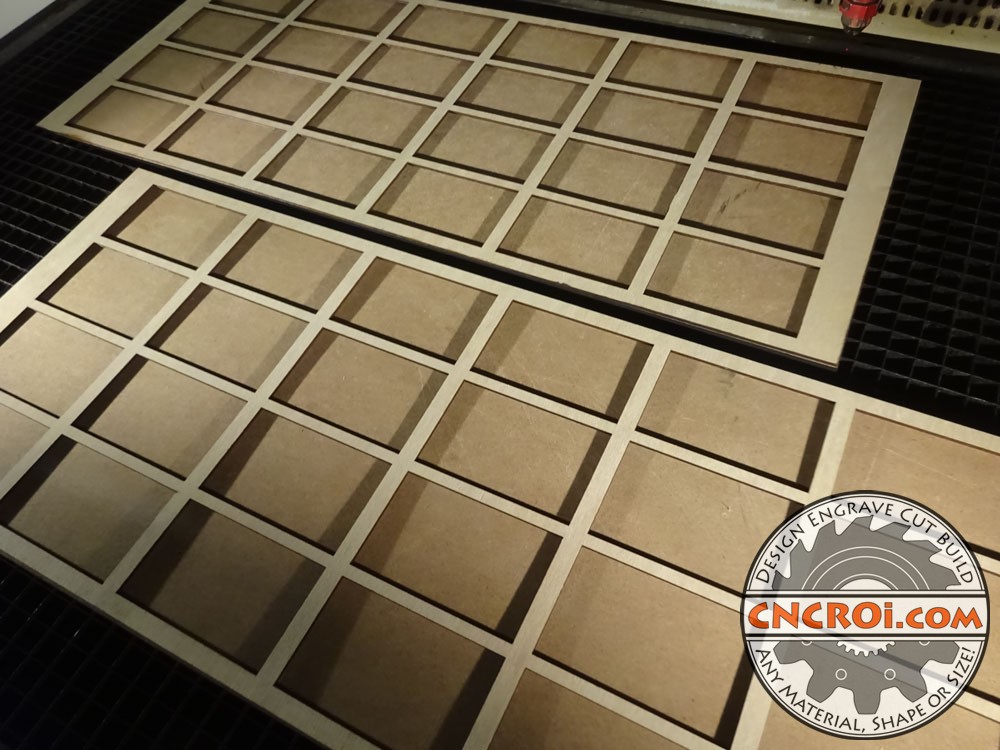

Here’s what a top of custom jig and fixtures looks like after being laser cut and cleaned-up, each rectangle is perfect like the last, with our Austrian wide-format industrial laser being accurate within 5 nanometers, all our stuff is dead-on!

Each material has a cost and benefit, there is no perfect material, if you need something soft, we can even make custom jigs out of foam.

Whether it’s 1/8″ MDF or two inch solid stainless steel, you need custom jig and fixtures, CNCROi.com can make it for you.

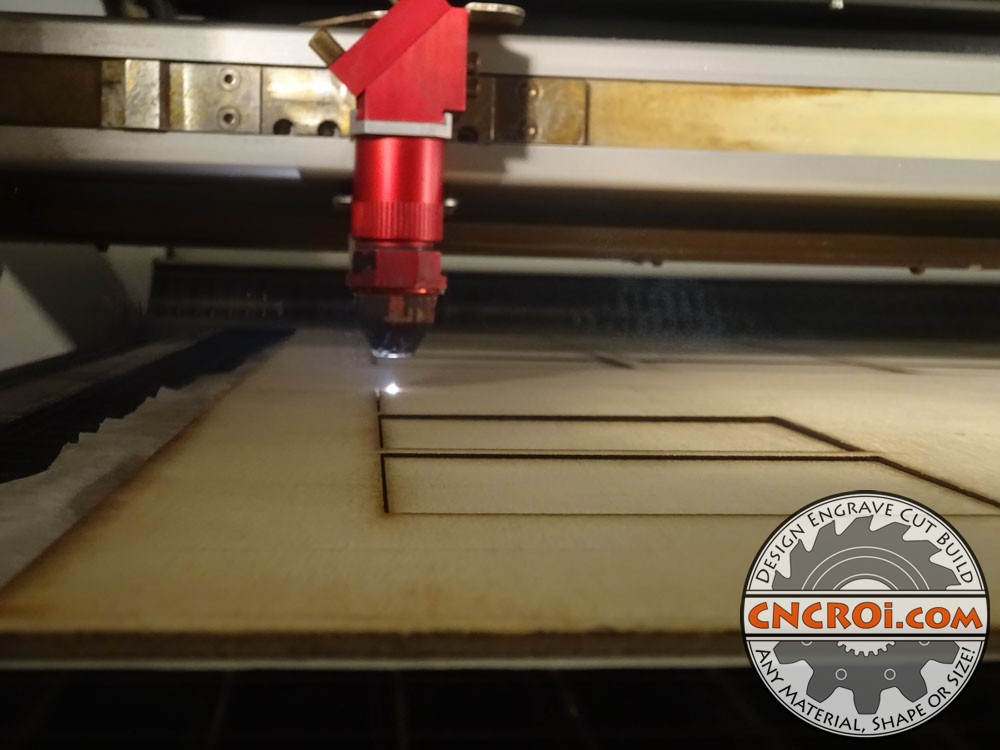

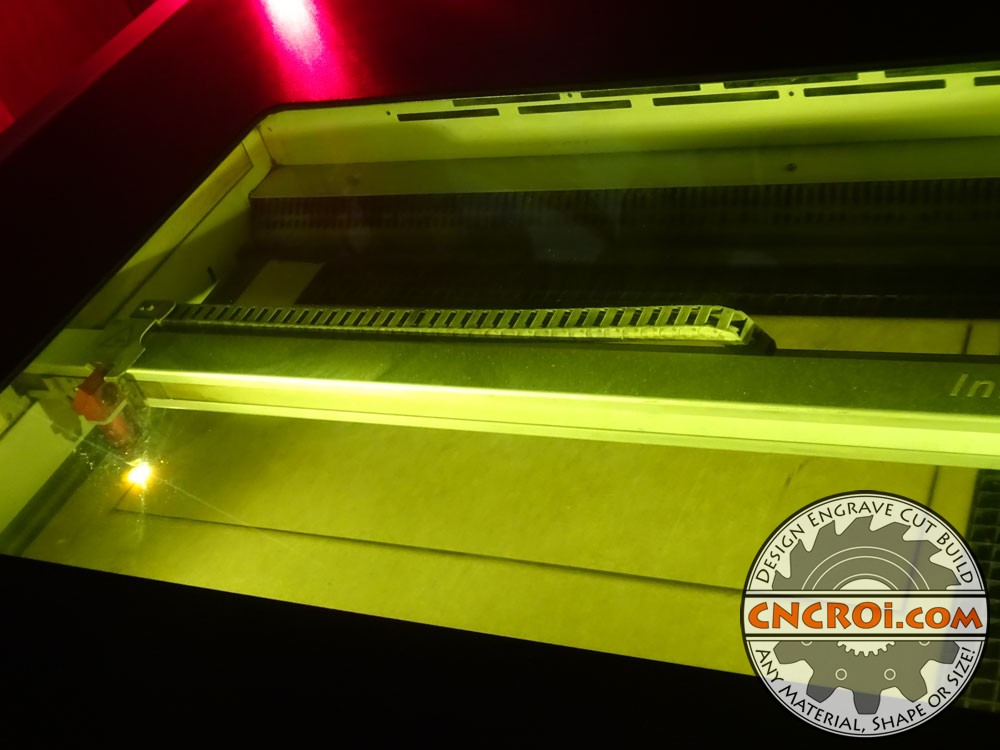

Now CNCROi.com‘s CNC laser is cutting though 1/4″ or 6 mm MDF for the backing to the 1/16″ or 2 mm plywood, plywood is strong and durable, MDF has a good weight to it and is sturdy, together when glued it’s a pretty awesome combo when it comes to custom jig and fixtures.

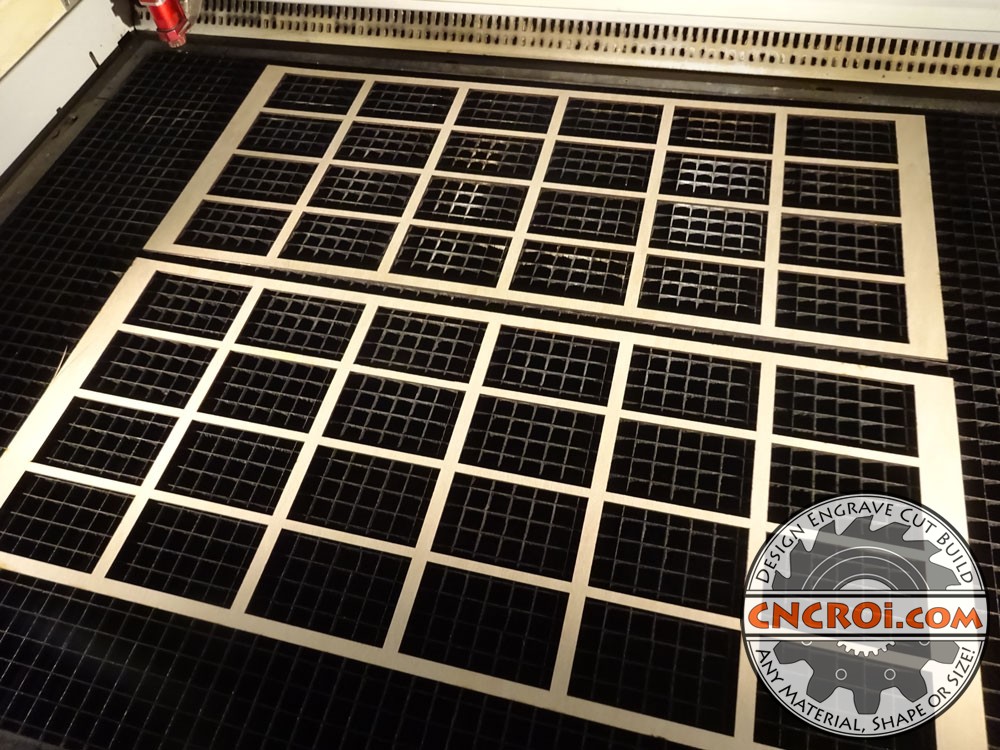

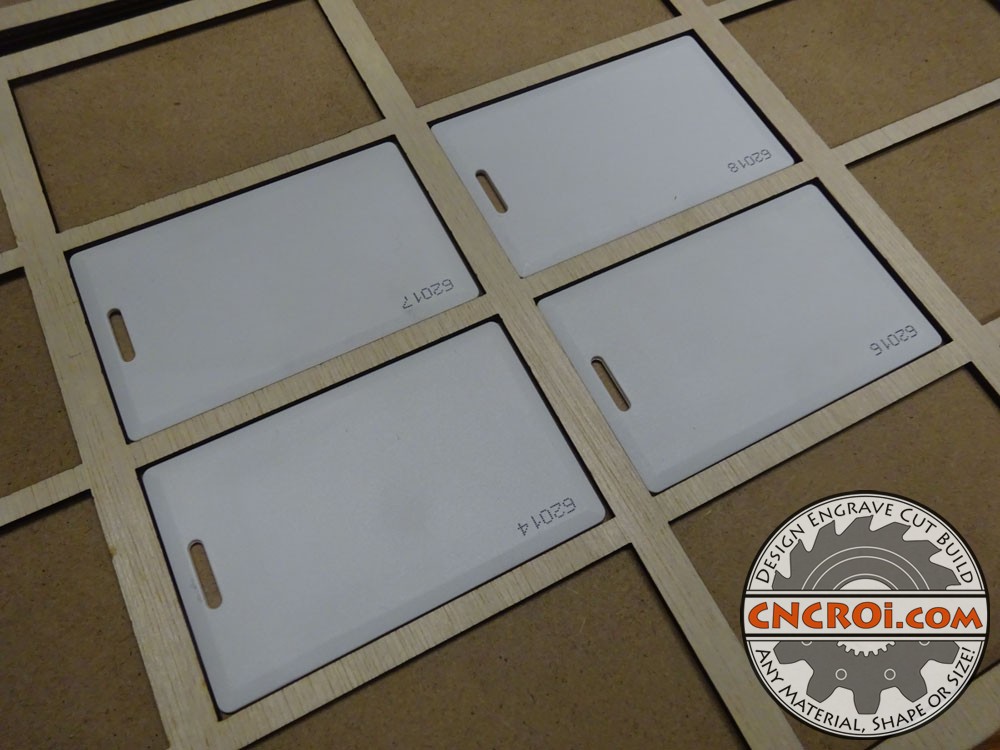

Here’s the end result, no glue applied, our customer will put it together at their end on these custom jig and fixtures for their UV printing business.

Here’s what these custom jig and fixtures will hold, a perfect fit with about half a mm of play, there is nothing worse than having to hammer items into a jig and use a screw driver to pull them out.

Need custom jig and fixtures for your printer? Contact CNCROi.com right now!