Custom Laser Cut Gasket Production

CNCROi.com can laser cut custom gaskets in an endless variety of rubbers, foams, metal and plastics to suit your application perfectly!

Before we get a bit too ahead of ourselves, let me list you some of the materials we have access to that are more geared towards custom gasket production which we have access to in raw “sheet form”.

Red Rubber (Buna-S), Neoprene, Silicone, Nitrile, Highly Saturated Nitrile, Cork/Nitrile, Fluorocarbon, EPDM, Neo-Nylon, PTFE, expanded PTFE, UHMW-PE, BA-U, BA-50, BA-CF, BACF-4000, Grafilit® SF, Grafilit® SL, Grafilit® SP, Mild Steel, Stainless Steel 304, Stainless Steel 316L, Aluminum and Copper in a variety of thicknesses.

You have an endless variety to choose from and there are other materials as well we can make these custom gaskets from so just send us your spec and we’ll work something out! Today’s focus is on showing you the incredible precision we can offer you by making the exact same gasket design but one inside the other.

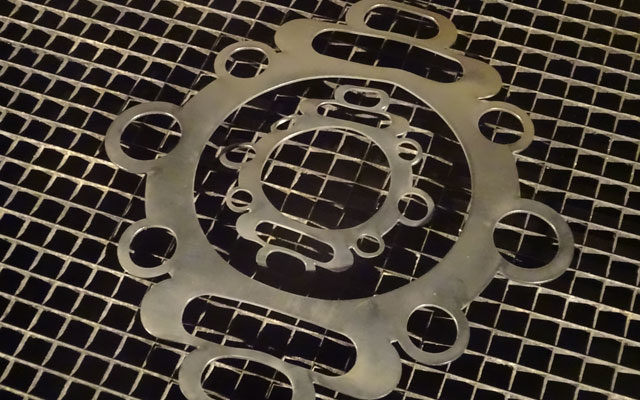

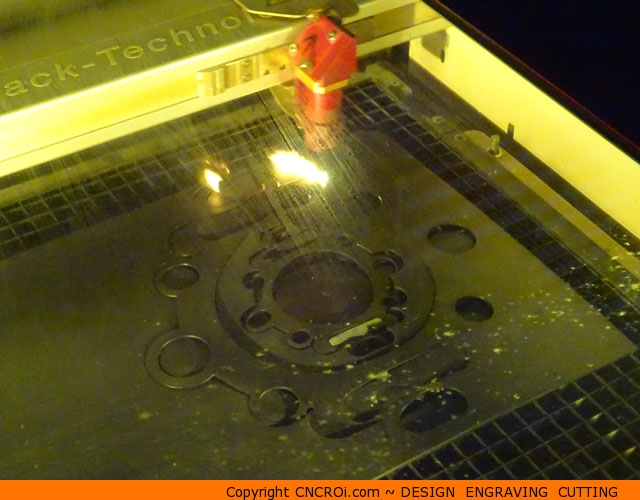

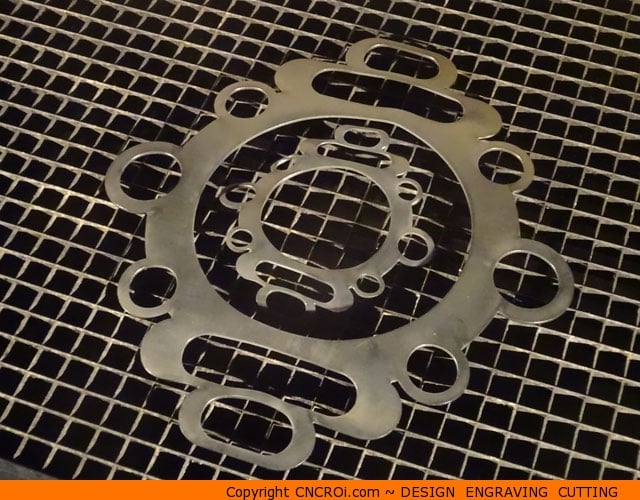

This is a rather flimsy plastic, it’s an off-cut from a job we did a while back so I don’t remember exactly what the customer spec was on this but it produced perfect custom gaskets for our customer, they were in the lighting industry and used these in their sealed housings.

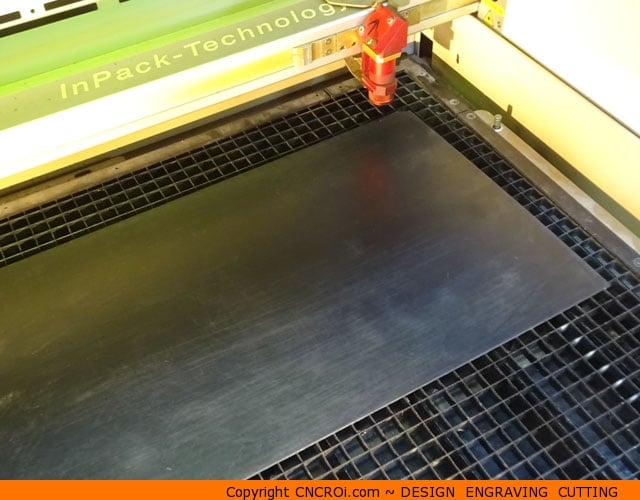

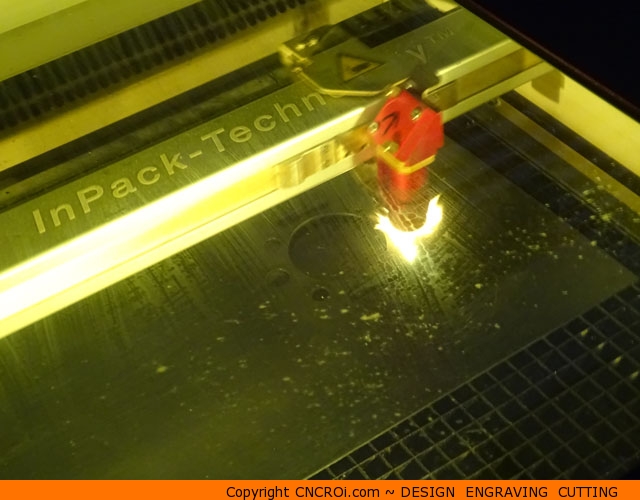

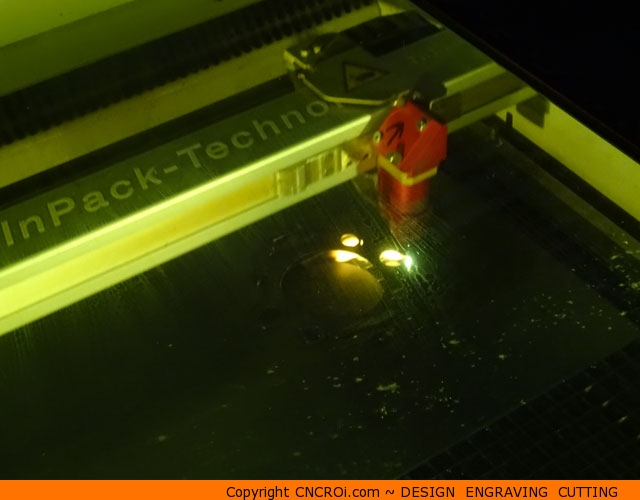

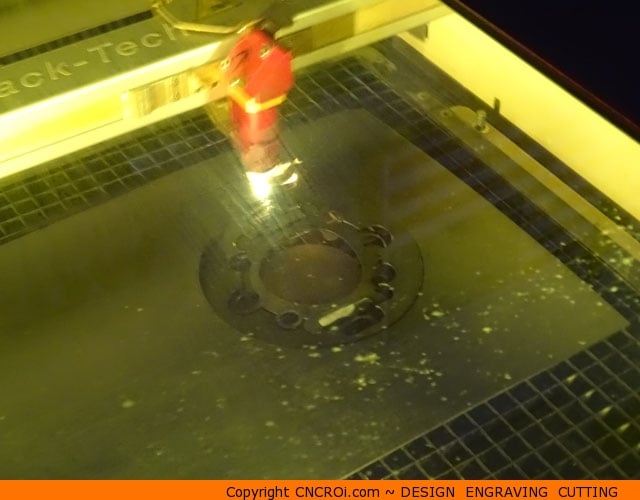

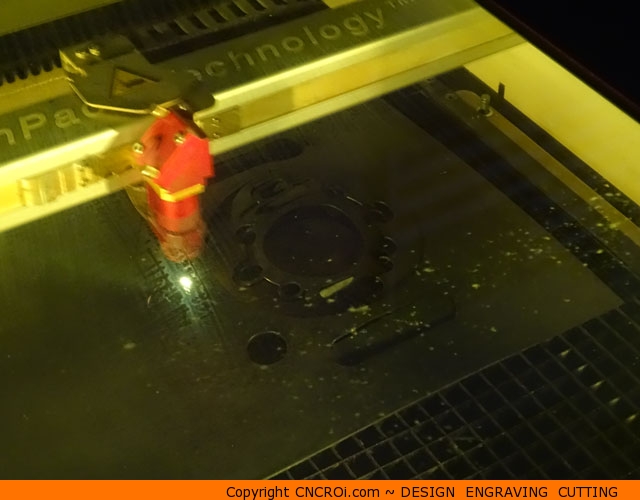

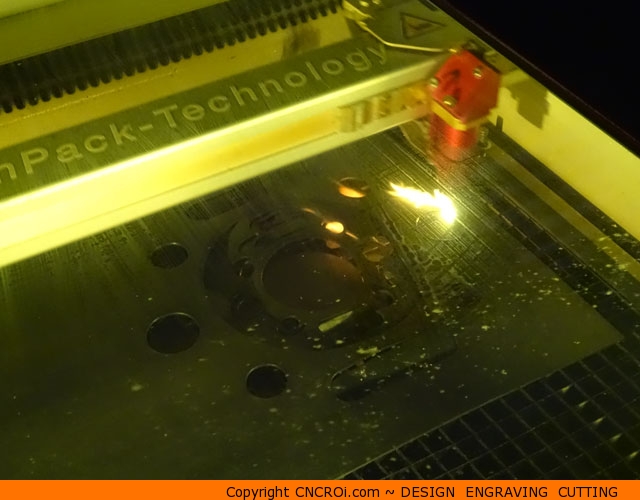

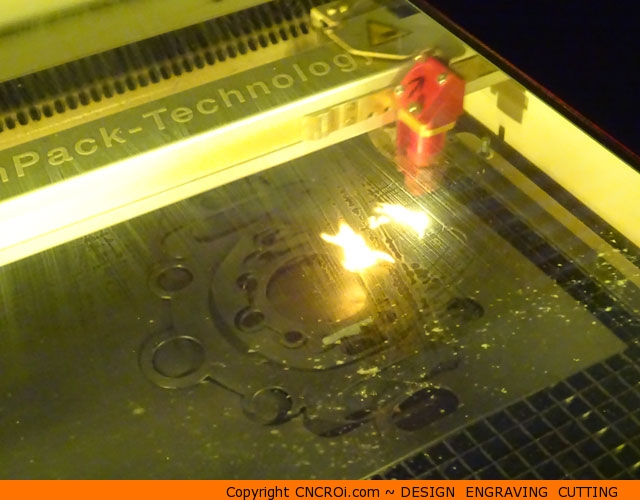

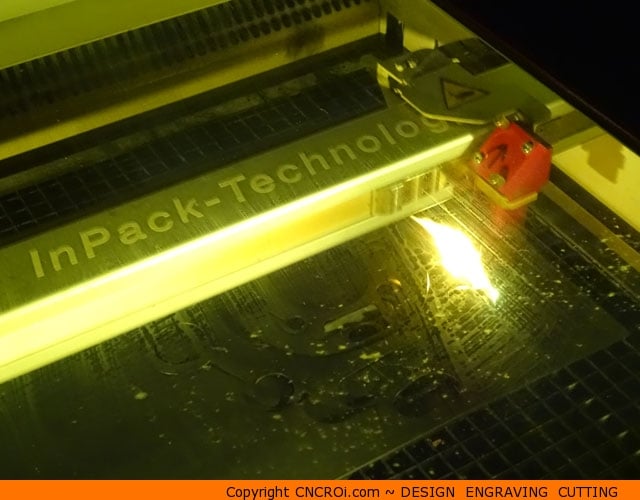

As it’s very hard to film black on black, I upped our industrial Austrian CNC laser settings up a couple of notches to give it extra flaming power, nothing makes black come out better than flames! Of course, for real production, this is kept to an absolute minimum to minimize warping.

The first step was CNC laser cutting out the far smaller custom gasket that sat in the hole of the far larger one. This design was just one randomly created by us to show you the precision of our process, this is not a customer file so we could have made it even more complex or simpler based on YOUR spec.

When we custom produce a gasket, we cut out the inner parts before the outer parts to minimize any movement of the material, this is as true whether it’s 304 stainless steel or UHMW-PE, laser or waterjet (except for stamped of course).

The advantage to our CNC processes when it comes to custom gasket production and manufacturing is that each one is the same as the other (or different, as you wish) so even small volumes with different gasket “shapes” or large batches that need to all be identical isn’t any problem for CNCROi.com!

Different materials produce different gasket results, so it’s important that you not only try to specify the material you want your custom gasket manufactured in but also the thickness and any unique aspects such as serial number engraving or other identification marks you wish on it as well ahead of time.

All this flame does slightly distort this plastic gasket but I decided for demonstration purposes to just go with upping my settings to make the photography and filming a bit more exciting as, let’s face it, gasket production isn’t the most exciting process in the world as our powerful extraction and air compression systems generally make quick work of any fire.

You can now see the finished product, this material is 1/32″ or less than a mm thick, hence being so prone to warping, the settings we generally use for this custom gasket production using this material is about a third of what I used in this blog post.

If you are looking for custom gasket manufacturing, totally to your spec from material to design, contact CNCROi.com right now!