Custom Wood Veneer Cards: Poplar, Wenge, Ash, Zebrawood & Padauk

CNCROi.com uses a wide variety of wood veneer species to do our work, from custom business cards through to custom furniture, today we’ll take a look at Poplar, Wenge, Ash, Zebrawood & Padauk.

You can watch the previous video of this series titles Yellow Heart, Alder, Butternut, Mahogany and Red Cedar: Real Veneer Wood Laser Engraving & Cutting below.

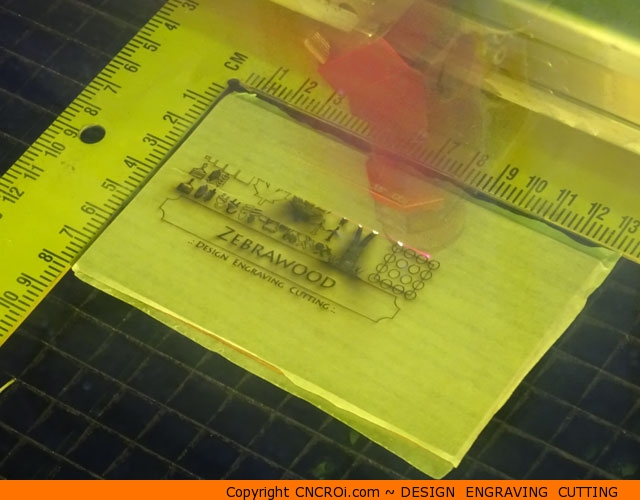

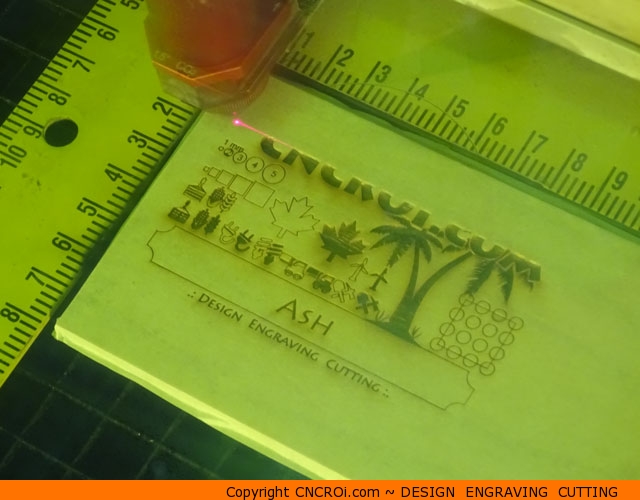

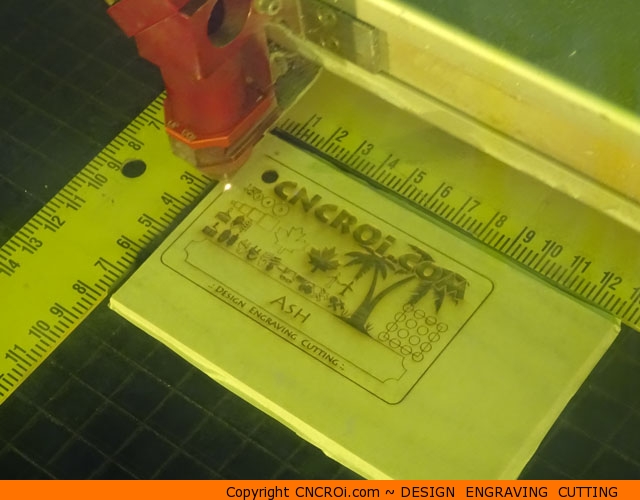

Let’s take a look now at each real wood veneer being laser engraved and cut by our top of the line Austrian wide-format industrial laser.

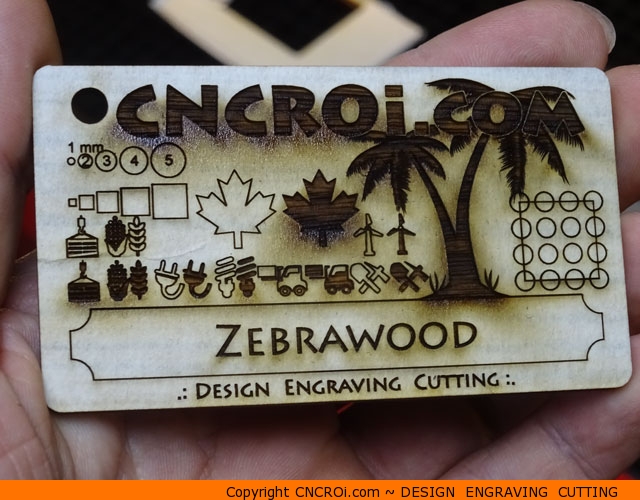

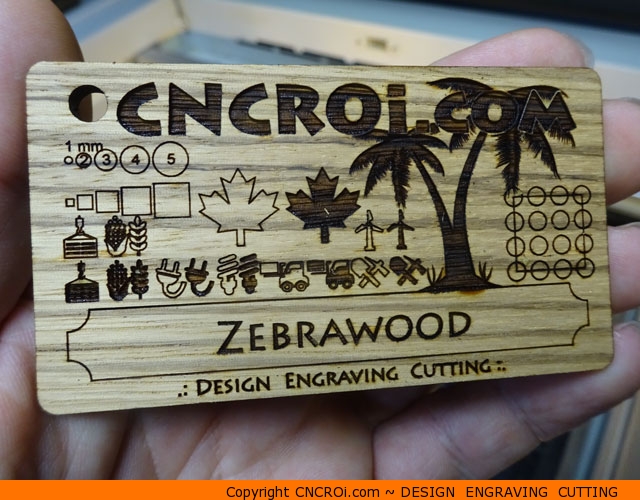

The first real wood veneer we’ll take a look at is zebrawood, it’s a wonderful material to work with as it has just the right density and grain consistency for amazing CNC laser results.

It also doesn’t weight too much and available in sizes ranging 1/16th through to 1″ (roughly 1 mm x 18 mm), as are all the other wood veneers in this blog post.

The really nice thing about zebrawood though are the resins, although they are dark and messy, this is perfect for applications requiring high contrast like custom business cards, unique ID badges, wall plaques and the list goes on.

Zebrawood is also amazing for corporate awards which we can design here in-house at CNCROi.com.

As all our wood veneers are REAL WOOD, it means we can sand them without taking off a contrasting layer like we have issues with when it comes to plywood. Nothing beats REAL WOOD for a host of applications and you can always refresh the surface by sanding it without any issues.

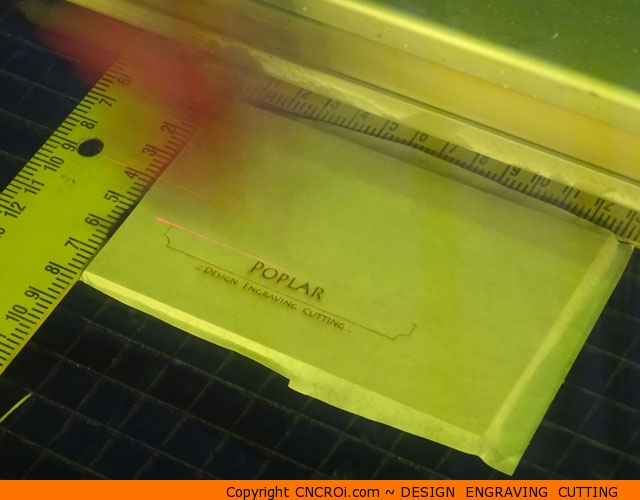

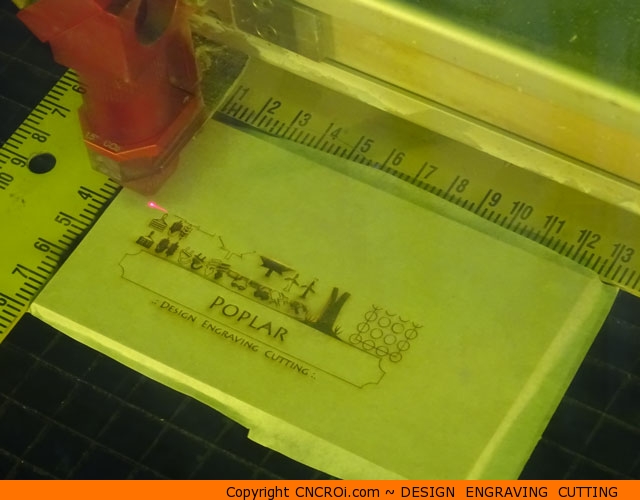

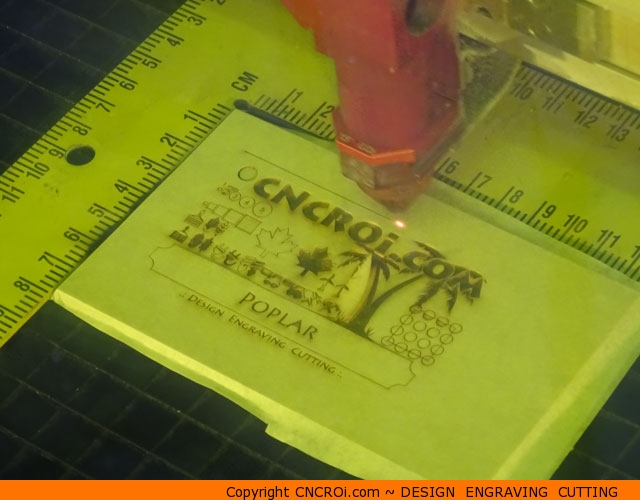

Next-up is poplar, it has its place, it’s messy and not very high contrasting but great for one-off molds and castings.

As mentioned, we specialize in custom applications and sometimes the first look at a material that might not suit once application is perfect for another. The advantage of poplar wood veneer over zebrawood is cost, it’s cheap, just like basswood which we’ll review in a later blog post.

As such, it’s very easy to work with and as it has a low density, not a lot of production time is required to engrave deep into it, unlike say, oak or other hard woods.

As with all our wood veneers, we can achieve up to a thousand DPI density depending, for some applications, 125 DPI is overkill but others, 1K isn’t enough. It depends on what the customer wants, and that’s what we work from.

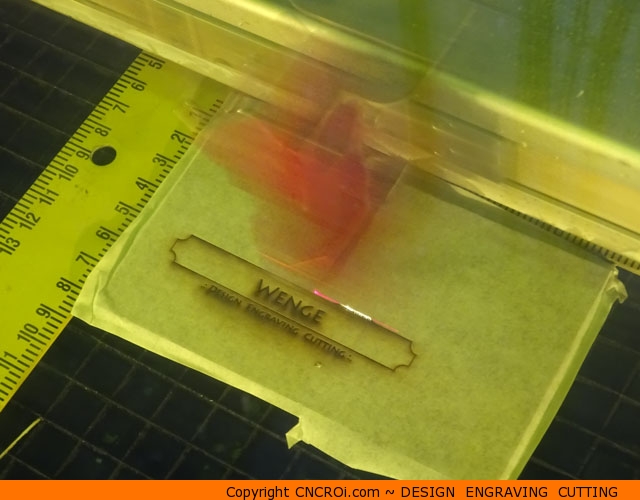

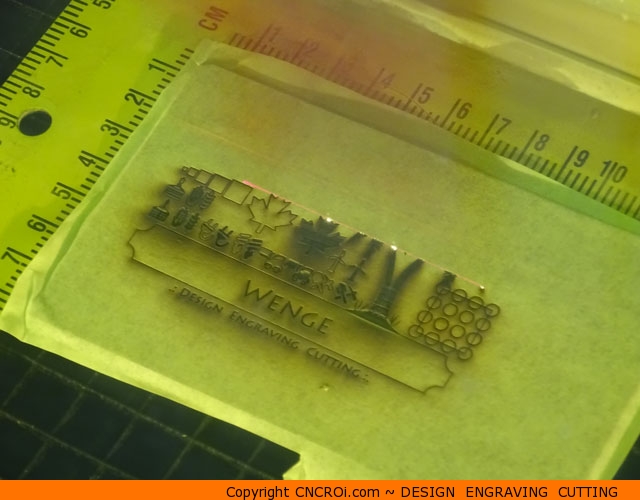

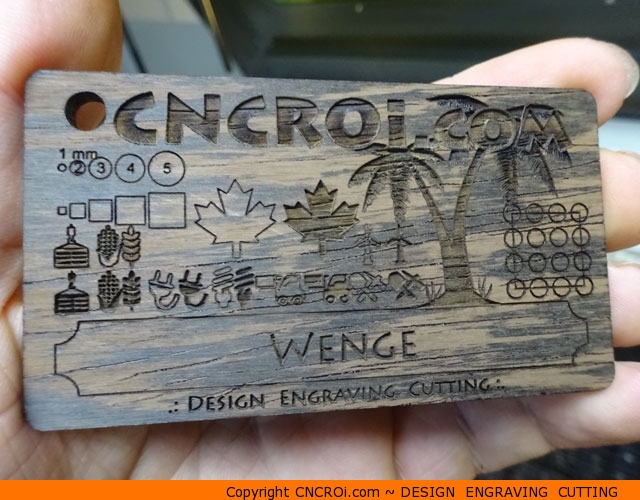

Next-up on the custom laser wood veneer services we provide is wenge. Wenge is an interesting wood as it’s solid and resembles walnut but it’s also just as expensive too!

Wenge is great for contrasting inlays, as is walnut, so mixing this with a lighter colored wood like pine or white oak or even cedar produces dramatic and beautiful results.

Wenge is also a very durable wood, it’s strong and has a very nice distinctive grain pattern to it, if you want something to look aged, wenge is a great choice!

The grain on wenge is also deep, so the surface has some nice tactile characteristics to it, sort of like what oak has after its aged a bit in the environment but without having to wait for this characteristic to develop.

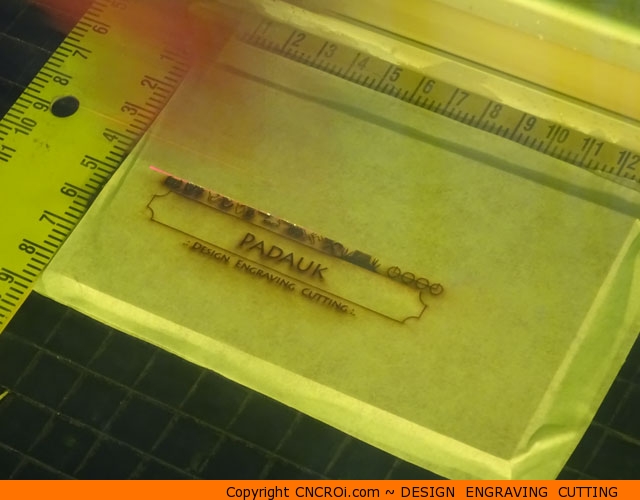

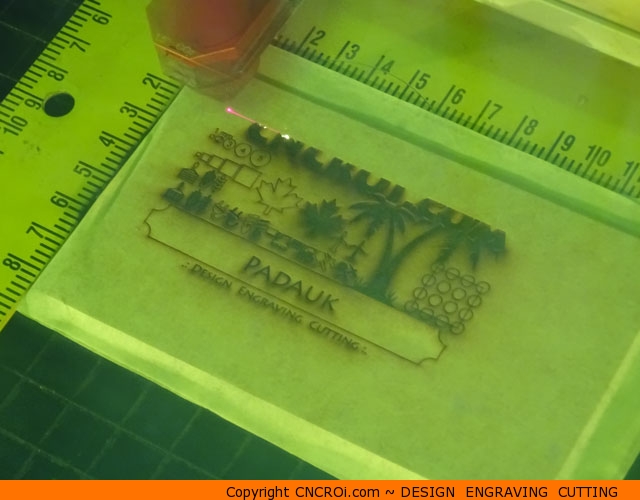

I really like the deep color of padauk, again, for applications where high contrast is required for custom inlays, padauk along with bloodwood is really at the top of my list when it comes to custom wood veneer.

It engraves very nicely and because the engraving itself produces a nice contrast, allows for a lot of applications where additional contrast in inlays is required, think of a portrait using different woods stuck together AND THEN engraved once everything dries.

Padauk is also not a widely known wood when it comes to the general public so giving business cards made out of this material is a great way to achieve additional attention and to break the ice.

As for cost relative to thickness, padauk costs about the same as bloodwood, with the difference being bloodwood is a bit deeper red than the orangy looking padauk real wood veneer.

Next-up is ash, again, another nice wood to work with, it has just the right density for cost with the added advantage of having a very light color. That’s why it’s great for portraits and inlays because the contrast is just about perfect for those applications.

The wood also isn’t as hard as say, white oak, so we get a good depth on it without having to use too much power or slow things down. For industrial lasers, the higher the density of the material, the more power and time is required to achieve the same result vs something that’s less dense, like basswood.

The top surface consistency of ash is also very good for adhesion of masking, unlike wenge and other materials where it’s full of deep markings from the gain.

The engraving color is not as hard as other materials on this list, but it is there and with a little light sanding, produces fantastic results for a wide variety of custom REAL wood veneer applications.

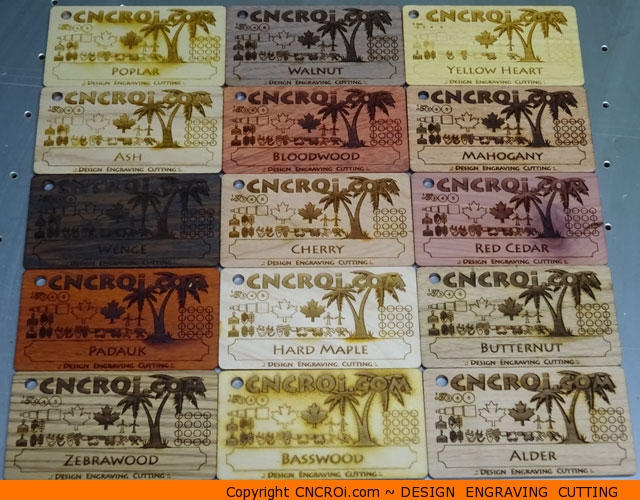

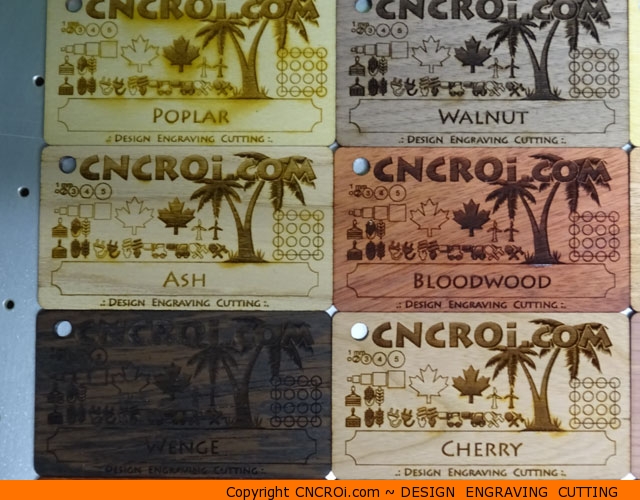

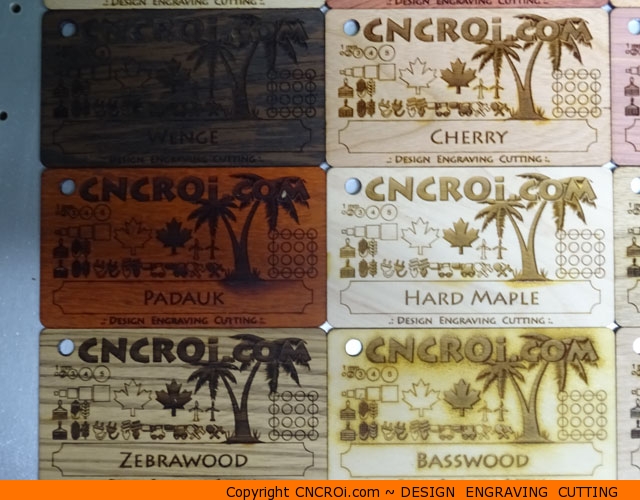

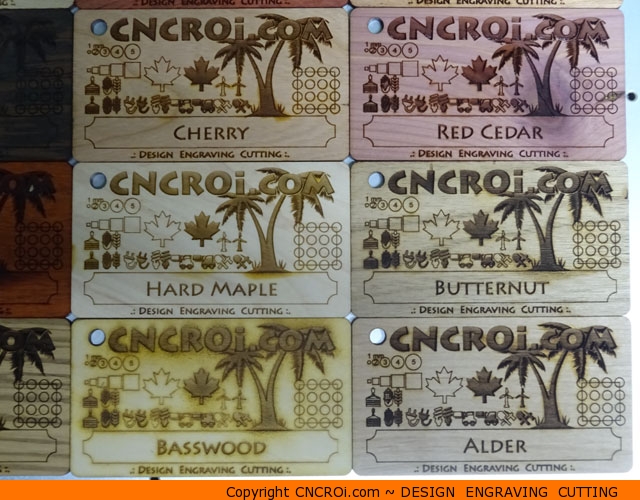

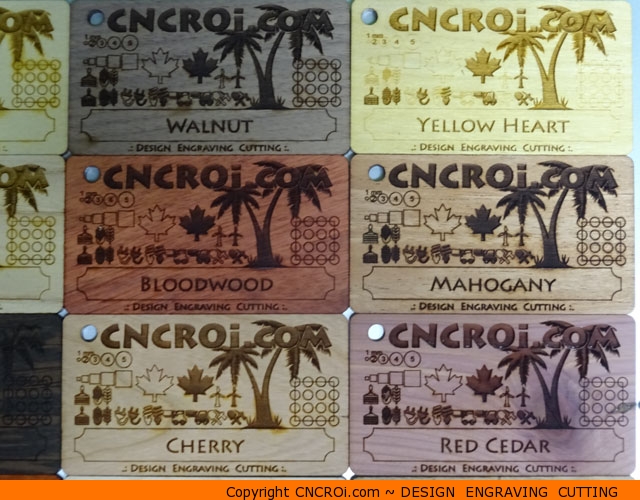

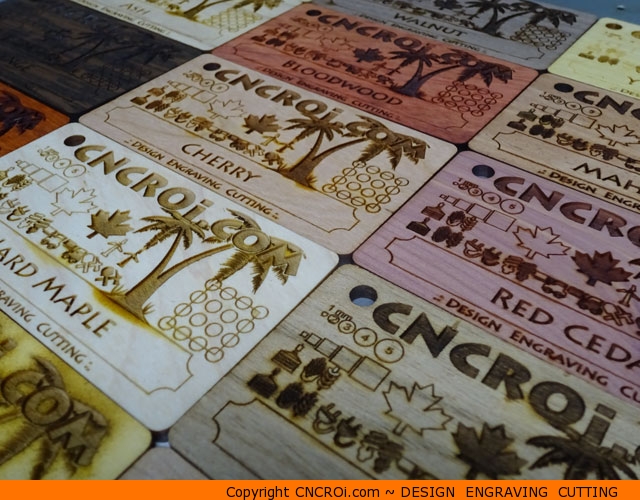

Here are a few pictures to help illustrate the differences in color vs engraving.

You can see how the wenge is deeper brown than walnut but also immediately see how basswood, which is by far the less dense wood in this whole list, is similar to poplar regarding the look of resins vs material. The more smoke damage you see, the less dense the material or trouble masking has regarding surface adhesion. That’s why I didn’t sand these, to show you this.

Red cedar also smells great, the best of the bunch by far, followed by pine and cherry wood veneer.

Cherry is also a very nice wood to work with, it’s very strong, similar to oak and produces a very consistent engraving, a bit deeper in color to hard maple.

Butternut and alder are very similar in results and can be easily interchanged without anybody really noticing, it’s just the grain pattern that’s a bit deeper in the butternut.

These real wood veneers were all engraved and cut using exactly the same settings, as such, when you look at them at an angle, you can clearly see right away which wood is denser than the other.

A light sanding on all of these would immediately remove the surface smoke stains by the way.

Are you looking for something made out of REAL wood?

CNCROi.com has a broad range of species, thicknesses, sizes and the expertise to work with all of them regardless of application.

Contact CNCROi.com right now for all your custom wood veneer applications!