Custom Lexan Polycarbonate Machine Tags

CNCROi.com had a customer ask us for something rather unique, custom polycarbonate machine tags that needed to be permanently fiber marked. This is how we went about making them! Watch this video to give you a bit of background then we’ll jump into production!

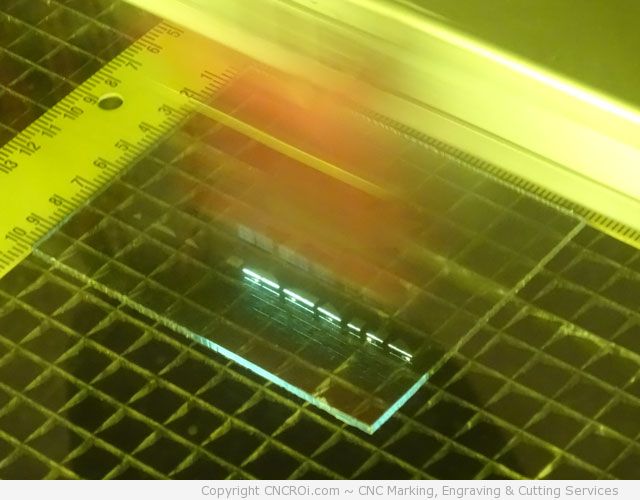

The problem with cutting polycarbonate (lexan) with a CNC laser is the burned yellow edges it produces, it isn’t pretty, we can of course clean up the polycarbonate machine tags.

Taking a zoomed-in look on the edge, you’ll see the problem… it isn’t something that looks nice on a machine, the left is laser work, the right is router work. The quality on the cut edge of the router is far superior!

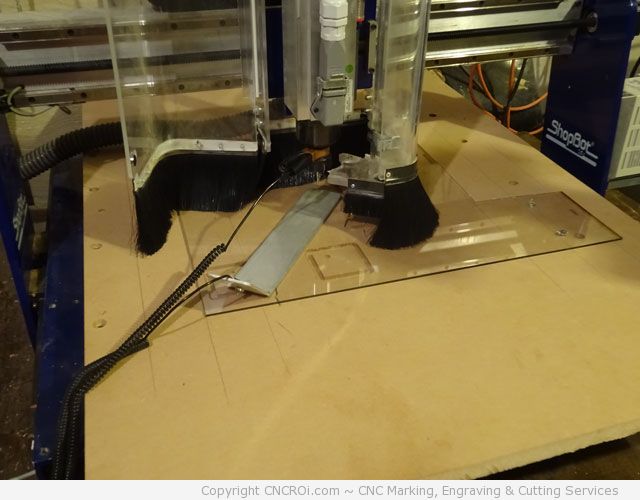

The first step towards making these custom polycarbonate machine tags was to use our ShopBot Desktop to cut out the blanks, in this case, they were to be rectangles but in reality, we can cut them out to be any shape or size required.

After zeroing the machine using our aluminum plate with a ground (quite a different method than our CNC laser), it was time to make the drill holes into the polycarbonate to make sure it didn’t move. I placed temporary ones into the lexan for the initial drilling but they wouldn’t be strong enough for the cutting.

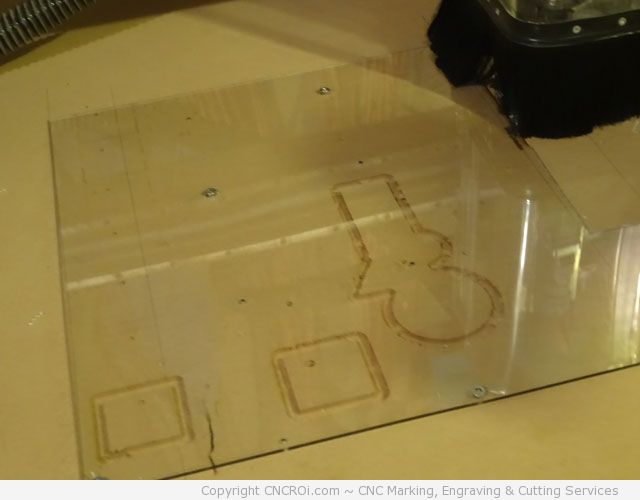

After inserting a few well placed screws, it was time to cut them out using our polycarbonate bit. We have a good diversity of bits in the shop as we never know when clients will throw something cool at us that needs cutting with timelines that prevent us from ordering stuff in as the lead times are too short. There are many options when it comes to custom polycarbonate machine tags.

Where our CNC laser produces polycarbonate vapor, our CNC router produces polycarbonate chips when it comes to making polycarbonate machine tags! After all these custom machine tags were cut out, each identical to the other – which is why we used our CNC router to cut them out instead of a jigsaw or bandsaw – it was time to stick them in the laser.

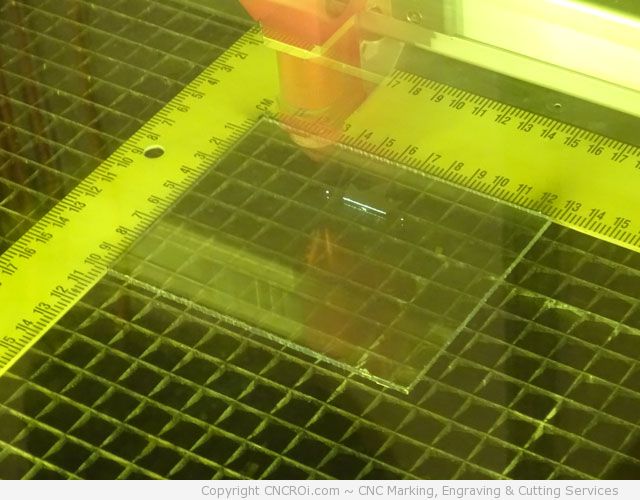

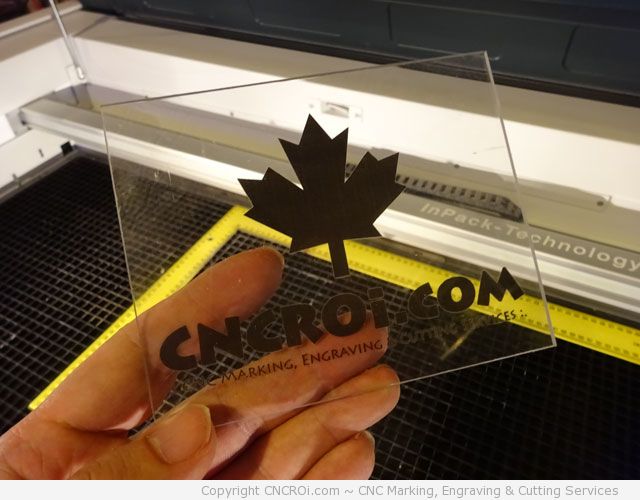

For this process, we used our Austrian wide format industrial CNC laser. As our machine has two tubes, a CO2 and Fiber, it allows us to color change polycarbonate without burning it which is pretty neat. Using a CO2 tube produces less than stellar results without anywhere near the contrast we acquire using our fiber tube.

You can see the edge quality is a bright green/blue when the laser light reflects through it. If we had cut these using our CO2 laser, you would only see a thick black charcoal looking edge, not this clean edge.

As the polycarbonate machine tags were color changed, there were no fumes produced or vapor, it’s a very “clean” process that will last forever. The nice thing is, due to this massive investment CNCROi.com made into this machine (including others, more to come), you get the benefit of things that would otherwise be impossible to achieve.

The nice thing about using this combination of CNC machines is that we are able to produce custom polycarbonate tags of any size or shape in-house AND fiber mark just about anything onto them afterwards. All professional, all identical, all meeting spec.

Take a look at it from a few different angles and you’ll see the clarity of the one in the image above is far superior (edge quality wise) than the one on the bottom. Note that the bottom image wasn’t reverse engraved, so you end-up with a tacky tape like texture. For polycarbonate machine tags, it would have made cleaning more difficult so that’s why it was reverse engraved.

If you are looking for a professional company to handle your custom laser cutting, marking, engraving and etching… as well as design, you’ve found CNCROi.com!