Custom Machine Tag Solutions

There are a lot of options when it comes to custom machine tag solutions but today we’ll focus exclusively on the metal ones, specifically stainless steel and anodized aluminium.

Why not laminates?

Laminates are a great material, they are relatively cheap, available in a wide variety of colors and thicknesses but they do have issues in an industrial space. As they are plastic, they tend to dry out over time (cracking), they dissolve and break apart if washed with detergents and chemicals (think food safety) and are at best, a temporary solution.

We do a lot of laminate work, but for machines, once our customers see our capabilities with custom metal production, 9 times out of 10, they switch. Stainless steel and anodized aluminium, although costing more, will outlast the machine they are stuck on and you need to put them in your will to pass them onto future generations.

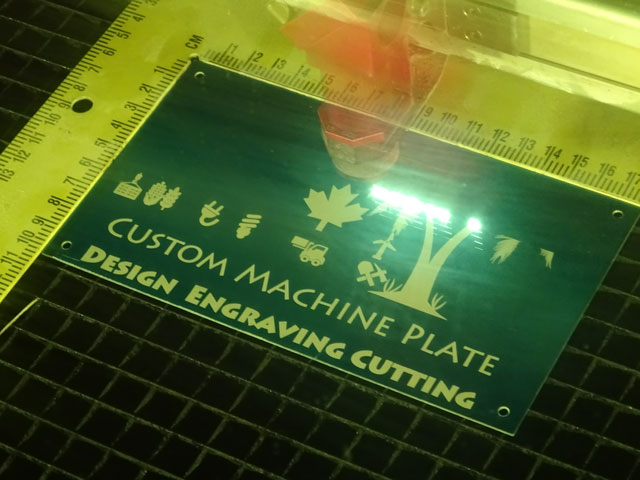

Custom Anodized Aluminium Machine Tag Solutions

Although stainless steel is available in a wide assortment of surface finishes, they all end-up looking like stainless steel regardless, the finish (brushed to mirror) just affect the reflectivity of the surface.

With anodized aluminium, you have access to a rainbow of colors, from green and blue to black and yellow and literally any color in-between.

As you can see from the above video, the color of the laser work is always an off-white which is essentially what’s left after vaporizing the anodization off the custom tags and other things we fabricate using this material.

To give you an idea of the diversity of what can be made using just anodized aluminium, here’s a video of custom luggage tags I made a little while back, we’ve since expanded this area quite dramatically but I just haven’t had the time to update the video.

And regarding the resolution we can achieve on custom anodized aluminium tags and plates, we generally engrave at 600 dpi which means even the finest details and text come out great, sharp and clear!

And that’s why one customer’s custom anodized aluminium machine tags are another’s custom anodized aluminium business cards!

Anodized aluminium is a WONDERFUL material, it’s more cost-effective than stainless steel and dramatically more durable than the laminate option. There are a few caveats though, if you want to go FULL CUSTOM, then there will be certain volume requirements if you want to go beyond what we keep in stock at CNCROi.com.

Custom Stainless Steel Machine Tag Solutions

Now that you are an expert in anodized aluminium options that we can offer you after watching all those awesome videos made in our shop, let’s switch gears to stainless steel. It goes without saying that stainless steel itself is a premium material and annealing it is an incredibly slow (costly) industrial process done with a fiber laser tube.

CNCROi.com DOES NOT use ceramic bonding onto stainless steel, it isn’t permanent and will fade, crack and peel over time, we do things the right way the first time, FIBER LASER TUBE!

We generally stick with 304 stainless steel when it comes to fiber annealing stainless steel, unless your application warrants it (like a marine environment, where 316SS is best), it’s totally fine for most applications. It’s easy to work with and produces fantastic annealing results.

We’ve also worked with other metals, brass to copper and generally, once our customers have enjoyed their custom stainless steel tags, they never go back to other options.

A common question I get is can you weld these 304SS tags onto equipment and other metal plates? The answer is absolutely YES!

Annealing is an oxidation process, we are not adding or removing anything from the metal, just super heating it and then cooling it down using oxygen. As such, you can not only weld these custom stainless steel plates to whatever you want but can also bend them, cut them or anything else without damaging the annealing.

There are an endless variety of applications where stainless steel is by far the best material to use, especially in the food and military categories where permanence and legibility are critical and harsh environments are ever-present.

Something to keep in mind though with stainless steel is that it is a heating process, so if your logo or applications calls for A LOT OF ANNEALING, we’ve actually bent plate in our shop due to this, you want to go with something thicker.

For instance, that custom 304SS stainless steel coaster above, if you had lots of vertical or horizontal lines across it, 0.02″ would be too thin, you’d need us to fabricate something using 2-3x thicker plate.

Custom Brass Machine Tag Solutions

Although we don’t do as much custom brass machine tags as we do stainless steel or anodized aluminium, it is something we can also work with you on developing and producing. I guess the biggest reason why we don’t do lots of custom brass work is that it tends to tarnish over time and costs even more than stainless steel. Regardless, the work we do on the brass is annealed and permanent.

Custom Polycarbonate Machine Tag Solutions

Yet another option when it comes to custom machine tag production is polycarbonate, it’s a wonderful material but tends to be used most for custom stencils, including PETG and mylar than it does for custom machine tags.

Oh yeah, we anneal polycarbonate too, it’s just as permanent as stainless steel work we do except it’s transparent, which is neat!

I hope that’s a good summary of what we can do for your business, something to keep in mind is that this all done using our Austrian wide-format industrial laser, it’s a CNC, which means repeatability and accurate are second to none!

Regardless of your custom requirements, contact CNCROi.com and we’ll make something awesome for you and your machines!