Custom Magnetic Puzzle Jig: CNC Routering 5/8″ MDF

Making a custom magnetic puzzle jig allows our customer to make repeatable work using their UV printer onto metal objects with precise positioning.

Most of the jigs CNCROi.com fabricates for customers are made out of MDF, it’s the great default material to begin with then go from as volumes and quantities go up with tougher materials.

The major advantage of MDF is that it’s relatively easy to acquire, machine and work with in a production environment.

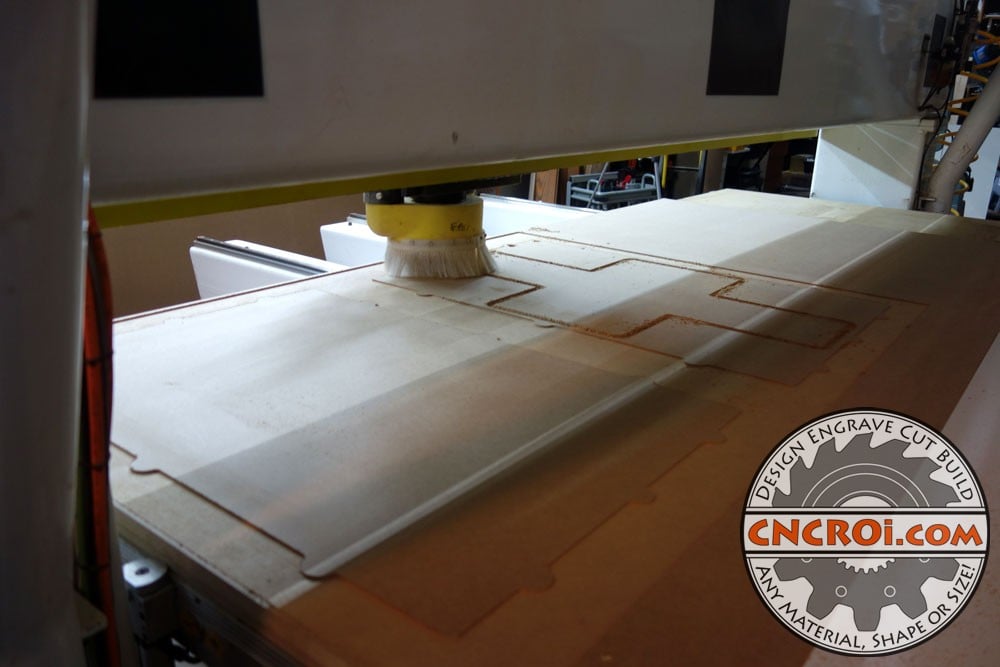

As this is a reverse jig, meaning we are leaving the surface intact for the product that will be UV printed and carving out under the product that will hold the magnets, installed by the customer in specific areas, care must be taken to make sure the proper depth is created and maintained while CNC routering the custom magnetic puzzle jig.

To give you an idea of scale, the size of my CNC router bed is 5 ft x 10 ft, you can see that these two puzzle pieces are MASSIVE and that’s just to hold ONE part!

The top picture shows my tooling options, it’s incredible going from zero tool changers to four and now 19… its something that just can’t be described at just how liberating it is to have that many options and more importantly, precision, when producing custom projects for CNCROi.com customers.

I’ve been making custom jigs for YEARS using a variety of equipment at CNCROi.com.

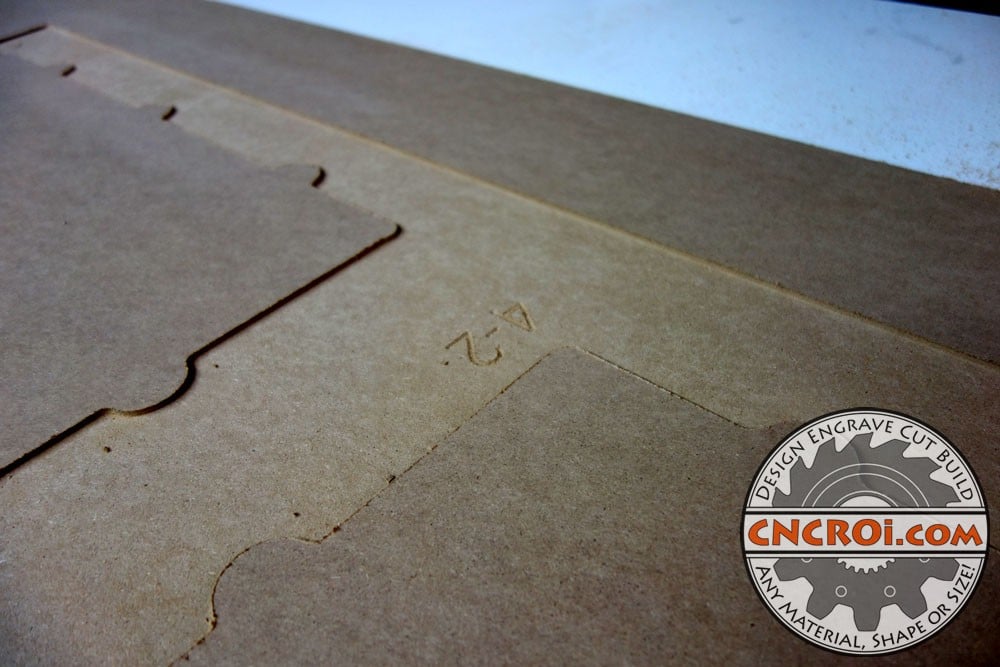

Although CNCROi.com is only making two of these custom magnetic puzzle jigs, labeling which is which is still important in a production setting.

On my old CNC router, I installed LED lights along the gantry to allow for better lighting when routing, you don’t really need it much for this type of work but when it comes to making custom molds, it can come in handy to get an idea of the stepper spacing and overall integrity across a 3D surface.

This may look like a random set of tools used one after the other at CNCROi.com to produce this custom magnetic puzzle jig but there is actually some thought behind the processes used, basically, each tool is progressively creating more details into the jig while at the same time, adding as little stress to the overall MDF jig during production as stress = warping.

There is no perfect material for making jigs, each material has a plus and minus when it comes to using it in a production enviornment… and I’ve literally tried everything at CNCROi.com for both personal the business use.

There is quite a bit of dust created during the routering of this custom magnetic puzzle jig, the vacuum system picks-up most of it while the the rest is cleaned-up manually after production at CNCROi.com.

The reason that this custom magnetic puzzle jig doesn’t lift-up while being pushed and pulled in endless directions and pressures is because we have a very powerful vacuum table that can literally suck your hand through the spoilboard, this ensures efficient production without having to resort to screws and other hold-down methods.

Once these two custom magnetic puzzle jigs are fabricated, you can see how clean the surface is, there is no deviation involved on the Z (height) axis, the depth is consistent throughout because our overhead gantry is thousands of pounds of rigid steel.

The bad thing about acrylic is that it warps from heat, but the advantage of acrylic is that it can be used for a variety of printing project that require a bit of leaway in placement and positioning.

After a quick clean-up, you can see how fantastic these jigs look, a clean surface means very little in production can go wrong because there is no random things on or in the jig that can affect the placement of the product height wise.

You’ll notice these two custom magnetic puzzle jigs were produced separately but at the same time at CNCROi.com, as such, if there is any lack of precision in our CNC router, it will be immediately noticeable because these are puzzle pieces that interlock.

The puzzle fits perfectly, there is still a bit of dust around that’s causing not a perfectly seamless fit but they mate exactly as they should.

Of course, using different colors allows you to immediately see if something is filled or not or something was forgotten to be removed.

What’s amazing is that you can barely make out the machining marks on the MDF, when you have a 9 000 pound machine with incredibly tight SK tool holding and a massive industrial spindle, the vibration is so minimized that things are absolutely perfect!

In the pockets you see in the photo, magnets will be placed by the customer in order to hold the items they need to UV print upon.

Need custom magnetic puzzle jigs? Contact CNCROi.com right now!