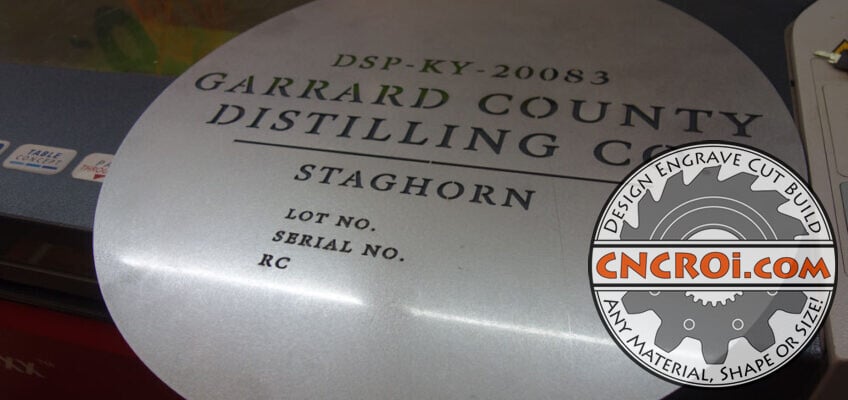

Custom Metal Barrel Head Stencil

We’ve made lots of custom metal barrel head stencils though the years at CNCROi.com, here’s yet another one!

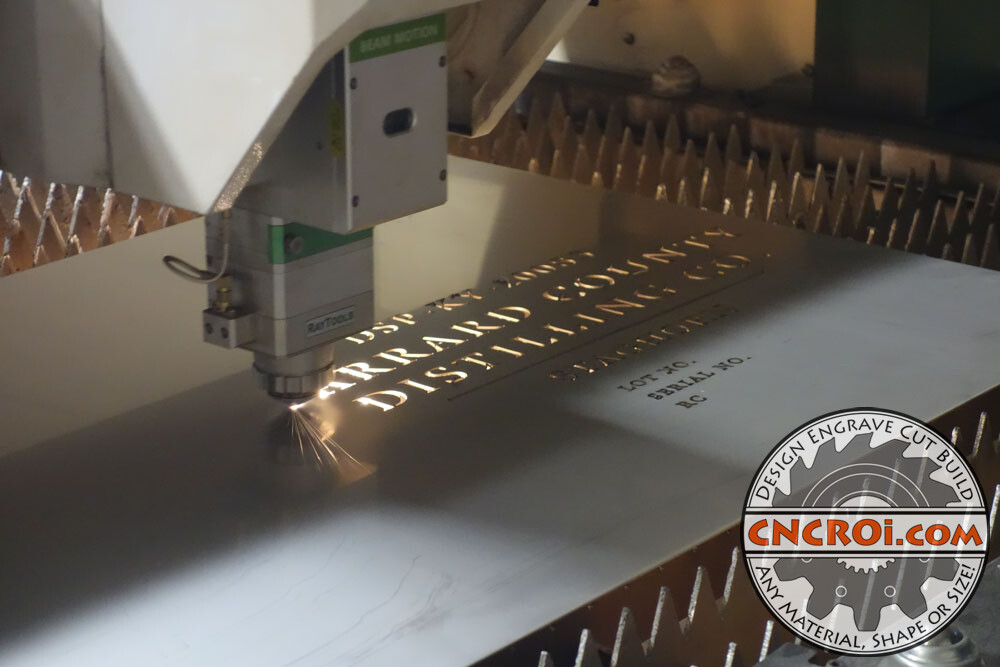

What makes these projects fun is that each one is unique to the client’s requirements, in this case, 16 ga 304 stainless steel 2B was used to make this custom metal barrel head stencil.

The difference between 304SS 2B and 304SS #4 stainless steel is just the finish, #4 has a brushed finish look while 2B is more of a matte grey, this is just the surface finish, both are still 304 grade stainless steel.

The reason this doesn’t matter, 2B or #4 finish in this case for the custom metal barrel head stencil is because once the customer receives this, it will be spray painted, so the surface finish will only be seen for a fraction of the life cycle of this metal stencil.

The reason CNCROi.com used 2B rather than #4 finish for this specific stencil is because I had it laying around, it happened to be the right size for this project, so it won as generally it takes a few days for metal to arrive to the shop for processing.

Another option for custom metal barrel head stencil production would have been mild steel, I tend to avoid this because it isn’t as corrosive resistant as stainless, and yet another option is aluminium, again, for the same reasons, and a lower melting point, if the client ever decided to use a propane torch, I prefer the metal they are doing this onto it to be steel as it has a far higher melting point.

Of course, if you want other branding ideas, we also make custom BBQ grills too, and in that case, generally plasma is the winner because the details are large enough to not require the tight cuts that are made using laser or waterjet.

I tend to over-build things for CNCROi.com clients, even if this custom metal barrel head stencil was made using aluminium, it’s “probably” OK as rarely does the actual temperature of the propane or whatever gas they use to brand their barrel heads will stay on the metal long enough to actually melt it but if I’m going to do something, I might as well do it right.

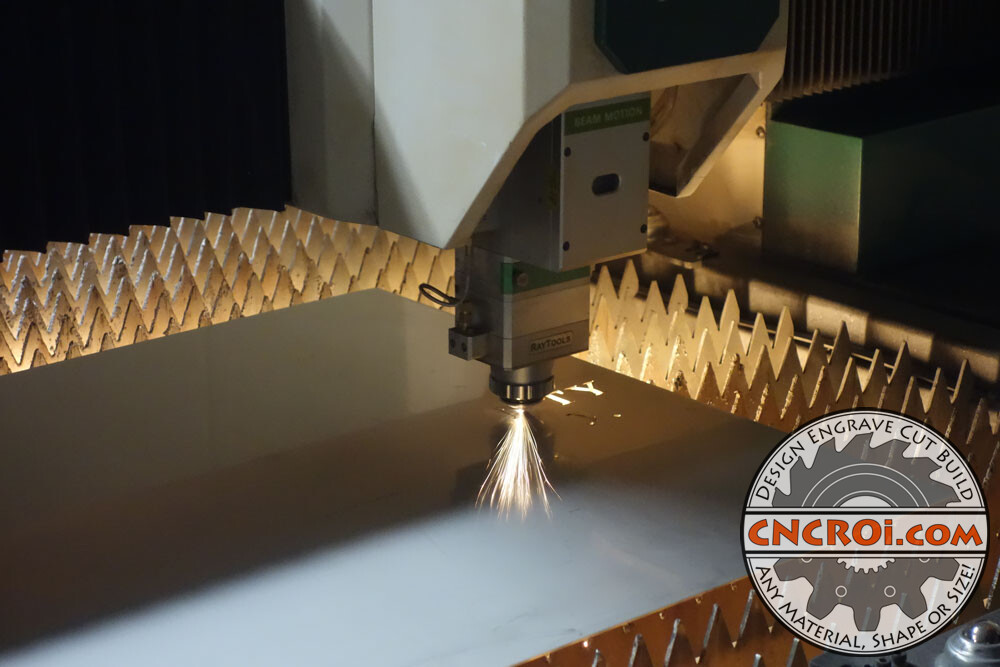

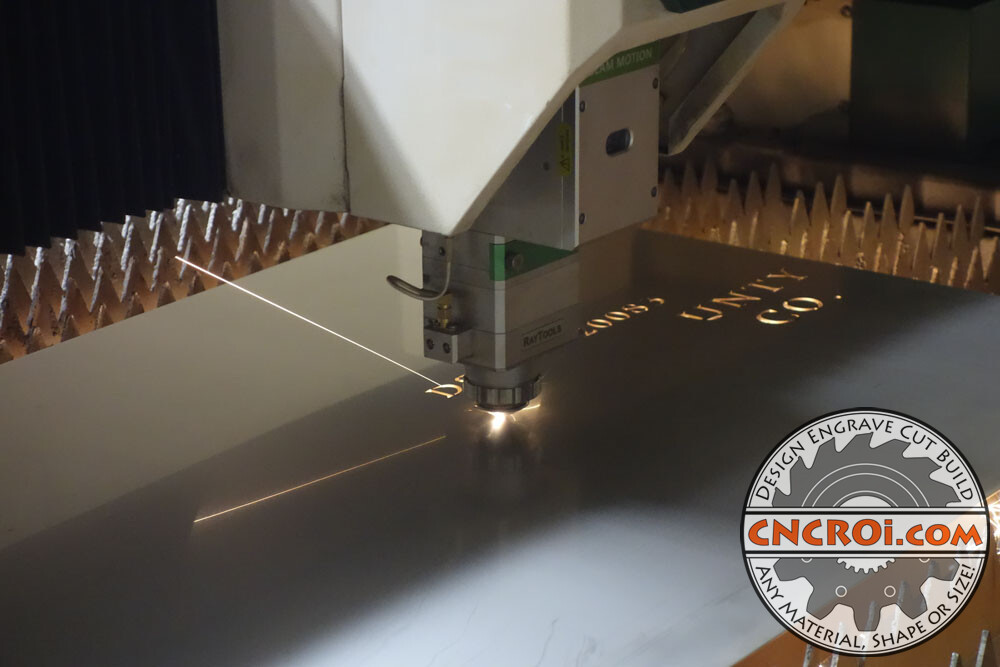

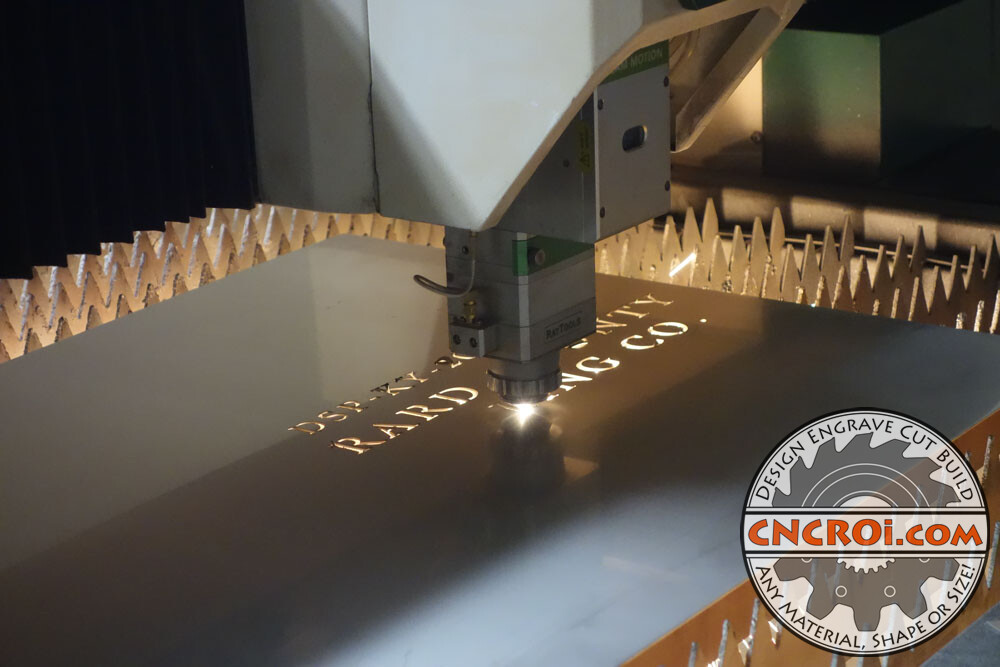

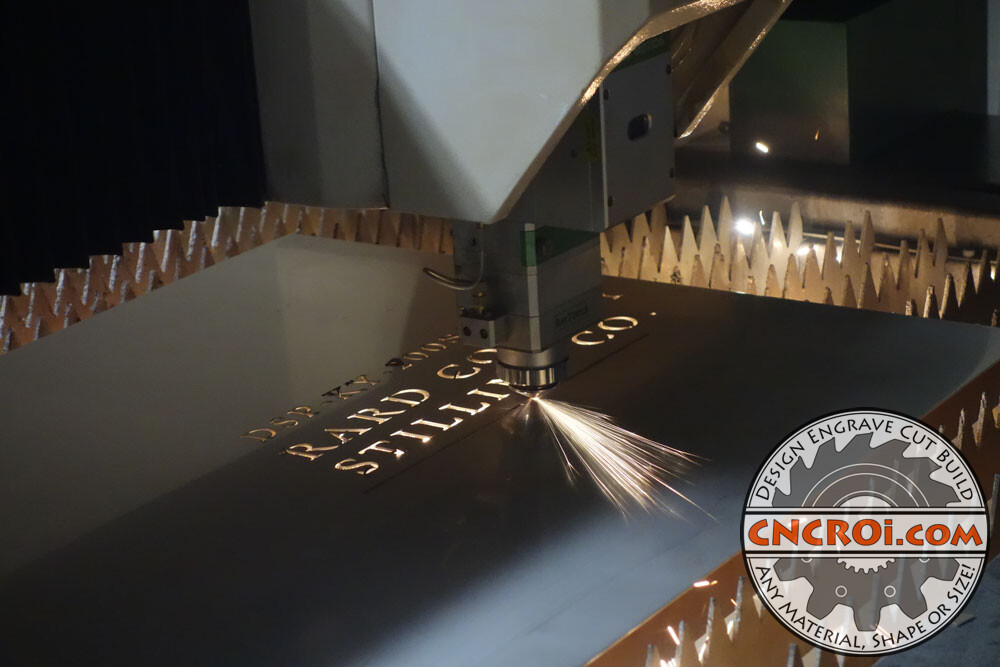

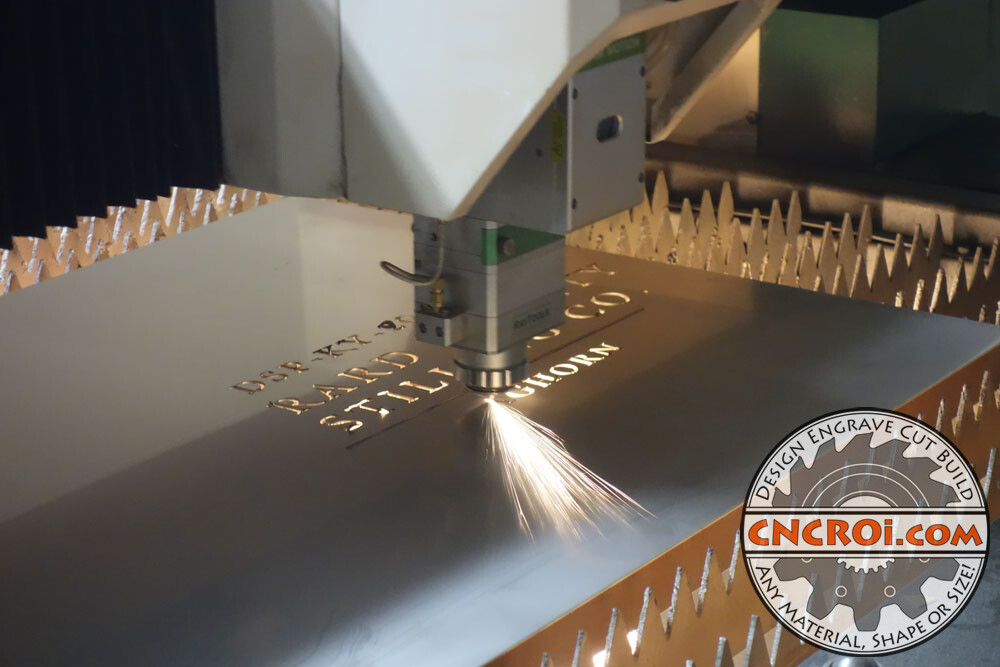

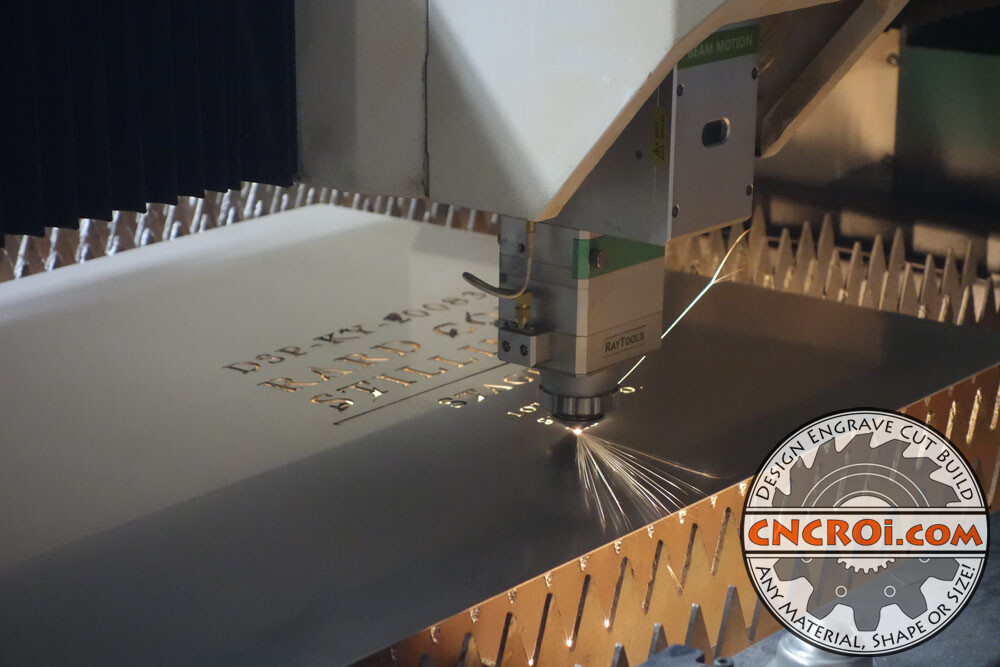

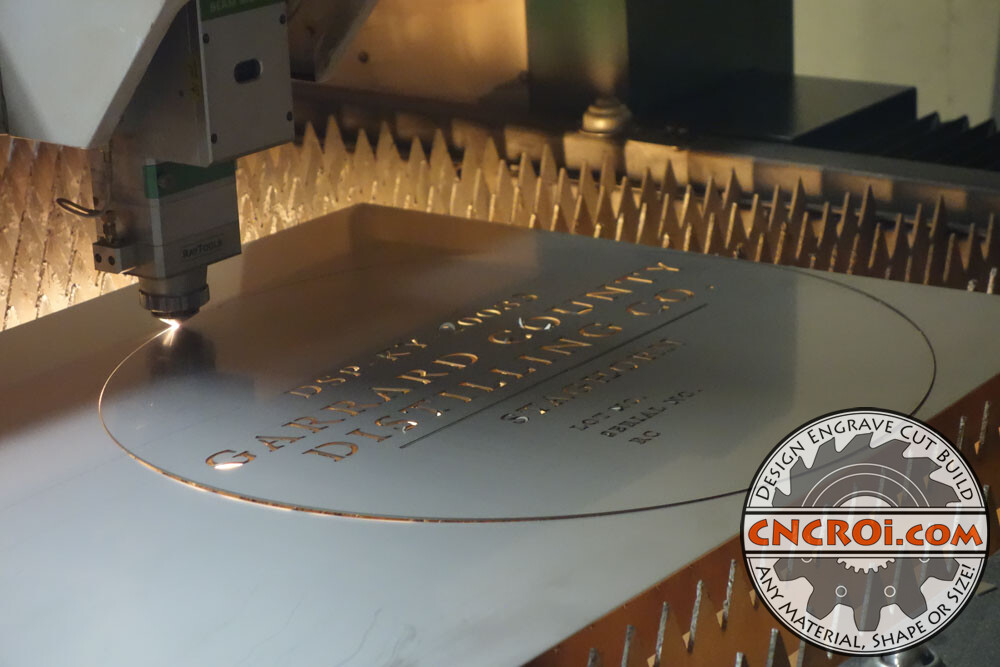

Due to very tight tolerances on the custom metal barrel head stencil, in this case, the fine and small text, the best tool for the project was a fiber laser cutter as waterjet or plasma, have a larger kerf (cutter diameter).

The nice thing about CNCROi.com is that we are machine and process agnostic, meaning, if you wanted this stencil out of quarter inch titanium or 1/8″ polycarbonate, we’d make them as you require within the design specs you assign.

CNCROi.com also has extensive experience making molds and dimensional carvings to augment our stencil making capabilities.

Whether you have a simple or very complex design, CNCROi.com can cut it right for you the first time and ship it right to your door.

The nice thing about having a custom metal barrel head stencil is that it can be used almost infinitely though the years, it’s so beyond anything you can get on the market right now, fire doesn’t wear this out, spray paint won’t wear it out and certainly wood won’t pose any issue to this either.

Laser cutting metal can be done using a number of different methods, at CNCROi.com, we have CNC plasma cutting, CNC waterjet cutting or CNC laser cutting so which ever tool can do the best job, that’s what we will use to do the projects our customers need us to make for them.

When it comes to cutting out stencils, just about any level of detail or amount of cutting is possible, but you have to remember that this is still a stencil, so inner parts need to be supported.

The nice thing about laser cutting metal is the very tight details that can be achieved, you might think this isn’t necessary for a custom metal barrel head stencil, and you would be right, but with CNCROi.com, if you can make something better, we might as well do so to have great happy customres that give us repeat business.

Stencils can be made using a variety of materials as well, in this case, it’s stianless steel, but we could have made this out of aluminium, wood, plastic or any other material you can imagine, this is the flexibility CNCROi.com offers you.

What happens to all the inside parts cut out from the metal that will form the finished custom metal barrel head stencil? It just falls through the table and a certain amount of it also becomes dross and vaporizes away as well.

Most of the stencils we make at CNCROi.com are polycarbonate, if you aren’t using a propane flame on the stencil, it’s a very worthy consideration.

You’ll also notice that there are a lot of sparks that are produced, regardless of if we are plasma cutting stainless steel or plasma cutting, this mostly happens during the initial piercing and the actual “initial” cutting of the metal before it breaks through, at which point, those sparks you see ABOVE the material go underneath, hence you see the glowing under the sheet.

After the inner parts of the custom metal barrel head stencil are then we can cut out the outline, this assures that nothing moves during production, keeping things “full sheet” as long as possible is the most important for high quality outputs.

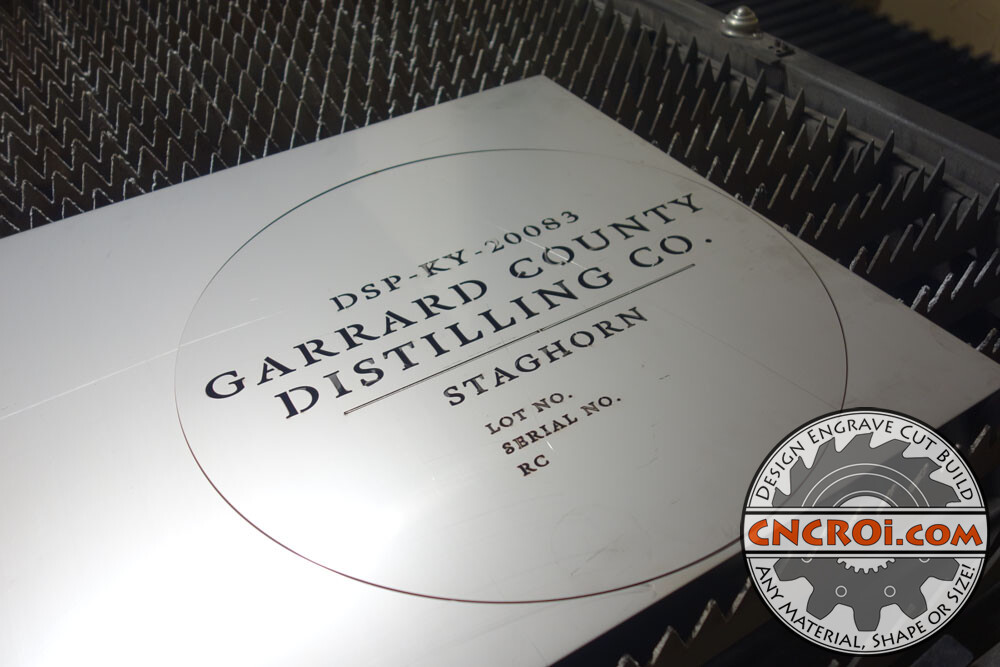

Below is the finished stainless steel custom metal barrel head stencil, the nesting on this was pretty tight but everything fit perfectly and even the highly detailed, due to the small size, wording at the bottom of the stencil.

Waterjet cutting produces a very nice sanded edge and if there is the possibility of heat affected zones on the finished stencil with too many tight details, then it’s a clear winner over plasma or laser.

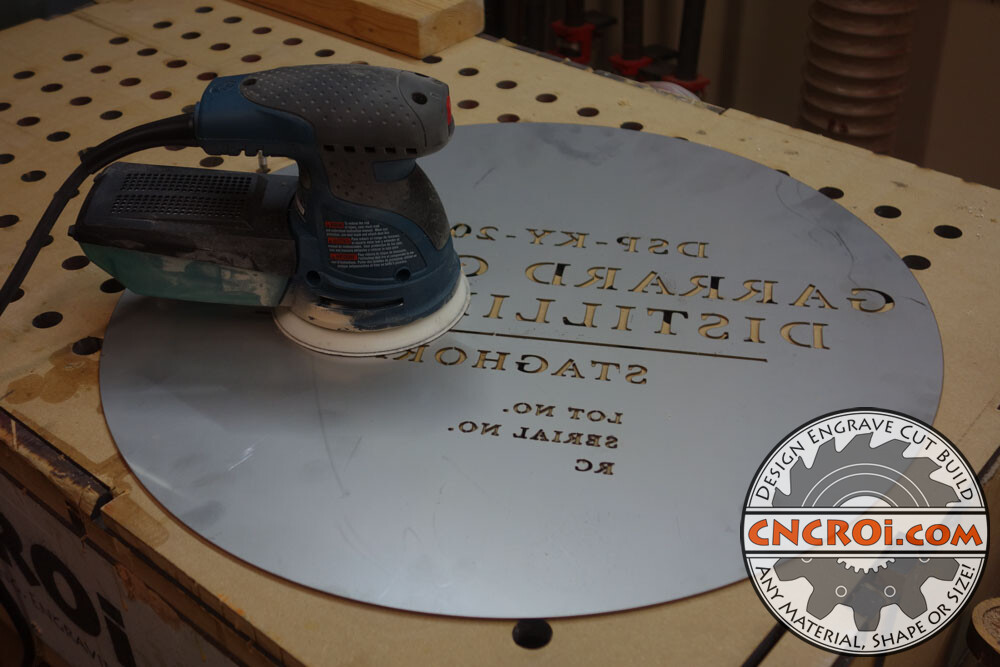

There is dross on the underside though, this is very minimal but still there, so that’s why I use my orbital to break it up and remove it so that the customer doesn’t cut themselves handing this and more importantly, this lays flat on the barrel head.

The orbital gives a nice finish to the overall custom metal barrel head stencil as a bonus, not that it matters, this will be covered with spray paint in very short order.

Need a custom metal barrel head stencil? Contact CNCROi.com right now!