Custom Metal Stencil

Custom metal stencils are fun to make but CNCROi.com can make a custom stencil out of literally any material so let’s take a quick look at the infinite options we offer you.

Making a custom metal stencil can be done using several different machines, CNC waterjet as we’ll explore in this blog post, CNC laser and CNC router with each having an advantage and drawback regarding production costs, turnaround and consumables.

This is a sheet of cold-rolled steel which will be CNC waterjet cut to create our flowery custom metal stencil, the design can be anything at any scale or material so there are lots of options to suit the needs of CNCROi.com‘s customers.

Custom metal stencils as seen in these photos is quite a different process to the second toughest alternative, which we do with our industrial Austrian wide-format CNC laser, polycarbonate.

Where the CNC waterjet requires the custom metal stencil to be sand blasted and cleaned, the polycarbonate version is very much stick it into the machine, take it out and ship from CNCROi.com‘s production HQ.

The mud you see is from the sand that goes into the nozzle along with the 60 000 PSI of water shooting out, the sand provides the grit that allows the water to go through the metal, without the sand, there is no cutting through metal using waterjet.

The custom metal stencil is basically underwater during most of the production, this keeps noise levels down and fumes, as the grit hitting the cold-rolled steel produces lots of friction, which ends-up being fumes of mostly steam.

The bubbles you see coming up are actually from the water being shot down through the custom metal stencil then redirecting to the upper surface of the cold-rolled steel, though with dramatically less PSI spread-out over a larger surface than the initial jet of sand and water used to cut the metal.

Using a CNC waterjet allows CNCROi.com to cut materials in lower volumes that wouldn’t be cost-effective using a laser or design not suitable for CNC routers, when massive production runs are required, there is also stamping, which we use as well.

Which technology or process CNCROi.com uses to produce the work depends on the budget, materials, timeline and design tolerances.

This design for instance cut out of cardboard can be done using just about any machine, but CNC waterjet would be less than optimal because wet cardboard isn’t something that makes sense for custom stencil application onto a material.

The outline of this custom metal stencil is just being cut out now using the CNC waterjet, you can see the sand build-up on the surface and on the sheet of metal, it isn’t from the initial cut, it’s from the sand shooting back up through the finished piece and depositing on the surface.

Of course, if you want one-time stencils to use for a project, CNCROi.com can produce those for you as well on material as thin and disposable as paper.

This custom metal stencil is now finished being cut out from the cold-rolled steel.

Straight out of the CNC waterjet, the metal starts to tarnish and rust pretty quickly on the very top surface, as a result, the next step is to sand blast it using CNCROi.com‘s industrial sand blaster which is so big, I can fit in it!

It is hard to flip things around and manipulate them within the sand blasting environment, as a result, having something put the flat piece of metal really helps, especially when wearing thick rubber gloves.

After the sand blasting, you can see how the rusty and discolored metal becomes a solid grey, which looks great on its own without any additional work.

This custom metal stencil will be used for another project video and blog post down the line to show what can be made using metal, so it wasn’t finished or sealed using a protective layer on purpose after being sand blasted.

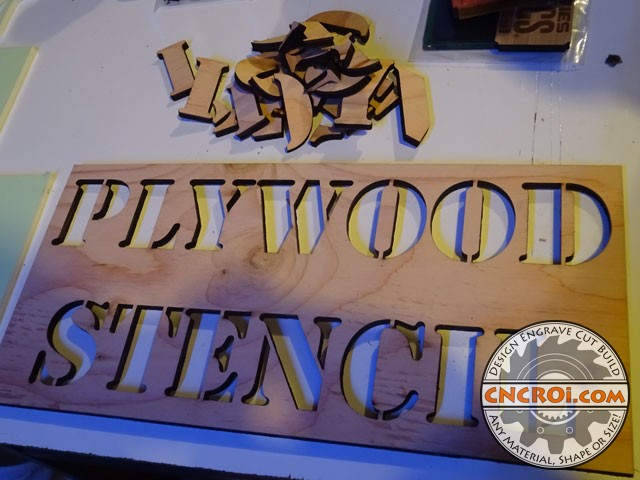

By comparison, you can see the laser cutting plywood stencil below, plywood, like cardboard, isn’t something you want to put in a waterjet as wood and water with sand isn’t a good mix when it comes to using it in the final stencilled application.

The nice thing about our CNC laser stencils, regardless of material, is that the cut line is so thin, that CNCROi.com can make two stencils and perfectly put the output of one into the other.

Even if they are different thicknesses, which is a pretty neat feat to achieve, not possible using CNC waterjet as, like our CNC router, you’d have to make this 4x in order to produce two workable inlays.

If you need a custom stencil, any shape, size or thickness for your needs, contact CNCROi.com right now!