Custom Metal Tag Production Guide

CNCROi.com does a lot of custom stainless steel and anodized aluminium fiber marking and annealing but a question that keeps coming up is how CUSTOM can a custom metal tag be? Let’s go through the options!

CNCROi.com knows inches, mm, pounds, kilograms, tons and so forth… so send us the unit of measurement you are most comfortable with and we’ll make it work!

1 cm = 25⁄64in = .39 inches / 1 in = 2.54 cm

Please note that we can do these tags out of laminate, wood, Corian, leather, acrylic etc… you can send us your spec work in inches or mm and that’s what we’ll use. Most of what you see below is the same regardless of material used.

Custom Metal Tag Size

The first thing we need to know is the size of your tag you wished to have produced. Do you want 1 inch or 2 ft square? Some weird shape or even a variety meaning each one is slightly different. What I tell customers, to save both of us a lot of time, is to run through this list below and generate a complete drawing and send it to us in DXF, PDF or EPS file formats.

Custom Metal Tag Material

Do you want the tag to be made out of 304 (standard), 316 etc. stainless steel? Do you want a specific shade of anodized aluminium like red or to match a specific pantone you need it color matched to?

Custom Metal Tag Thickness

How thick do you need the metal to be? Generally, .05″ or .025″ for anodized aluminium with stainless steel being all over the map. The thinner anodized aluminium is extremely lightweight but if you want to screw it to things, the thicker tag is recommended.

Custom Metal Tag Finish

If this is for marine environments, 316SS is a must but we can get a coating added to other materials to protect them if you must use anodized aluminium or other corrosive prone materials, clear powder coating does add a slight yellowish tint to the finished product though.

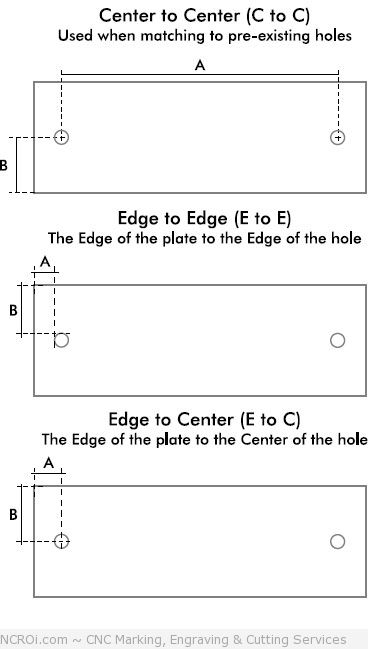

Custom Metal Tag Hole Locations

How many (if any) holes do you want in your custom metal tag and where do you want them to be? If you are welding these tags to your machine, no holes are necessary but if you are riveting them to it, it’s a great feature to have. Here’s a graphic to help you out.

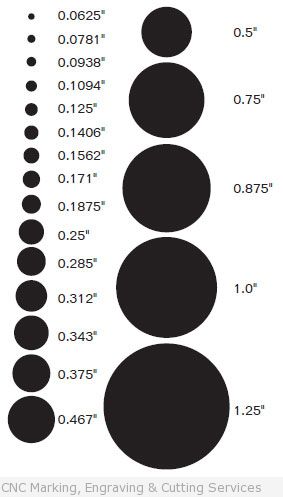

Custom Metal Tag Hole Sizes

Generally, metal tags all have the same hole sizes but if you are getting something custom and needed different hole sizes in different areas, that’s available too! Here’s a general guide that’s to scale to help you out. By the way, these are punched holes, not drilled.

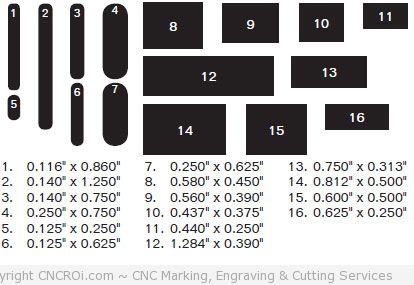

If you need other shapes punched instead or with the above holes, here’s a general guide to help you in that department as well!

Custom Metal Tag Backing

We do offer adhesive and magnetic backings but generally, I tell people to stay away from it especially for industrial applications. You want to screw, rivet or weld these plaques, not use 3M double-sided tape.

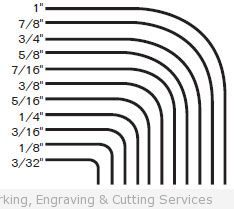

Custom Metal Tag Corners

Based on the application, you may not want 90 degree corners but something a bit curved. We can do that too!

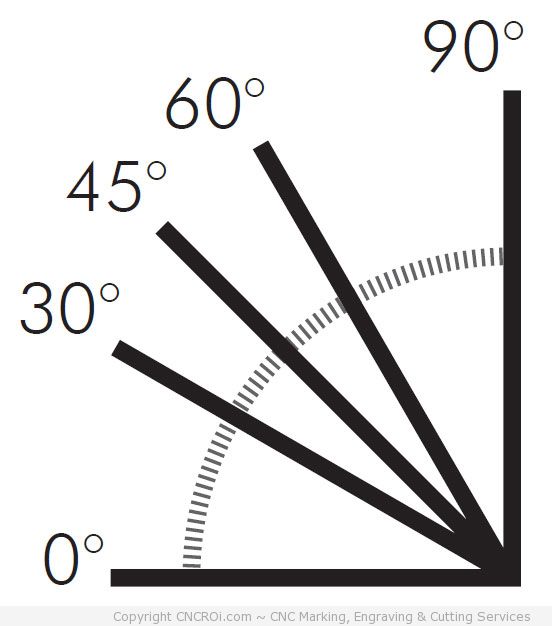

Custom Metal Tag Bending

After your tag is CNC fiber annealed, etched, marked or engraved – material depending – we can then roll into a cylinder (at one extreme) or bend it how every you wish using our pan and box sheet metal equipment!

Custom Metal Tag Quantity and ETA

We need to know how many custom metal tags you will need and when you’d like to get them. If the quantities are pretty big like 20K custom 304 stainless steel CNC fiber laser annealed, we’d make a jig and send them out to you in batches of whatever suits you and your timeline best.

BUDGET AND PRICING

Obviously, the more “custom” you need your tag to be, the higher the price but this can be offset by quantity. Sending us a detailed drawing, preferably in a vector file format but you can sketch something out too is by far the most efficient method for us to generate pricing. We really do need to get an idea of your budget though as there are generally some “stock” custom options that will reduce the price if you are looking at hitting a specific price point.

For instance, if your goal is a custom 4 x 4 square inch plate, we can reduce the price by 2/3rds by going with a 2 x 2 square inch plate… if you originally had specs for 6 holes, bringing that down to 4 will reduce the price and the list goes on. Some designs have a lot of fiber marking required, annealing is expensive so changing to anodized aluminium will reduce it quite dramatically. This is why knowing your price point is very important to us and will save both of us a lot of time.

Ideally, you’d send us a drawing with material information on it with a quantity and pricing range for custom metal tag production. Have a question? Contact us!