Custom Metal Tags: Plasma Cut, Fiber Etched

Custom metal tags can be made to any spec at CNCROi.com using our a variety of capital equipment options based on volume and type.

https://www.youtube.com/watch?v=kpTA718xa5I/

For these specific custom metal tags, we used our CNC plasma cutter to make the tag and then our galvo fiber laser to produce the permanent etching into them.

As these are relatively small 304 stainless steel tags, I grabbed a piece of scrap that I keep for just these types of applications to cut the tags out of, the best use of material is getting as much value out of it before sending it to recycling.

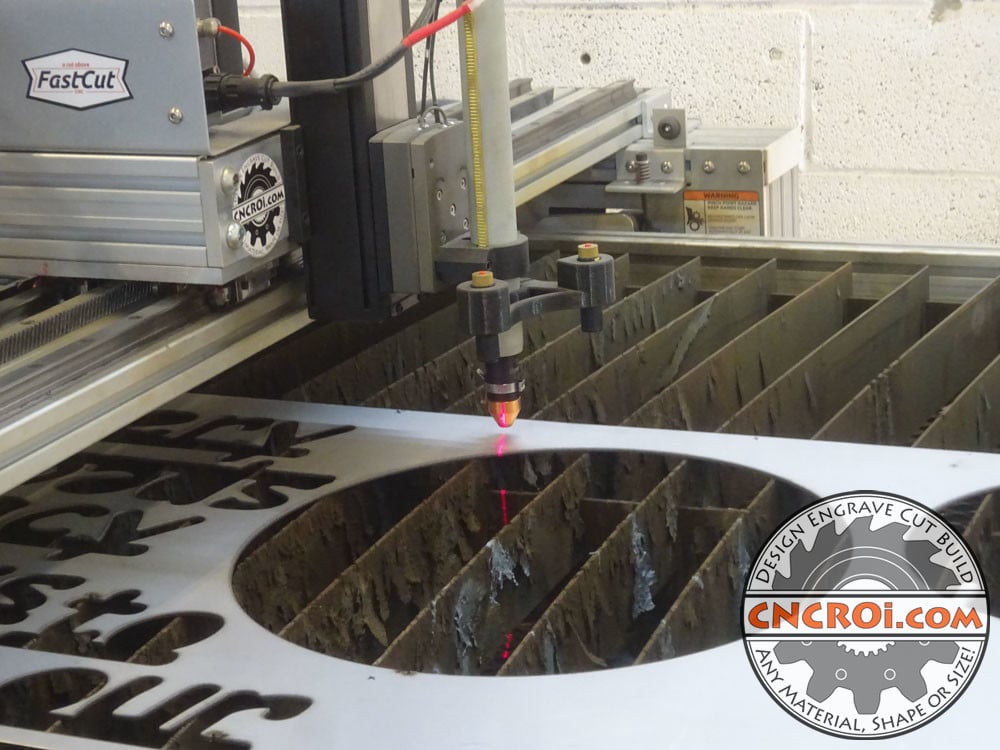

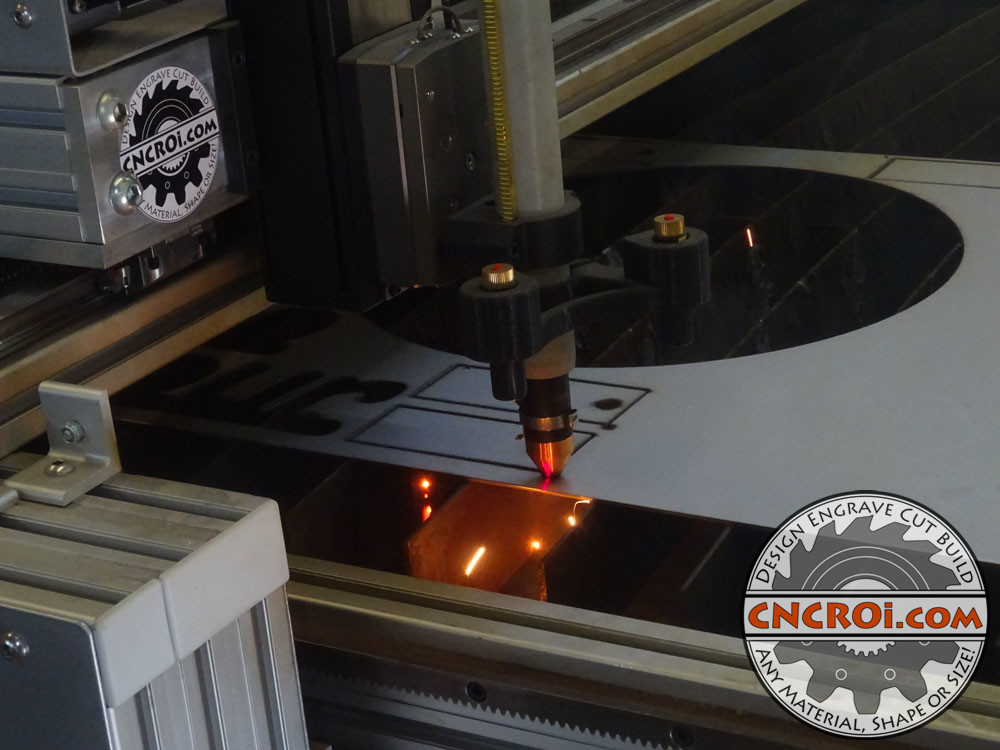

CNCROi.com plasma cut the inside of the holes on these custom metal tags first followed by the outline.

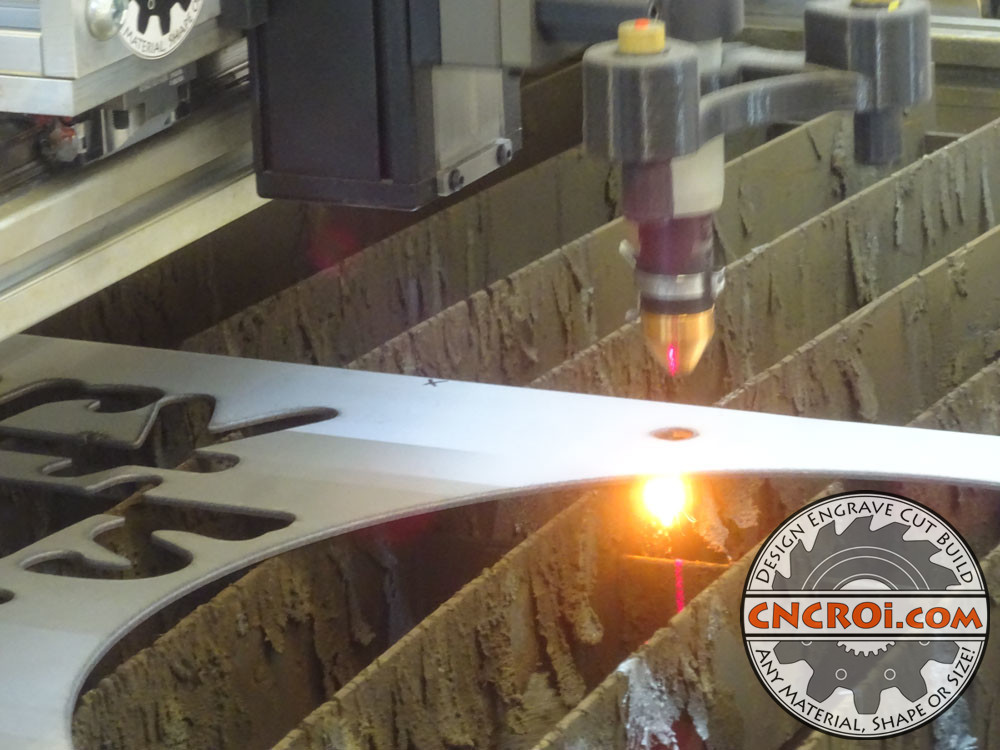

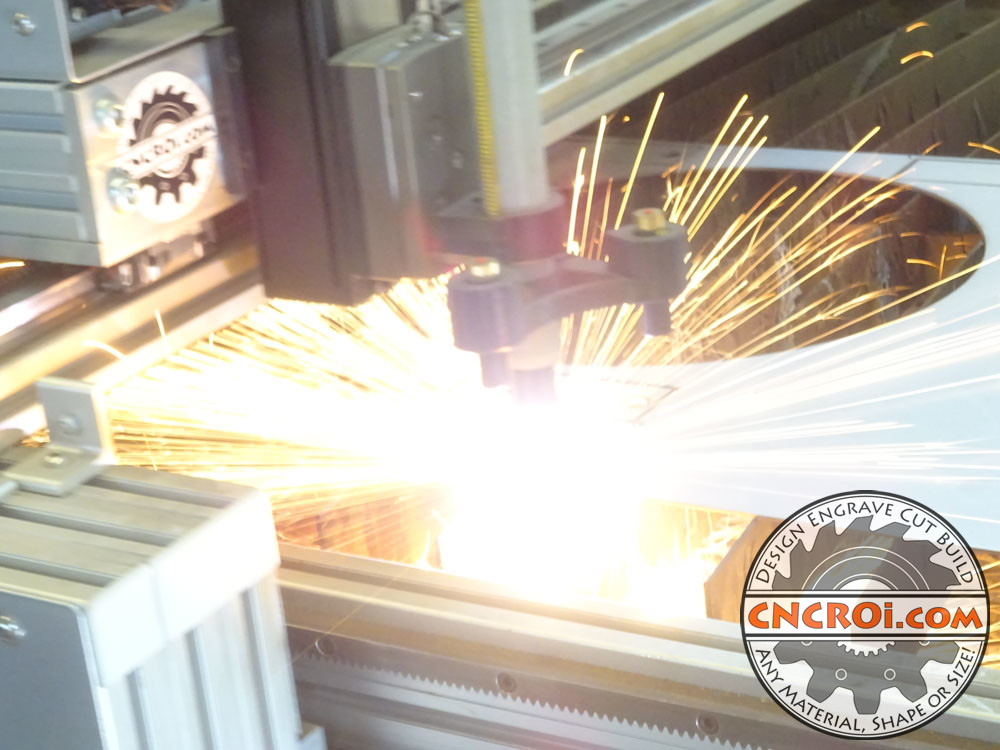

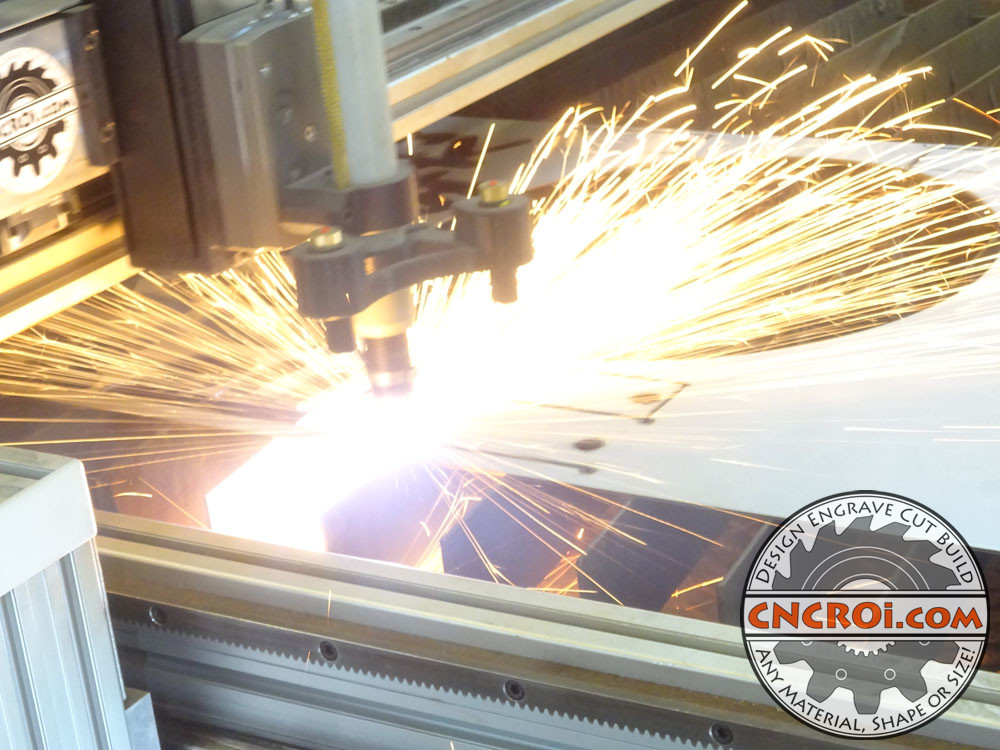

Look at those awesome sparks from the plasma cutting process at CNCROi.com, what I especially like about stainless steel are the fireworks that occur during production of these custom metal tags.

Of course, CNCROi.com isn’t limited to just plasma cutting, we can also cut using our laser and watejet, it all depends on the material and spec required.

https://www.youtube.com/watch?v=nwjTw7nENko/

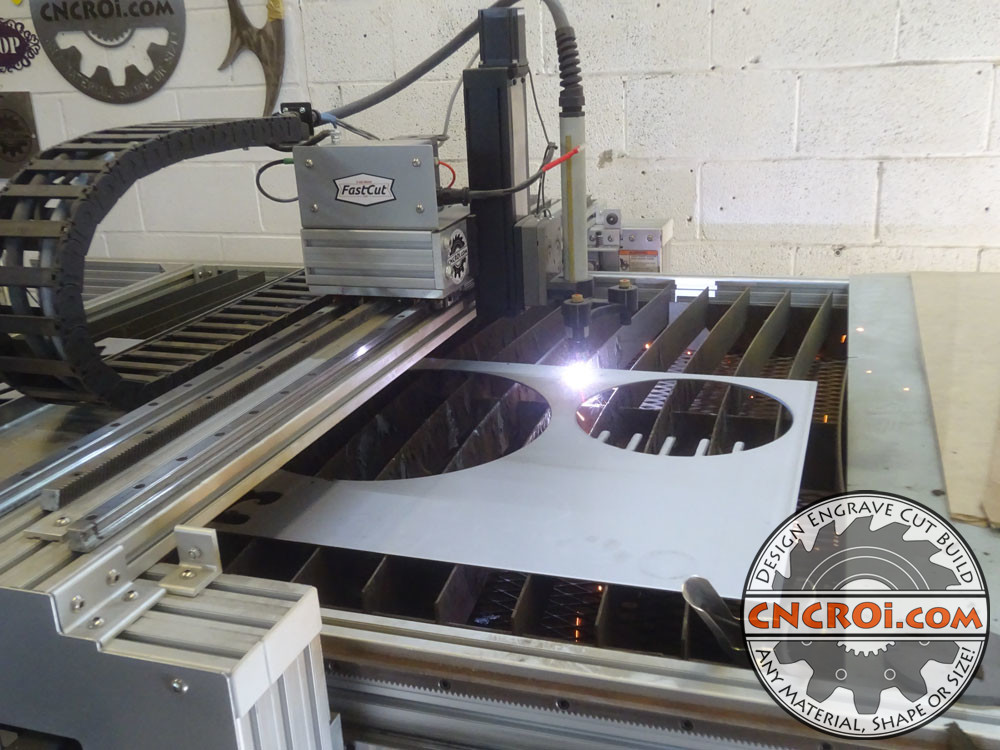

Our machine producing these custom metal tags is able to cut up to two inches thick of metal, this is roughly 1/8″ or 12 ga so you can see how much overkill our system is to produce these specific tags for our customer.

Our CNC plasma cutter is able to cut any type of steel you may want your custom metal tags cut from, and further etch to pretty much any spec you can come-up with.

CNCROi.com also cuts custom BBQ grills, generally out of stainless steel which is yet again, a wonderful use of plasma cutting technology.

https://www.youtube.com/watch?v=StBesadXpkw/

When it comes to making custom metal tags, you have to remember that any further fabrication applications such as welding, are not affected by our tags – in other words, if you weld these tags to your product, the etching will not warp or peel off regardless of the heat generated during that process.

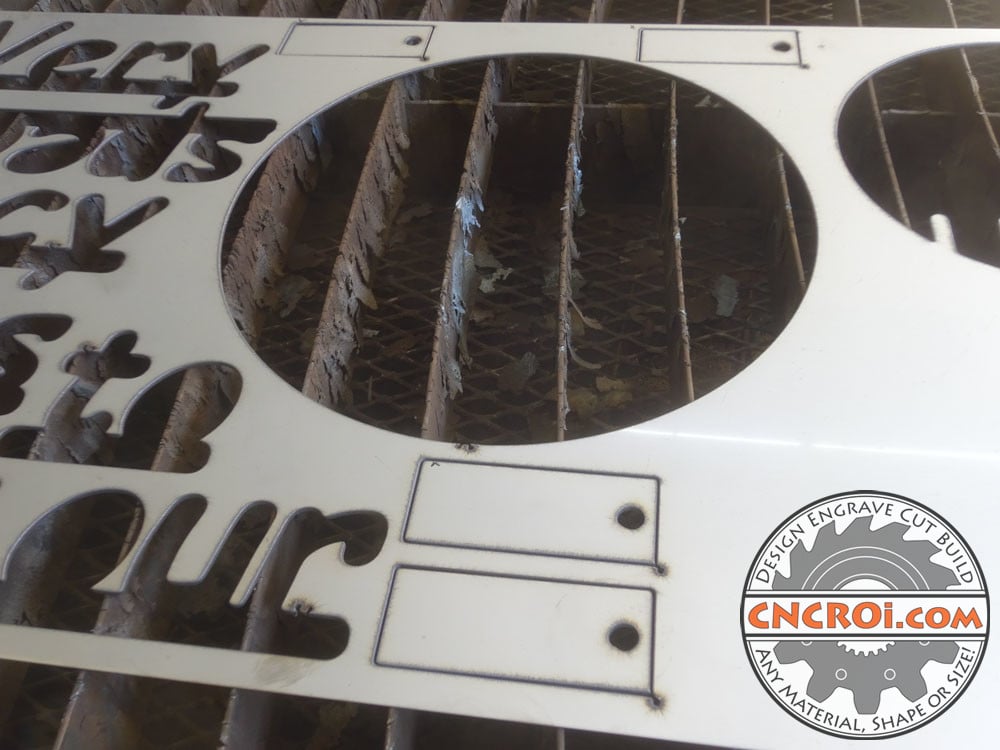

There are a few spots on this piece of well used stainless steel scrap that were a perfect fit for these custom metal tags, no point in throwing away good material just for the sake of using a “new” sheet.

The bright light you see in the image below is a good representation of the arc that occurs from the plasma head to the table grounding it, it’s the space in between that the plasma is actually formed and that’s what is cutting these tags out like a hot knife in warm butter.

Even highly detailed items can be plasma cut, and of course paint does wonder on custom metal tags if you so wish it.

https://www.youtube.com/watch?v=ygB1tfsdAzw/

I am in the middle of renovating the shop so the location of this CNC plasma cutter will change in the coming weeks to make room for more equipment, it will also involve an improvement to the exhaust system, having both a system above the table and within the table rather than just the current downdraft on the table.

CNCROi.com can also help you with the design process if you aren’t sure what fonts to use or sizing for your custom metal tags.

It’s really hard to get in-focus pictures at CNCROi.com with all the fireworks shooting out from the plasma arc cutting through this stainless steel.

Here’s a good comparison of mild steel vs stainless steel as far as plasma cutting is involved, so you can see how the fireworks are different between the materials.

https://www.youtube.com/watch?v=jaKn8PzDg1E/

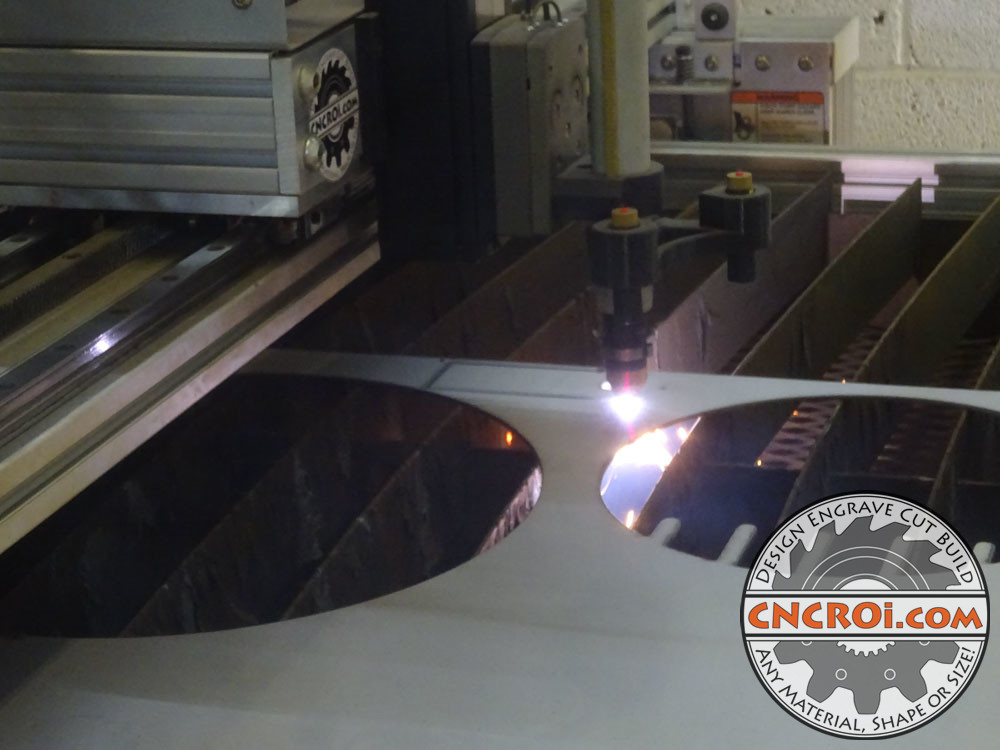

The power of the plasma arc is amazing, it’s hotter than the Sun and after spending years cutting metal by hand, an absolute joy to be able to control with the precision only possible using CNC technology.

The plasma cutter can control itself, via programming by CNCROi.com, when it needs to turn on (producing the ark that cuts) and off – below you can see the exact moment when the arc turns itself off after finishing the profile of the custom metal tags.

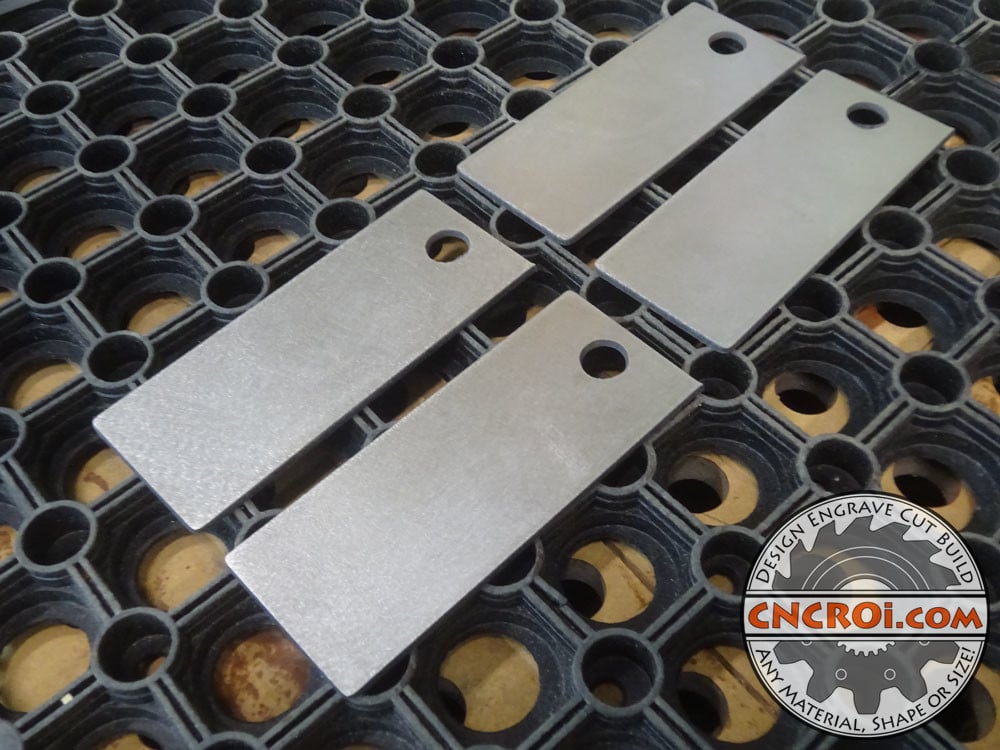

You can see the four tags cut out of the sheet of stainless steel, they are all identical and ready to be taken out of the sheet to go onto another life as a machine tag.

Fiber laser etching can literally involve any black and white image and using whichever font you wish.

https://www.youtube.com/watch?v=mOsxRyCauCU/

Before CNCROi.com heads over to the galvo fiber laser to permanently etch these four tags, it must be cleaned-up and for that process, we just use an orbital sander.

This transforms the tags from ugly with dross to exceptionally clean and ready for our laser system to put in relevant information on them on one side.

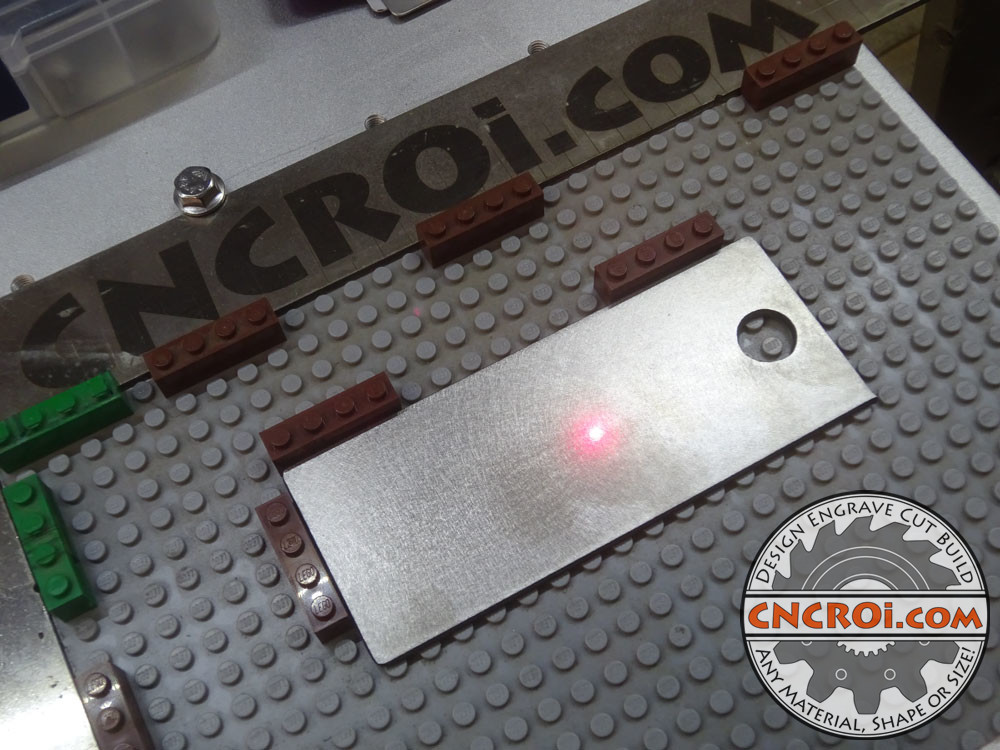

Part of repeatability involves having a fixture that can work perfectly for the application involved, and in this case, the lego is wonderful, and the same technology I use with my other fiber laser source.

The finished custom metal tags below look amazing and are ready to be shipped to the customer to use for their equipment labeling requirements.

Need custom metal tags? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=Kd9btyqS2Jc/