Custom Ornamental Fretwork Production

CNCROi.com makes custom ornamental fretwork for a large number of applications, it’s a great way to add design elements to any design or architectural element.

This is certainly not the last time you’ll see some amazing custom ornamental fretwork on this website, we’ve done everything from vintage fretwork for buildings through to very unique room dividers and even window coverings.

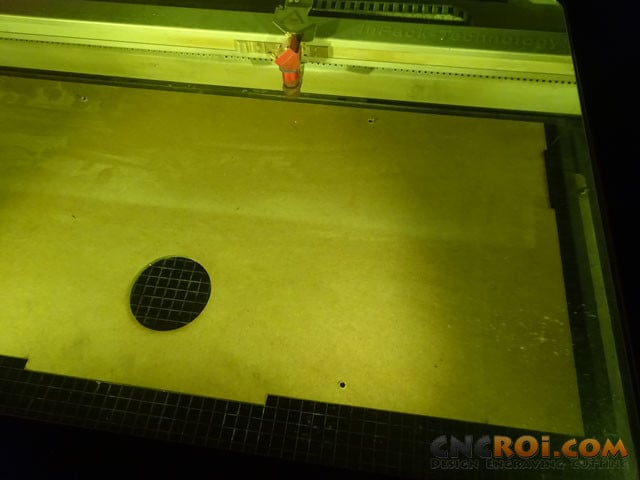

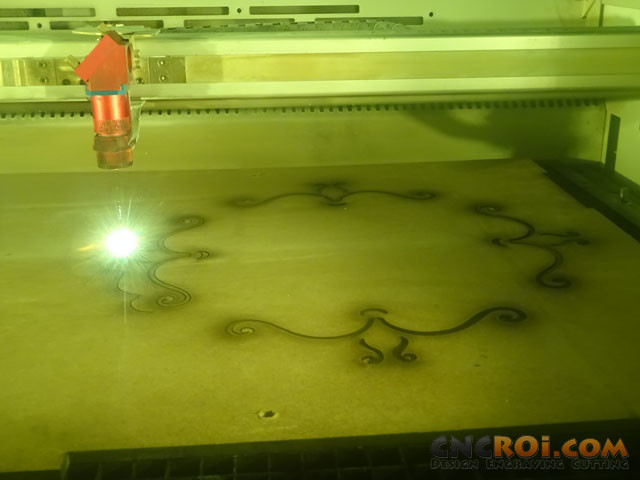

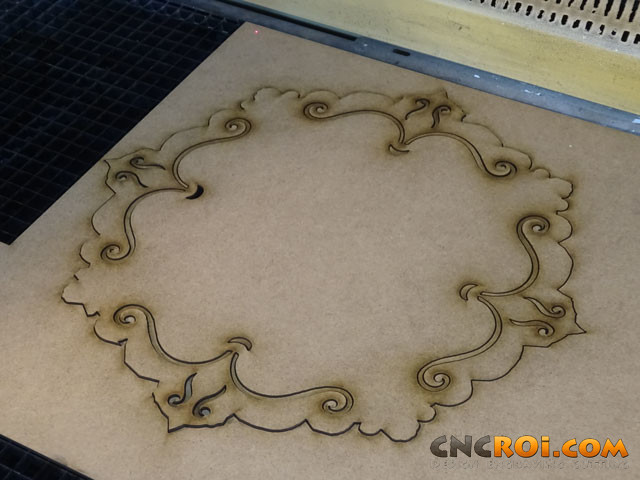

In this case, we’ll make custom ornamental fretwork in the shape of a bowl or dish.

This can be used for a wide variety of applications alone, from wedding or corporate plate changers to mirrors, birthday cake platters, whatever you can imagine including a picture frame if we cut out the inside and added another layer for the “ornamental” stuff.

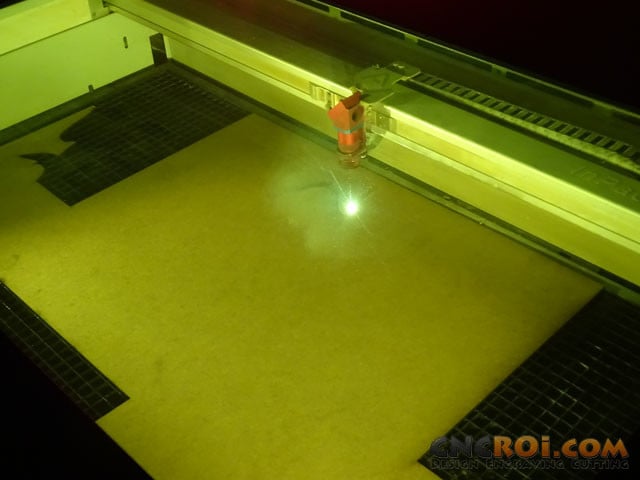

This custom ornamental fretwork dish will be made out of quarter-inch (6 mm) material, in the second half of this blog post, we’ll do the same design out of 1/8th inch (3 mm) just to show you ultimate machine repeatability so if you contracted us to make five or a thousand, they would all be identical.

As CNCROi.com makes everything on-demand, we can easily mix and match this custom ornamental fretwork with other matching elements, for instance, if you wanted a bunch of these with rectangular versions, we can do that too.

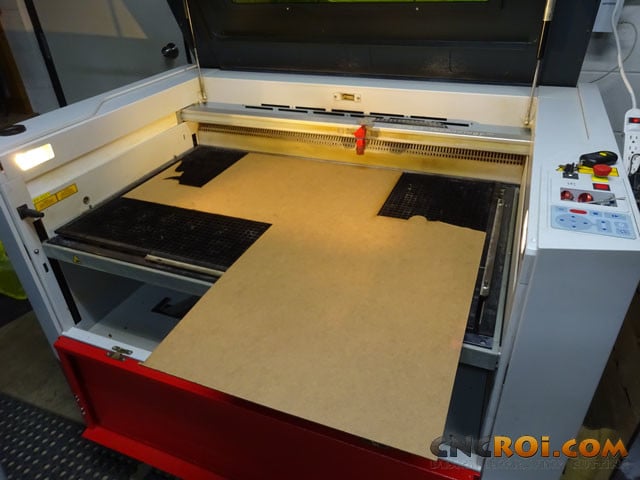

In both these cases, we used regular MDF, it’s easy to paint, works and sands very well and isn’t very expensive material which works fine as it’s generally painted afterwards anyways, no point in making this out of red cedar only to paint over it!

This could have been anything, stainless steel through to Corian or a hardwood like zebrawood or an acrylic.

It’s completely up to your budget and volume requirements, CNCROi.com has the suppliers, the equipment and the passion to transform just about anything you want into reality.

Regardless of the material we use to make your custom ornamental fretwork with, it will be done professionally, within budget and timelines we establish.

All CNCROi.com is custom, from start to finish for all our customers, we start with raw materials and get the design issues sorted then get right into production and then ship it out!

Additionally, we are completely scale independent, meaning if you wanted this to be HUGE or very small, custom ornamental fretwork can be quickly and efficiently produced in unlimited quantities.

We can even optimize the design into pieces for easy transport, so you aren’t stuck hauling around a massive piece that’s more likely to break but can assemble on-site.

In the above example, all these custom ornamental fretwork elements have the same information engraved onto them but let’s say you wanted these to all have unique elements, that’s no problem!

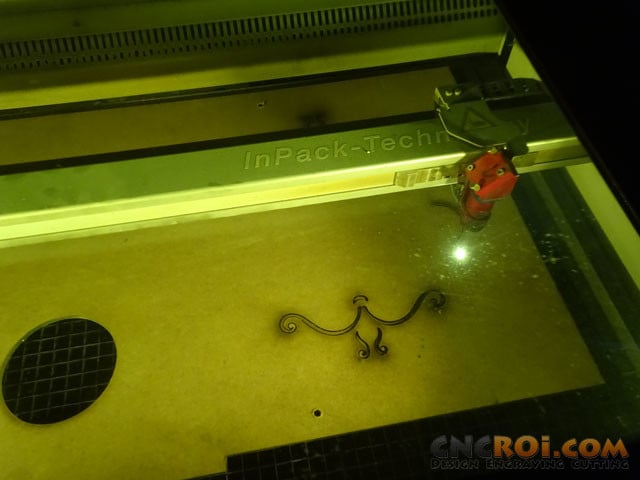

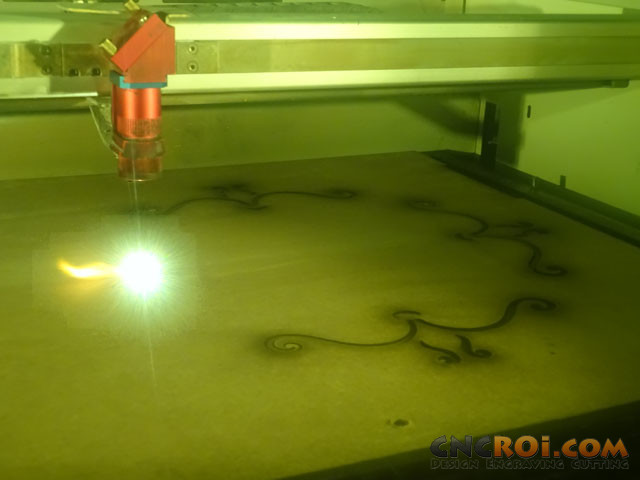

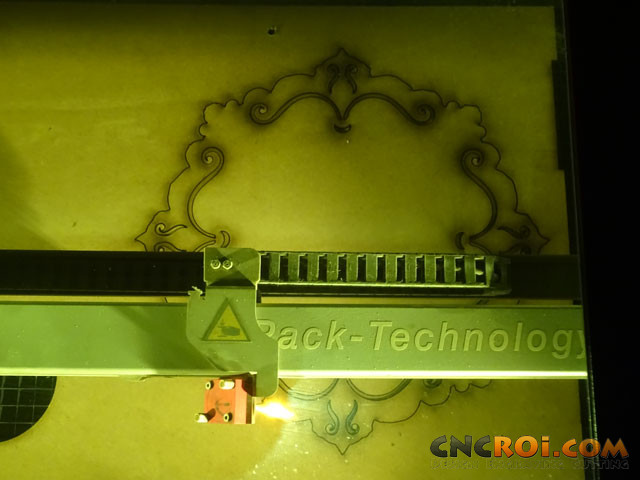

Even incredibly tight design details are wonderfully preserved, the amount of design complexity or refinement are just as endless as your material and sizing options with CNCROi.com when it comes to custom ornamental fretwork.

If you are wondering, MDF specifically, how thick we can go, here’s an example of the results cutting through half-inch or 12.7 mm thick MDF. This is a video CNCROi.com produced earlier but we’ve sine gone even thicker and as you can see, dramatically thinner as well.

Although this isn’t highly detailed custom ornamental fretwork, all the corners on this maple leaf are sharp and clear, and as such, the fretwork details of this design would be just as sharp, repeatable and precise across the board.

Whether the material is extremely thin Formica or very thick Corian or solid lumber, these production features generally hold true.

If the material we are using isn’t flat, that also isn’t an issue for us, as we have plenty of clearance on the material using specialized lenses from our Austrian manufacturer.

As a result, our Austrian industrial wide-format CNC laser offers you incredible design possibilities on even the hardest or softest of materials!

Let’s say you wanted this design to actually be part of a mirror that you hung on the wall, CNCROi.com has done that many times, here’s an example of one we made and it even included custom paint filling to add color to the mirror surface!

Acrylic is available in an endless variety of thicknesses, transparencies and color variations and shades, and there are even more options out there when it comes to lamacoids that are UV exterior grade or anodized aluminium though minimum quantities do come to play with more exotic materials.

The reason that this custom ornamental fretwork done onto MDF wasn’t masked is that we plan on painting them so all this smoke and resin build-up on both sides of these samples makes no difference as it will be covered-up post-production.

For an idea of what this would look like, in clear acrylic, watch this video, although the application is different, it could have just as easily been made into the custom ornamental fretwork we are showcasing in today’s blog.

Each material has a plus and negative attached to it, and the optimal decision of which to use depends on your application.

For instance, you don’t want to use an expensive material like Corian only to paint over it, likewise, you don’t want to use a very heavy and thick material if you plan on carrying it to and from trade shows.

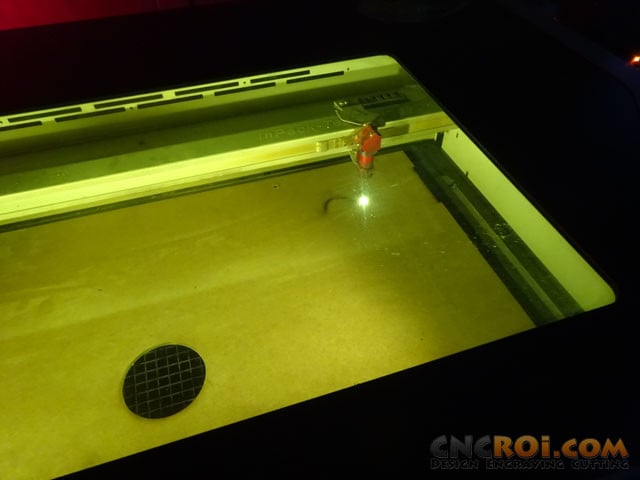

What’s neat is that in the above photo from CNCROi.com, there is actually an invisible laser beam going from the right to the left mirror of our Austrian industrial wide-format laser.

The tube is in the back of our dual-sourced machine, which means the beam goes through multiple mirrors and then finally a high quality lens before it hits the material below.

The final results look amazing, the cut is consistent across the board and the inside parts of this custom ornamental fretwork come right out, just like the outer piece of scrap did.

The quarter-inch or 6 mm thick MDF custom ornamental fretwork came out great, let’s say you didn’t have a big budget or the application didn’t require something as strong as this, well, we can cut it out of material that’s half as thick!

That’s the power of custom that CNCROi.com brings to you, ultimate flexibility across materials, sizes and design.

As we have a huge machine, we can actually take-on even bigger jobs by opening-up the front and back to feed project material through, this comes in extra handy when we are doing large format signage engraving on lumber and other substrates that are especially bulky.

Cutting thicker material does take longer, so you pay a double penalty in a way, the material costs more the thicker it is and it takes the laser longer to cut through it, though engraving speed isn’t affected as it’s only on the surface.

So, if you are on a strict budget, but have a material you can’t deviate from, one way around that situation is to simply have CNCROi.com use thinner material (if available).

This holds true with most materials, especially metals, acrylics and woods.

CNCROi.com is also able to make these using a variety of materials, whether it’s our industrial laser, CNC router or sand blaster, we use the optimal equipment to produce the best results for our custom demand customers.

That custom house number sign we made out of cedar could have been made in the design of this custom ornamental fretwork quite easily and vice versa.

Something you may not be aware of is that CNCROi.com can also make custom furniture and anything else you want, so if you wanted this custom ornamental fretwork to be a mirror on a dresser that matched is in style and materials, we can just as easily make that too!

We have full 3D design capabilities, so even if you weren’t a designer yourself, we can design and show you the work before even the raw materials were made and the design elements for our designs complete.

The curves you see in this custom ornamental fretwork can be as numerous, complex or simple as you want, it doesn’t make a difference whether there are a thousand little details to them or none at all.

Now that this custom ornamental fretwork dish is finished, you can see and directly compare it to the thicker version above, there is no difference.

Although if we were off a few fraction of a mm or inch wouldn’t be needed or noticed for this applications, our industrial clients notice with their QA departments, as such, you benefit from their strict requirements even on far simpler and flexible projects.

Another thing you may want to consider is the placement of your ornamental details, if you have too many things in a design that are cut, you are weakening the substrate quite a bit, so it’s a fine line when it comes to design options when it comes to design esthetics and durability.

If you were wondering how fine a detail on a thicker material we can achieve with our industrial Austrian CNC laser, here’s a project we did to show you just that and it even included a brief cameo by our industrial sized sand blaster!

As for the inside parts that we cut out, they are actually still very good! If you want us to keep the elements that we cut out of your custom ornamental fretwork, just let CNCROi.com know ahead of time and we’ll bag and ship that along with your custom project!

Here are the two custom ornamental fretwork samples side by side, the one with the inner elements on top is 1/8th inch or 3 mm thick, one on right, 1/4 inch or 6 mm, both MDF.

To give you another idea of scale, here’s me holding one of them up, these are a very decent size but by no means the biggest we’ve ever made nor the smallest CNCROi.com has ever produced.

Need some custom ornamental fretwork? Contact CNCROi.com right now! We are as passionate about what we do as our customers are in their businesses!