Custom Plywood Jigs: For Printers

Custom plywood jigs are a great solution for a variety of print shops, whether you have UV printers, screen printers or a shop doing lots of units where precise repetition is required.

https://www.youtube.com/watch?v=5n7YQ41R5F0/

Plywood jigs are fantastic because they are strong, cost-effective and very resilient for many different applications.

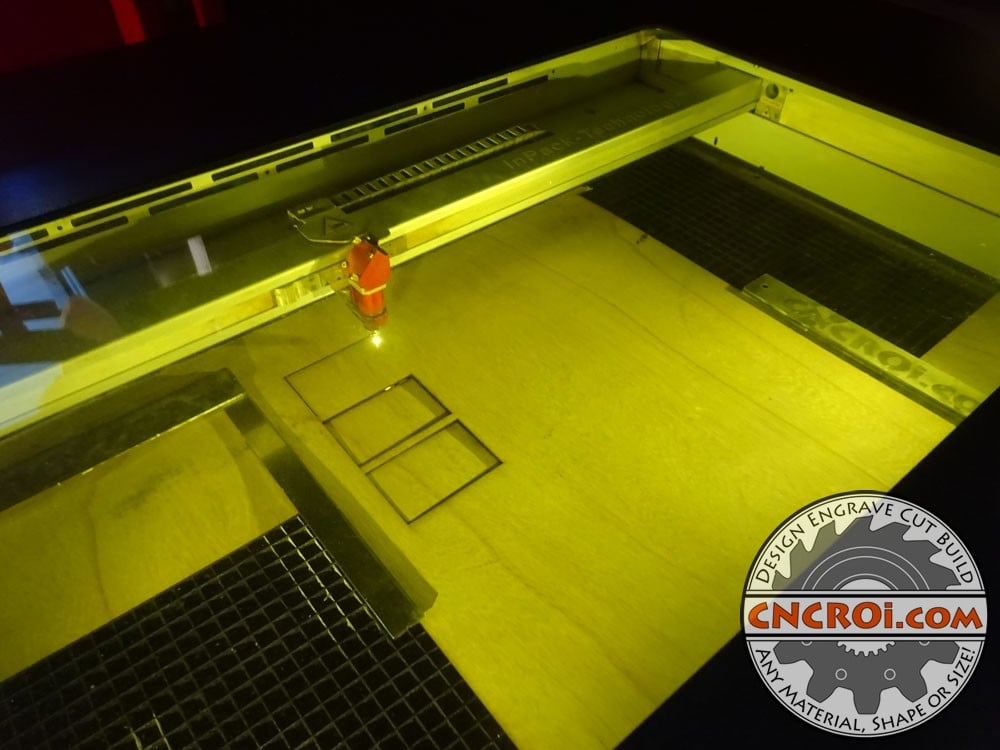

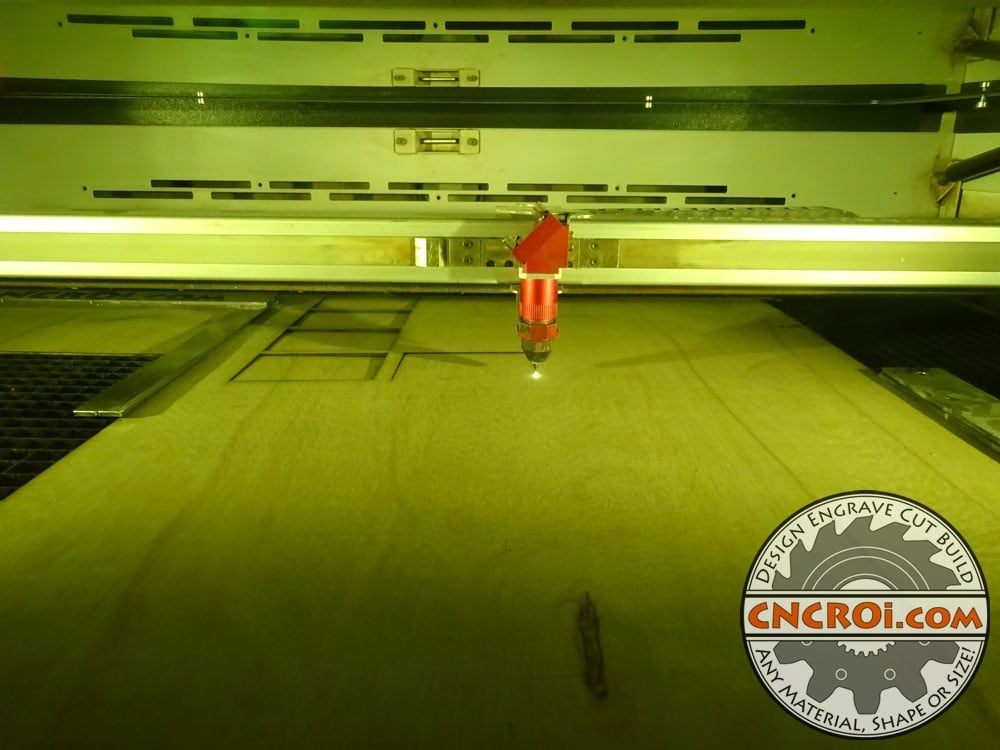

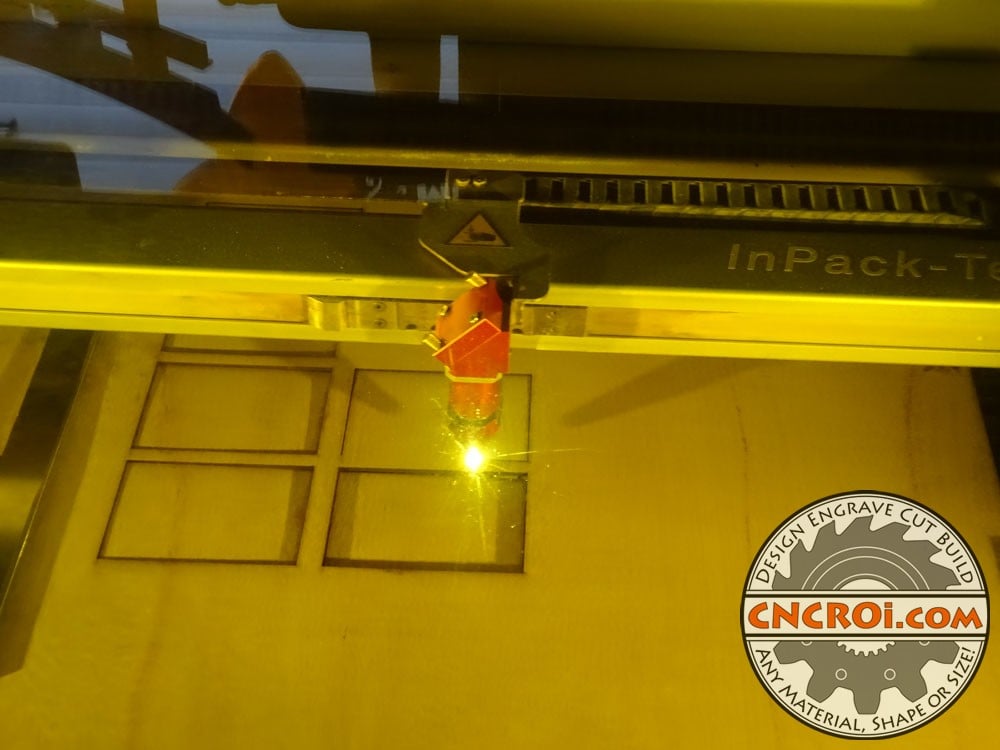

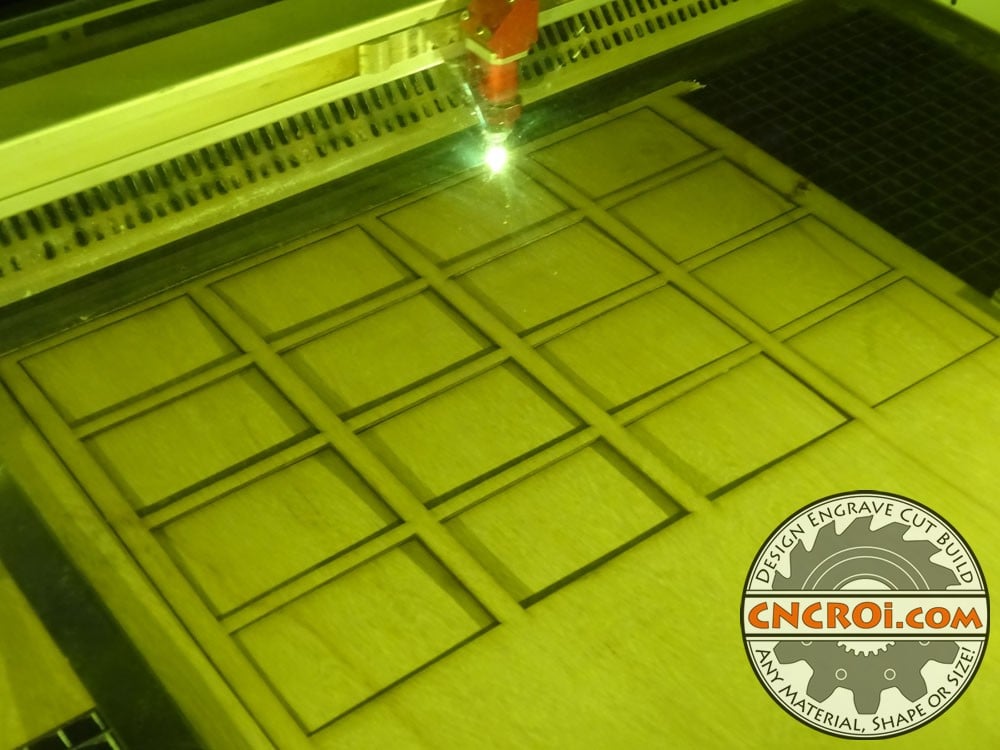

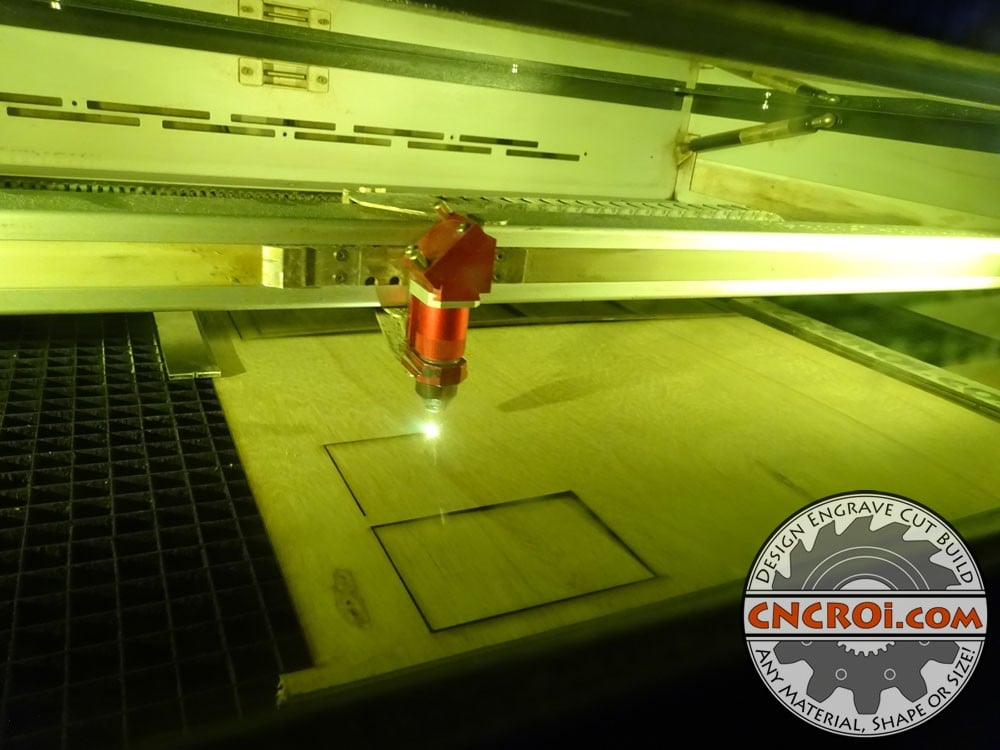

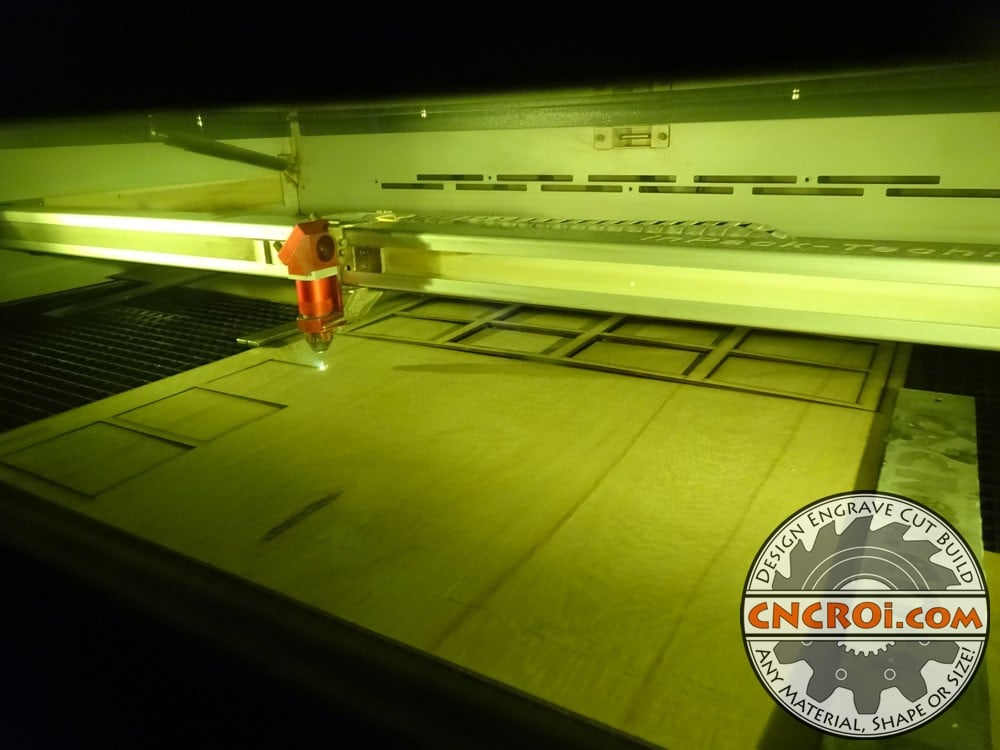

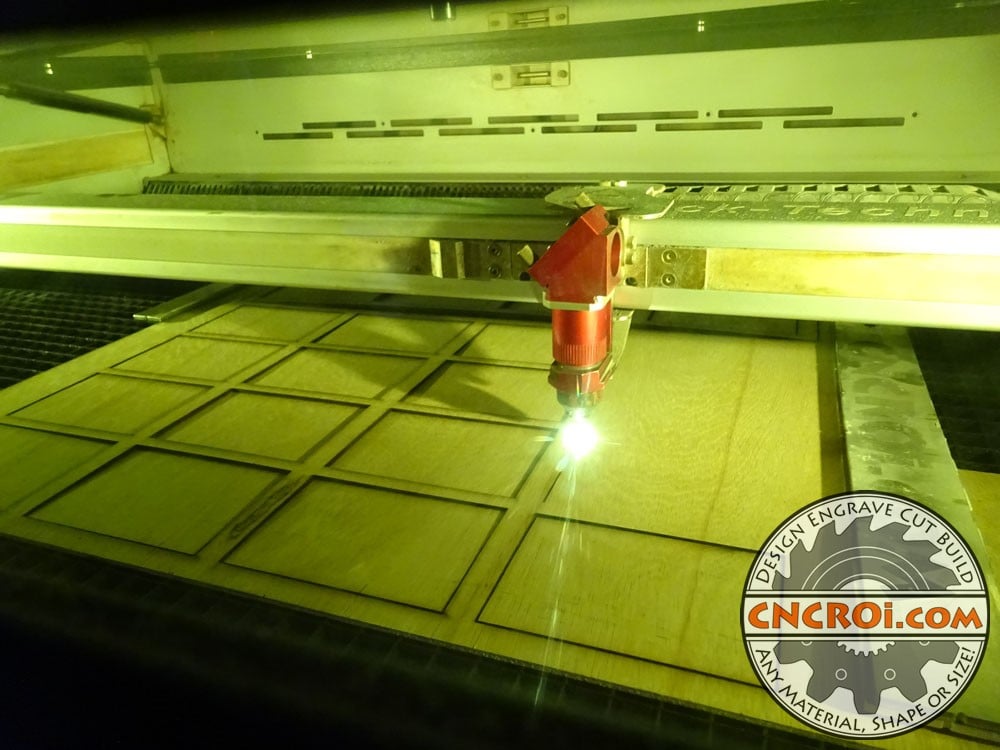

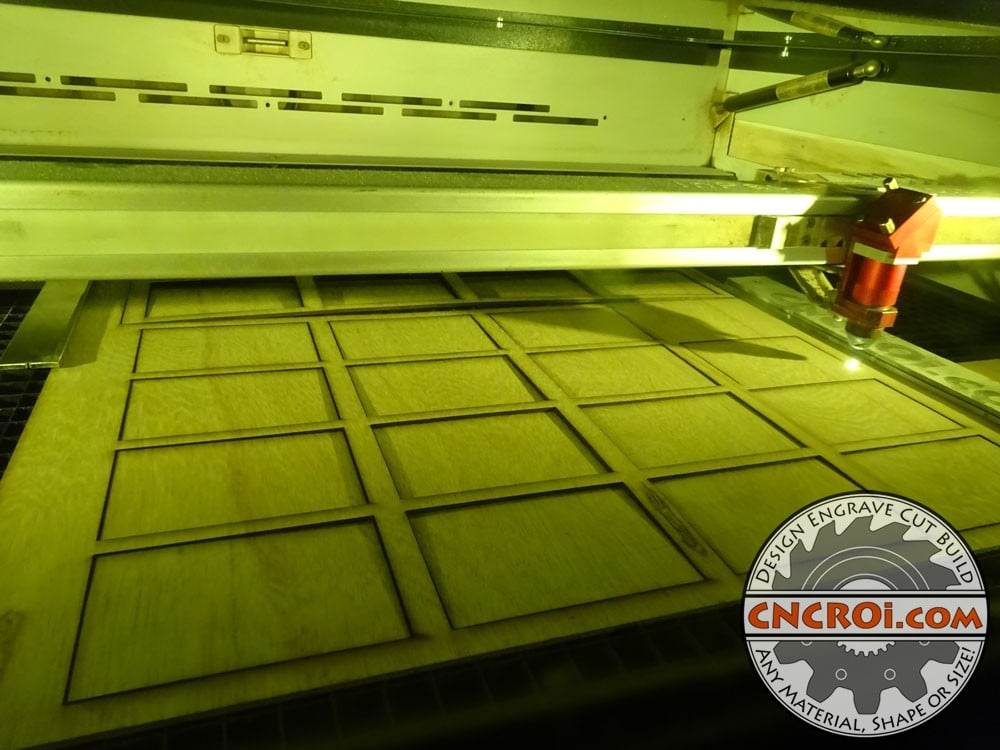

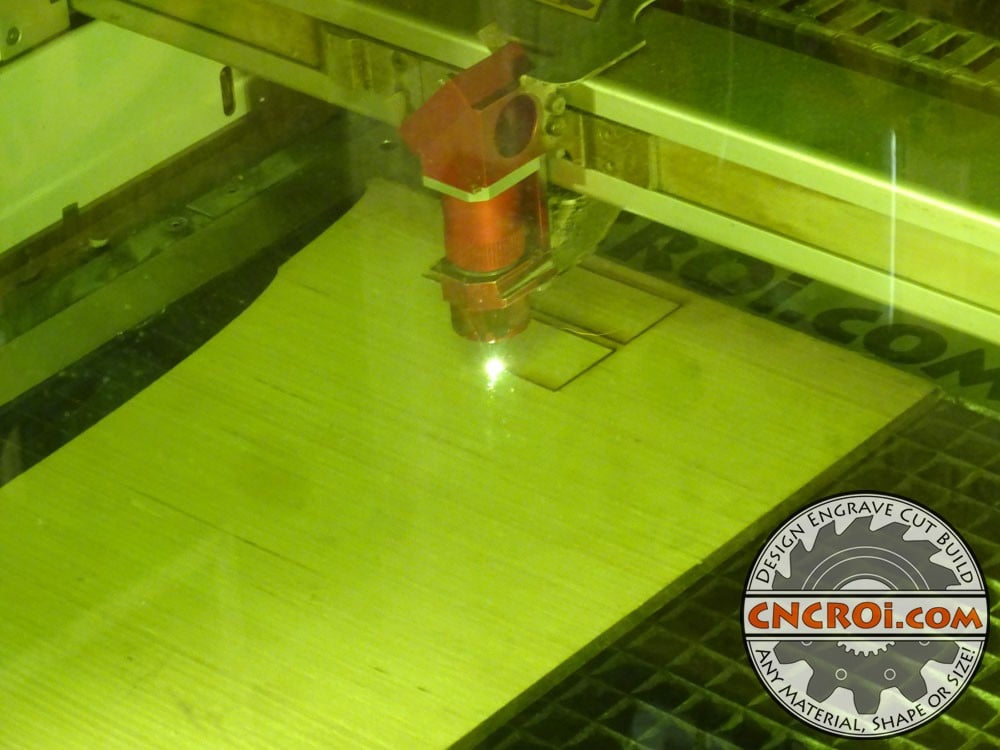

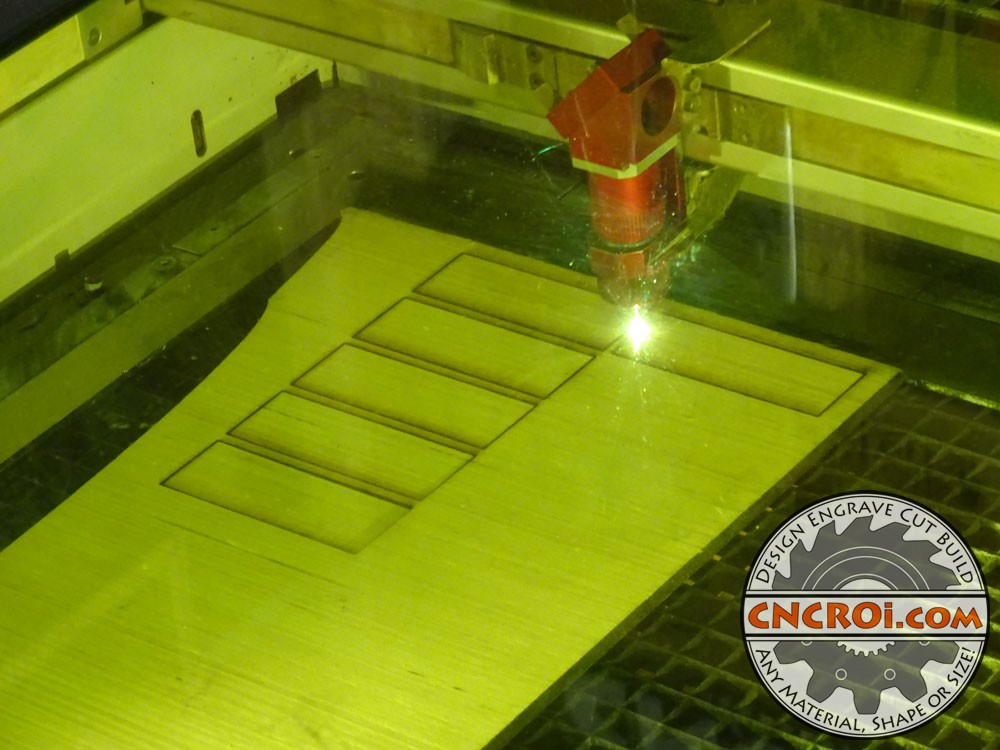

Plywood jigs can be made in a variety of different ways, but generally CNCROi.com makes them using our industrial wide-format Austrian CNC laser over our American ShopBot PRSAlpha, reason being, we can produce sharp inner corners with the laser while this isn’t possible with a router.

Making custom plywood jigs is pretty straight forward, the customer traces out (or sends us items to trace) what they want the plywood jig to hold, then we cut it out from the spec they need in the volume required THEN we glue it together and ship.

The nice thing about custom plywood jigs is that gluing them together (or not) is optional and plywood itself is available in a variety of hardness and thicknesses so CNCROi.com can make multi-layered jigs if required.

The options when it comes to custom jig manufacturing are endless, if you don’t have a vector file or aren’t familiar with design programs, no problem, just sketch-out what you need made by CNCROi.com and we’ll convert that into a format that our machines understand to make the perfect jig for your application.

There are a lot of alternative materials when it comes to custom jig production, acrylic to metal, but we’ve found MDF and plywood to be our go-to standard here in the shop so that’s what I suggest to our customers needing custom jigs to go with as well.

CNCROi.com isn’t just a supplier of custom jigs, but we are also our own customer, using custom jigs extensively, we’ve tried a variety of materials and build processes to come down the road where we pretty much make everything one or two layered, MDF or plywood.

When it comes to custom UV printer jigs, we’ve made A LOT OF THEM, we’ve found that just regular MDF works best, it’s cheap, it works very well to make modifications at the customer’s end (easy to sand clean) and is incredibly durable.

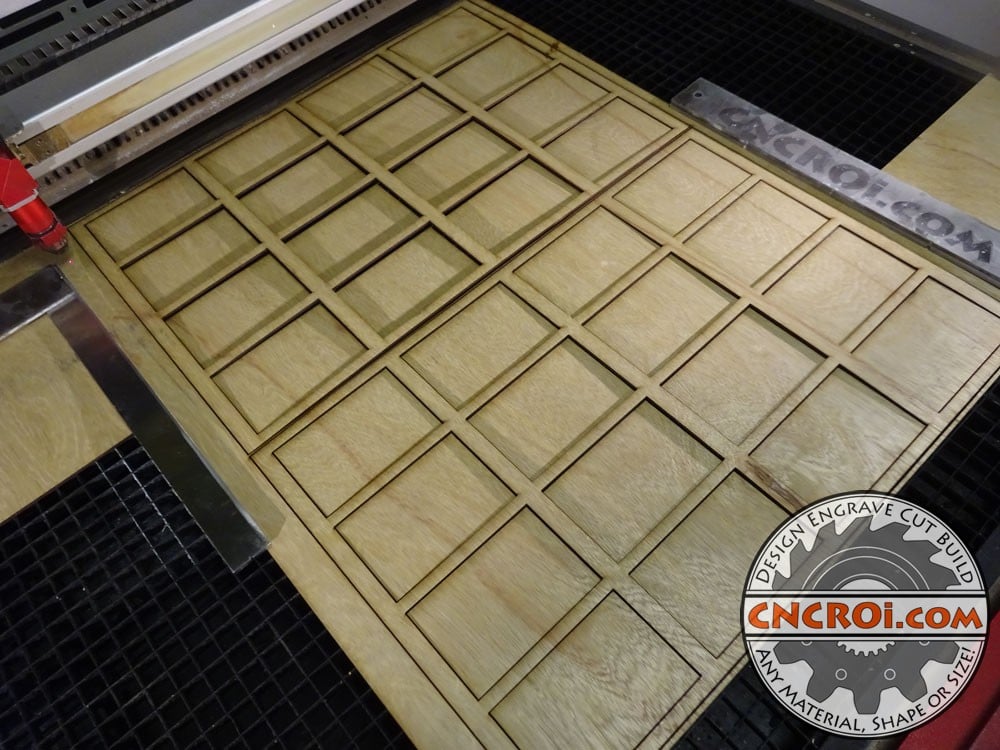

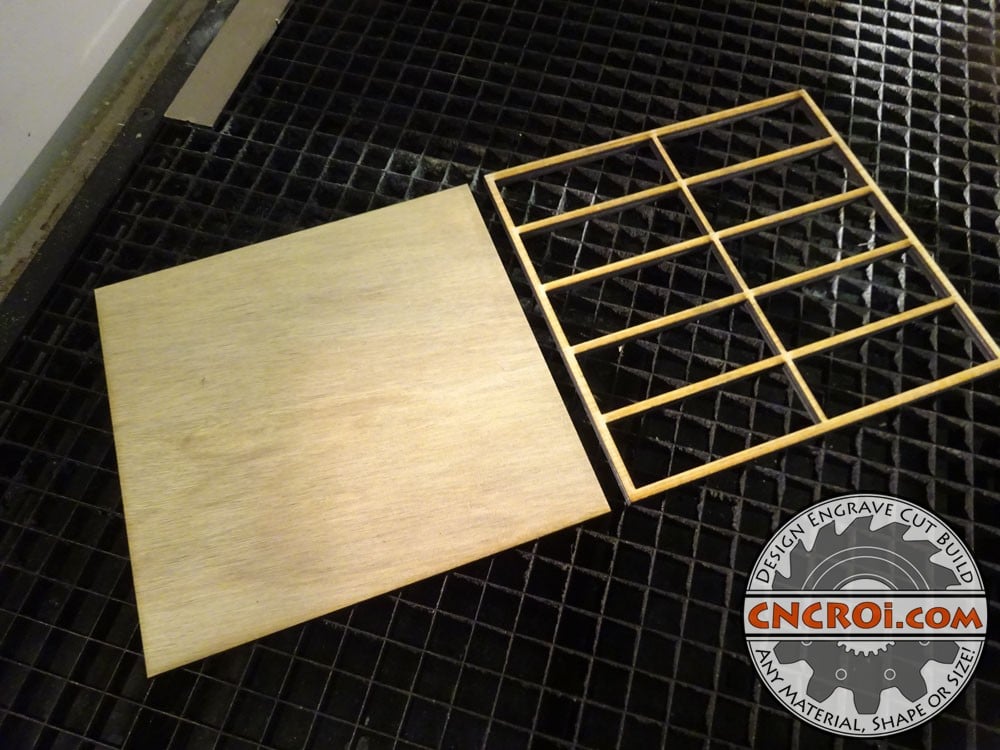

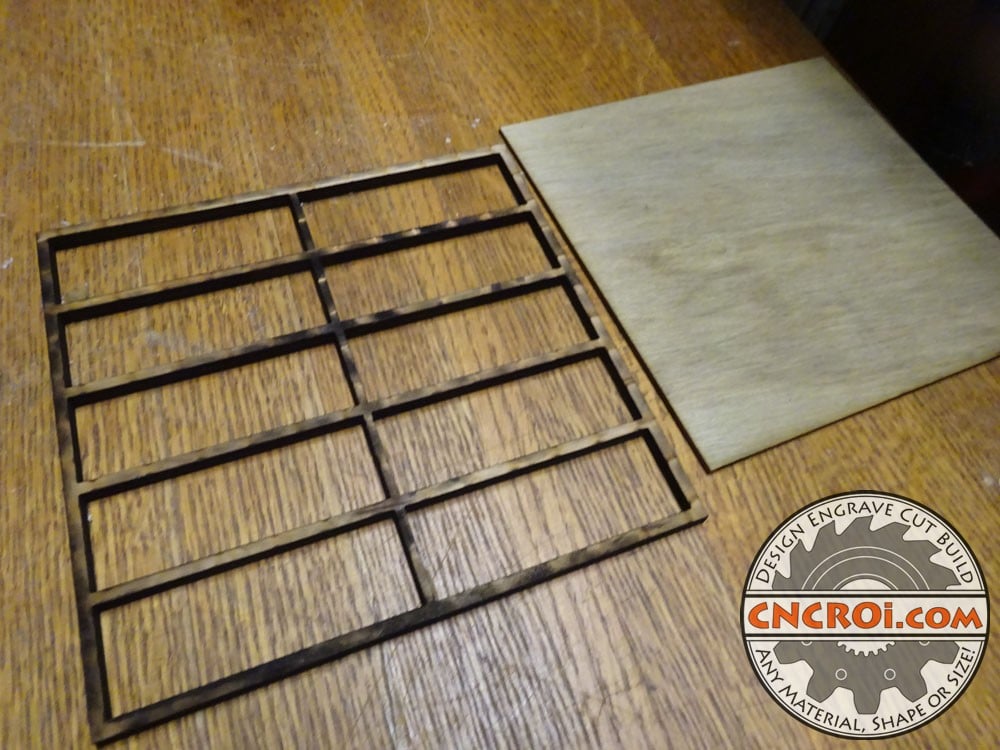

For this round of custom plywood jigs, CNCROi.com used 1/8″ thick plywood that will be doubled-up with glue to produce the finished jig, the build is simple and it works very well.

Producing custom plywood jigs on-demand allows total flexibility regarding sizing and shapes that you wish to have cut out of the jig.

When we make two layered jigs like the one shown below, you have one that has holes in it and the other without (or with tab holes to remove items) but I’ve found that leaving about 1 mm or 1/32″ of give around any given object makes putting items to be branded in and out of the jig to be just perfect.

Acrylic sometimes works very well for custom jig production, but it’s not always the best choice, it’s always best to consult with it regarding your material options and the designs you wish to have made by us beforehand.

Having high precision machinery at CNCROi.com is great, but it’s the experience we have making jigs that really sets us apart, we are a custom fabrication shop and as such, our customers throw interesting projects to us all the time, and making jigs is generally part of that production process.

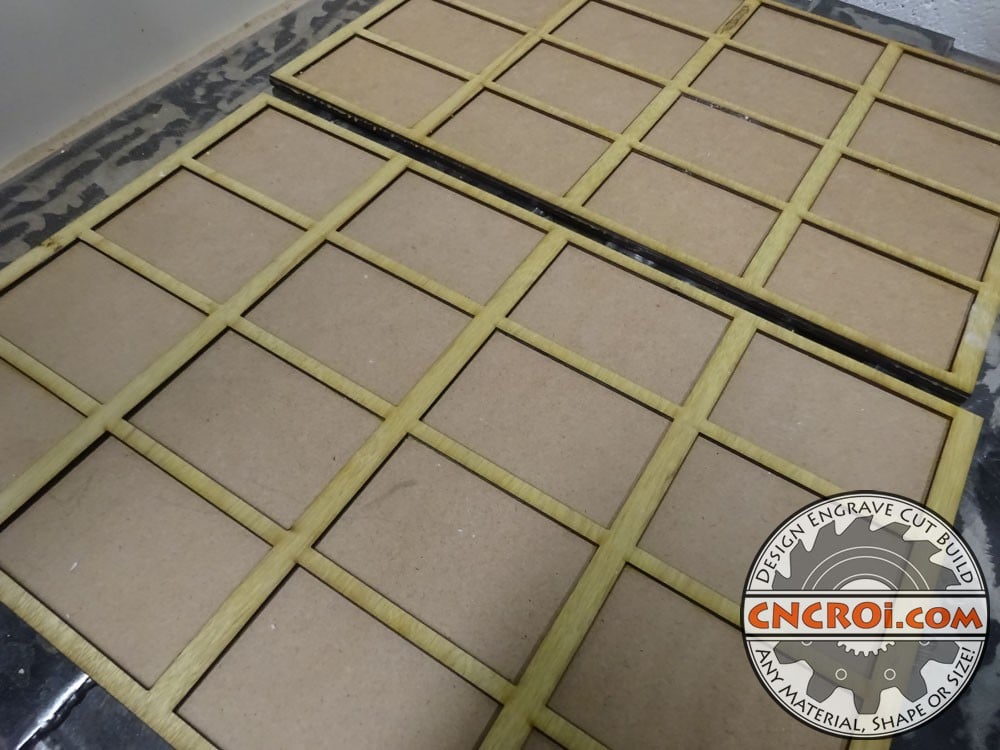

Here you can see how I applied glue in all the areas of this jig, it will then be flipped over and left to settle…

Whether you have a flatbed printer that can handle a few or thousands of units, personal or industrial, CNCROi.com can make it for you!

With some heavy weights to make sure NOTHING MOVES while things dry, I’ve found that glue can be very slippery when wet and as such, putting weight directly onto the jig to make sure it doesn’t move one bit makes a massive difference.

Once the glue is dry, it’s time to do a quick test-run of these custom plywood jigs at CNCROi.com.

At the same time, we made a few smaller custom plywood jigs for the customer that held less units of a different shape for their custom UV printing name badge business.

Jigs are essential for many of CNCROi.com‘s custom metal fabrication end of things for producing repeatable results.

Again, the plywood we used made perfect sense for this application, it doesn’t hold onto heat like metal would and its light weight but very sturdy without any warping.

Now that this mini custom plywood jig is finished, you can see they are identical minus the holes.

A bit of glue needs to be applied to the back then it’s left to dry over 24 hours, sure, it would be ready in less than an hour if needed, but better safe than sorry when it comes to jigs to give it plenty of time to bond properly.

Need custom jigs of any size, shape or material?

Contact CNCROi.com right now!