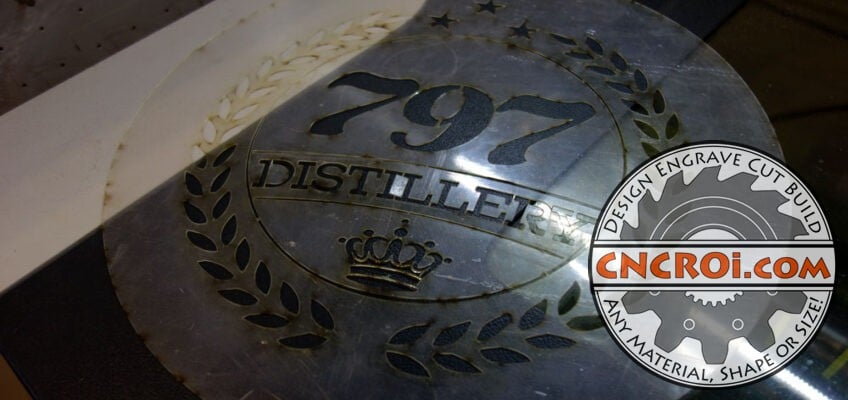

Custom Polycarb Barrel Stencil: CNC Laser Cut

When it comes to custom polycarb barrel stencil production for spray painting (branding) wine, whiskey or other product barrel heads, CNCROi.com makes them to your specifications.

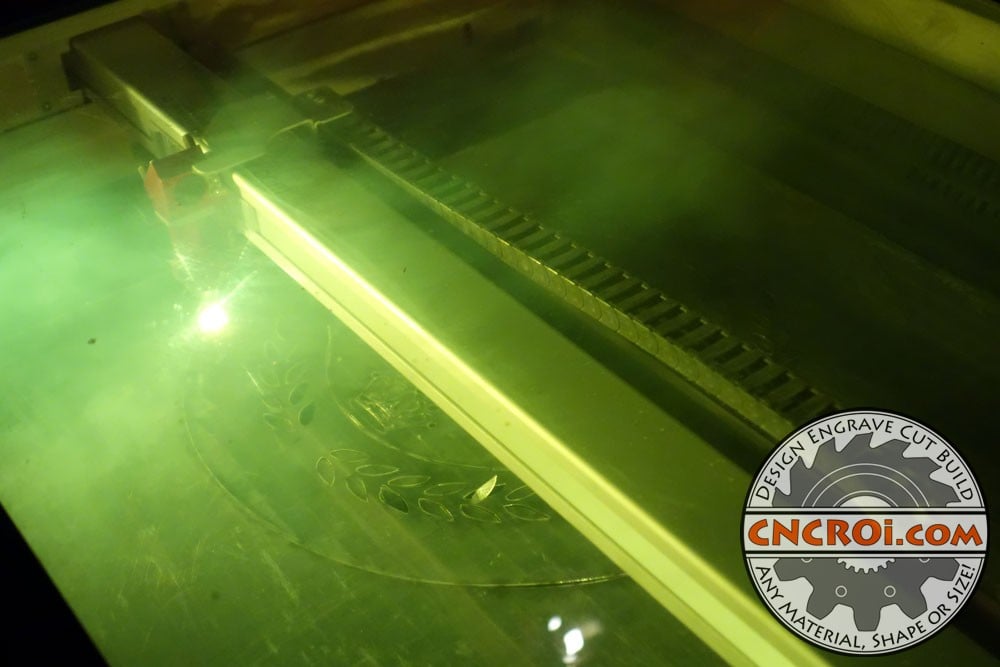

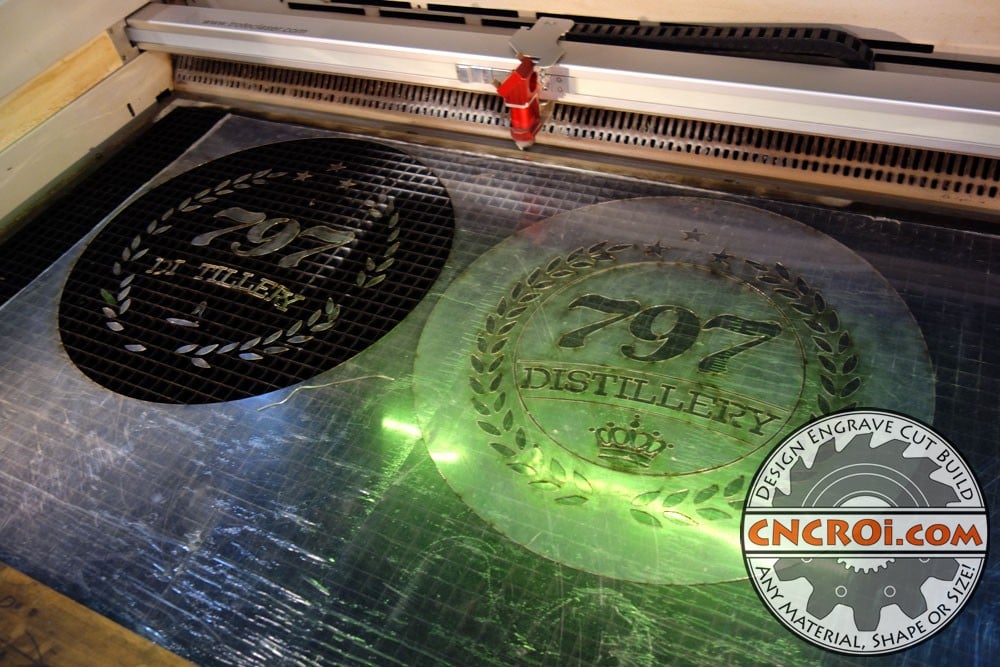

For this custom polycarb barrel stencil, CNCROi.com added in some necessary support material from the customer’s design file and it was made and shipped in very short order thereafter.

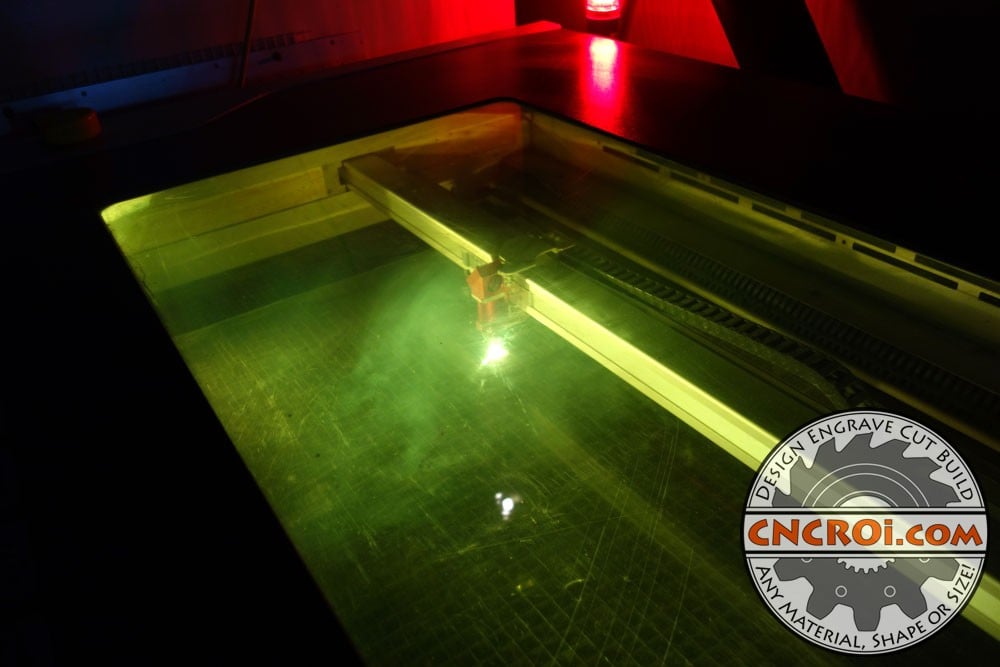

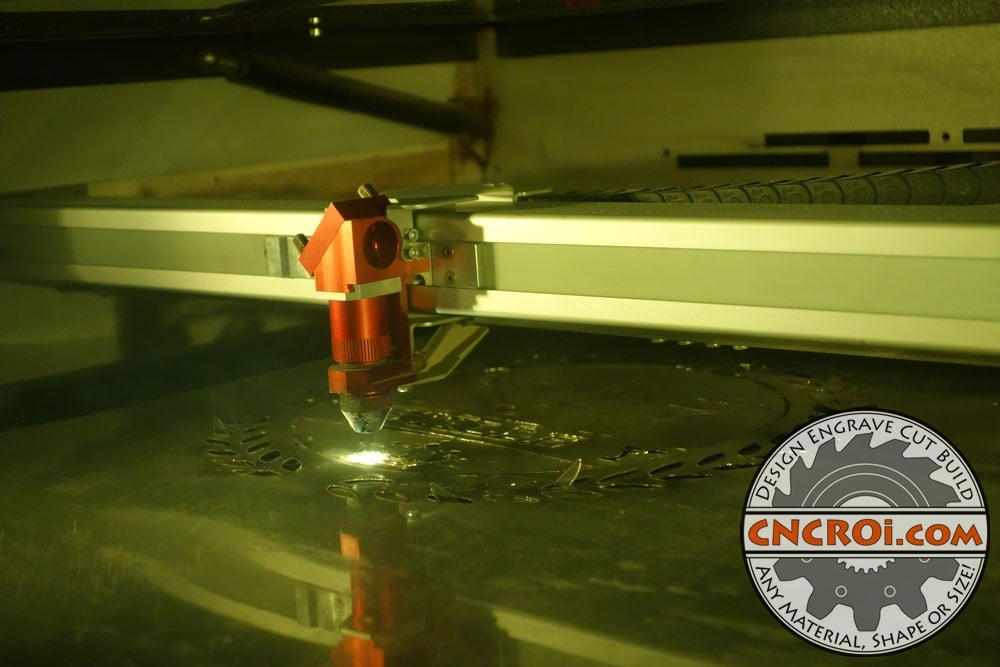

There are a number of different ways to process a custom polycarb barrel stencil for a design to go from digital to physical, but CNCROi.com has found that our laser does the best job cost-effectively when it comes to making these for our customers.

Your only real limitation that exists when it comes to making a custom polycarb barrel stencil is having a design that can be made into a stencil, adding supports is pretty staight forward but sometimes the customer’s designs are too highly detailed so then we need to do something using text or a simplified outline in order to allow the customer to benefit from using a stencil that’s actually possible to be made as a stencil.

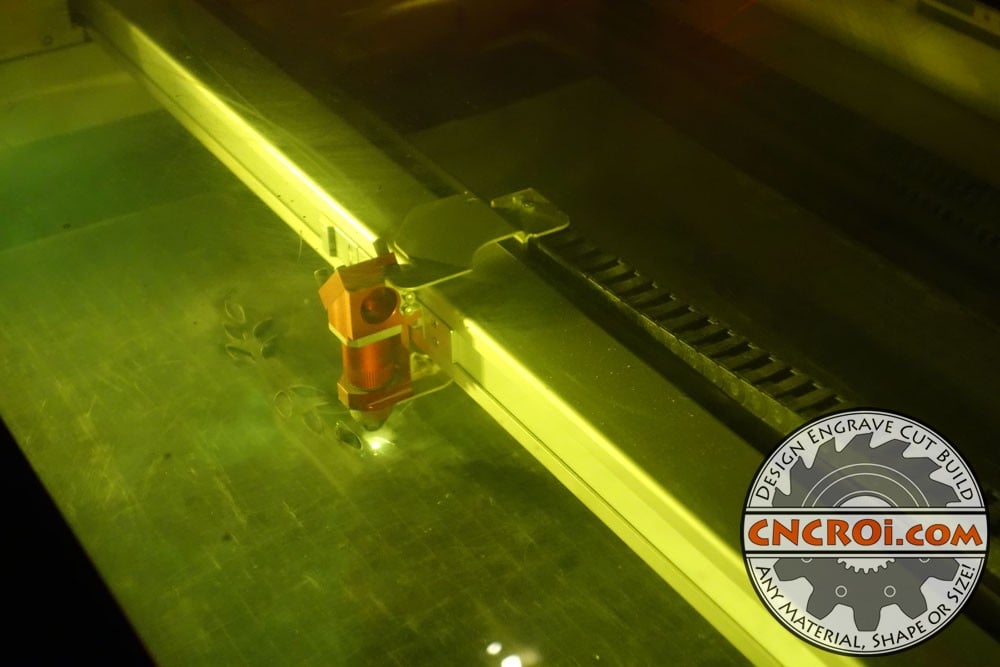

The nice thing about laser cutting polycarb is that it’s a relatively straightforward material and process, there is no flattening required, it lays flat by itself, there is no need to pre or post anything, just lay the polycarb on the laser bed and cut.

When it comes to flexibility, you can have elements you overlay onto a blank stencil to customize it however you wish.

When it comes to polycarb, it cuts the same as mylar, they are honestly interchangeable when it comes to branding applications using spray paint, they weigh just about the same thing, roughly the same thickness and use the same cutting settings when it comes to laser cutting this material.

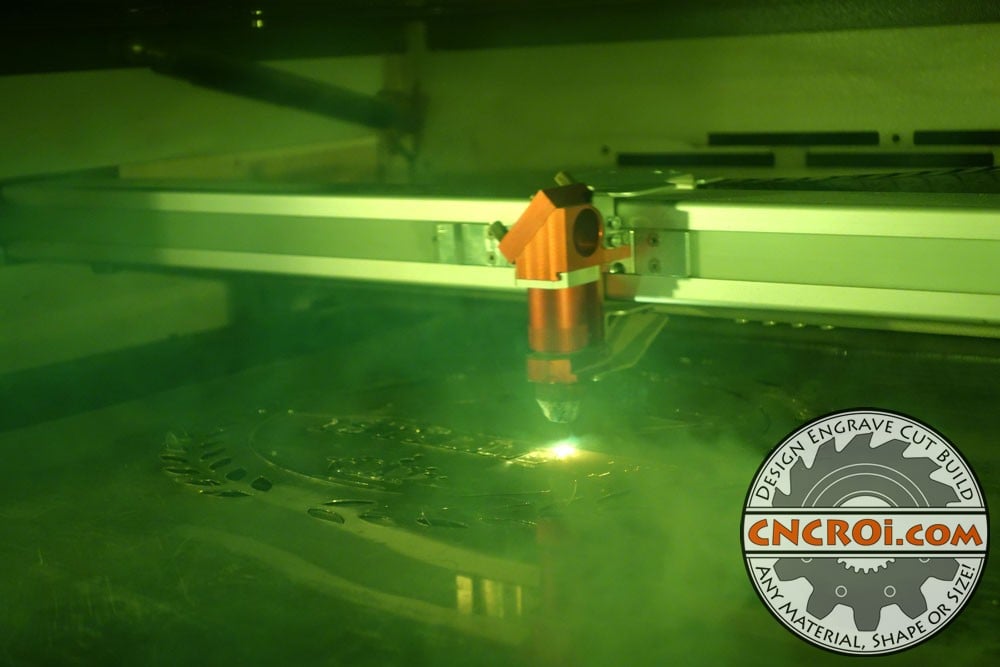

There are some off-gasses created during the cutting process at CNCROi.com of this custom polycarb barrel stencil but they are quickly evacuated from our laser before they build-up to levels that can cause combustion inside of our machine.

Although plastics such as this are relatively thin, they generally stay flat because we have compressed air shooting down onto the material and as mentioned, air all around the stencil being evacuated, so there isn’t any time for the build-up of heat that could cause concern.

Shapes can be made into stencils too, just make sure the silhouette is a solid one.

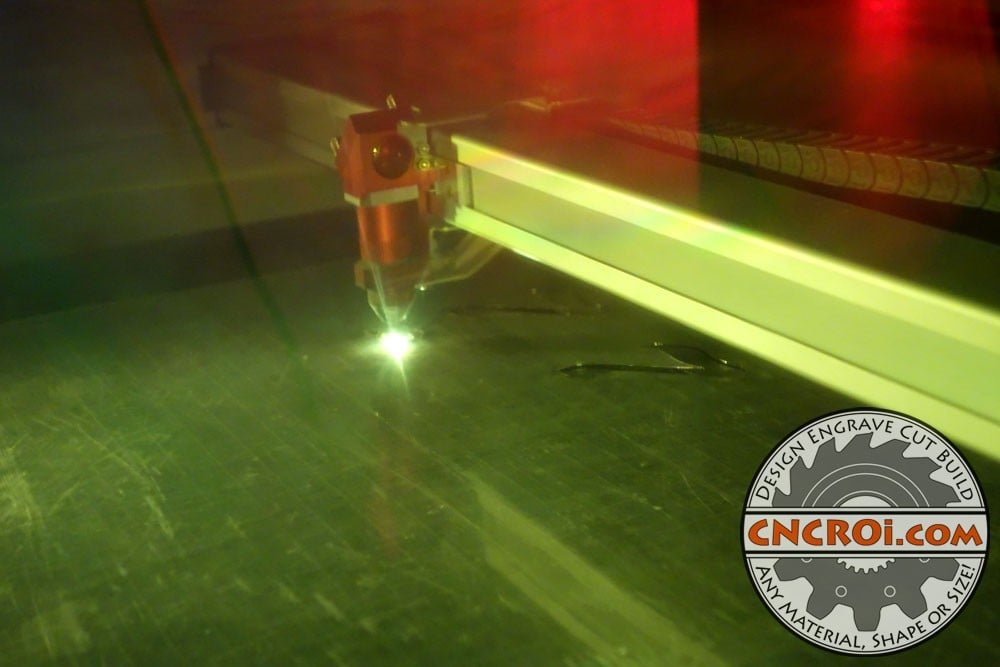

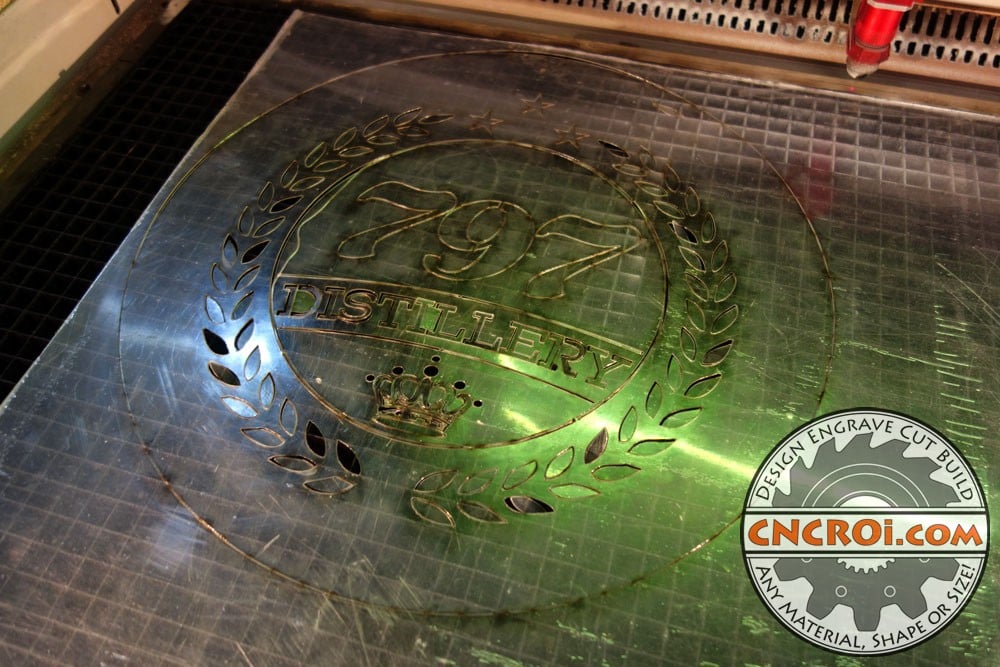

Laser cutting plastics such as this is a little tricky because, as you can see in the picture above, sometimes inside parts of the soon-to-be stencil might flip up and over an area that needs to be cut again, essentially, doubling the thickness of the material to be cut (scrap plus original material) but luckily, the compressed air shooting out of the nozzel pushes most of this away and our laser is more than powerful enough to cut through both layers if needed.

Regardless of your design, it’s vital that inner parts are supported properly, not only for use after the stencil is cut but also during the cutting process itself so we don’t end up with parts of this custom polycarb barrel stencil flying all over the place in the machine.

Regardless of the material, the same issues remain, whether this was stainless steel or ultra-thin polycarb such as this, material popping-up can be a hazzard, as such, cutting is actually the very first and valuable test to make sure the stuctural integrity of the stencil itsel is strong at CNCROi.com.

Regardless of the machine CNCROi.com uses to make stencils with, router, laser or plasma, the accuracy and repeatability is about the same, with a few caveats regarding pre or post set-up but they are incredibly minor and have more of an affect based on materials used.

If you want a big stencil or a small one, or whatever scale you want, we can make it for you in just about any material… mix and match at your heart’s content.

Mylar and polycarbonate are interchangeable regarding stencil production, the end result is identical and although technically polycarbonate should be more durable, when it comes to stencil use in general, they are about equal in my book.

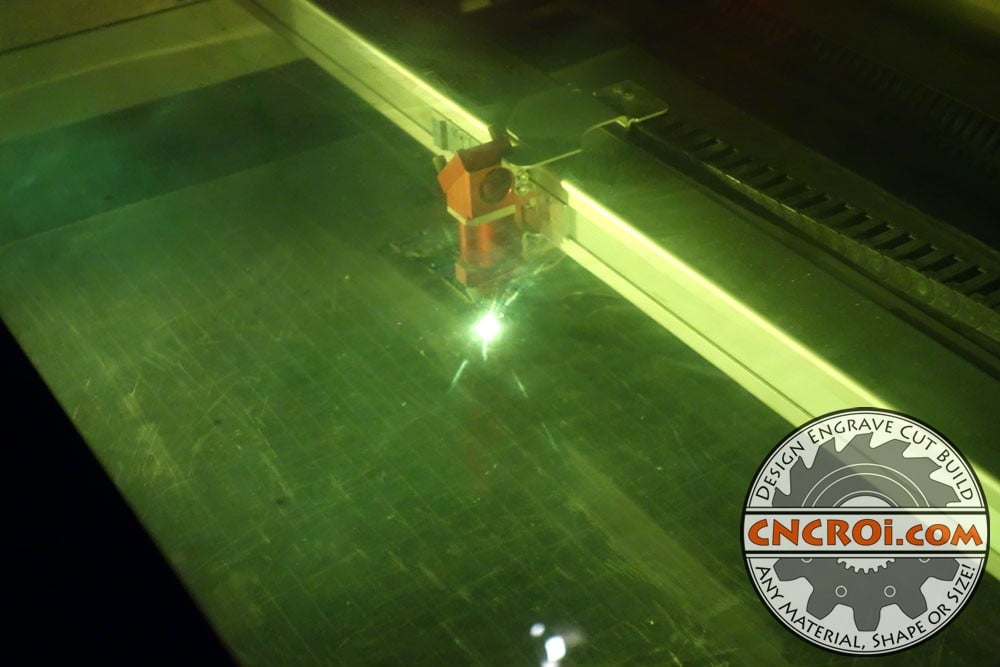

For this custom polycarb barrel stencil, production, like it has with hundreds of other stencils such as these, went very well and the process is very much optimized from many years of experience making said stencils.

As for turnaround time, generally, CNCROi.com can get a stencil cut and shipped within 24 hours once the design issues are sorted as we keep stock of various materials for just this purpose, steel to plastic.

After all the inside parts of the custom polycarb barrel stencil are cut out, the next step is to cut it out of the sheet of polycarb completely, this maintains the integrity of the overall stencil and makes sure nothing moves during production until the final step is complete.

CNCROi.com also makes lots of tik tok stencils as well, the biggest difference other than not being round is that they require a qr code.

The finished stencil looks great, this will be used for thousands of custom barrel head branding applications and the nice thing about this is that if the customer ever needs more stencils or wants to switch to using propane, CNCROi.com can cut the design file again using other materials such as stainless steel using the same file.

I really enjoy making custom stencils at CNCROi.com, each customer has their own design that have their own areas of intrigue and I love hearing the feedback from them at how much branding they get accomplished cost-effectively using said products fabricated by us.

There is some smoke stains on the completed custom polycarb barrel stencil, you can see it along the edges, but this has no affect on the stencil and will be covered-up the first time this is used to brand barrel heads.

Need custom polycarb barrel stencils? Contact CNCROi.com right now!