Custom Polycarbonate Parts: CNC Routing 1/4″ or 6 mm

Custom polycarbonate parts are made by CNCROi.com using both our CNC router and CNC laser, the tool we use depends on the specs involved by the customer.

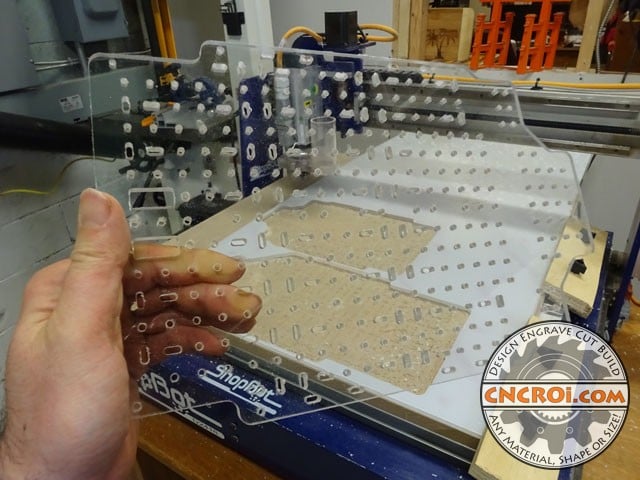

For this project, due to the thickness of the custom polycarbonate parts, which is quarter-inch or 6 mm, we had to use our ShopBot CNC router to produce the finished piece.

I really love CNC routering with my amazing Shopbot, I compare it to a manual car, where our Austrian wide-format industrial laser is an automatic one, there is so much more, in a different way, that you need to account for.

Whether you want custom furniture or parts of projects, CNCROi.com has you covered all the way!

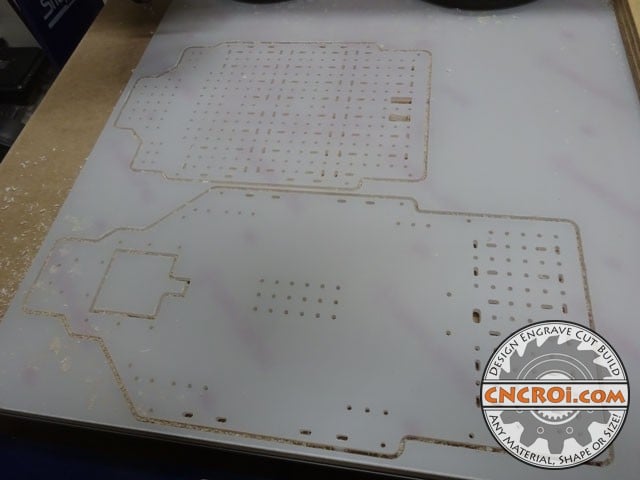

The polycarbonate we used for these custom parts was cut into smaller sheet forms and then fed through the CNC router until all the parts were produced.

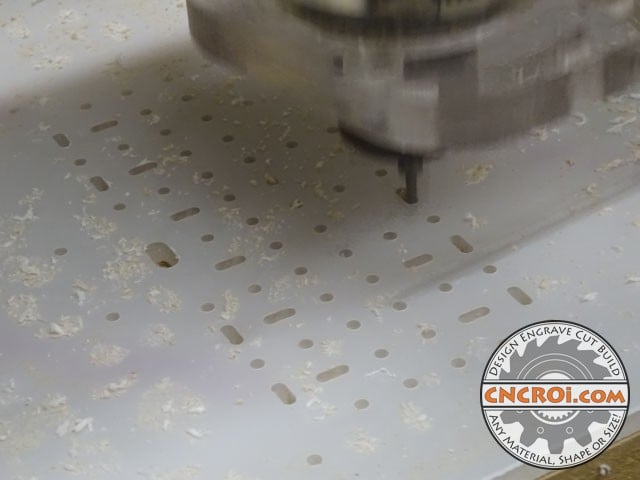

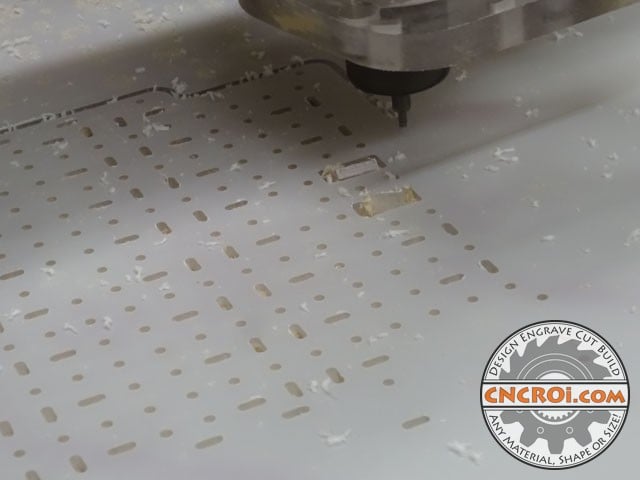

Where our Trotec laser cuts by burning, our ShopBot cut by milling, removing chips of material rather than vaporizing.

These custom polycarbonate parts are going to be incredibly tough, this is bullet proof glass and you have to be the incredible hulk to be able to break these.

This material, although thinner by half, it just as tough as Corian which CNCROi.com also makes lots of projects with using our CNC router.

Normally I run our extraction system on the head of our CNC router but for a good video and photograph for “this run of parts” I took it off, it just keeps the shop cleaner to have it on there rather than having chips flying all over the place.

Our Shopbot CNC router made a production run of these custom polycarbonate parts in a very accurate matter, there is no difference between our laser and router when it comes to precision.

CNCROi.com has extensive experience using our ShopBot CNC router, in this case it’s custom polycarbonate parts but I’ve literally made HUNDREDS of models using this amazing tool across a huge variety of materials.

I’ve been using CNCs for a very long time, it’s fun to look back at the stuff I was making YEARS ago from the other side of the planet, the above Sydney Harbor Bridge was made while I lived in Perth, Australia before moving back to North America to found CNCROi.com.

What I especially like about using our ShopBot CNC router when it comes to make parts is how much more is going on, you have an overhead gantry going up and down, different noises, stuff shooting out and so forth.

If you look at the video I made showcasing these custom polycarbonate parts being CNC routed, you’ll see that I blow off all that surface polycarbonate chip on a regular basis, just to double-check the quality of the production holes, to make sure they are all have sharp edges.

If you aren’t familiar with CNC routers, here’s a quick video I made showing you this amazing tool we have in our CNCROi.com shop.

And we can make big things with it too!

After years of designing products in the virtual world, it’s the ShopBot CNC router that allowed me to bring them into the real world before I acquired my own laser from Trotec.

For this project, we were just cutting out some custom polycarbonate parts but we could have made a whole model using this amazing material, it would be totally bulletproof.

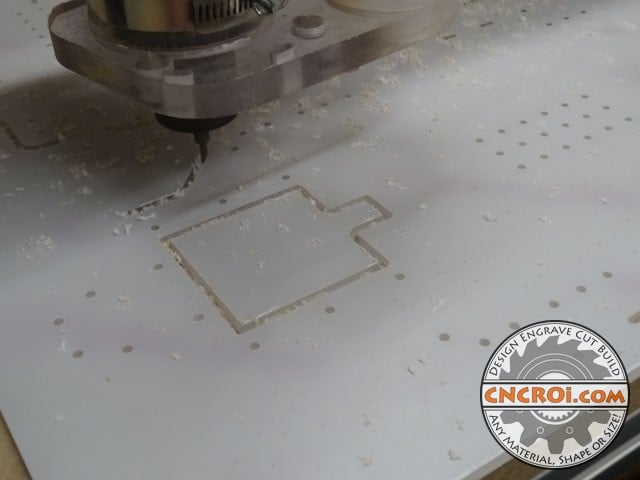

For this CNC router project, CNCROi.com just used a 1/8th straight double flute bit, it’s such a versatile bit for a huge variety of project, the above Mangonel was made using the same bit (though, that one wore out long ago).

Cutting parts requires hold down and tabs when it comes to CNC routing because there is pushing and pulling of parts while with our CNC laser, there is no contact BUT the heat generated during the cutting of the polycarbonate can cause warping.

As I tell people, there is no ONE machine that’s the best, each has a positive and negative aspect to it, the advantage of CNCROi.com is that we have a wide variety of machines to work from to pick the optimal one for the project at hand.

This CNC router may be a “little” machine but it can make amazingly big things, it’s full-on industrial in capability and CNCROi.com uses it as both a stand-alone and part of a cog for making lots of different items, most of which are never shared on this website due to NDAs.

This run of two parts is now complete, the custom polycarbonate parts have a mask on both sides, the polycarbonate is optically clear, we just leave the masking on to protect it from scratches though marks and other things always happen on polycarbonate.

We could have also made these parts out of PETG but that material isn’t as strong, again, like each machine type, each material also has a plus and negative to it.

Of course, another “clear” option though nowhere near as strong is acrylic.

After a quick clean-up, you can see how great these custom polycarbonate parts come out, totally see-through and accurate to spec.

The advantage of CNCROi.com is that we also have an industrial FIBER laser, in addition to a CO2, which means we can color change polycarbonate.

This is just another level of custom that allows us to make special identifications that are PERMANENT either on the front or reverse engraved on the back should the client want to further personalize their custom polycarbonate parts.

We’ve actually done this for projects before, check out these custom polycarbonate and Pine coasters with insert.

Here’s a close-up of what our CNC laser can produce, as the custom wedding coasters above was a thinner polycarbonate, it was better to laser cut them while the Pine was CNC routered.

We’ve also used the “scraps” of one tool to make art for another, Yoda has been in the background of a lot of videos since I made this and it’s a wonderful reminder as to my origins.

And reverse engraved, showing the shine and if you need something flush to clean often, that’s the choice you want for custom polycarbonate parts.

Of course, we also use polycarbonate for custom stencil production too!

If you need something made out of polycarbonate, contact CNCROi.com right now and we’ll make it for you to your spec in the volume you require.