Custom Pottery HDPE Embosser Mold

Making a custom pottery HDPE embosser mold requires quite a bit of tooling to achieve because no one machine is perfectly optimized for the design that this needed to be made with at CNCROi.com.

https://www.youtube.com/watch?v=PU7PEzwJ2Dw/

There are lots of material options when it comes to making custom molds, in this case, HDPE won, but it could have also been aluminium or acrylic as well.

I have quite a bit of HDPE in the shop currently, a few jobs came through the door and small parts as the one you see here are tough to throw away considering the cost of this material and the endless applications this could be used for and a custom pottery HDPE embosser mold was a perfect durometer fit to suit what the customer needed us to fabricate for them.

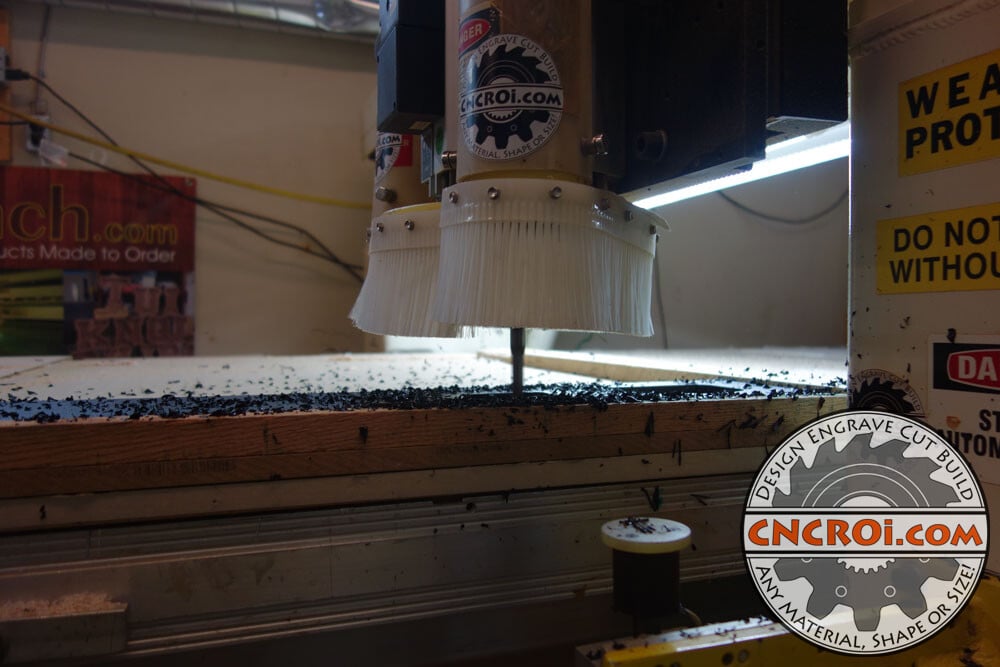

Due to filming and photography requirements, I decided to use a dust shroud that was a little short for this project, which means the static cling of the HDPE flakes got on EVERYTHING, but it makes for more interesting content than just a shroud that magically produces a finished result in secret.

HDPE cuts extremely well, but like all other plastics I’ve worked with over the years at CNCROi.com, there is a static charge to it after cutting that just gets on everything in the shop, and there was a lot of HDPE flakes produced while making this custom pottery HDPE embosser mold.

https://www.youtube.com/watch?v=fBhPZho7bcs/settings

If you remember this from a few blog posts back, the customer initially wanted to try this using the more cost-effective acrylic option but based on their feedback, something more hardy was required for their specific application.

The design for this custom pottery HDPE embosser mold had two challenges in it, the first, I had to produce the mold out of a plastic that required a flush surface, something that’s impossible with plastic of this type using a laser, yet I needed very fine details that just aren’t possible using a router… so I had to do a mix and match of processes between the router and the laser to produce it.

This isn’t the first nor will be the last time that I use the synergies of machines to produce the perfect final product, in this case, it was the router and laser, but I do this A LOT with the plasma cutting and fiber laser etching as well, and it works extremely well!

The router has XYZ feedback, which means, when I tell it to go 3/8″ deep, it goes 3/8″ deep, while the laser doesn’t have this vertical (Z) feedback system, it can’t due to the nature of that beast, as a result, I had to dig into this piece of HDPE at the thickness required by the customer then allow the laser to do the etching and cutting out to spec.

https://www.youtube.com/watch?v=BcJ1Ct6bETo/

HDPE has a variety of applications for CNCROi.com customers, it’s a good all around plastic, similar in this regard to acrylic and polycarbonate.

The biggest challenge when it comes to doing projects like this is alignment, both machines have the same tolerances built into them, but having an accurate reference point between the two machines is the tricky part, not just for me, but for customers we make custom jigs for as well at CNCROi.com.

You’ll notice that I have this HDPE piece on another sheet of MDF screwed down, that’s because long flexible pieces like this are hard to hold down properly using only vacuum and thus, screws work great, but I didn’t want to mark-up my sacrificial router table with screw holes, so using the vacuum to hold the sheet in place that I then use to screw things into place works great.

The production of this custom pottery HDPE embosser mold is a relatively quick process due to the industrial machinery I have at CNCROi.com, it’s like using a gun at a fist fight, the mold itself is roughly 6″ square (the customer needs not only the mold you see but the outside part too), and the table on my router is 5ft x 10ft!

We have a lot of experience with custom mold production, big or small, we do them all.

After the laser has done it’s initial pocketing into the HDPE material, the next step is to use a carving bit to add the extra bevels on the inside and also give me a shallower trench for the laser to cut this mold from.

Again, sticky HDPE chips flying everywhere for better content for you the reader.

You’ll of course see machining marks on the surface of this custom pottery HDPE embosser mold, they don’t matter, it’s just various levels of polishing achieved when the bit is doing its work, no different than the patterns you see when mowing your lawn, the lawn is all the same cut height, it’s just the way the light reacts to the angle of the blades, or in this case, HDPE surface.

Job like this, which require multiple bits to achieve the finished result, are really amazing to me, haven used a router without a tool changer for more than a decade, moving to this was amazing as I don’t have to manually reposition bits, which slows things down so much and creates a possibility of errors as well.

Another option for this specific custom mold production would actually have been Corian, the downside to this though is that if it falls, it shatters and breaks quite easily under heavy pressure, HDPE has a bit more give with less hardness to it.

The custom pottery HDPE embosser mold is now pretty much done regarding the routering, I just have to cut it out and move this to the laser, as you can see, lots of HDPE chips all over the place and some of them came home with me, are in the car etc… they get EVERYWHERE.

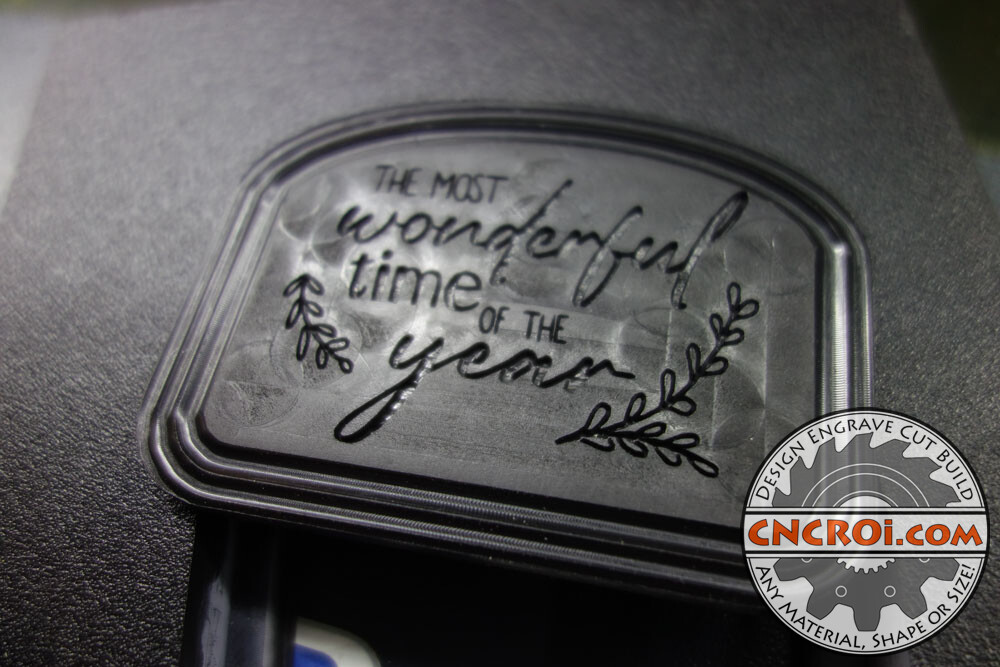

After a quick clean-up of the custom pottery HDPE embosser mold, you can better see the mold taking shape, now it’s time to go ahead and engrave the inside with the details the customer requires.

The diameter of the engraving with a laser is infinitely smaller than that of a bit, so a few passes on this HDPE produced the depth the customer required, again, no two way feedback system for height (or depth), as a result, this must be done by eye and digital calipers.

The nice thing about laser engraving is that it’s a non-contact method of production, unlike the router that’s pushing and pulling a spinning bit through the material, the laser has none of that, it never touches the work piece under the head.

https://vimeo.com/manage/videos/189660662

Acrylic is a great option for molds as well, most of the pottery molds / embossers we make are actually made using this material.

You can now see the finished custom pottery HDPE embosser mold, shop lighting is really not the best and it’s doing some weird things on these photos but everything is perfect.

This custom pottery HDPE embosser mold will be used to make a mold that will then be used to make an embosser by the customer for their pottery projects.

Need a custom mold? Contact CNCROi.com right now!