Custom Resin Inlays: CNC Routered Black Walnut

Custom resin inlays can be CNC routered out of any material, in this case, we did two examples in Black Walnut serving boards.

https://www.youtube.com/watch?v=yaAAkwLWOXw/

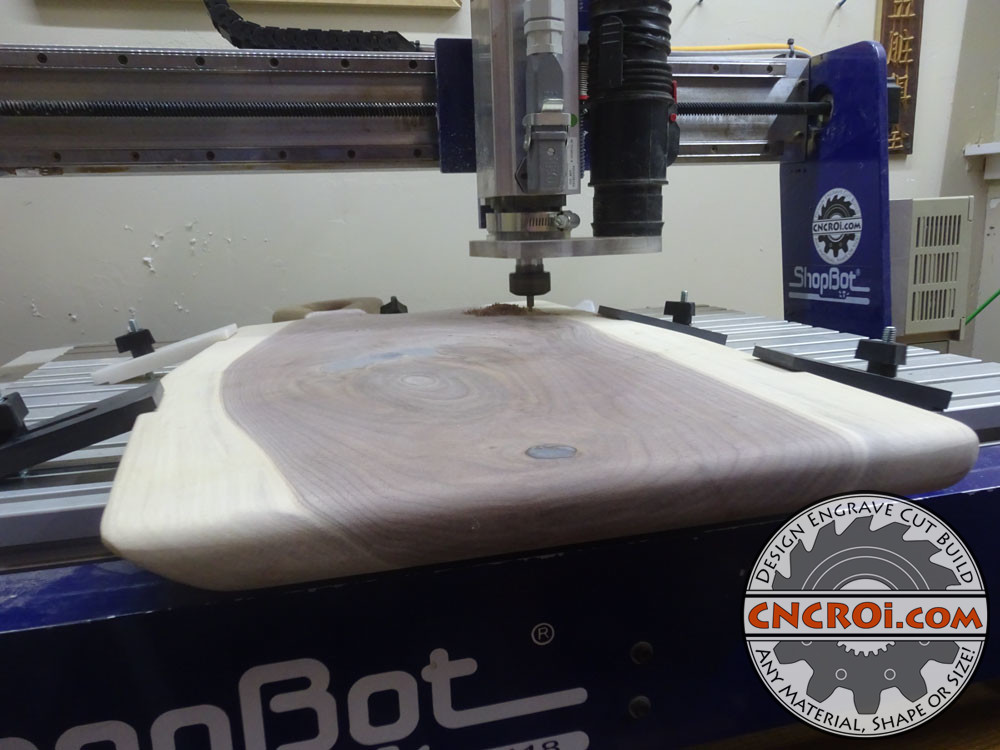

CNCROi.com has two CNC routers, a little ShopBot Desktop and a larger ShopBot PRSAlpha full sheet machine so your sizing options for custom resin inlays are infinite size wise.

When it comes to design options for custom resin inlays, they are infinite, CNCROi.com also has a laser that can perform similar duties though as I discuss in the video, it does have drawbacks.

Of course, the resolution of the inlays can vary depending on the design but the smallest bit we’d use with our CNC router for this purpose would be 3 mm or 1/8″ in diameter, so that’s your smallest level of visible detail achievable for custom resin inlays.

Of course, larger boards are done using CNCROi.com‘s bigger machine, and yes, you can use paint and other products for the inlay, you are not limited to epoxy resin.

https://www.youtube.com/watch?v=SZbDwgCE8iw/

The major advantage of CNC routering out details into wood, in this case a quarter inch or 6 mm deep in the black walnut live edge, is that grain density doesn’t play a factor for depth, unlike the laser which would follow the grain pattern to determine depth.

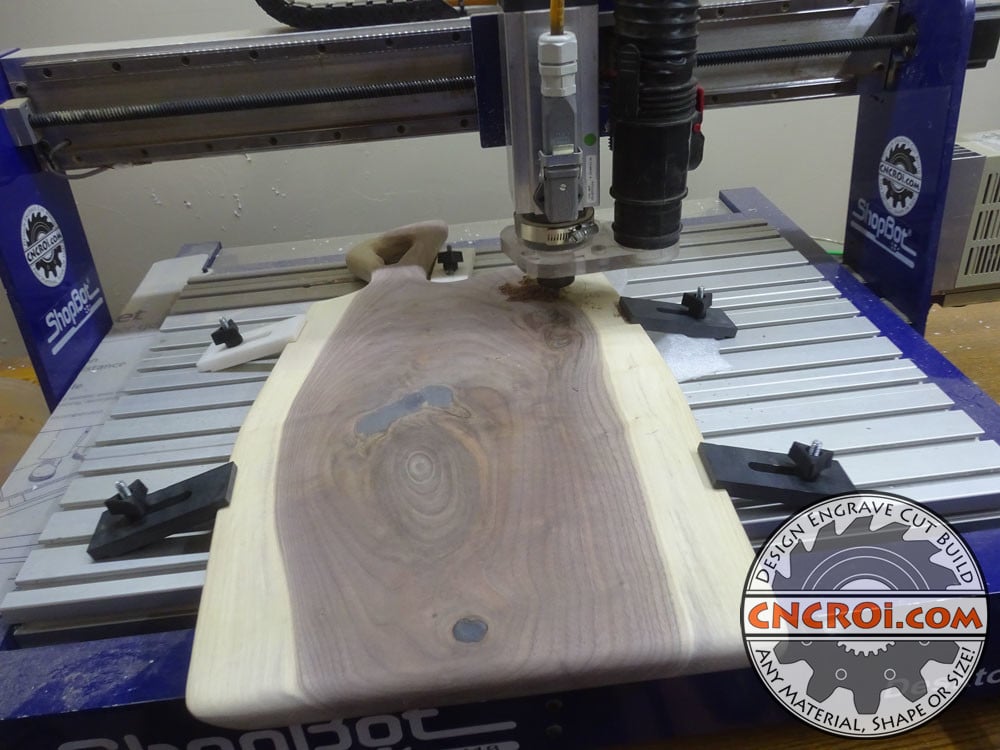

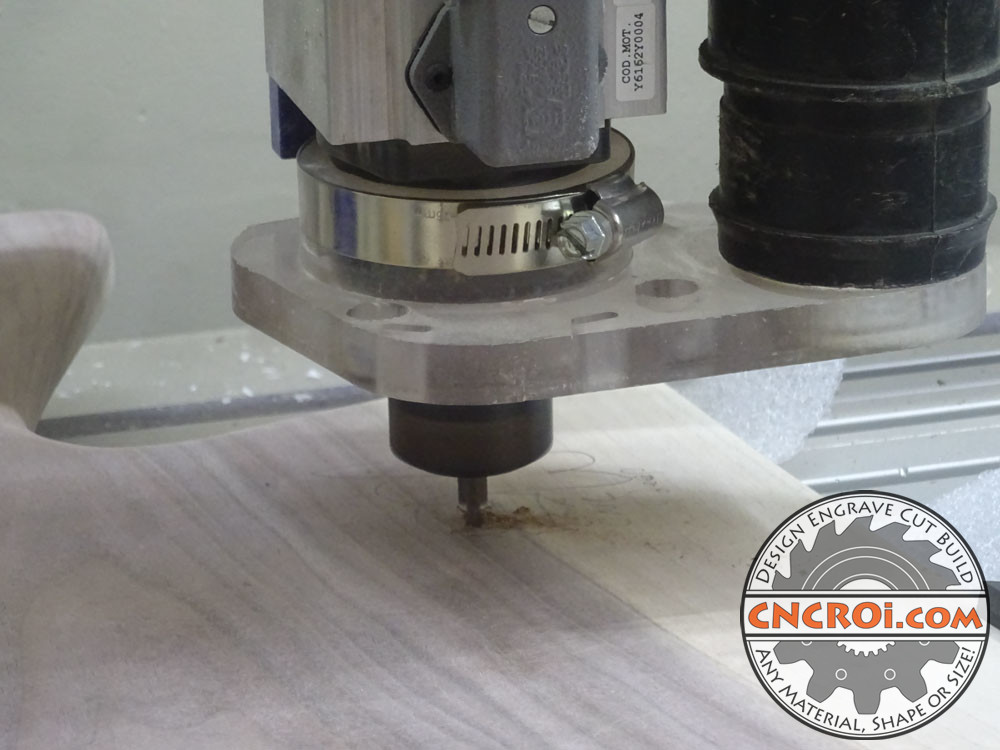

CNCROi.com typically does this type of work using a dust boot but for video sake, I just took it off, the results look a little messier but it beats looking at a video of just a dust boot moving around on a wooden board.

The drawback to using our CNC laser for this type of work is that some additional processing is required as well, sanding of the surface, though a bit of that needs to be performed in the inlay as well due to the smoke for the laser settling on the surface or burrs on the router in the inlay itself.

You can also customize the wood and species to have the design you want, the nice thing about having more than one machine at CNCROi.com, we can produce different results to your desire.

https://www.youtube.com/watch?v=RVIYUnOMUyE/

If you look at this black walnut board, you can already see that it was epoxy filled right above the knot in the middle of the board, so it gives you an idea of how smooth it looks once dried and cured.

The major advantage of custom resin inlays is that you can literally have any color or mix of colors you want on the board itself, you are not limited to only paints but real hard surface alternatives which you can literally eat on that don’t weaken the board.

The little pieces of wood you see forming around the bit in these pictures and video are the material being removed from the board, again, generally that’s picked-up by the vacuum system when we have a boot on it so it never has a chance to build-up like you see here.

Just to give you an idea, CNCROi.com can also work with producing inlays in solid surface materials.

https://www.youtube.com/watch?v=jb-rQCDsIwM/

Due to the limitations with the bit diameter, you want an image that’s relatively large, yes, CNCROi.com can make a custom resin inlay that’s far smaller using a smaller bit but it likes to break as well due to the forces involved.

Unlike our CNC laser, the CNC router is actively putting forces into the wood to cut it, that’s why you see the four point hold-down to make sure the board doesn’t move during production.

That being said, the results still look spectacular after CNC routered out the custom resin inlays for these set of boards.

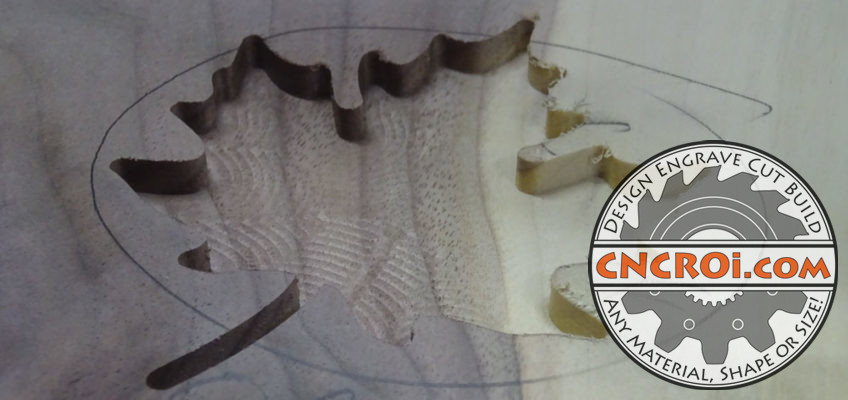

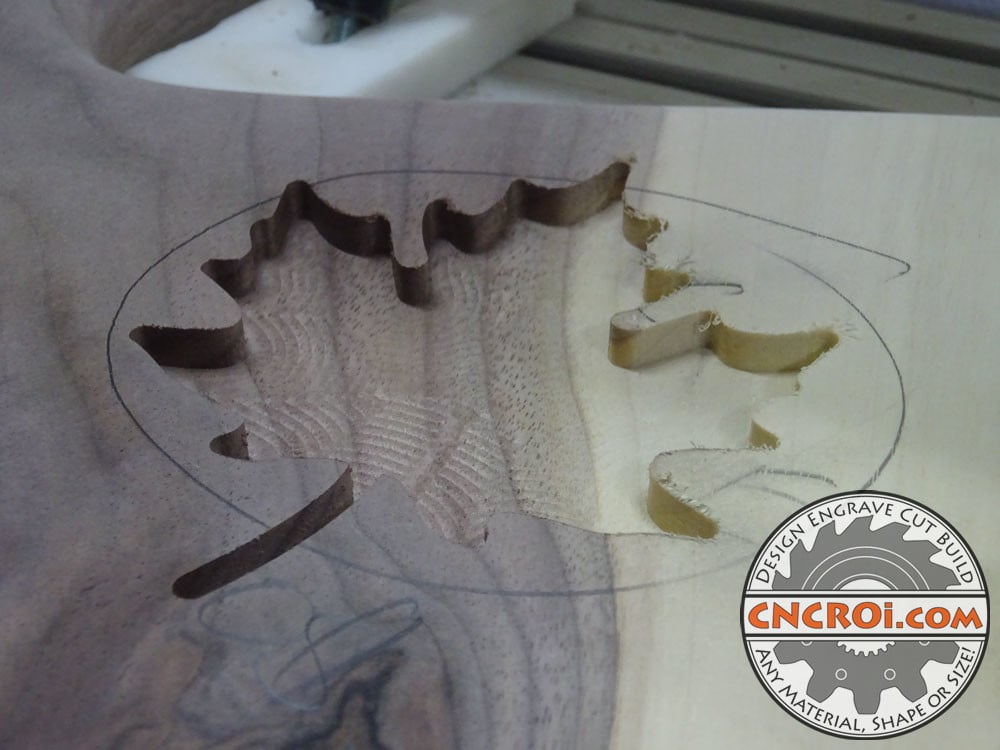

Here’s the maple leaf in another angle, next up for the custom resin inlays, we’ll do a four leaf clover, same bit, same settings, different board to be filled by the CNCROi.com customer.

Although not filled, the nice thing about CNCROi.com‘s laser is that we can just as easily produce contrast using nothing but charcoal and you could then put a clear epoxy resin over it if you wished.

https://www.youtube.com/watch?v=3b4Ok4mzSc4/

The process is the same, input the design, create the tool paths and then start the CNC routering process to create the custom resin inlay of the four leaf clover, same depth too as the maple leaf.

The four leaf clover carved out of the black walnut is as easy an epoxy fill as the maple leaf or any other design, a quarter inch 6 mm depth is plenty to then run the board through a planner and sand it flush with the rest of the wood.

If you also wanted to just use sawdust and glue to fill the board back up again for a non-epoxy resin result with only a little dye, that would work fine.

Solid surface material has incredible durability, it’s great for a huge number of applications.

https://www.youtube.com/watch?v=lzScZjA4v1I/

For boards that are larger or require more extensive work, CNCROi.com also has a full sheet 5 x 10 CNC router which can do the same work as this smaller machine, just the set-up is a bit more extensive which is why I used the small machine instead.

When the dust boot is on the machine, the process takes the same amount of time so there isn’t any difference production wise for these custom resin inlays.

We are not limited to small items, we can also make furniture pieces to your spec.

https://www.youtube.com/watch?v=5ub-mIc9MH8/

CNCROi.com has over a decade of experience designing and fabricating items using CNC machines, whether it’s laser, router, plasma or waterjet – we have the equipment to make amazing work in short order and ship it right to your door.

Whether you want an elephant, a whale or any other shape carved out of anything (resin works with other materials too), CNCROi.com can make them just as easily with the same or deeper depth.

The small pieces of wood you see in the above image are just chips that break when the carving bits get too thin, not an issue as you saw from the images of the flat bottom surface.

Need custom resin inlays? Contact CNCROi.com right now!

Need custom resin inlays? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=gBCN5tmn8bg/