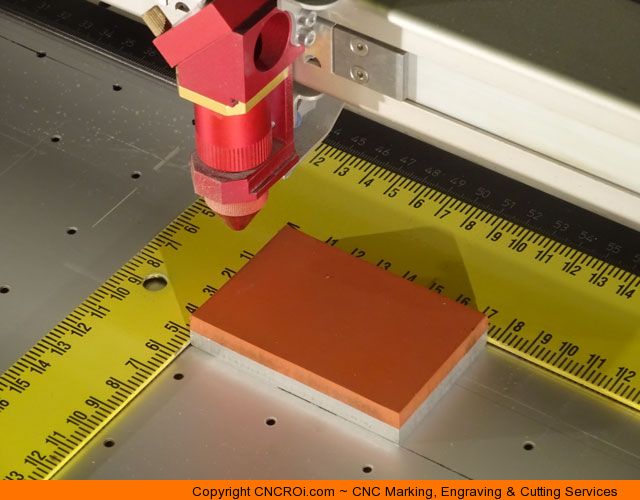

Custom Rubber & Aluminium Hot Stamp Mold

Do you have a need to regularly feed your consumer or industrial grade hot stamping machine custom rubber and aluminum molds? CNCROi.com is your custom supplier with quick turnaround and top quality service regardless of size or durometer.

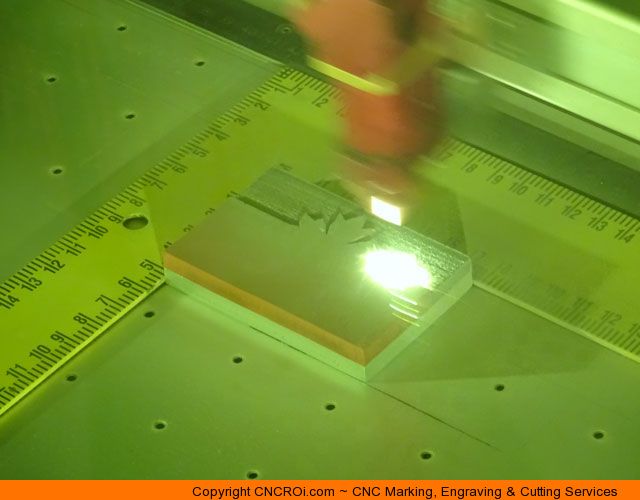

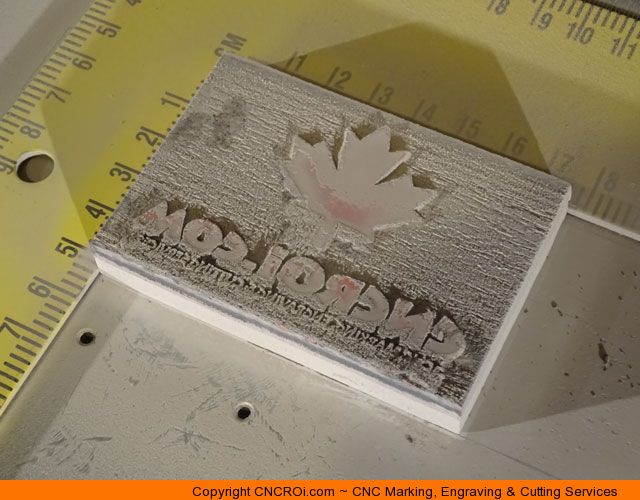

The process behind custom engraving a hot stamp mold is the same as regular stamps except the durometer is far higher, which means we need more power to vaporize a design into the dramatically harder rubber. More material density means more power to achieve similar depth.

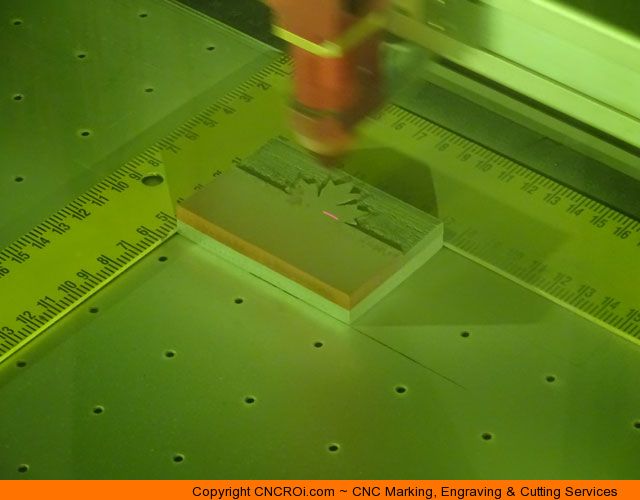

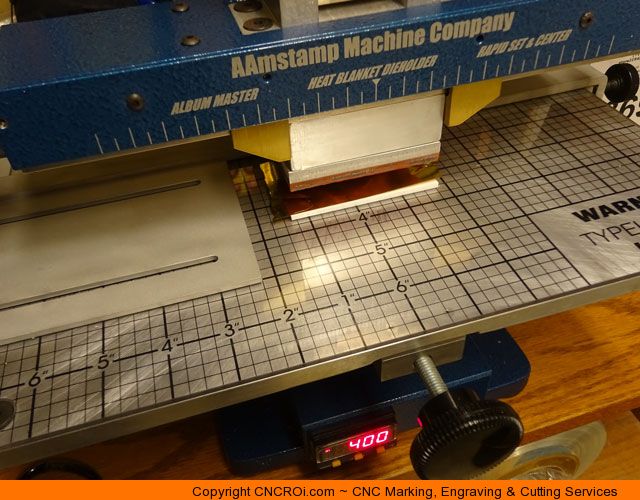

The reason these stamps are harder (more dense) with an aluminium backing compared to regular stamp molds is due to the fact that this needs to LAST, harder material lasts longer than softer and it needs to hold heat. Hot foil stamping is a heat and pressure method of marking plastics and other materials, this means it needs to last a long time under strenuous circumstances that would break down “normal” rubber stamps.

The “traditional” method of making these hot foil stamps is a very labor intensive process involving heating these up with a metal formed stamp or hand making them depending on the complexity and size. I’ve also personally seen customers hand carve these in their shop, something I can’t imagine doing day in and out with such a loss of accuracy and precision. It’s truly an artistic trade when properly done!

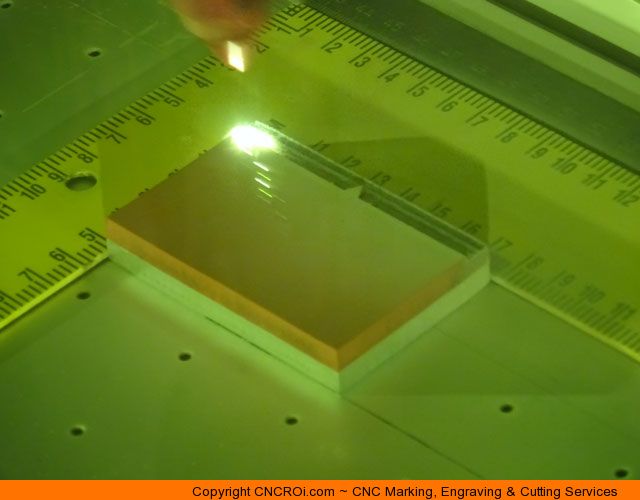

For CNCROi.com, we use a digital file and directly work off the raw stamp, cutting it to size then engraving away the details with up to 600 dpi resolution (depending on the density of the rubber and depth). The shoulder is consistent and available in a variety of depths and drop-offs. These can be used with foil or melting into the material the customer wishes to have custom branded.

Our method is also very cost effective, you have incredible flexibility as per materials (these are available in a variety of durometers, thicknesses and shapes) and repeatability for multiple machines that simply cannot be matched using any other method of production. Throw-in the fact that our general turnaround time for hot rubber stamping molds is 24 hours, not weeks, and you really have a winning combination using CNCROi.com as your custom mold provider.

The process of CNC laser engraving a hot stamp rubber mold is a messy one with a laser but thankfully, our industrial Austrian machine is more than capable. Our machine comes from the stamping would as the parent company of the manufacturer of our laser, Trotec Laser, is Trodat. Trodat is the world’s largest stamp manufacturer in the world and built Trotecs, of which we have one, focused entirely on making the BEST stamp producing machine on the planet.

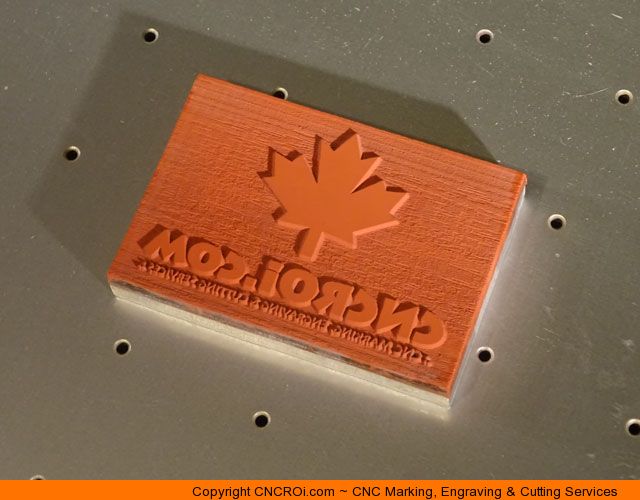

After cleaning-up the custom laser engraved rubber hot press mold, the results are nice and orange through brown depending on the durometer of the material this is made from. You couldn’t tell the difference between this and the traditional method except for a higher and more precise resolution with incredible repeatability.

There you go, a custom rubber hot stamp ready for production. Have a need for a custom stamp for your hot foil machine(s)? Contact CNCROi.com today!