Custom Rubber Stamp Making 101

I often get asked what makes a perfect custom rubber stamp? Well, here’s my advice after designing a whole bunch of custom rubber stamps both for the Trodat range and those for more specialized applications.

Don’t overfill the stamping area

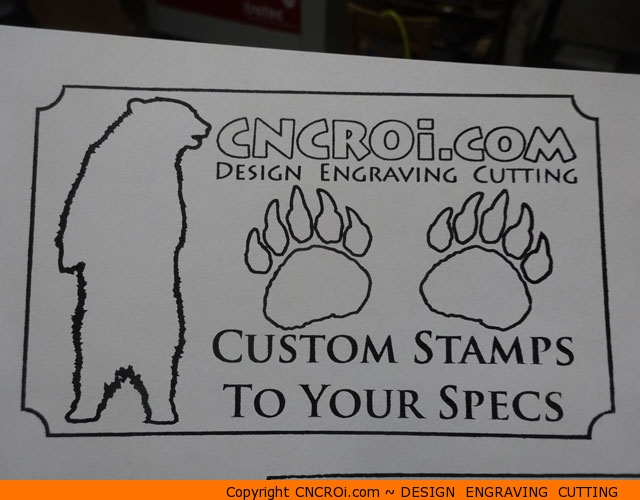

This custom rubber stamp below is WAY TOO BUSY, the results still look respectable but what I’ve found is that generally, less is more when it comes to custom rubber stamp production and the results achieved during imprinting. Having lots of details and fine graphics and text might look like you are getting value – you aren’t.

Custom rubber stamp production is the same “speed” whether you have a stamp full of stuff or with nothing in it, so the cost of either extreme in raw materials, laser time is exactly the same! If you have too much information and not a large enough surface area on your current stamp, upgrade to a bigger stamping area!

The goal of a stamp imprint is quick and easy messaging, like an address, stock number or corporate information, not to replace your inkjet printer.

Rubber stamps aren’t good for every stamping application

Rubber stamps are great, they produce amazing results on the right media but sometimes, you are better off using other technology as what might be optimal for one application isn’t necessarily so for another. For example, there is a reason why we make custom welding tags instead of stamps for welders who want to showcase their product.

The key factors you need to look at are

- Volume – the higher the repeatability of a “task”, the more stamping makes sense.

- Clarity – you have a short and brief message that needs to be “told” in a non-permanent fashion.

- Speed and durability – not all rubber is made the same, there is a wide range of durometers (hardness) and not all stamping mechanisms work well either in certain environments.

The goal of a custom rubber stamp is to make your job easier, not add additional hurdles to it.

Go BIGGER and STRONGER than you currently need

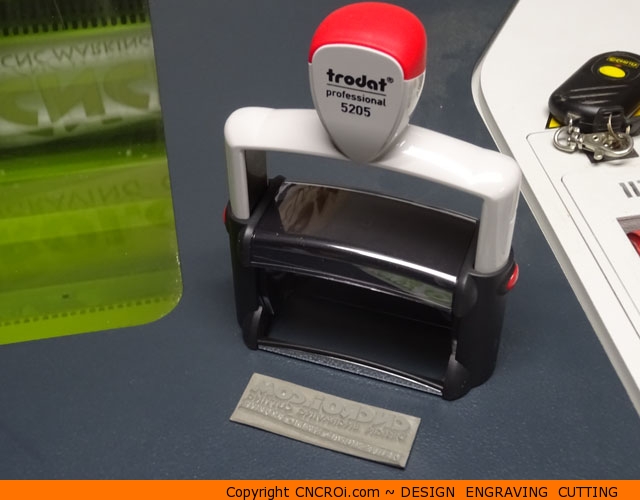

Although the Printy line from Trodat stamps is great, being all plastic and about half the price of their “Professional” – I still tell customers to go Professional even if their custom rubber stamping application isn’t heavy duty repetitive. I also tell them to go with a larger stamping surface than they really need as well. Why?

Well, if you want ultimate durability, go with the best in the market. It goes without saying that the quality of a steel frame is above and beyond anything you’ll get out of just plastic and as your needs change, so might your stamping requirements. Maybe right now, you stamp your address on an envelope once a day but maybe a few weeks or months down the line, this increases dramatically. It will save you money and time to just go with the stronger stamping mechanism right off the bat than to upgrade.

As for stamping surface, you OWN the stamp we send to you, go with something bigger as we can always make a smaller stamp but not a bigger one than the surface will allow. The cost differences are negligable so save yourself money, the environment and time and go PROFESSIONAL.

Older stamping mechanisms are still good!

Do you currently have an older stamping mechanism that’s working fine, you have plenty of ink already AND only the rubber has worn out? Well, instead of replacing the entire thing to get a new stamp, we can just make the rubber stamp for you and you can take the old one off and put the new one on!

This can apply to self-inking stamps, roller stamps or just about any rubber stamp out there. CNCROi.com works off raw rubber sheets, this means that we make the rubber part of a stamp on-demand, design through production, so you don’t HAVE TO buy a Trodat stamping mechanism from us if what you have right now works fine.

Not all rubber is good for stamps!

Did you get an amazing deal on the last rubber stamp you bought? Guess what, it probably comes from a third world country where the quality aspects of the rubber making it up just aren’t meant to last. Trodat’s range is good for thousands of impressions PER INK PAD (design depending), if you are stamping sand paper, of course the rubber will wear out faster but for most paper applications, the rubber stamp we make for you will last an incredibly high number of impressions.

Top quality rubber directly from Trodat’s factory is what we use. Top quality CNC laser developed by Trodat is what we use. Trodat, the world’s larger stamp manufacturer has our back from mechanism through materials.This is why you aren’t “stuck’ to using black ink when you order custom stamps from us because we get everything directly from the factory to your spec through our shop.

We also have a wide range of additional rubbers from reputable manufacturers for more specialized applications across a whole host of durometers.

Stamps are FUN

There are so many applications for custom rubber stamps out there, from art and crafts to corporate, weddings to mailing and just when I thought I saw it all, a customer approaches us with yet another application that I hadn’t thought of. There is a lot of really neat rubber stamp art out there, it can be done at any scale and only when you look up close do you notice that it was stamped instead of painted.

Something I really enjoy are little custom rubber stamps at the moment, like Trodat Mobile Printy range. It’s easy to carry in your pockets, takes minimal room in a brief case and is self-inking to boot! I’ll have a video of this shortly online.

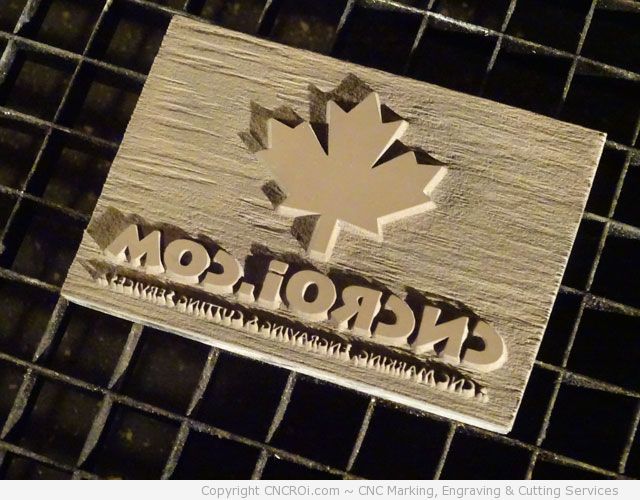

Optimal Rubber Stamp Designing

I’ve found that, thanks to the incredible resolution we achieve in our production process – which is a thousand DPI on specialized rubber – very fine lines come out fantastic when inked properly. Very fine details are achievable so you aren’t stuck to the traditional BLOCKY text you saw from eons past. The inks have improved dramatically, production methods are light years ahead AND designing options are now pretty much infinite.

This is why I find it more efficient to manually design a custom rubber stamp than to use an automated online design system for our customers. You have a job to do, if you are creative, send us the right file formats we need, but if you don’t have the skills and tools to make as stamp, expecting you to learn through trial and error is a bit of a waste considering we can turn something around faster than it takes you to learn whole new software to accomplish the same goal.

For instance, notice the “R” in “your specs” with a very fine border of “no ink” around it, this would have been impossible a few years ago, now we do this kind of precise work day in an out!

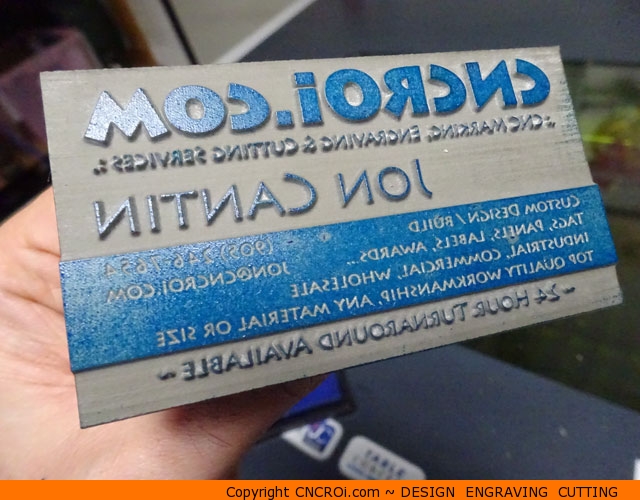

Custom rubber stamp don’t have to always stick out!

Although a bit more challenging design wise, you can totally have elements that both stand out and stand in on the same stamp. The design of a custom rubber stamp is as vast as your imagination, so making solid areas with inner “holes” isn’t an issue for us. You do want to keep a few things in mind though if you wish to have elements such as the solid band found in the custom stamp below.

- Make the elements thicker than you need, ink tends to build-up inside very small empty spaces.

- Don’t overuse surface area, remember that there is a very fine line when it comes to ink adhesion, the more surface area, the higher the chances of an uneven imprint.

- Don’t be afraid to test things out (or have us do it for you), we certainly don’t know everything about stamps and designing for them nor will we ever so testing for specific applications is often a requirement right off the bat.

Ask Questions!

CNCROi.com is here to help you with all your custom rubber stamp needs – if you have a question, please ask!