Custom Shapes & Designs: CNC Lasering MDF

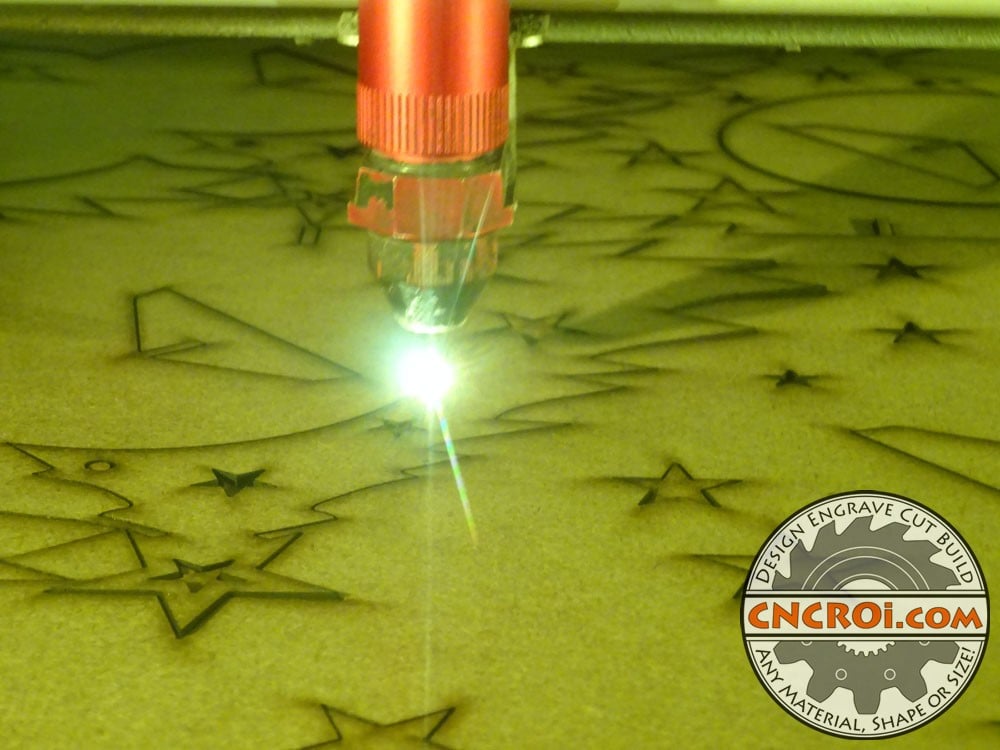

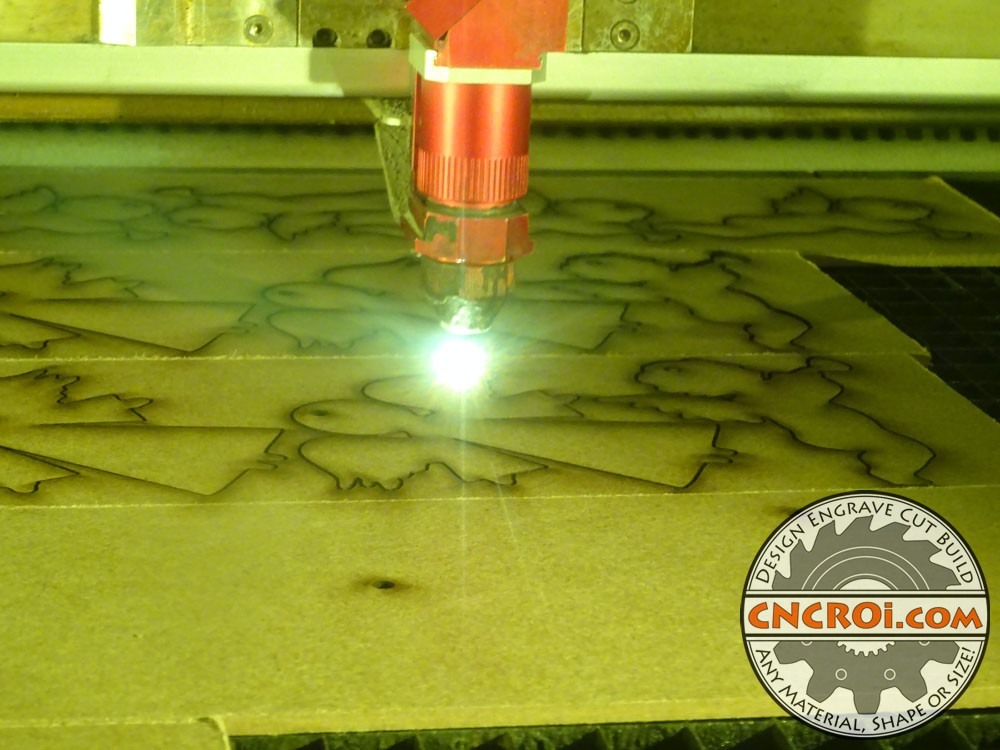

Custom shapes and designs can be cut using a variety of machines at CNCROi.com but the most popular by far is our CNC laser cutting MDF shapes.

https://www.youtube.com/watch?v=GkmbLBJAAB0/

The advantage our laser provides when cutting out custom shapes over our CNC router is that there is little mess, it basically comes off the machine and right into the package to be delivered right to your door.

Our Austrian wide-format industrial laser is great for a variety of custom shapes but sometimes our customers require us to use material that’s actually more optimal to CNC routering or waterjet cutting, things like metal, Formica or thicker / harder material.

Our CNC router is great for Formica applications while waterjet cutting is great for metal!

Having access to a variety of equipment and materials allows for great flexibility but MDF and laser is more often than not, the most cost-effective solution as waterjet + MDF makes sand infused mud while making small shapes with our CNC router requires quite a bit of set-up by comparison.

Having a variety of laser sources also allows CNCROi.com to make some pretty neat permanent branding on a wide variety of materials too!

When I first started CNCROi.com, it was laser all day everyday, but as we’ve diversified in technology and capabilities, this has allowed us to take-on custom shapes projects that otherwise just wouldn’t be possible any other way.

CNCROi.com has extensive experience designing and fabricating custom shapes, whether you want a simple 3D shape like the stand-up Christmas ornament holder below…

… or something a bit more complex like steamboat, CNCROi.com can help turn it into reality!

It’s pretty incredible what can be made using a simple material like MDF for our customers, it’s a material that paints incredibly well, is relatively cheap to acquire and cutting is a breeze as well as sanding, if needed.

A while back, I also developed a section on CNCROi.com focused on showing idea of custom shapes we can cut for you using any material, you can see that still today under the “Buy Online” heading on the top navigational bar.

Whether you want custom shapes in the “shape” of animals, plants, store fixtures, logos, events or what-have-you, CNCROi.com can cut it out in any shape, size or material.

What’s really nice about being diversified in our capabilities is that we can cut the same shapes out of different materials to match certain price points and retail averages.

So if you want something cut out of acrylic, polycarbonate, wood (name your species), Formica, solid surface material like Corian or just regular MDF, CNCROi.com can do it!

Your creativity isn’t limited to stock material either, we can cut out the shapes from cereal and pizza boxes too if you want color but not paint on your custom shapes.

Of course, painting does bring things to a whole new level when it does come to presenting custom shapes.

So there are endless possibilities with my company when it comes to making what you want for whatever application you may have in an orderly and passionate time frame.

If you are curious as to what the effects of the same 1/8″ or 3 mm MDF above can produce, here’s a family monogram that’s just glued together after being painted two different colors.

Mixing and matching different MDF options and putting them together produces amazing results, if you aren’t sure what you really want or how to go about having it made, no problem, we’ve got DECADES of experience in the custom fabrication world at your service!

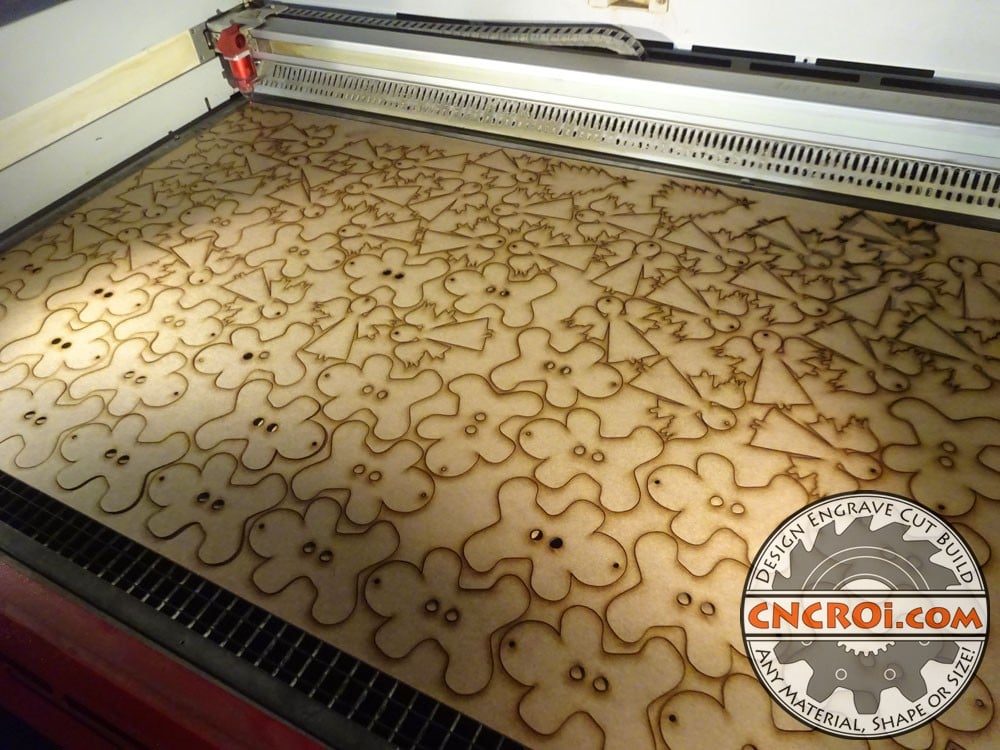

One common question I do get when it comes to custom shape production is does using scrap save you money?

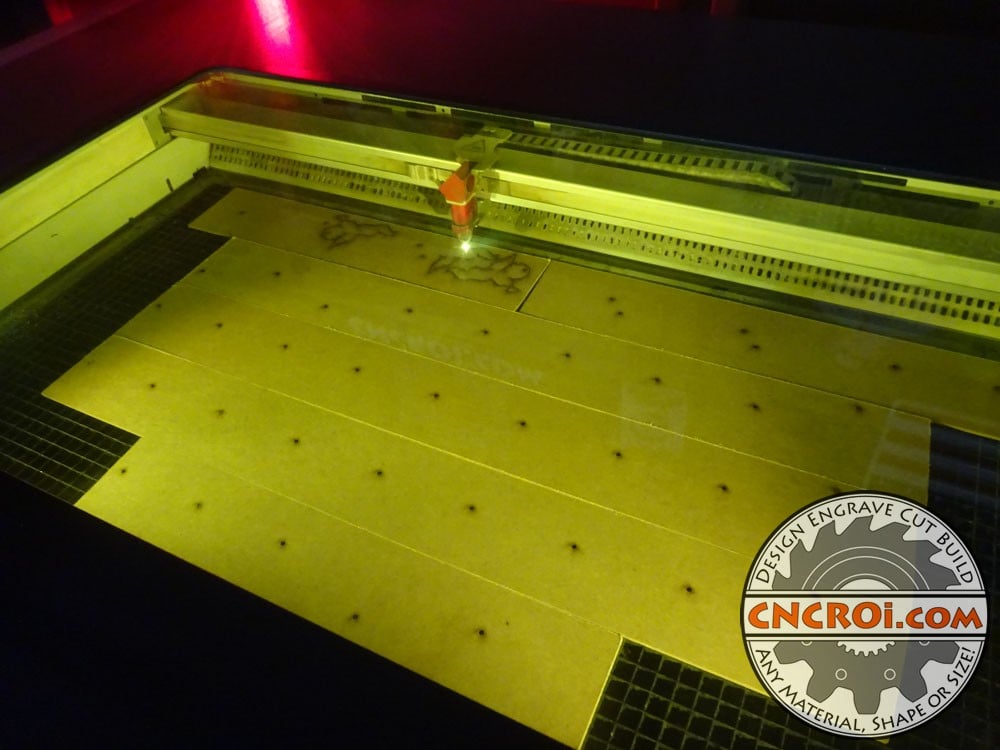

The answer isn’t actually as straight forward as you may think because of when we use scrap, CNCROi.com is limited as to the nesting options, so technically, yes, the material is paid for already but we are also producing a lot less for the given material and it isn’t an efficient production process neither.

Compare the use of material in the MDF wooden gears video below to the one being made in the picture above, notice how much more material is wasted in the above over the one below, now, that’s relative because we are using material that otherwise would have been burned in a warm camp fire.

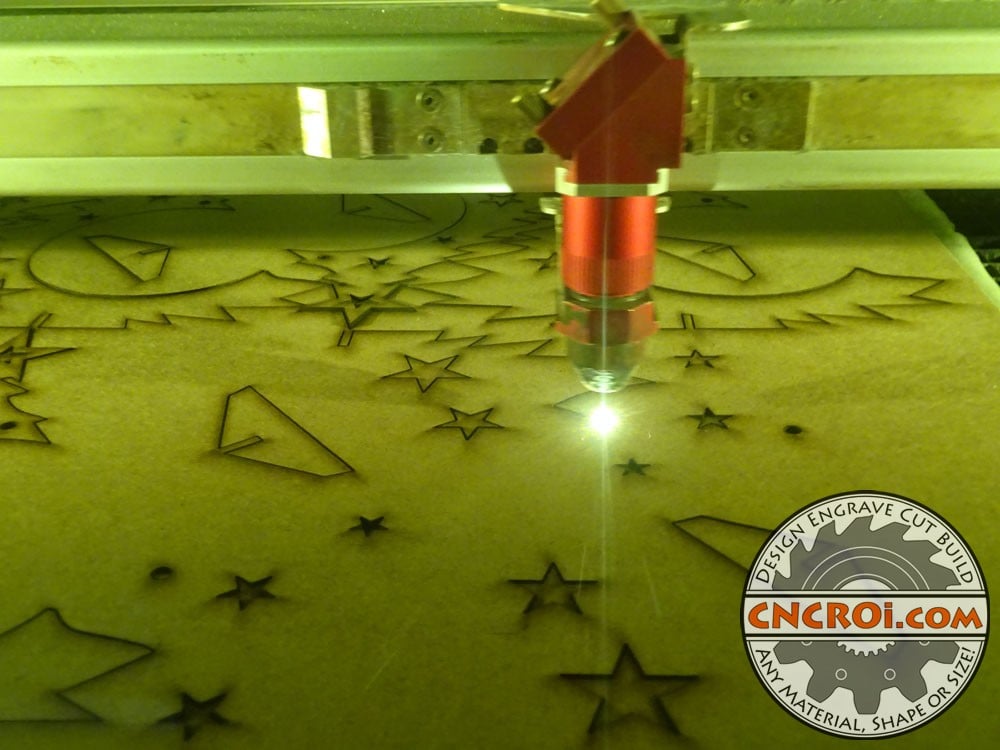

Nesting custom shapes means rotating, sizing and placing them on a sheet of material to cut the most out of the least amount of material, so by definition, using a full sheet is very efficient but using small sheets to spread out production isn’t.

Each machine produces differing levels of waste, when it comes to tight nesting of parts across a full sheet of material, nothing comes close to what our laser can do, then it’s a dead-heat between waterjet and CNC router cutting because each cut in a different way with their own quirks.

When it comes to custom shape production, I know I’m getting a bit into the weeds so don’t worry about much of this more inside baseball knowledge, generally our customers just leave it up to us to figure-out the best fabrication techniques for their project then we proceed from there.

As there is no force up, down or side-to-side with laser cutting, it allows for incredible part cutting precision and optimization on materials, a CNC router has the most force as it’s pushing a spinning bit through material while a waterjet has forces acting under the material as the water circulates up and down behind the material being cut.

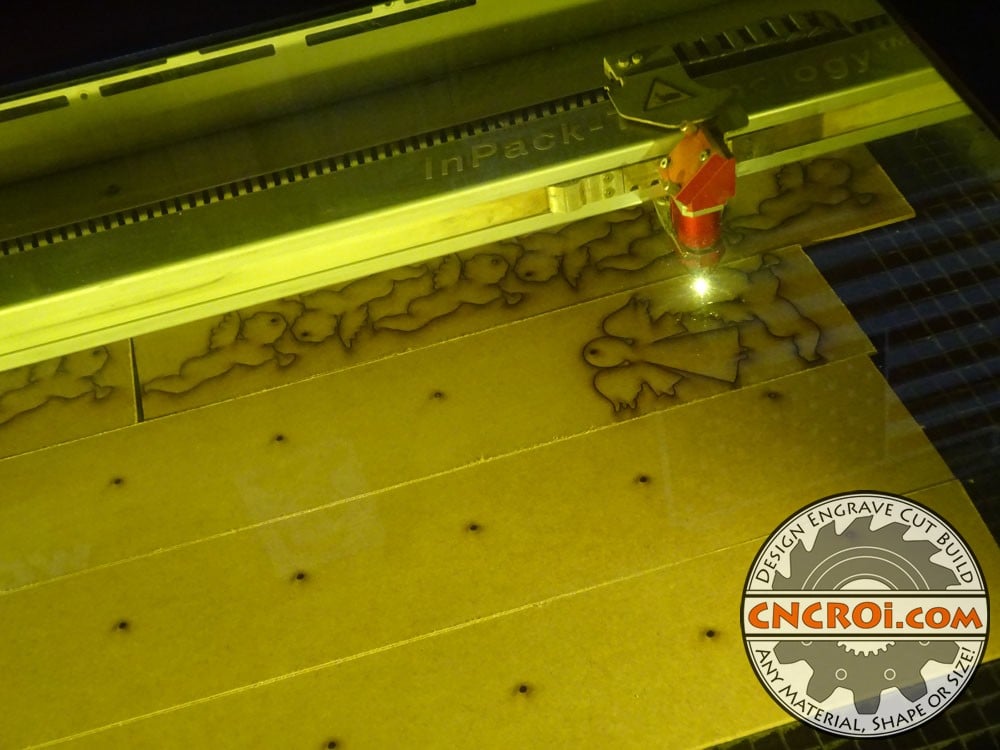

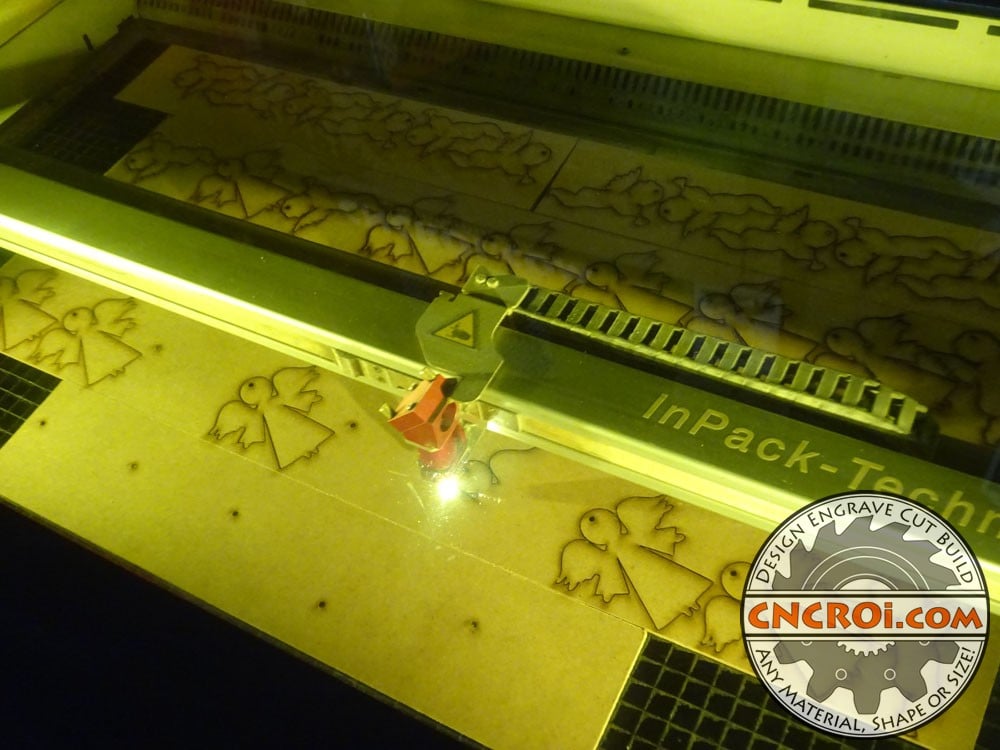

If you are wondering what heaven looks like, you can see it in all it’s custom shapes glory in the image below!

The angel shapes are all identical, the precision of our CNC laser is 5 nanometers which is basically perfect in every way, shape and form!

The custom shape options we provide you are endless, whether you want to send us a sketch you made yourself which we digitize, have something you want us to trace or there is a photograph of something you made that you’d like us to use as reference to make more of… we’ve done it all!

Need custom shapes? Contact CNCROi.com right now!