Custom Slot Lamps: CNC Laser Cutting Plywood

Custom slot lamps are easy to make out of plywood if you have the machine that can cut this material in one pass

I’ve designed hundreds of custom models in my past life at CNCKing.com and to test them all out, I used 1/4″ or 6 mm plywood.

So it was fun to go back to my roots for this customer that wanted custom slot lamps for their restaurant, of course, I asked them to provide the profile to make it really “their lamp” from which I designed a 3D model for approval before going into actual production.

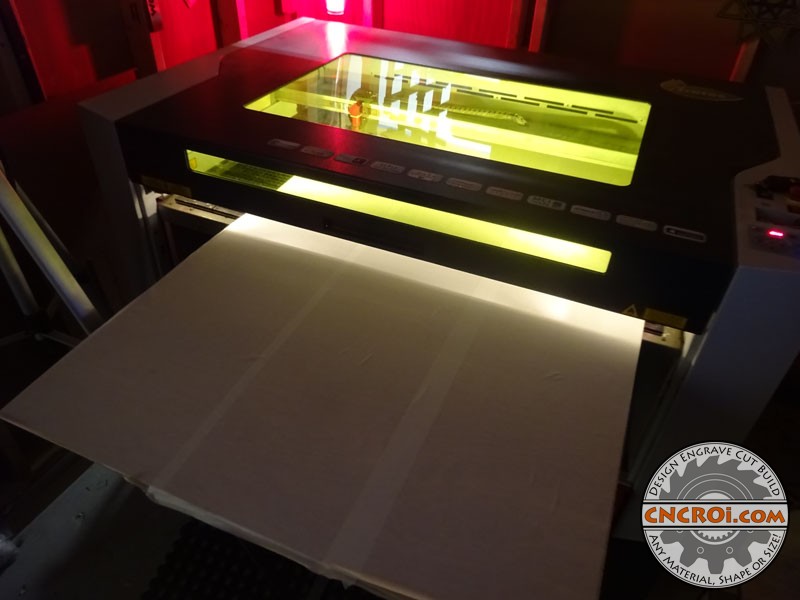

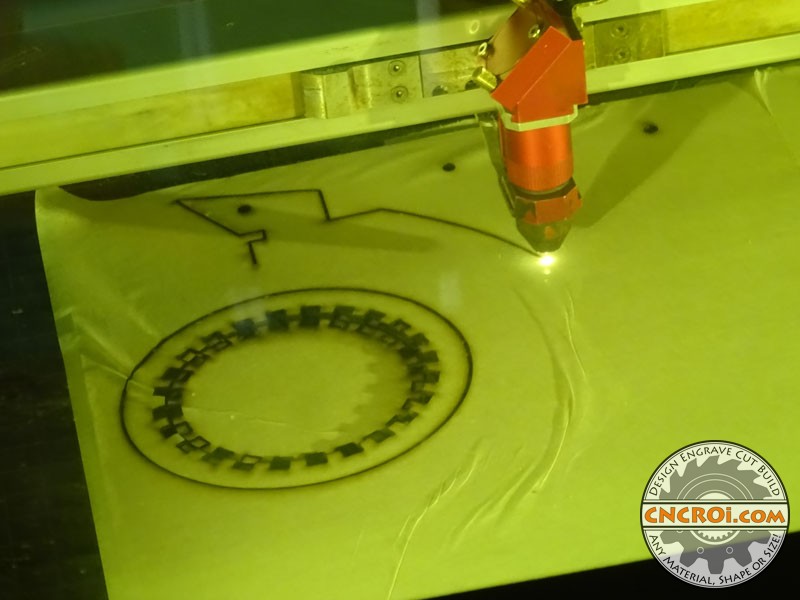

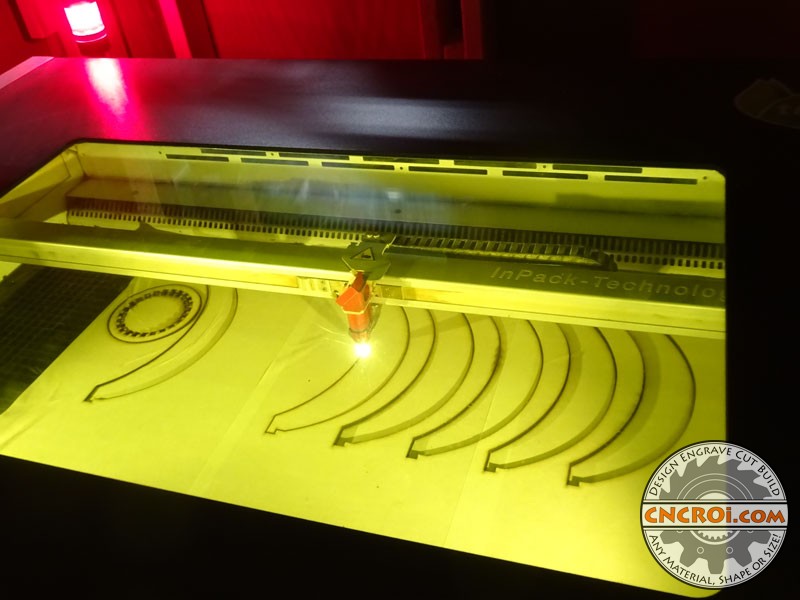

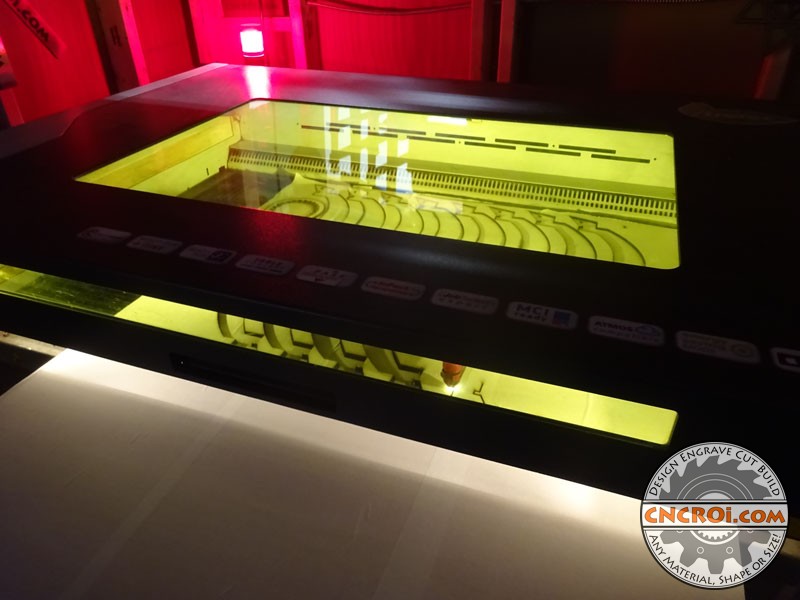

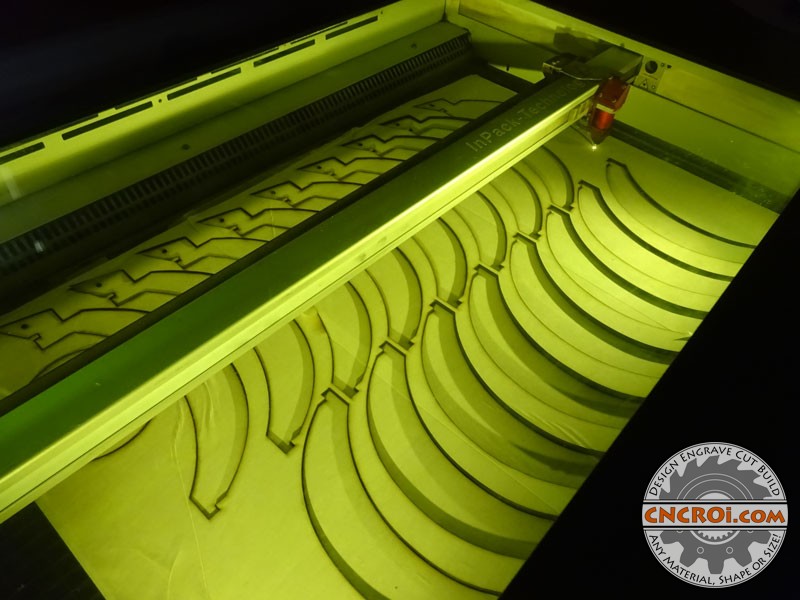

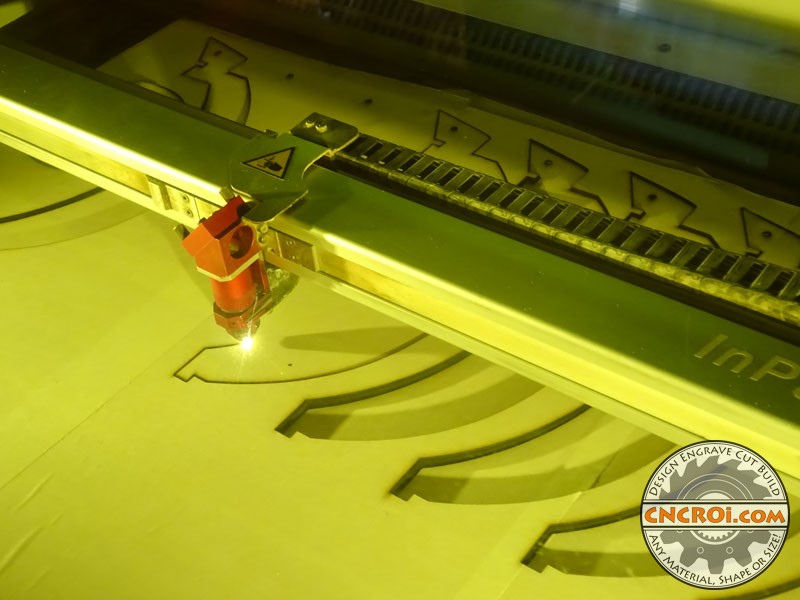

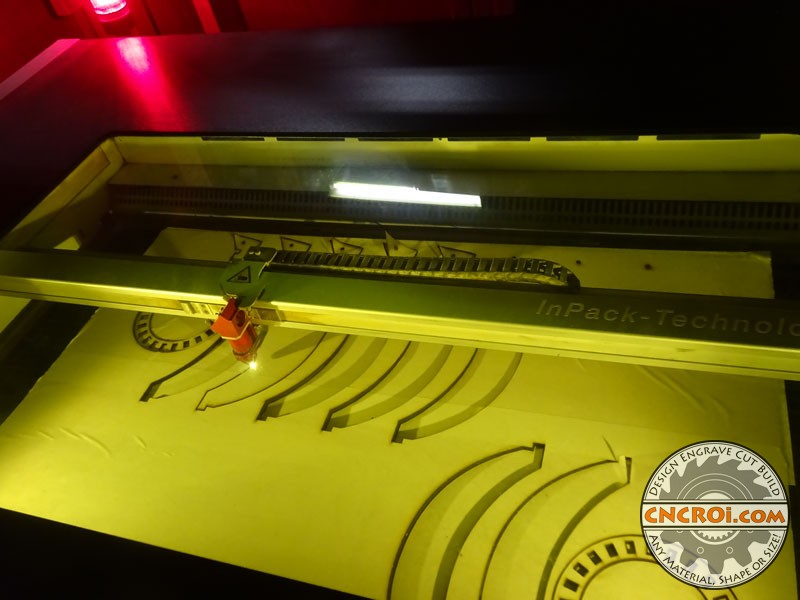

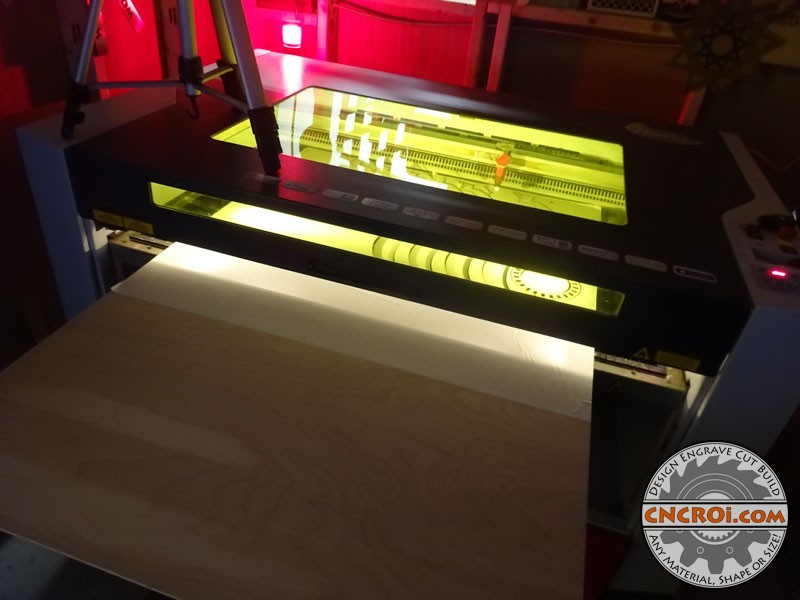

Having a wide-format industrial CNC laser with pass-through the front (and back if needed) allowed me to simply slide the sheet of plywood into the machine in steps as I cut out the various parts that will make-up the custom slot lamps.

The CNCROi.com advantage of using a 3D model to build this project first before cutting anything meant that on the first cut, everything would be perfect, which saves a lot of time and money.

If you aren’t familiar with 3D animation and modeling, here’s a 3D animation showing the assembly of the army transport truck I designed and stuck a video of higher-up on this blog post.

The custom slot lamps is basically the same concept, just a lot simpler.

The great thing about plywood is that it’s a very rigid material, but this comes at a cost, it also really likes to warp over time.

The other issue with plywood is that it’s made-up of “plys of wood” which means the outer veneer is very nice then the not so nice stuff making-up the cores aren’t very attractive and are generally a contrasting color.

This means that if you sand it a bit too much, you quickly get through the veneer and into one of the contrasting plys, as a result, CNCROi.com hand sanded this after production as power tools just work too fast when it comes to removing glue and burns on the surface of the veneer.

As mentioned in the video regarding the production of these custom slot lamps, I’ve made furniture using plywood before and the one that’s the best documented and used at CNCROi.com is our CNC laser station.

This was done with a lower grade plywood than these custom slot lamps, you can tell right away just visually that the CNC laser station looks a lot rougher than the lamp on the surface, but it’s been with me through two shops and still works just as well today as it did when I first built-it.

As I tell my customers, there are no perfect materials out there, each has a plus and minus and it’s my job to make something using as many +s as possible for your application.

Another common use for plywood in the shop are custom shapes, due to their strength over MDF, they work wonderfully and are easy to paint too.

Plywood in the shop can be cut using manual, power or CNC tools in the shop, it all depends on the design and the tolerances involved in order to produce the best result for the customer’s needs.

For CNCROi.com, plywood also works great as a backing for lamacoids or more fragile type work we do in the shop.

So yes, there is a lot of plywood that goes unseen in projects until I pointed it out but for the custom slot lamps we made for the restaurant, they were front and center plywood with only glue holding everything together.

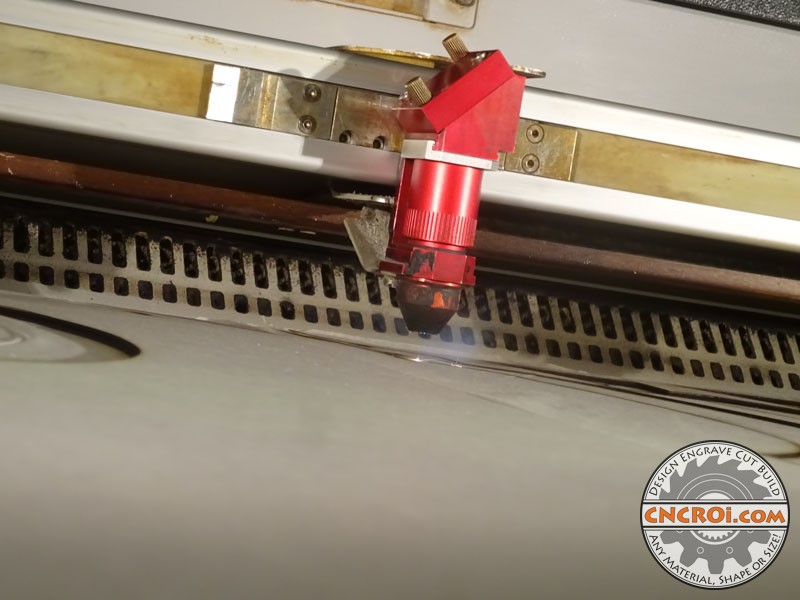

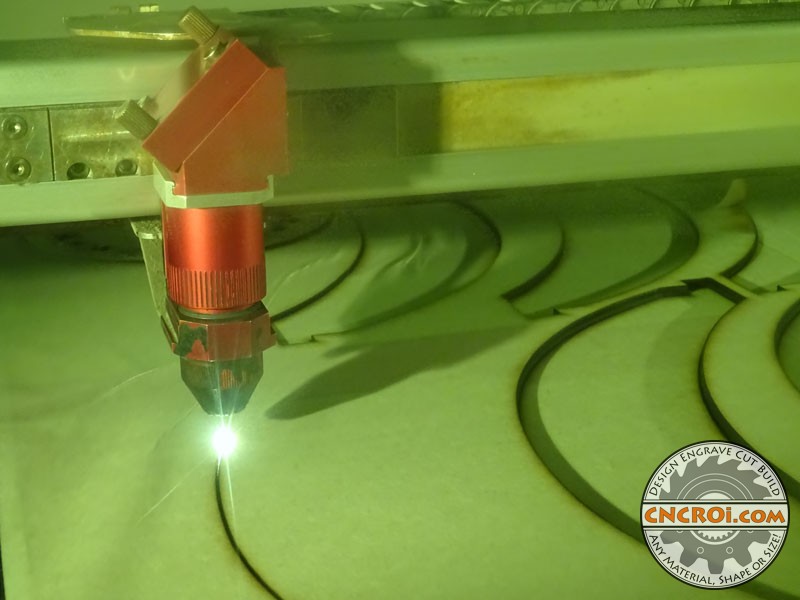

Our Austrian wide-format industrial CNC laser is a 140W CO2 which means that quarter-inch or 6 mm plywood is really like butter being cut with a hot knife, all the cuts are done in one pass, precisely and all the way through without issue.

Our Trotec Speedy 400 flexx also has a 30W fiber laser diode in there too, which we use mostly for metal etching and annealing, with a side of plastic color changing.

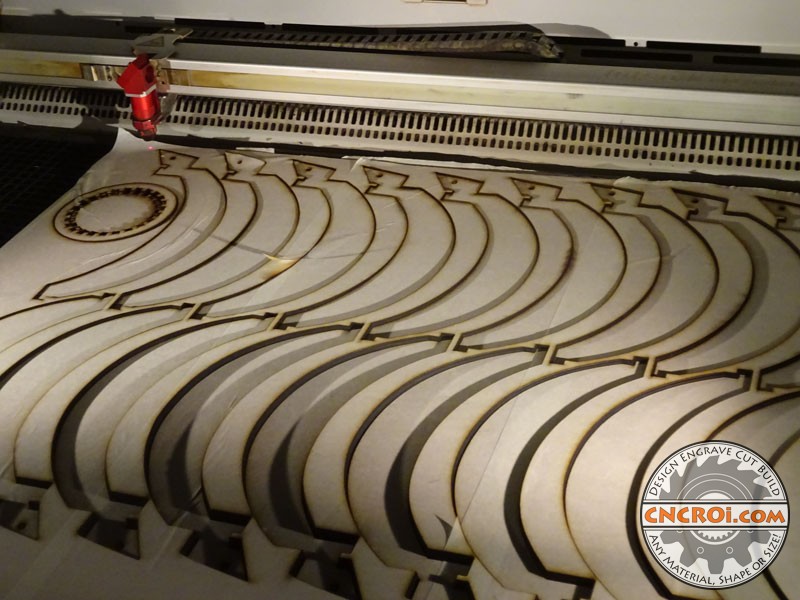

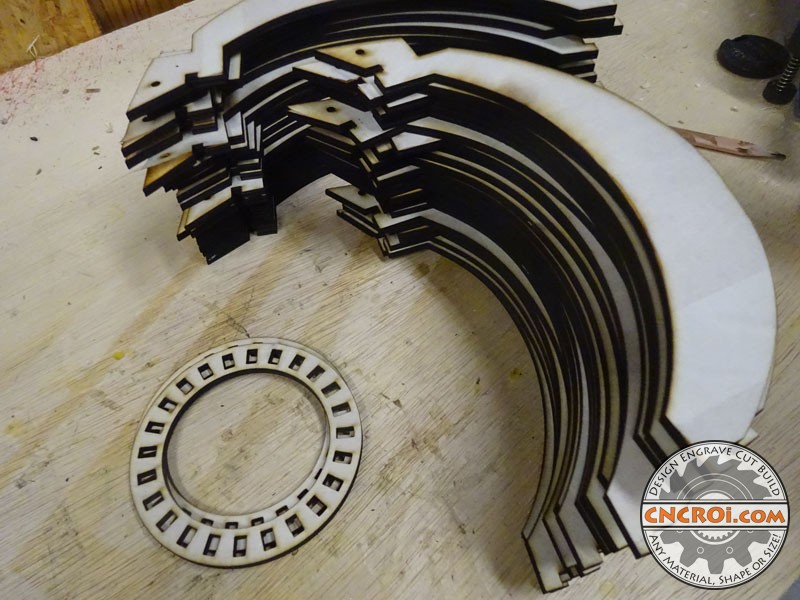

Once all the custom slot lamps parts were cut out, it was time to remove the protective masking from the surface, this was necessary to greatly lessen the amount of sanding required for clean-up.

Remember, unlike solid wood, plywood only has a thin veneer on the surface, the more sanding you do, the higher the chance of sanding through it, so CNCROi.com uses the protective wrapping to avoid this issue as much as possible.

To give you an idea, CNCROi.com does a lot of work using solid wood and if you watch this video, you’ll notice A LOT OF SANDING while literally none was performed on this custom slot lamp.

As solid wood is the same all the way through, sanding just makes it thinner, you don’t have a problem regarding going through the veneer into the ugly stuff, and that’s why it costs a lot more.

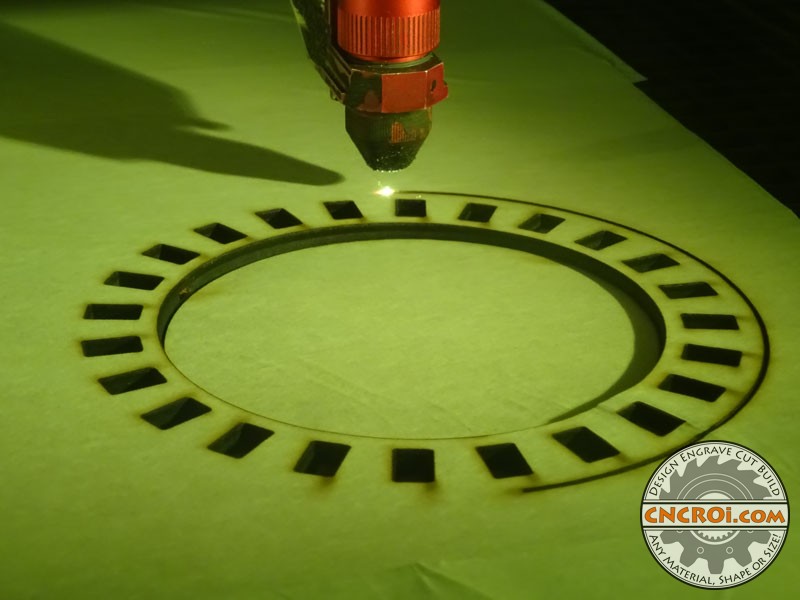

This design was a little tricky, because unlike most custom slot lamps, the way it’s held together in the top is using just glue and an interlock that’s INSIDE the lamp, not on the outside.

This means that parts want to fall out by default, and that’s also why most of these lamps are done with the ring on the outside to make assembly way easier, but CNCROi.com likes to make things different and that’s why I went the more difficult route.

As such, to ensure proper adhesion during assembly and drying, rubber bands were scouted to do the job, making sure nothing fell out.

The end results look spectacular, you don’t even see the inner ring, it makes for a far cleaner design that can be used in either vertical positioning as there is no longer any “up or down” to this custom slot lamp.

I really enjoyed making these two custom slot lamps, in all my years I’ve never cut or assembled a “lamp” and it’s been a while since I made something out of plywood in the CNCROi.com shop.

Our customers tend to go into the direction of more exotic woods and design requirements, from live edge work to 316 stainless steel.

The pictures of the finished custom slot lamps were shown after the glue dried but not sanded, so it’s a little rough here and there but once you stick a light bulb in them, and they are put in place, these will add a lot of atmosphere to the room they are in.

There are so many ways a custom slot lamp can be designed and fabricated, left as-is or covered with fabric, they will look great regardless of where you put them.

Need a custom slot lamp for your office or a whole bunch for your house? Contact CNCROi.com right now!