Custom Solid Surface Plaques: 1″ Thick Glacier White Corian Carving

Let’s make a series of custom solid surface plaques using 1″ thick Glacier White Corian being carved into shape using our Thermwood CNC router!

This is one of those projects where I greatly appreciate having access to so many tools on my Thermwood CNC router, some projects need just one tool, others need A BUNCH!

There were a few phases to this project, the first was a prototpye you saw in the video above that was laser engraved on one side and engraved on the other, with the idea being that I’d glue all these words onto the custom solid surface plaques.

That prototype revealed quite quickly that gluing was NOT an option with this project, both because of the intended application and the process involved – this was to be in the public which would be touched and as a result, prone to have pressures put on it that over time, would have caused issues with the adhesion.

So, we decided to make another prototype, this time, the letters were carved out of the plaque, this was half inch but the real one would be 1″ thick, and that worked so great… it’s what we went with!

This shows you the difference between laser engraving Corian vs using CNCROi.com‘s CNC router to do the carving, each technology as it’s costs and benefits.

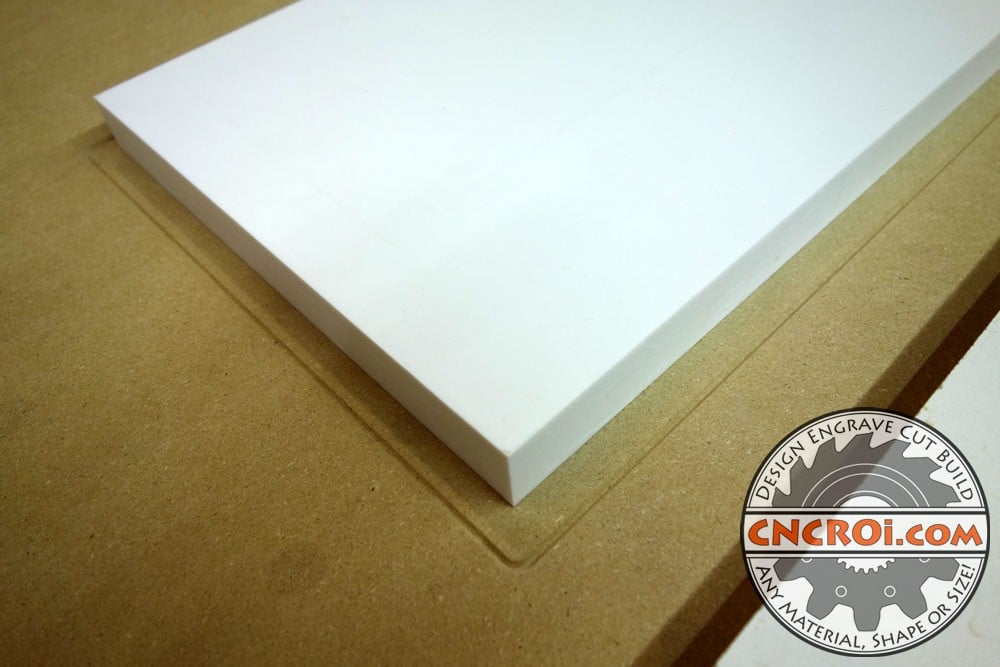

For various reasons, I ordered the 1″ thick blanks from my supplier that were a little oversized from which CNCROi.com would carve out all the details on each plaque.

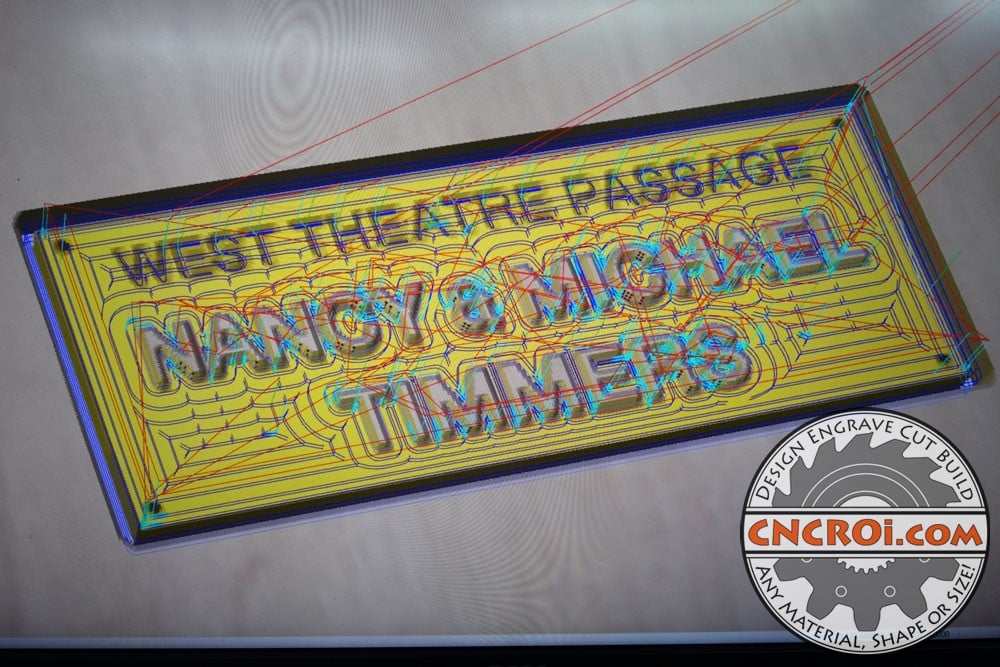

The above screen is all I see in my Thermwood during production, which is why it’s so important to have another piece of software to actually build-up the model and simulate it before going into actual production of each custom solid surface plaque at CNCROi.com.

I cannot imagine manually writing the G-Code to make these plaques, it was a very heavy file and I ran the whole project at 25% normal speed just to make absolutely sure that the Corian wasn’t stressed at all as Corian is incredibly durable, but also very brittle.

Although Corian can be bought in roughly 100 different colors and shades, the customer decided to go with Glacier White and it really looks great!

The nice thing about laser engraving Corian is that we can get very fine resolution that isn’t possible using our CNC router to do the same.

Corian is essentially compressed acrylic, hence being both durable and brittle at the same time, so it machines great but it’s quick to dull tooling as it basically becomes compressed particles of gritty plastic.

Although I could have easily done all the plaques in one shot, for my sanity with such long run times, I decided to just do one custom solid surface plaque at a time, it’s great having an absolute machine, meaning even in the advent of a power failure, if nothing is moved, I can start the machine right-up but I wanted to take my time with each plaque at CNCROi.com.

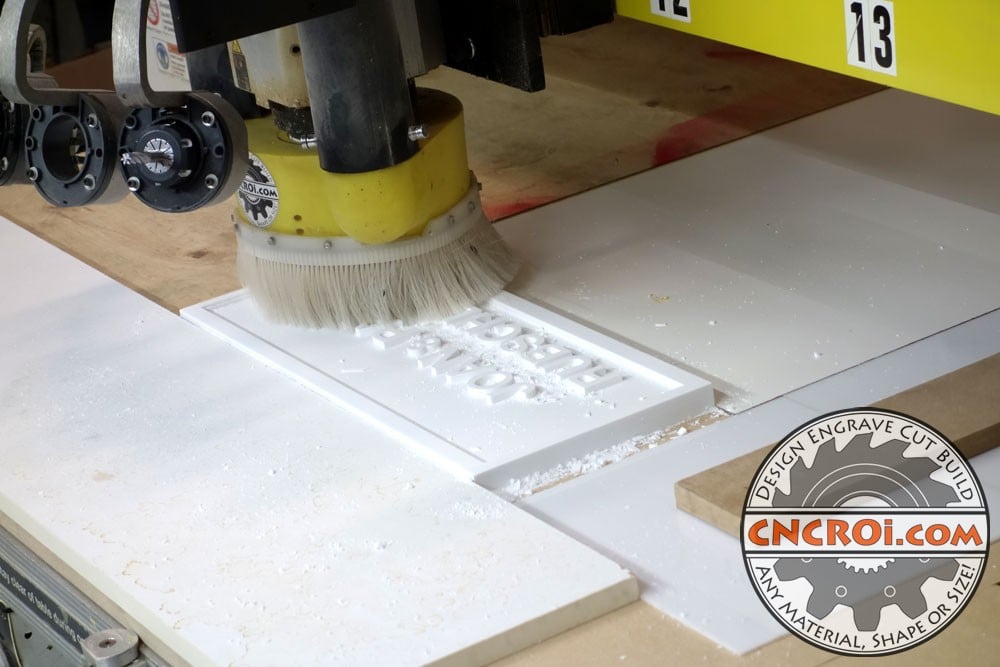

When it comes to carving out the custom solid surface plaques, the process is really no different than if this was MDF or any other material I throw onto the bed of my CNC router… but there is a key difference, due to the weight, only a little of it ends-up being sucked-up by the vacuum system.

Corian can be carved quite easily, it does actually machine very well.

This is why you see the custom solid surface plaques covered with Corian particles, it’s similar to a rubber stamp CNCROi.com laser engraves, but this weight is also an advantage because unlike wood, it settles quickly onto a surface rather than float around in the air for hours or days later.

This is the first time I carved out Corian in this manner and I have to admit, it looks and feels fantastic!

The height of the letters is quarter inch and the carving into the plaque is about 2/3rds of that which produces a really incredible effect!

Of course, if you wanted Corian to be painted after carving using our CNC router at CNCROi.com, that’s possible too!

For quick and easy positioning, I actually carved out a reference square on my CNC router table, as long as I had roughly half an inch on all sides after I put my blank onto the table, I knew I had things centered properly even if the angle was a little off when I placed it there, I was still well within tolerances.

You have to keep in mind that although my Thermwood CNC router is dead-on X, Y and Z, I am not, as a result, having oversized plaques means that even if I am 1 degree or a fraction of an inch “off” my reference line, it makes no difference, as the machine can carved out the plaque and cut it out exactly with absolute precision!

You can see in the above photo that the oversized blank is doing it’s job, that being said, I was actually pretty pleased with the consistency of these scrap outlined blanks after the custom solid surface plaques were manufactured at CNCROi.com.

Corian is great for a variety of signage applications, it’s incredibly durable, resilient and paint fills very nicely.

As these plaques are all made using a mechanical process, they required a further refinement and that was accomplished using my industrial sandblaster at CNCROi.com to remove the machining marks and cut the sharpness of all the edges down a bit.

For this custom solid surface plaques, over the course of several days, I’d make a few plaques, then at the end of the day, I would sand blast them, repeating the process again the next day and the next until everything was done at CNCROi.com.

If you are wondering about the weight of these finished custom solid surface plaques, it was about 55 pounds, the plaques themselves were 20″ x 7.5″ @ 1″ thick, so although I gave them a pretty good weight loss plan with my router, they still had some heft to them.

I’ve been carivng Corian and other solid surface materials for YEARS at CNCROi.com, there is always an application where this works out better than steel or wood, but like those materials, it has it’s place depending on the aethetic you are going after.

In the above photo, you can see there is someting on the “A”, that’s a label from the Corian supplier – it has absolutely no affect on the router doing it’s job and the sand blaster quickly removes this… not sure what kind of adhesive they used but those stickers were on there good.

In the above photo, you can see my placement system before sealing off the vacuum bed all around so as to increase the holding power of the Corian during production, for this to work properly, NOTHING could even vibrate or move, so this is why I wanted maximum power put onto these custom solid surface plaques.

Having access to both routers and lasers at CNCROi.com means we can produce optimal results utilizing the best of both worlds.

Overall, I was very pleased with how these custom solid surface plaques came out, there were lots of great ideas provided by the customer and when tested out, actually were proven valid and that made the finished product that much better and more solid!

You can really see the amout of Glacier White powder coming off these custom solid surface plaques at CNCROi.com in these photos, can’t imagine how bad it woud be if it weighted less and was airborne!

As mentioned previously, after a batch of custom solid surface plaques was manufactured at CNCROi.com, the next step was sand blasting them to a matte finish.

I actually liked the finished texture of the Corian after sand blasting, it really began to feel like stone with a perfect gritt to it.

After all the custom solid surface plaques were sand blasted, cleaned-up and reviewed, it was time to ship these guys out to their waiting customer!

Need custom plaques? Contact CNCROi.com right now!