Custom Stamp Production

Custom stamp production, we do it all the time here at CNCROi.com in both “custom” and “standard Trodat” mode!

Although I’ve focused on showing our custom stamping options here at CNCROi.com, what many people may not realize is that the parent company of Trotec Laser – of which we have a top of the line Speedy 400 flexx – is Trodat, the world’s larger stamp manufacturer! Where does our stamp rubber come from? Trotec Laser / Trodat!

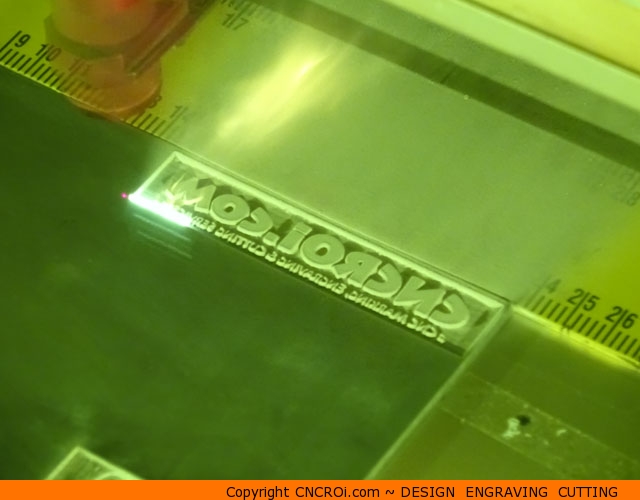

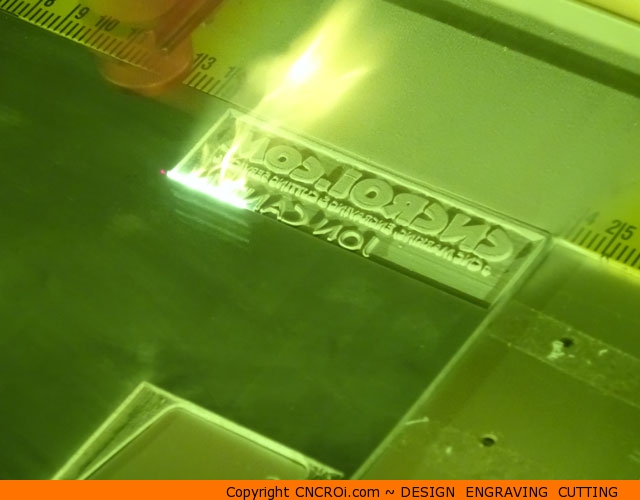

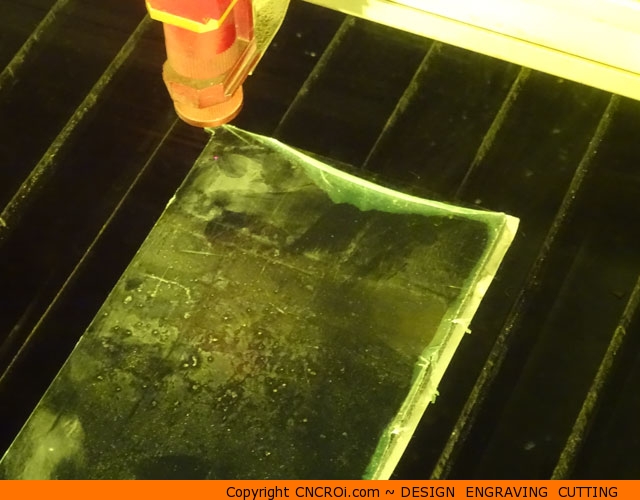

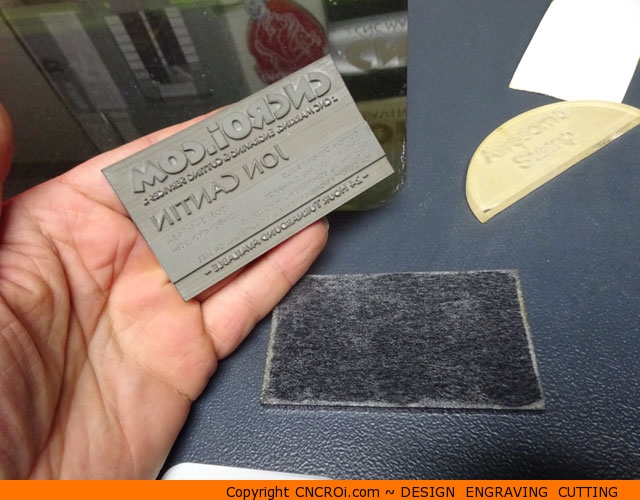

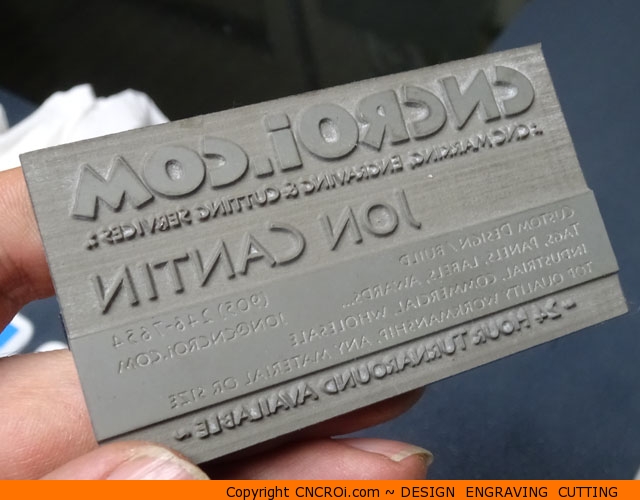

In this case, we are using the natural gray which is slightly different from the typical reddish rubber in that during production, it doesn’t smell like a decomposing body while being laser engraved and cut. We have some clients though that, due to their specialized application, need us to work with the other rubber types which is fine.

Our Trotec Laser was designed by Trodat to be the world’s best stamp manufacturing laser on the planet for their own use and by extension, this level of optimization and precision also lends itself to a host of other materials which you see at CNCROi.com.

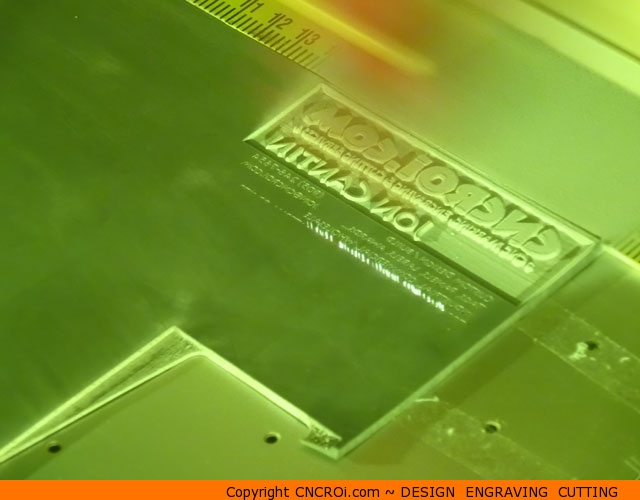

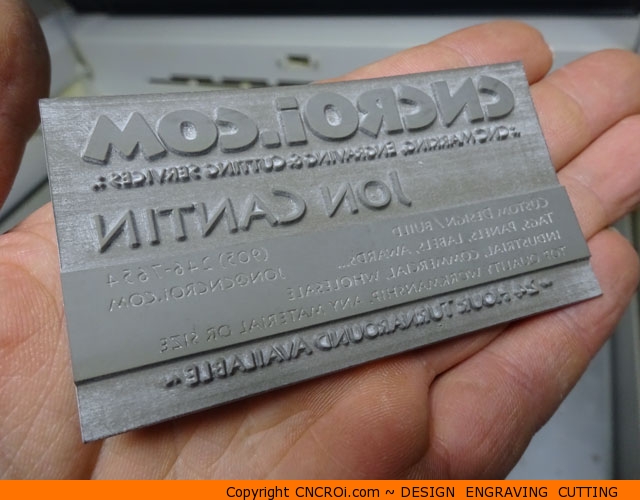

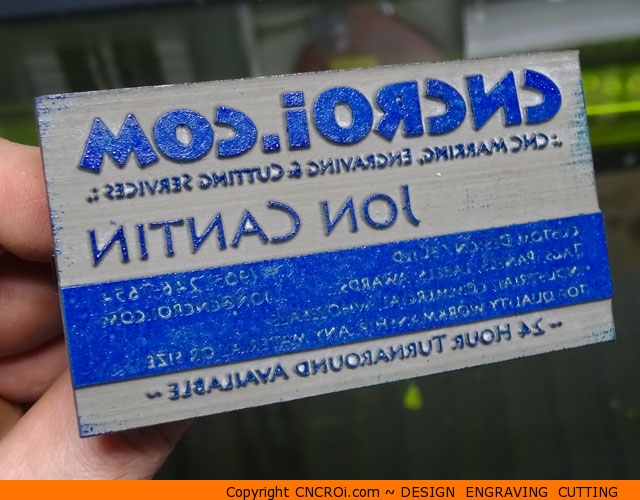

In this case, I thought it would be fun to laser engrave my business card as a physical stamp just to showcase what you need to watch-out for when making typical stamps. For our customers, were generally produce stamp in the 500-600 DPI range but we’ve made some stamps up to a thousand DPI as well as way lower depending on the application.

We also have access to raw rubber in a host of durometers from very squishy low durometer rubber to extremely stiff higher grades. For instance, if you want to roll rubber onto a printing drum, you want a lower durometer while for hot press machine molds, you want a far higher one.

Our stamps are all custom-made on-demand but we can also make standard stamps that fit across a wide variety of Trodat stamping products. Yes, we are an official reseller of the entire line of Trodat stamping products from self-inking stamps to delrin seals.

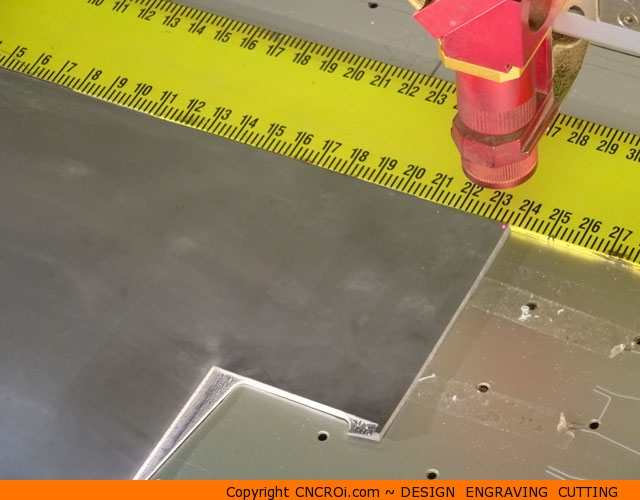

As you can see, our stamp looks AWESOME! We aren’t done yet, it’s time to create a custom mechanism so that the custom rubber business card stamp shown above is flat and easy to use. For this, we typically use 1/4 inch or 6 mm thick acrylic with industrial grade double-sided tape.

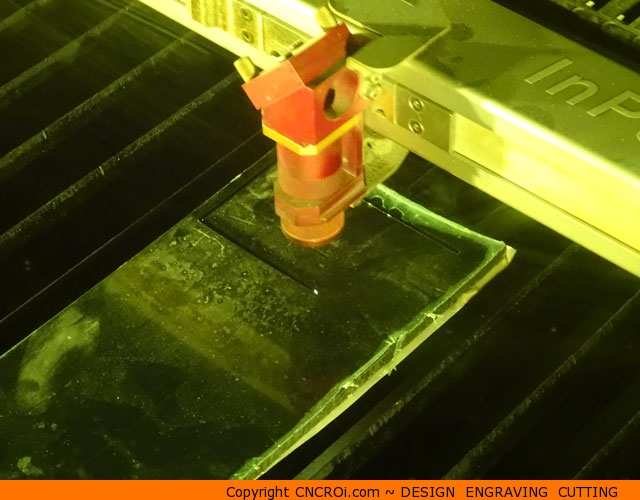

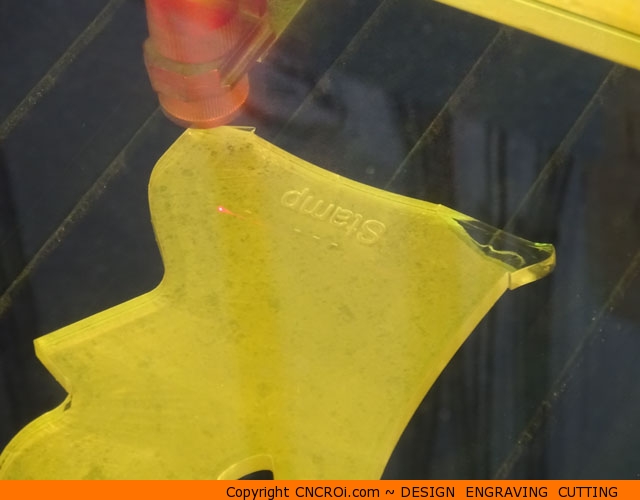

Laser cutting this material is easy, we have a fantastic CNC laser straight from an Austrian factory! It vaporizes acrylic just as easily as rubber stamping material! In fact, we had one application where we actually engraved acrylic for use as a stamp for one of our customers.

The precision is totally accurate within 5 nanometers, the square-cut out of the acrylic is the exact same size as the rubber stamp cut earlier, which means applying one to the other is a seamless process.

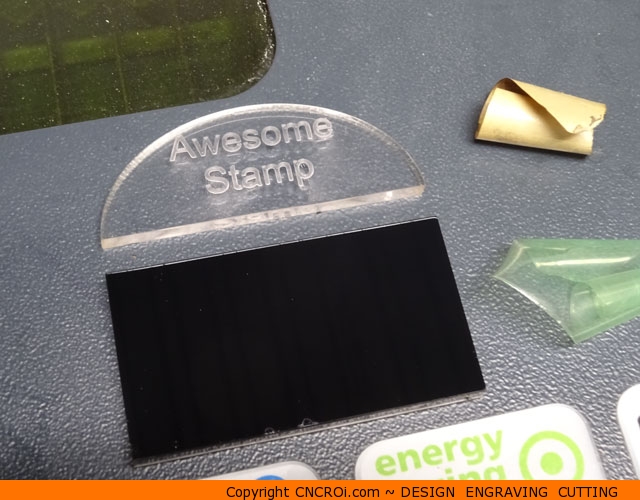

Next-up is cutting the transparent holder for the flat acrylic board. It just makes grabbing and using the stamp easier, as this is an Awesome Stamp, it was engraved as such as well.

The “white” paper you see on the underside just makes clean-up easier as the vapors stick to that instead of the transparent 1/4 inch or 6 mm acrylic.

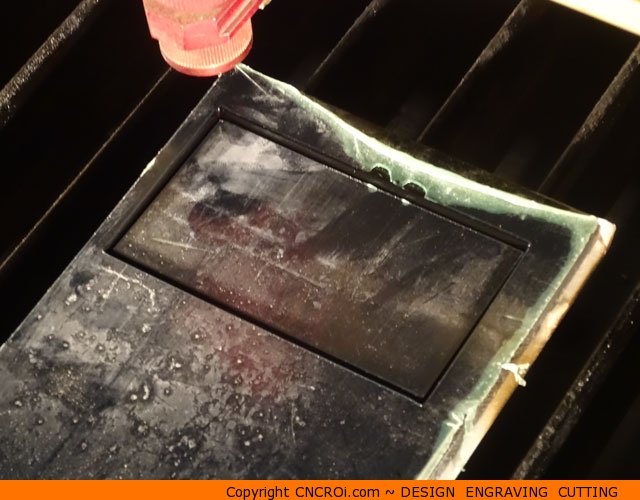

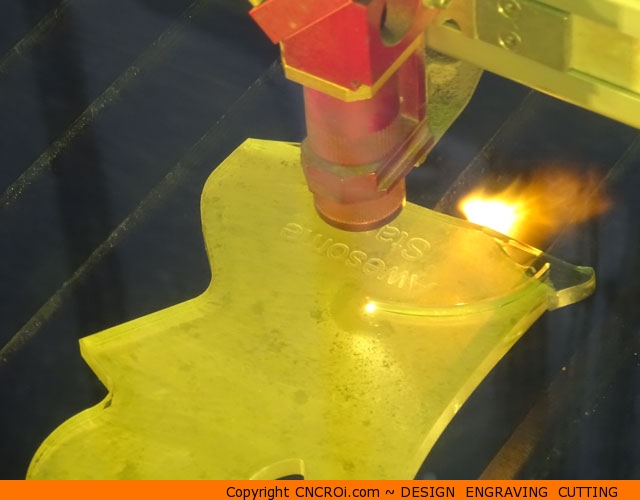

Both pieces, the black acrylic and the transparent one, are bonded using acrylic cement but before we get to that process, I wanted to show you some fire. We get this when making stamps and cutting acrylic.

We have a highly optimized system with a vacuum table, gas kit and other features which help us to better control the energy dissipation within our industrial wide-format Austrian CNC laser.

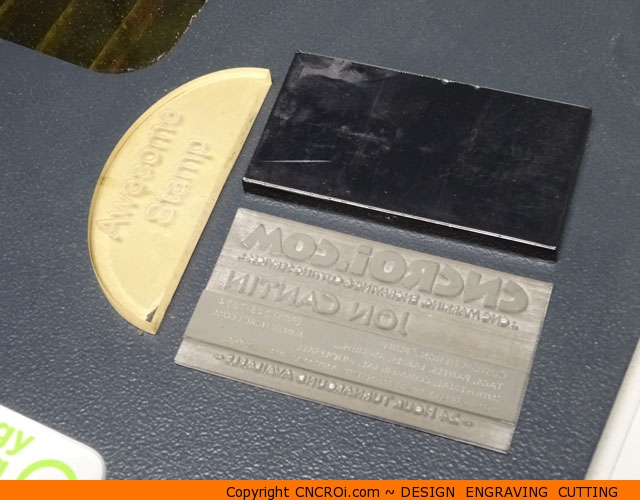

Now you can see all the components that go into a custom stamp, the two acrylic pieces and the rubber. The double-sided tape looks burned but it’s fine, it’s just a protective covering.

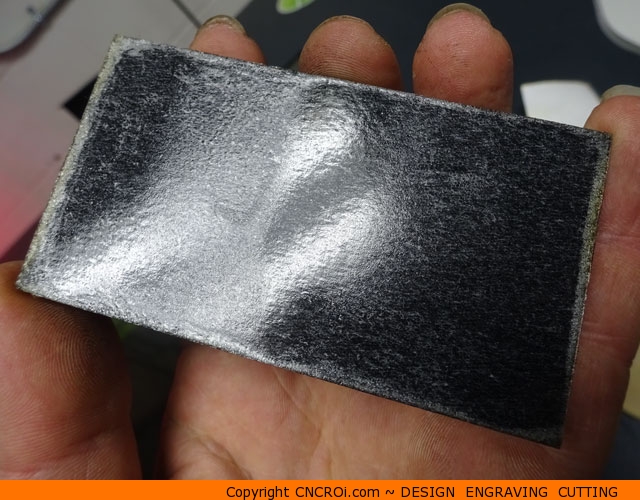

Removing it reveals the underlying, incredibly sticky, double-sided underside.

Basically, stick the stamp onto the acrylic, placing this by eye is fine, just takes a little patience as this a one-time process, it’s incredibly difficult to remove the rubber stamp from the custom cut acrylic which is what you want!

Now that both are put together with a little pressure to remove air bubbles, the bottom part of this custom rubber stamp is complete.

We now remove the protective covering on the top of the black acrylic and the underside of the clear acrylic and proceed to bond both together.

The stamp is a little dirty but that’s easily cleaned-up. The stamp is now ready to stamp business cards!

The rubber underneath looks great with a little additional clean-up so it’s time to dive this into an ink pad and see the results.

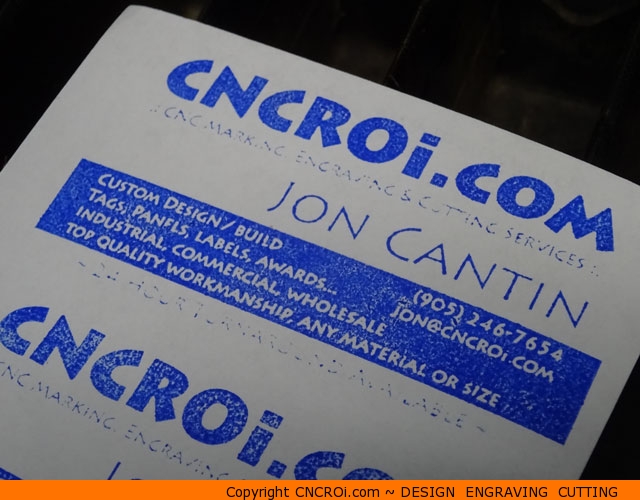

This is the right amount of stamp ink to apply to a custom stamp…

while this is a little too much.

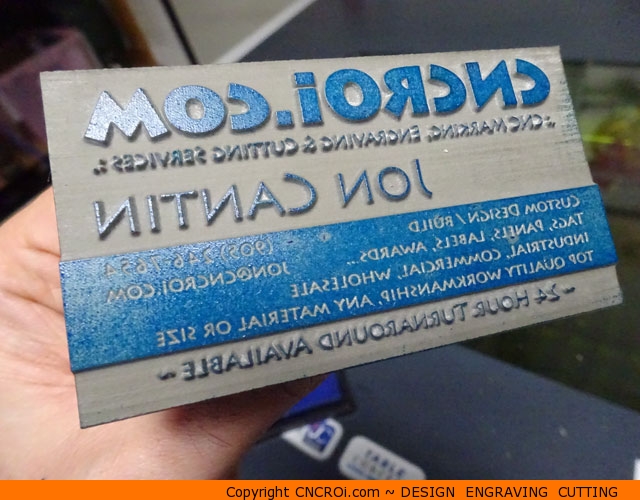

The results look very promising, going back on the design, you can see that the tag lines are a little too thin, there isn’t enough rubber there to hold a proper amount of ink.

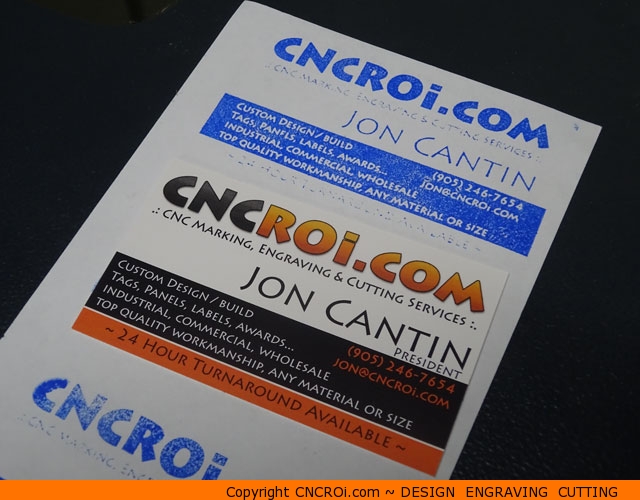

Comparing it to our business card, you can see the result are very respectable, I’m sure thickening the tag lines will make those come out far better.

It takes some practice to get proper stamping done, you generally want to do it on something with a little give, we did this on our Trotec Laser’s metal frame, not the best substrate so a proper set-up will produce a more consistent result.

You can see the texture of our Trotec Laser’s metal frame in the stamp! Looking for custom stamps and standard Trodat supplies with stamps too? Contact CNCROi.com right now! You can also order your stamps on our e-commerce site, check it out.