Custom Steel Barrel Stencil: CNC Waterjet Cut

Custom steel barrel stencil production can be made by CNCROi.com in any shape, size, design or material.

https://www.youtube.com/watch?v=mEDJyj24G_8/

The advantage that CNCROi.com offers you as a customer is absolute and total flexibility, we aren’t stuck using only one machine, we have 4 different ones and counting which means we can optimize our production to your application rather than trying to fit a round peg in a square hole.

This is a very vital distinction, as there isn’t any perfect process or machine to make whatever you need CNCROi.com to make for you, whether it’s a steel barrel stencil that you want to use a propane torch with or a polycarbonate one that you plan on using spray paint with, each has a benefit to cost ratio.

If you are wondering what another design would look like on this same stainless steel material, here’s another one to set your sights on.

https://www.youtube.com/watch?v=fhwwm4DgLSA/

When I first started CNCROi.com, my goal was to be completely machine and process agnostic, meaning if a customer wanted something made with A, we made it using the best technology available, even if what would be needed for optimal results was machine B.

This is why I’ve invested heavily in machinery, processes, materials and training so that I can produce the absolute best product for our customers, whether it’s CNC plasma, CNC waterjet, CNC laser or CNC router, CNCROi.com has the best tool for your given application.

I’d say off-hand, about 85% of this stencil could have been cut with our CNC plasma cutter, but that 15% would have had to be heavily modified, so the simplest solution was to boot-up the CNC waterjet and use that technology to make this custom metal barrel stencil.

Of course, CNCROi.com can also cut plywood stencils using our CNC router.

https://www.youtube.com/watch?v=dz27x1cdrt8/

Where CNC plasma exceeds in speed, CNC waterjet exceeds in the size of material remove, it’s like comparing a router bit to a laser beam, the waterjet is very hard to beat and did a wonderful job for our customer for this custom steel barrel stencil.

The one big disadvantage to CNC waterjet for this specific application was speed, it’s a very slow process, especially for a custom steel barrel stencil with this much detail, but it’s well worth it, this came out beautifully!

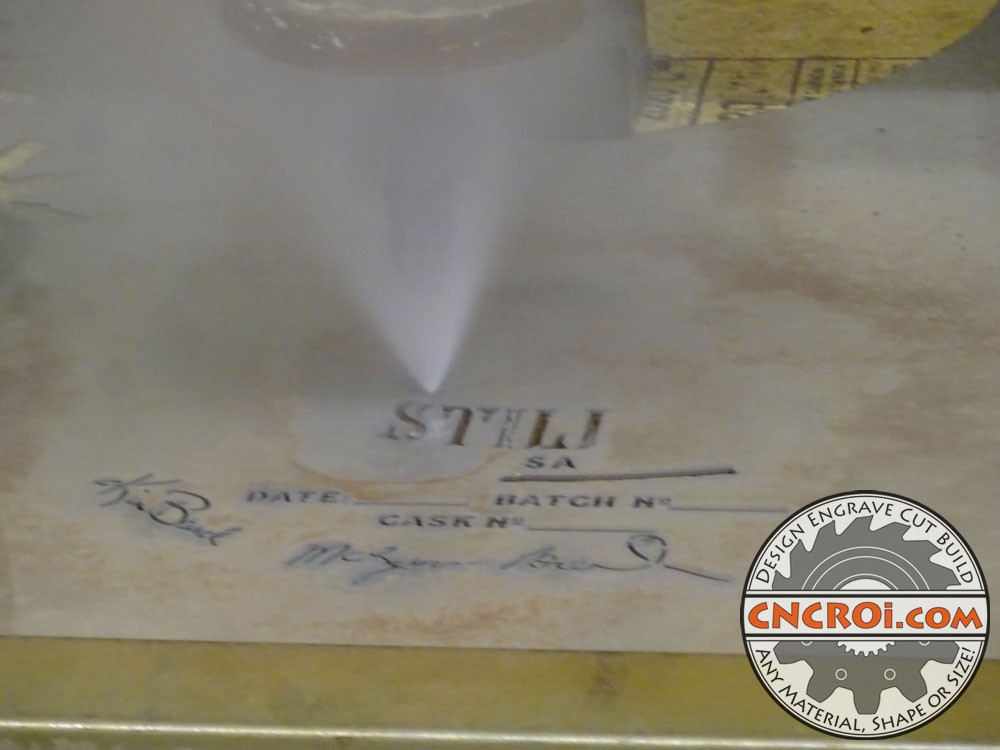

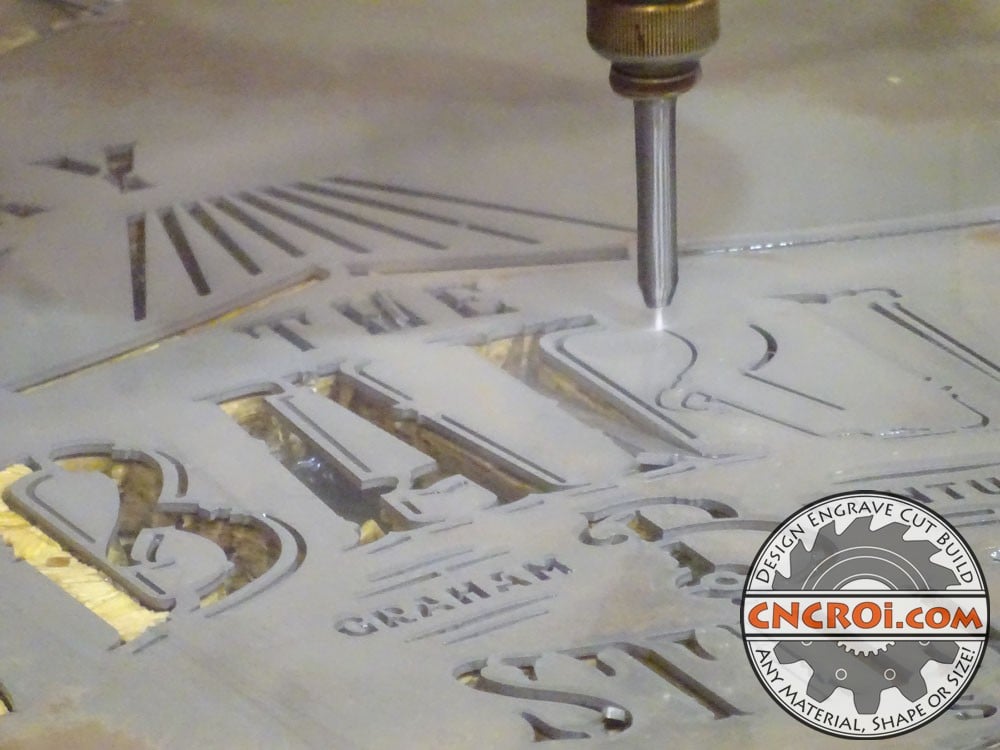

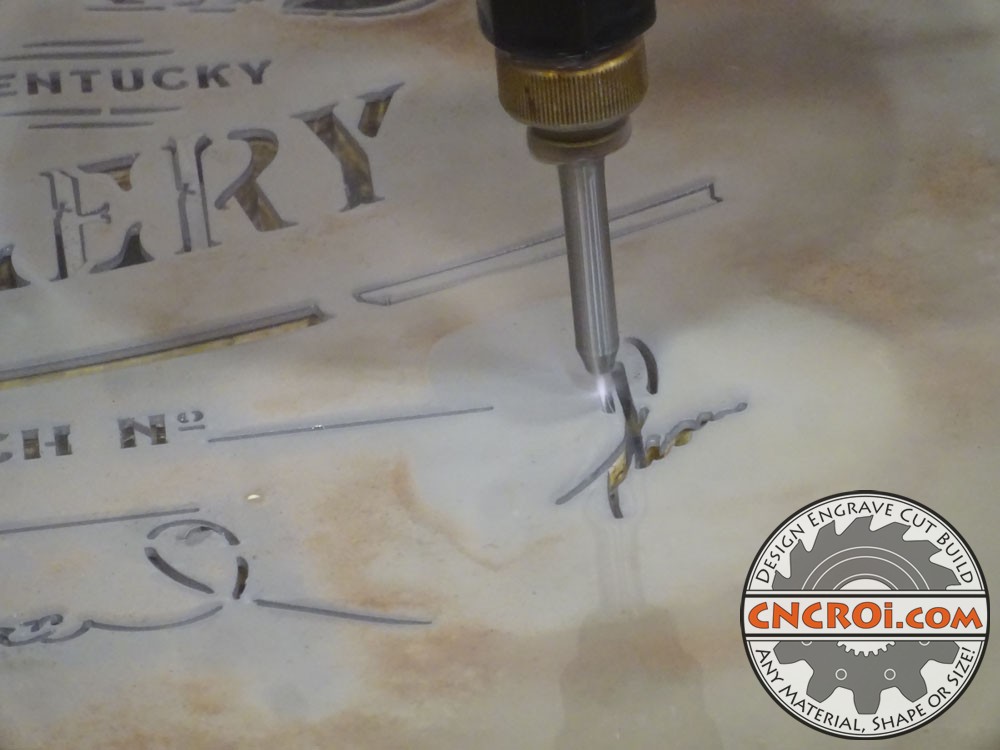

You can see the size of the water stream in these photos, which is hard to capture on film, it’s tiny, for rough comparison, a CNC plasma would be 2-3x wider depending on the material at hand and amperage.

Of course, CNCROi.com also has a laser, so here’s a stencil being made using that process onto polycarbonate.

https://www.youtube.com/watch?v=xxFljG9iFJY/

This custom steel barrel stencil had a lot of very tight details, regardless of what machine we used with this, the precision would have been the same, all our CNCs are essentially interchangeable regarding accuracy digital to physical cutting or engraving.

The difference is the thickness of the cut, higher detail, you end-up hitting a threshold limit of the machine’s capabilities, the other advantage of CNC waterjet is that it’s a cold cutting process.

Our CNC plasma literally melts the steel with a gas that’s hotter than the Sun, which is fantastic for cutting metal fast, but metal doesn’t like to become too hot, otherwise it starts to warp.

And if you are curious, here’s what the differences are between a metal and polycarbonate stencil.

https://www.youtube.com/watch?v=xxFljG9iFJY/

For this custom steel barrel stencil, there are a lot of details very close to one another, as such, this heat issue that may have come into play using our CNC plasma simply doesn’t exist with the CNC waterjet, it cuts by wearing down the material, not vaporizing it.

CNC plasmas make lots of smoke, CNC waterjets make lots of water, so regardless, the process is “dirty” either for your skin or your lungs but CNCROi.com has safeguards for both so this doesn’t really come into play.

Among the first stencils I ever made was actually out of cardboard using my CNC laser.

https://www.youtube.com/watch?v=Utii11V_bRM/

When it comes to making custom steel stencils for branding use, because it’s metal, it allows you to use a propane torch to permanently brand the wood you put this onto, put the flame in the hole and the wood burns where it makes contact.

The nice thing I like about the results from CNC waterjet cutting is that the edges are already clean, they have been essentially polished with sand and water.

You can see the incredible precision we can achieve at CNCROi.com with the CNC waterjet, even signatures come out amazing, do keep in mind that this is a stencil, so additional support bridges needed to be added.

Just using regular plastic for certain applications for stencils is perfectly acceptable as well.

https://www.youtube.com/watch?v=b54_VdpHAq8/

The material we used for this is stainless steel, we can just as easily cut mild steel or anything else but the nice thing about stainless steel is that it’s very corrosive resistant.

Making a stencil out of mild steel is cheaper but it will flash rust, aluminium is another option but it’s more expensive and needs to be coated or anodized to protect it from the environment.

After all the inside parts were cut using the CNC waterjet through the stainless steel, 304 grade, it was time to cut it out of the sheet of steel.

One of the most fun stencils that I’ve done using polycarbonate is that of a bird, it just looked so beautiful.

https://www.youtube.com/watch?v=-fCItLVr2pk/

Cutting all the inside parts first means nothing moves, then cutting it out makes sure that CNCROi.com produces the most accurate and high quality custom steel stencil possible.

You can see after clean-up what it looks like, not much of a difference with shop light but add a bit of showroom light…

And the custom steel stencil looks way too nice to use as a stencil, the shine is amazingly beautiful.

Of course, how do you pack a CNC waterjet custom steel barrel stencil? In a MDF laser cut custom package of course.

Need a custom stencil? Any shape, size, material or design? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=OU-sTGF_pw0/