Custom Steel Button Panel

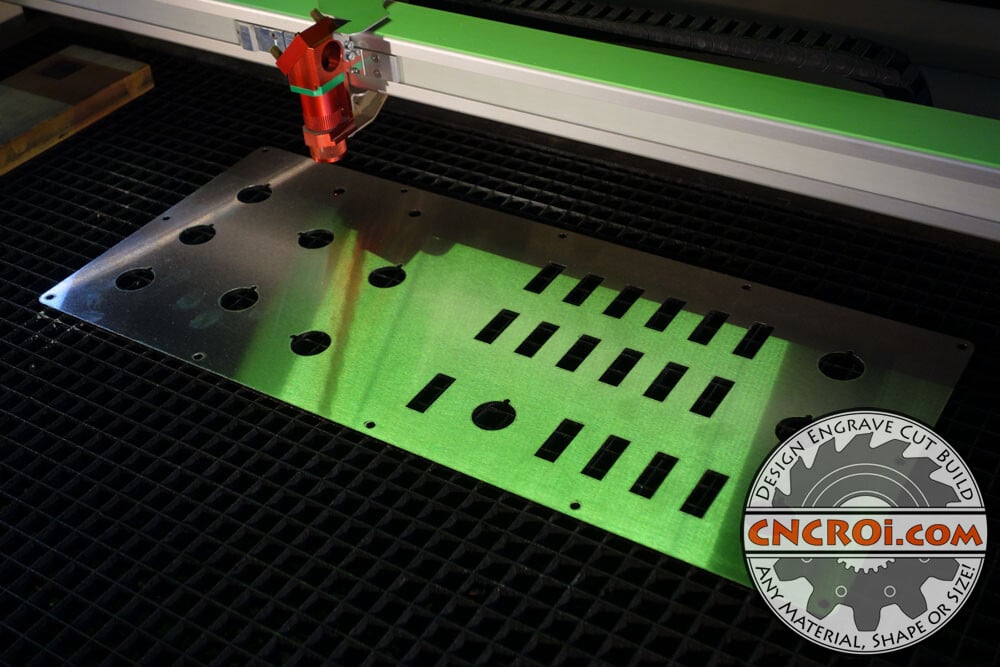

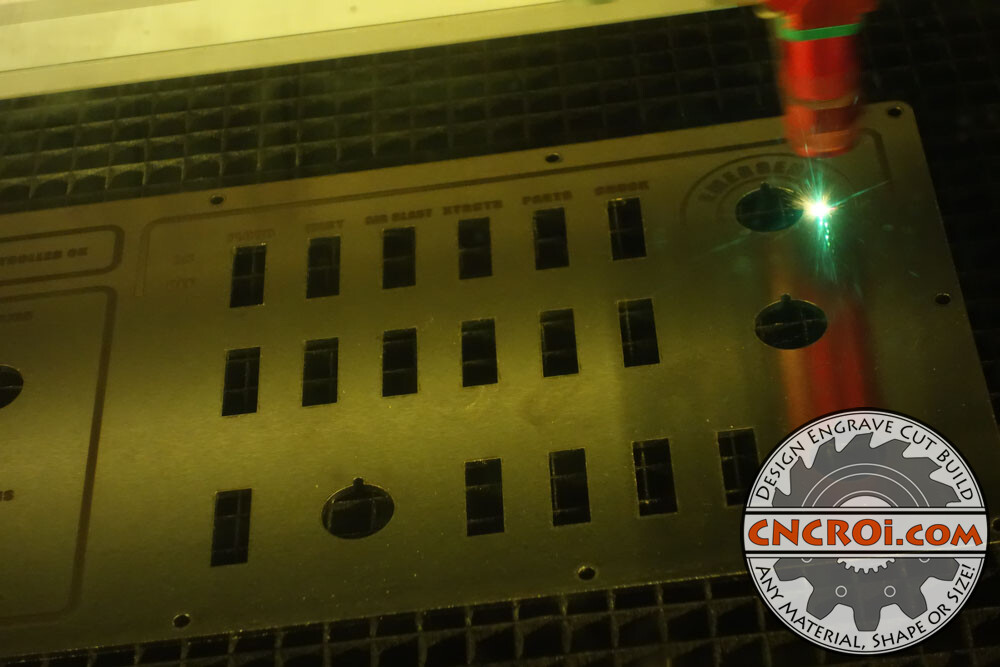

CNCROi.com has years of etching and cutting experience, here’s an example of our work, a custom steel button panel made using 11 ga 304 stainless steel with #4 finish.

A custom steel button panel provides a robust and versatile control interface for a wide range of applications, whether you need a custom steel button panel for industrial machinery, home automation systems, or specialized equipment, CNCROi.com can create a tailored solution that meets your specific requirements out of literally any material.

Before diving into the design process, it’s crucial to determine your needs and specifications for the custom steel button panel while considering the purpose of the panel and the specific controls or functions you require.

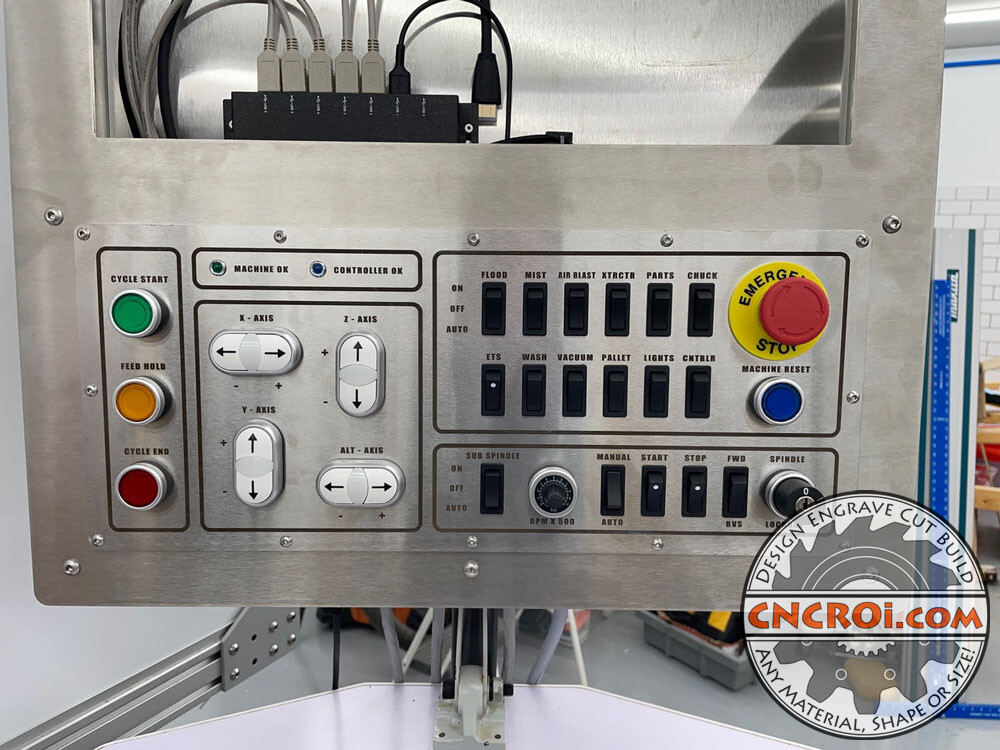

Make a list of the buttons, switches, indicators, and other components you need to incorporate into the panel, making sure you have room for your fingers to navigate said components and most importantly, can easily see the etchings that CNCROi.com will be performing on the surface, whether it’s anodized aluminium or stainless steel or even wood or a plastic variant.

Of course, CNCROi.com can make additional components to augment your control panel, think lockout tags or lamacoid stickers.

Consider the following questions when designing and proofing your custom steel button panel:

- How many buttons or switches do you need?

- Do you require LED indicators for status feedback?

- Are there any specific labeling or marking requirements?

- What are the size constraints for the panel?

By answering these questions, you can create a comprehensive list of requirements that will inform the design and layout of your custom steel button panel.

Consider the following factors when designing the custom steel button panel layout:

- Ergonomics: Ensure that the buttons and switches are positioned in a logical and ergonomic manner, taking into account the intended use and user convenience.

- Grouping and labeling: Group related controls together and provide clear and concise labels or markings for each control element. This enhances usability and reduces the chance of errors.

- Size and spacing: Consider the dimensions of the panel and the size of the components to determine the appropriate spacing between buttons and switches. Allow for adequate clearance to prevent accidental activation.

- Indicator placement: If incorporating LED indicators, position them strategically to provide clear visibility while maintaining a cohesive design.

Use design software or online tools to create a digital representation of the button panel layout, of course, CNCROi.com can help you out if you aren’t design proficient, you still need to sketch and measure things out though.

Visualize the final product and ensure accurate dimensions and positioning using templates and jigs if required, and yes, CNCROi.com can fabricate these for you as well.

Steel is an excellent choice for a custom steel button panel due to its durability, strength, and professional appearance. When selecting steel for your panel, consider the following factors:

- Material type:

Choose a type of steel suitable for your application. Common options include stainless steel, carbon steel, or powder-coated steel, each offering different levels of corrosion resistance and aesthetic appeal… don’t forget anodized aluminum as well, it’s perfect for certain applications. - Thickness:

Determine the appropriate thickness of the steel based on the size and rigidity required for your button panel. Thicker steel provides more durability but may increase weight.

Projects bit or small, CNCROi.com can make it, this is the Custom GitHub Arctic Code Vault Fabrication.

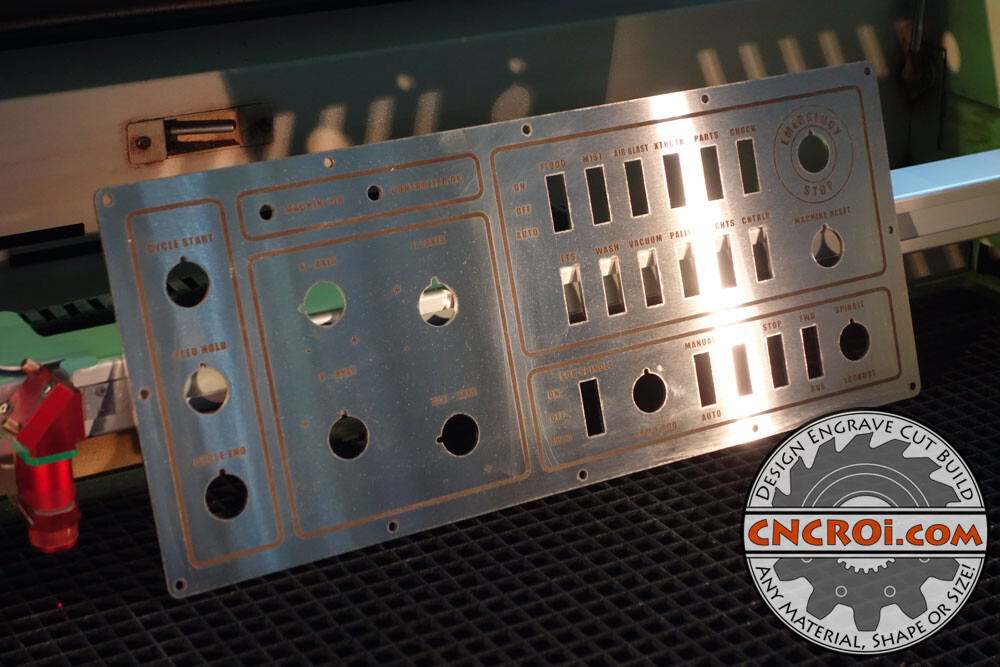

Once you have selected the steel material, it’s time to proceed with fabrication, again, the vast majority of these custom steel button panel by CNCROi.com are stainless steel #4 finish but if you prefer another type of material, we can fabricate that for you as well.

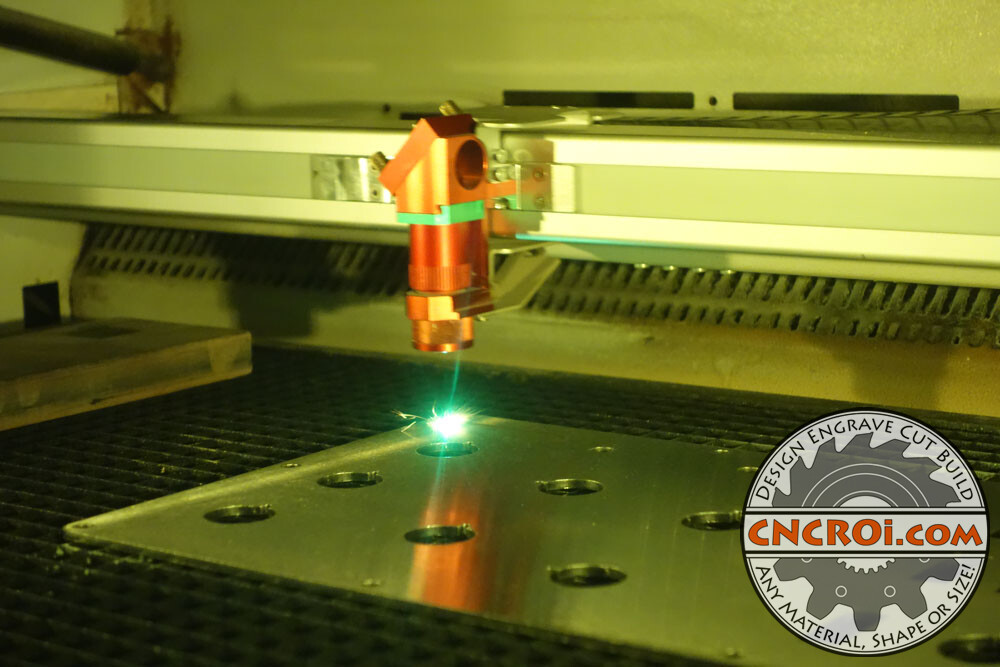

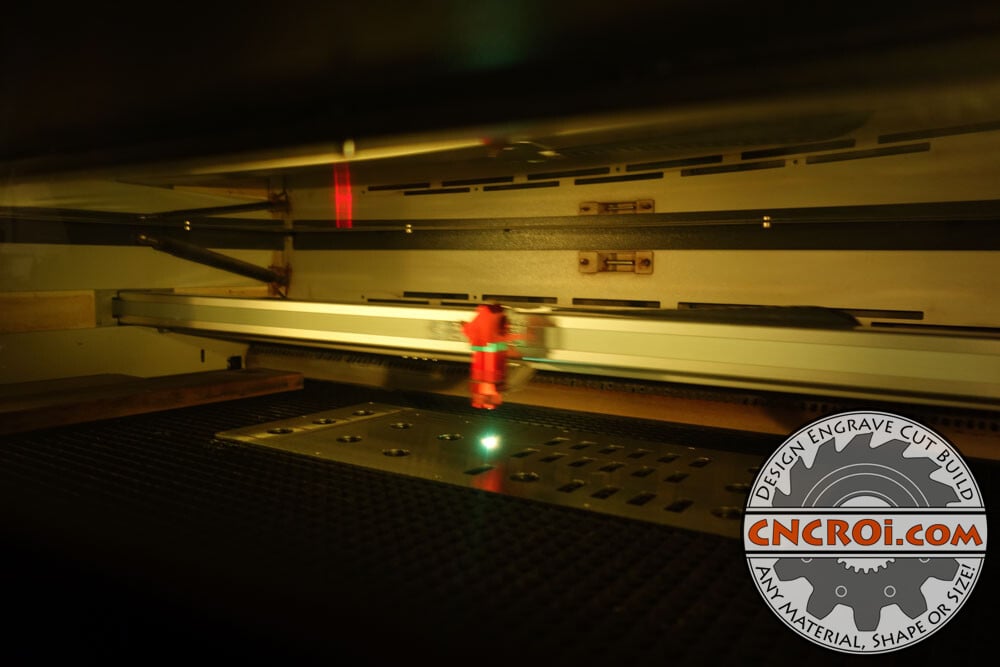

Now that you have a finished digital version of your custom steel button panel, it’s time to have CNCROi.com fabricate it for you, this means we turn your pixels into shrapnel in our shop.

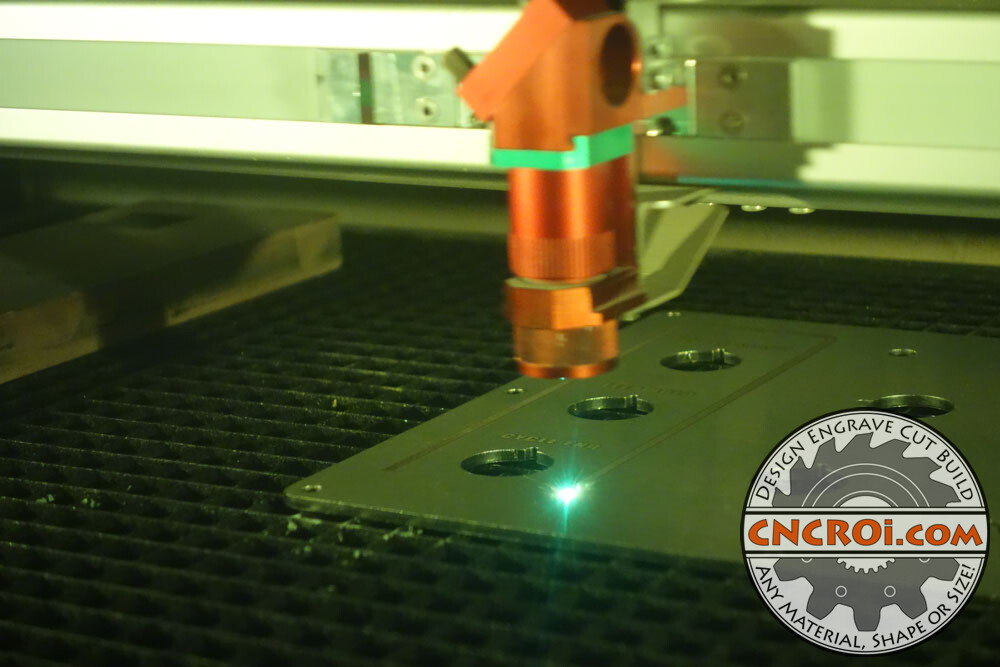

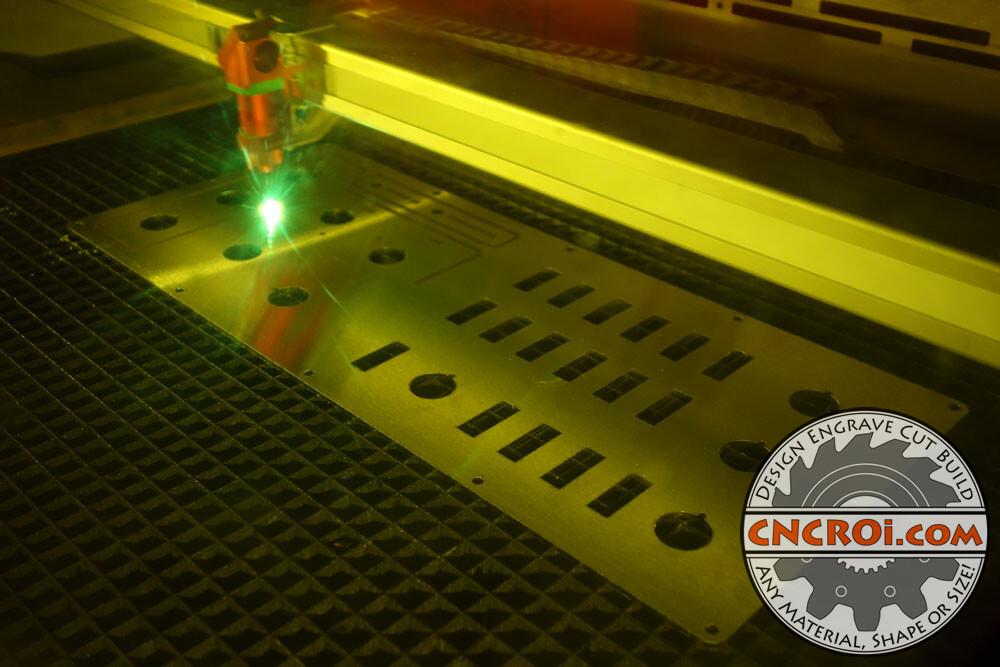

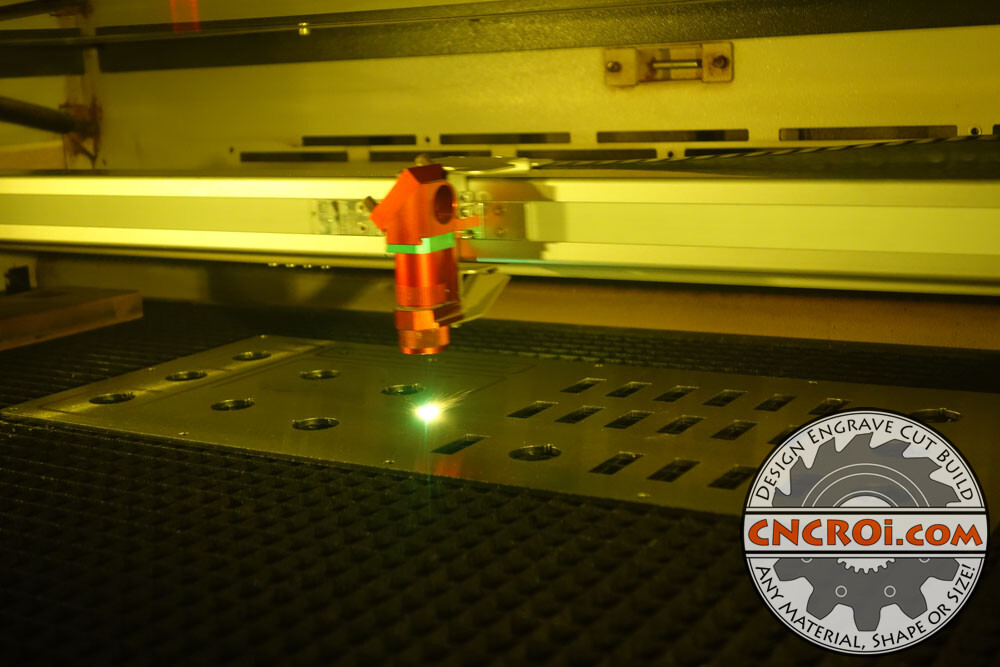

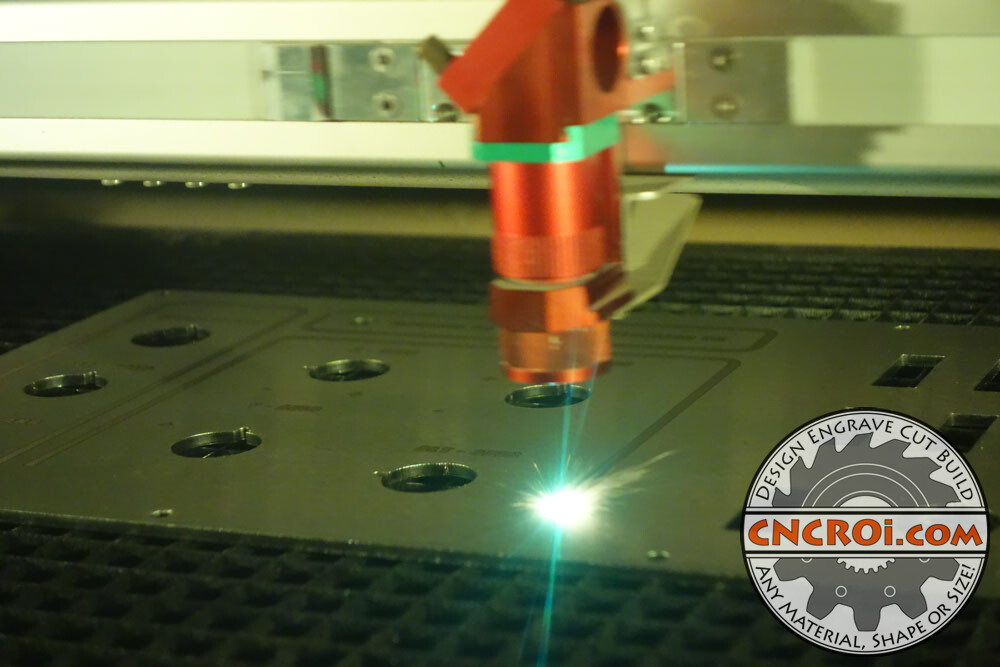

Once the custom steel button panel is actually cut, the next step is etching the surface, regardless of the material you end up using, the process is essentially the same, just differences in laser power and sources or if we are routing it, bits and feeds/speeds.

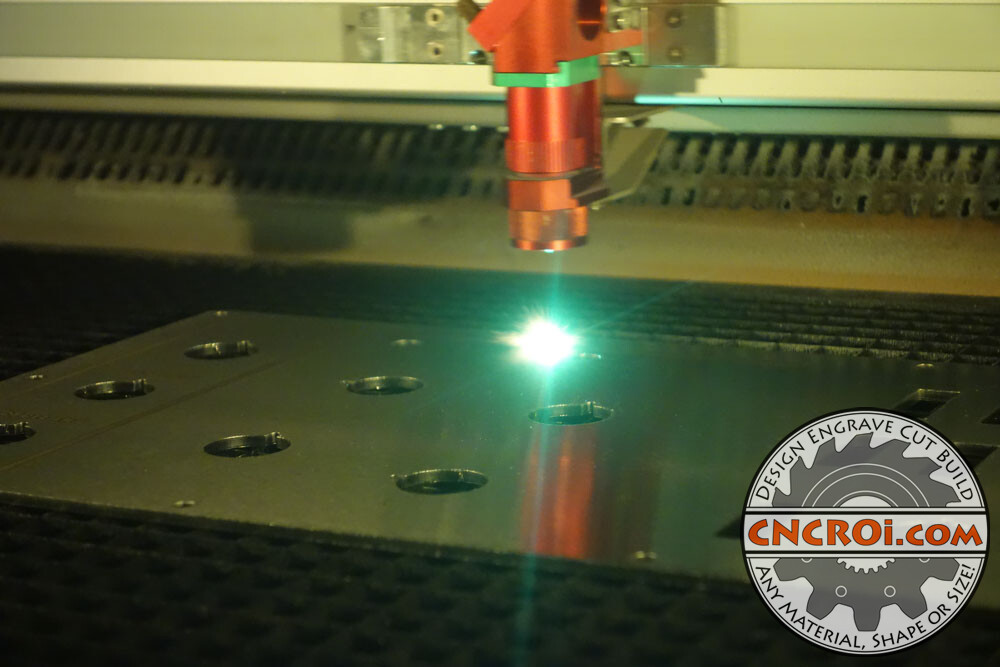

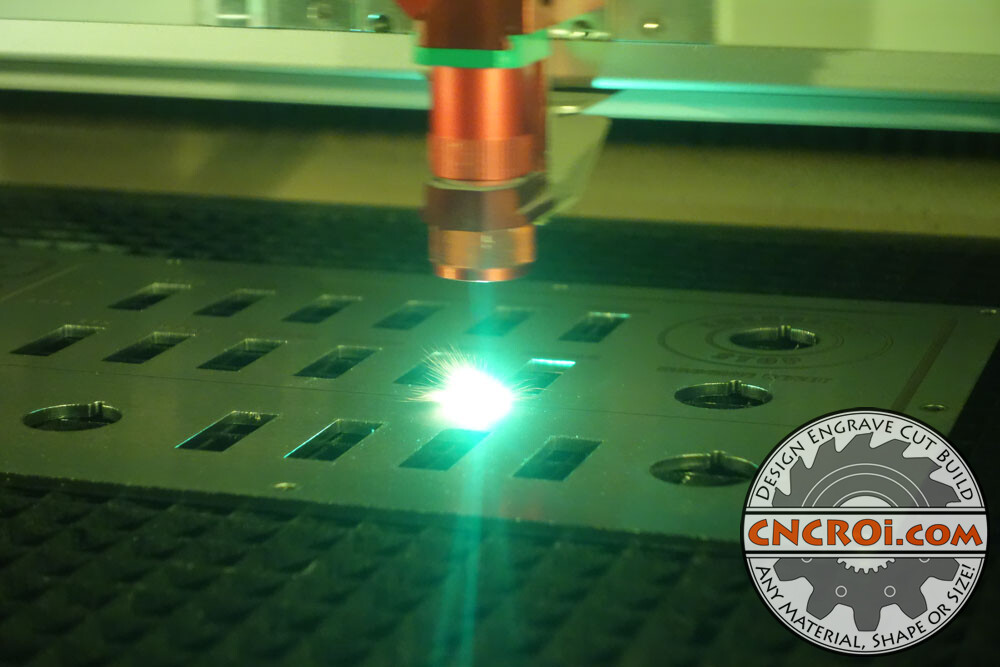

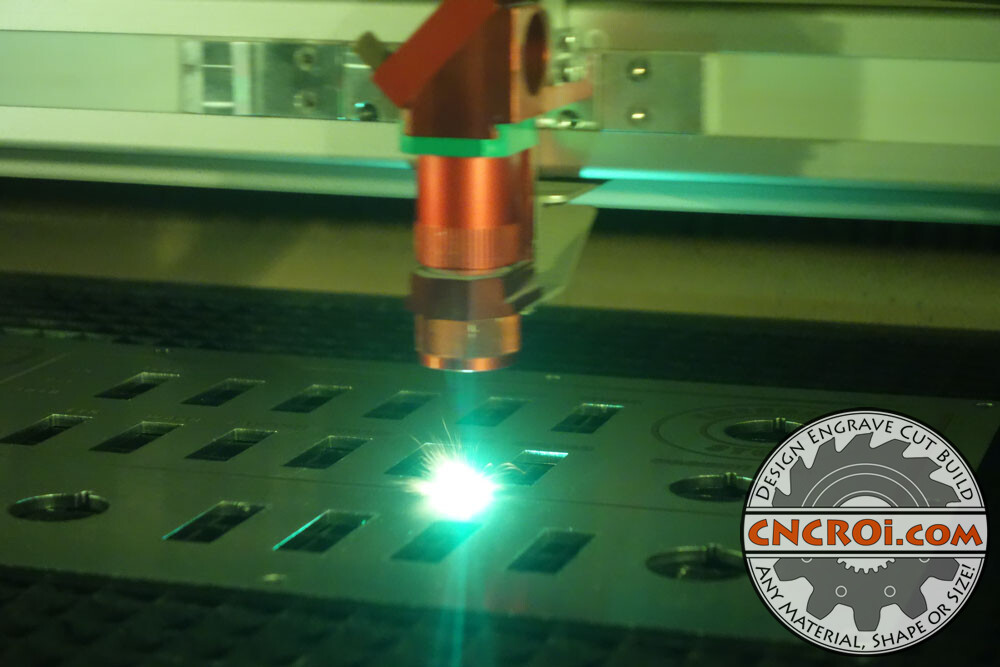

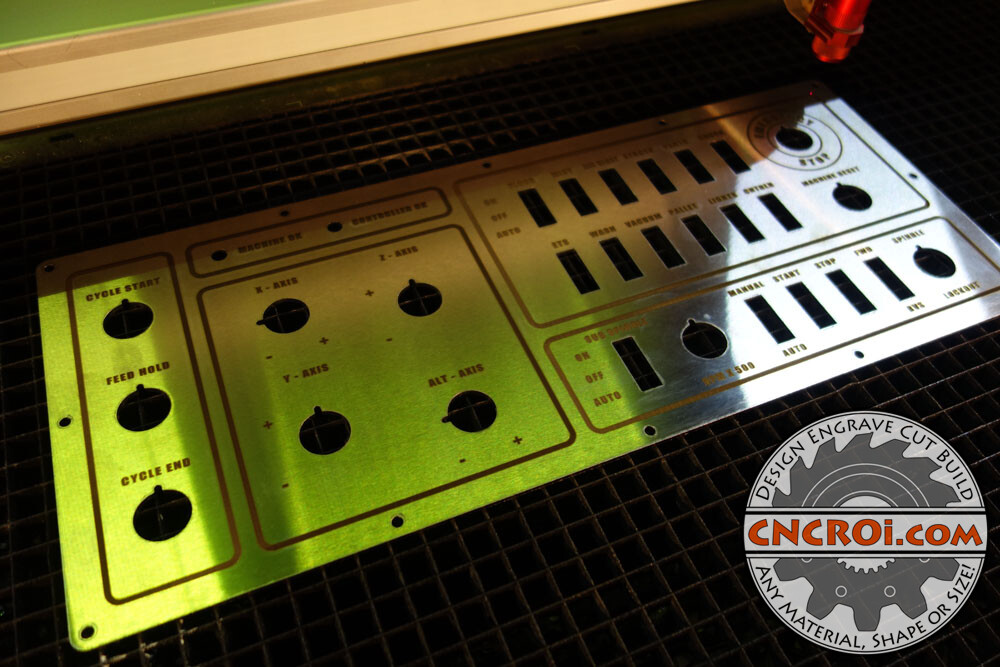

The gold standard, one CNCROi.com has employed for YEARS, is our fiber laser, we have both a galvo based fiber laser and a gantry platform, each has their benefits, for this specific project, the gantry system was by far the best solution though it’s still extremely slow by comparison.

For smaller projects, CNCROi.com‘s galvo does a wonderful job and of course, deep etching is far more cost-effective using this platform as well.

The nice thing about fiber laser etching (in this case) stainless steel #4 finish, is the permanency of the mark, meaning it will not fade, crack or peel over time unlike paint, dyes or name-your-alternative-process.

This means, as mentioned in the video, the etching is PERMANENT, so don’t just double or triple check your writing for spelling mistakes etc… have others quadruple check it as well as once this process is done, it cannot be removed.

CNCROi.com has years of custom industrial fabrication experience, so this custom steel button panel was relatively straight forward, cutting through etching but there are a few factors you need to keep in mind when it comes to this process.

By far the biggest issue we contend with is customers who want their custom steel button panel to be made as thin as possible, the thinner the metal, in this case, stainless steel, the more prone it is to warp from the heat generated by the laser, as such, this custom steel button panel project full of holes, 11 ga was the absolute minimum spec thickness wise that could be considered and honestly, I’d prefer 10 ga if I were to do it again for this CNCROi.com customer.

Of course, not all fiber etching has to be industrial in nature, I made my son Simon’s custom portrait using the same materials as this custom control panel for a very different effect.

The issue isn’t just the heat from the laser but the head build-up in the material itself, from the cutting through the etching, if one area has more heat than another, you guessed it, warping… though for this custom steel button panel we didn’t have any issues but a huge production run of these, going slightly thicker would be a good idea just to make sure.

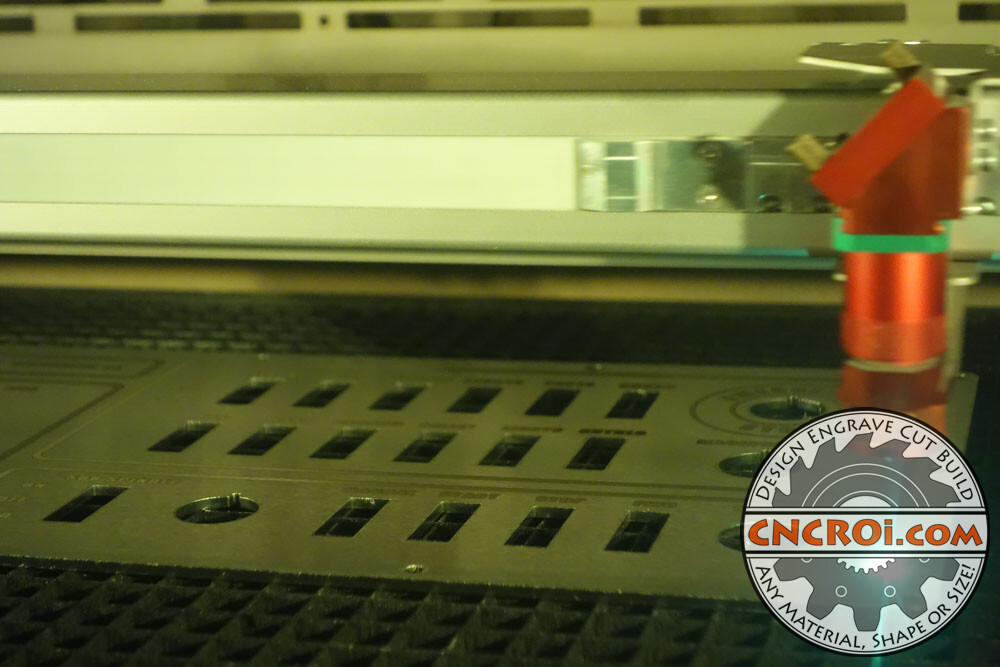

Once the fiber etching is complete, the panel actually looks a little brown from all the heat and debris created by said process at CNCROi.com‘s shop but that stuff comes right off with a cloth.

And there you have it, the complete custom steel button panel cut and etched by CNCROi.com, of course, you’ll notice that most of the jobs we do at our shop involved etching THEN cutting but when it comes to this type of work, I find it easier to do it the other way.

We’ve etched metal of all types and for endless applications, from saw blades to pots and pans, so whatever you need done, we’ve probably done it before.

The nice thing about stainless steel is the aesthetic of it, it fits perfectly in any light or environment, this custom steel button panel is bullet proof and will outlast any components put into it for eons to come.

It’s very hard to photograph and video stainless steel, especially with #4 finish, but you can get an idea of the clarity that’s possible with our fiber laser etching process and the sharpness and high detail we can achieve cutting it out as well.

And here’s a picture of the finished product being assembled by the customer, definitely not an off-the-shelf product and this is where custom fabrication really shines by CNCROi.com.

Funny enough, I was planning on getting a Haas VF2 or Tormach 1100MX a few years ago but ended-up replacing our CNC router instead with a 12 000 pound beast, but having a mill of this size is definitely in my future plans to further augment our capabilities at CNCROi.com.

Need a custom steel button panel? Contact CNCROi.com right now!