Custom Steel Hand Rail: FCAW & SMAW Welding

This custom steel hand rail was my first railling project I’ve ever done and wow did I learn a lot fabricating it using both flux core arc welding for the tack welding and shielded metal arc welding for the bonding at CNCROi.com.

I’ve done a bigger and heavier vault a while back but this was a whole other kettle of fish.

Custom GitHub Arctic Code Vault Fabrication

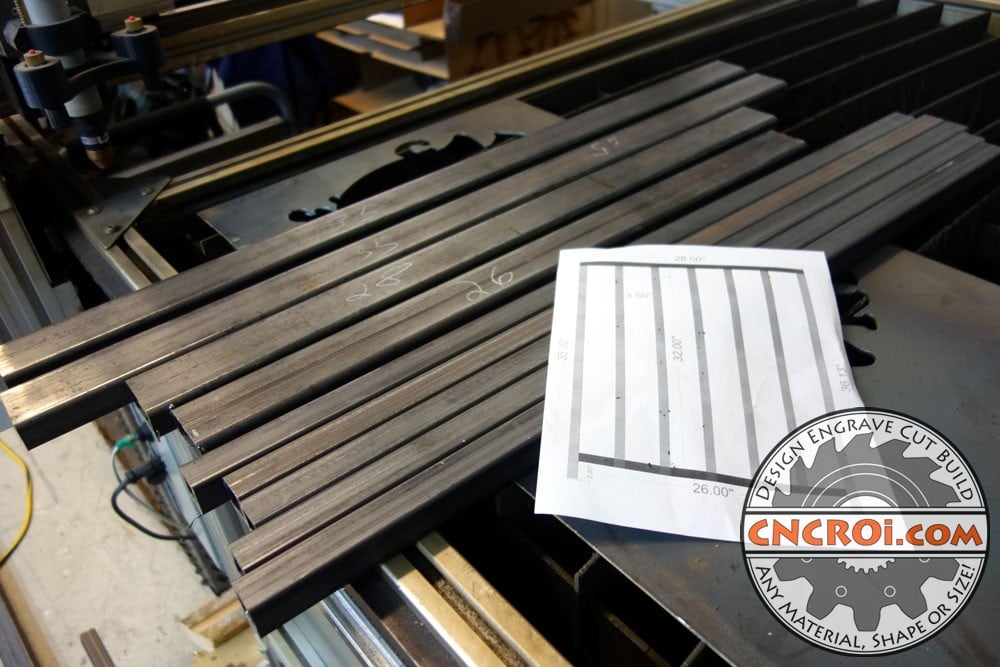

I wanted to make this custom steel hand rail from scatch, so it meant buying tubing that was 24 ft long and chopping it myself to the specifications of the project, material used for this project was as follows

- 3 (quantity) x 1/8″ (wall thickness) x 1″ square x 24′ (length)

- 1 x 1/8″ x 1″ x 2″ x 24′

- 1 x 1/8″ x 2″ square x 24′

This gave me plenty of extras just incase I needed it at CNCROi.com, which, you’ll read at the very end, I did end-up needing as the client wanted an additional 1/8″ x 2″ square segment to make the smaller rail section just a little longer, with the equivalent extra 2″ of 1/8″ x 1″ x 2″ to extend the top of the rail accordingly.

There were two parts ot this custom steel hand rail that would then be welded together on-site for various reasons, as such, being my first railling project, I decided to make the smaller one first and apply those lessons to the bigger one!

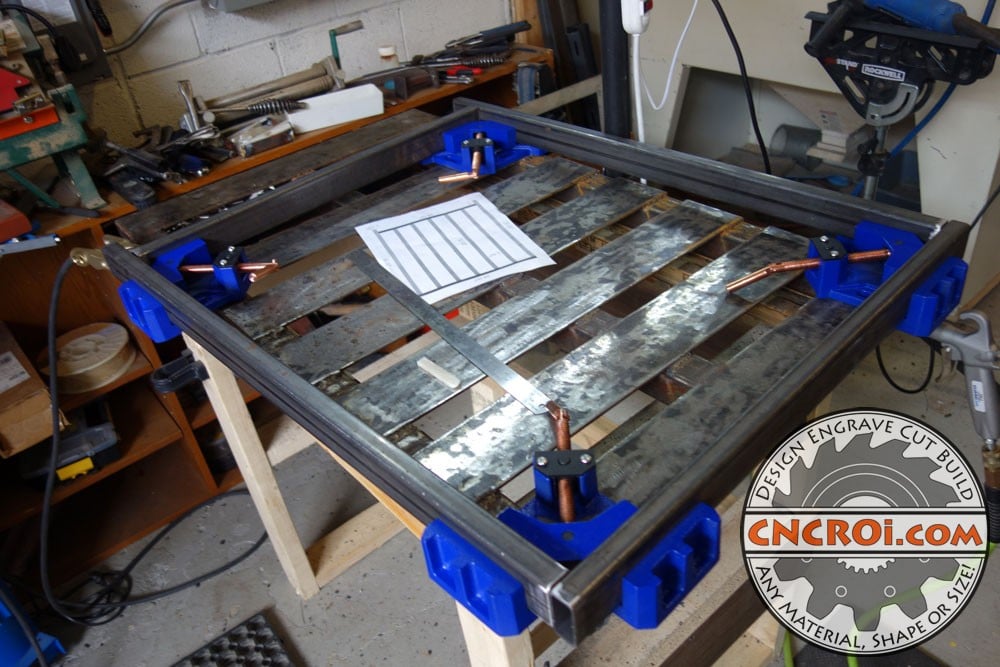

My goal with this project was to be within 1/8″ X, Y and Z, this meant that the railing absolutely must be totally dead square, not having a fixture table (yet), I used corner clamps and lined thing as perfectly as possible before applying my tack welds using flux core arc welding to hold it together before flipping it around and doing the same on the other side (minus the clamps) after everything cooled down.

It’s amazing how little of a weld you need to hold metal together, unlike wood or plastic, a small little tack weld can easily hold a big project temporarily and make sure that nothing moves while doing the full welds that would be coming-up next.

The welding capabilities of CNCROi.com have continually expanded as I go through my two year college course, learning correct processes and methods has allowed me to pick the right machines for the stage of experience that I have and I’ve grown very fond of SMAW (stick) welding due to its versatility across pretty much all metals and processes.

The biggest enemy of welding is heat distortion, it sneaks-up on you and is more powerful than any clamps, so you can’t speed through a project like this if you want to maintain the initial specs assigned to a project like this… it’s so easy to screw this up by using improper procedures!

For the smaller custom steel hand rail segment, I tack welded EVERYTHING on both sides before switching over to shielded metal arc welding (stick), and even then, I was still being very methodical, keeping in mind that each weld was going to pull on the opposite side.

As such, when I made this smaller custom steel hand rail segment, I welded the front and back of the railling then let everything cool down before proceeding to the inside parts, even just a tack weld was plenty strong, then throw onto that full welds on both sides of the spindles, but aesthetically speaking, I needed to weld the inside parts as well.

There were certainly some questionable angles when it came to welding the inside of the spindles as I was severely limited position wise, but I was still getting good penetration and most importantly, worse comes to worse and it was purely a good looking weld, the front and back welds were plenty strong to hold everything in place anyways.

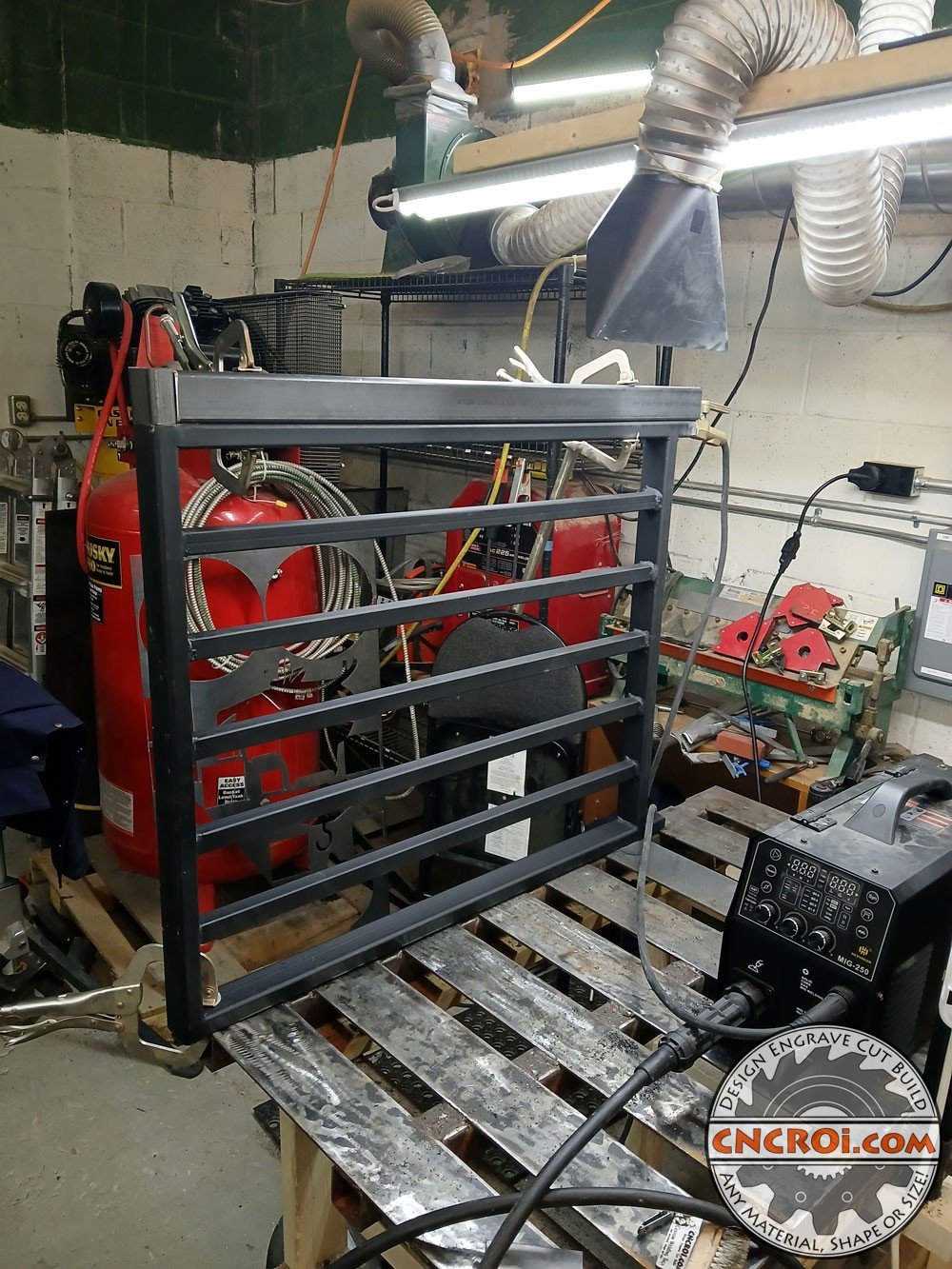

After completing the initial smaller railling segment, it was time to use the angle grinder to make the surface of the larger tubing, which was 1″ x 2″ and 2″ x 2″ with a 1/8″ wall, flush at CNCROi.com.

I’ve been helping welders across North America for almost a decade to brand their own products for repeat business, and I learned a lot from those interactions, and I’m happy to slowly be entering that world as well.

After carefully inspecting the small segment, it was time to switch gears and make the far larger custom steel hand rail segment, this was 3x longer, which means 3x more likely to have heat distortion and 3x more welding!

Like the previous segment, I continued cutting through tubing to create all my parts required for this custom steel hand rail, I rather enjoyed doing this, it’s quite different cutting metal with a chop saw over wood, which I typically cut with another chop saw at CNCROi.com.

As with the smaller railling segment, I used corner clamps for EVERYTHING, I was really debating making this as one large part or splitting it up into different parts then welding it together afterwards but I’m happy I got everything in one shot.

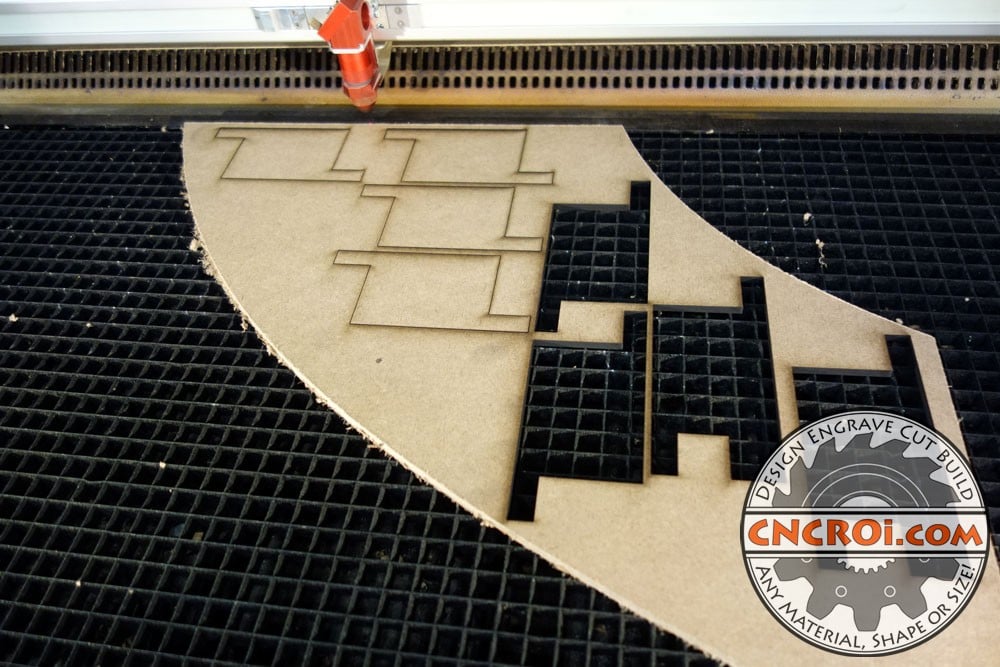

As with the smaller railling, I laser cut guides to make the spindle spacing a no-brainer using quarter inch MDF – regardless of the projects I do at CNCROi.com, if there is a call for something repetitive that doesn’t involve a machine, I’ve learned to get a machine involved somehow and leave my brain outside, regardless of how confident it may be.

With a mix of equipment, I can pretty much fabricate anything and welding was the final piece of the puzzle at the stage my business is now at CNCROi.com.

Something I learned doing this custom steel hand rail at CNCROi.com was that my welding teachers were right when they said that most welding jobs are actually layout jobs, with a little welding at the end… there is so much less “give” with metal over wood and if you screw-up, it takes exponentially longer to fix it!

As space at CNCROi.com is at an absolute premium, I decided to fabricate this larger segment of the custom steel hand rail outside, of course, when the thermometer is getting close to 100

The welding of the custom steel hand rail went exceptionally well outside using the FCAW and SMAW, the frequent water breaks gave time for things to cool and gave me time to review the welds and the overall dimensional measuring of the rail as I was fabricating it.

Plasma cutting has provided me with the caps and the other parts that otherwise I’d need a metal bandsaw in the shop to use with, though I plan on getting one of those eventually just for the extra versatility it can offer my business on projects.

As with the smaller rail segment, I ground down all the welds that were on the 1″ x 2″ and 2″ x 2″ tub parts, the spindles were left as/is for two reasons, one, the welds look great the way they were but more importantly, the angle grinder didn’t fit in there and I was certainly not grinding this by hand at CNCROi.com!

I was very happy with the welds I made using the SMAW process, there was a slight wind but porosity was an absolute minimum, which you can see by the little dots in the image below.

It took me a tremendous amount of time to tack weld this entire custom steel hand rail together and even longer to actually weld it together, but I really enjoy stick welding, I seem to have a lot more control over the end-product with this over FCAW, at least at my level of experience with it at CNCROi.com.

Waterjet cutting metal also provides a great surface, after clean-up, for welding projects, for certain applications, it really is the best tool for the job.

After welding the front and the back of the longer custom steel hand rail, I needed a bit of a break to allow everything to cool so that I could then weld the inner sparts of all the spindles, again, using SMAW but the new novelty this time was night time welding at CNCROi.com!

Night time welding actually welds pretty well, you’d think the darkness would be an issue but it isn’t at all as when you strike an arc, you got a massive light source right infront of you, there is really no difference welding day or night, other than not melting as much under all your personal protective equipment.

Aluminium is a material I haven’t worked with milling or cutting wise but I’m slowly expanding those capabilities as well.

The next step after both railling segments were complete, it was time to add some feel onto them, so they could be screwed by the customer into the flooring their house will have.

For that step, using 12 ga (1/8″) mild steel was more than adequate, this is the same metal that the tubing that makes-up the custom steel hand rail and by extention, the 1/8″ 7018 electrodes I was using for this project, so all the metals are the same.

I have a tough time throwing away “scrap” metal, or any other material at CNCROi.com for that because quite often, I need a little piece and like these railling feet, the scrap has more than enough material in it to be used for the given application.

Now that I know how to weld pretty confidently, I’ll be fixing-up things around the house and I want to make myself a new breakfast table for the house, lots coming soon!

The next step after making the small bottom feet, yes, I wore mostly sandles while welding this project, was to drill holes into them followed by welding them onto the bottom of the custom steel hand rail posts.

As nothing is ever square, parallel or flat in a house, I wanted to bring the railing and do the final welding there to make sure that things were as proper as possible, it doesn’t matter if my specs were dead-on or not, it matters how it looks and is positioned in its final resting place.

After the feet were welded in position, using the same FCAW and SMAW I used for the entire railling project, it was time to paint the entire custom steel hand rail.

Of course, when we did a test fit, we found out that it would look nicer if there was just a little more heft on the smaller rail segment that was against the wall, so I brought that back to the shop and added a 1/8″ x 2″ square tube with an extra 2″ of railing on the top using 1/8″ x 1″ x 2″ tubing.

It was now time to do a little touch-up and get this installed in the house, fully welded and screwed into place!

Here’s what the railing looks like once finished… need something custom, contact CNCROi.com right now!