Custom Steel Plate MDF Jig

This project created a custom steel plate MDF jig using our CNC router at CNCROi.com.

The applications for jigs are endless, each product, whether printed, etched or carved into, in volume, requires a custom jig in order to achieve repeatability and accuracy in a production setting, and yes, CNCROi.com makes those using a variety of materials, MDF through Acetal to Aluminium!

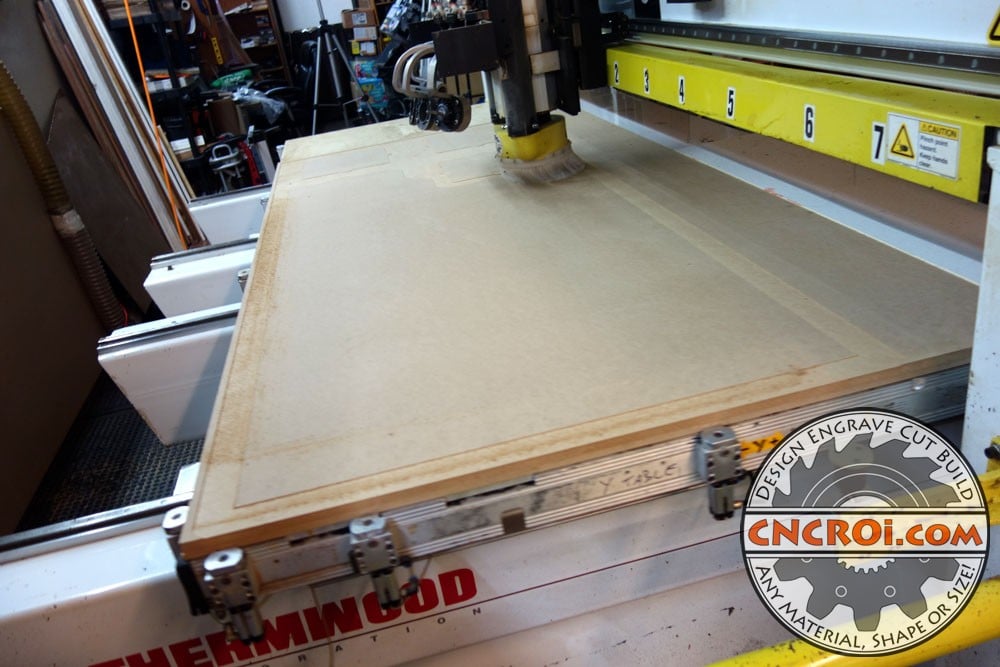

I’m quite busy at CNCROi.com on a variety of projects and initiatives but this is one of the last times you’ll see this spoilboard – I’ve run it down to minimum specs and have since replaced it with a fresh 3/4″ and wow does it seem thick compared to what’s in these photos and videos.

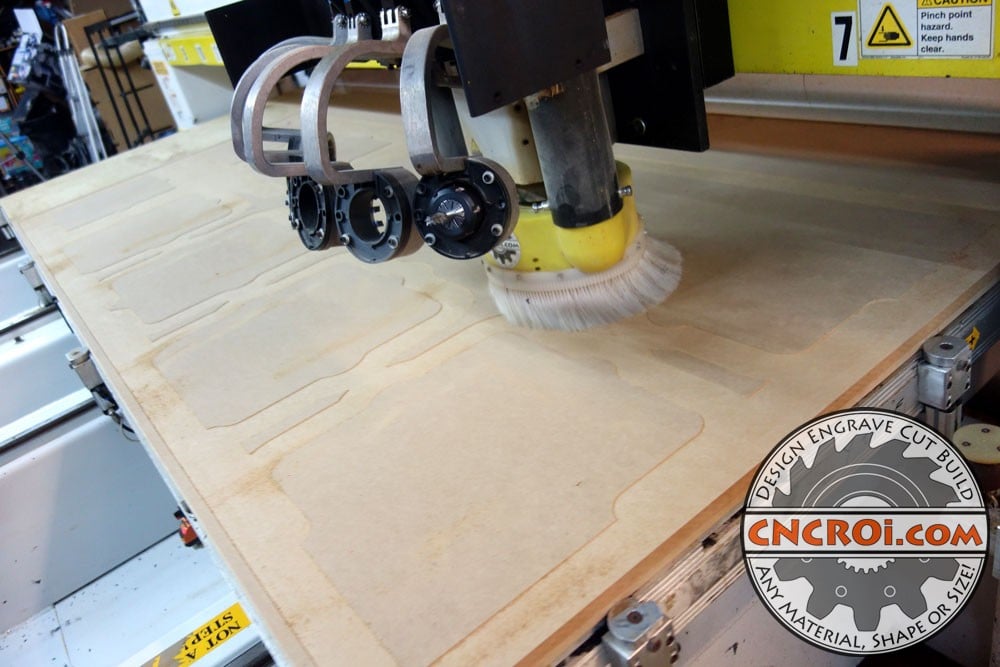

There is a tremendous amount of saw dust created when making this custom steel plate MDF jig, I’m shaving and carving down the MDF and all that very fine particulate dust has to go somewhere.

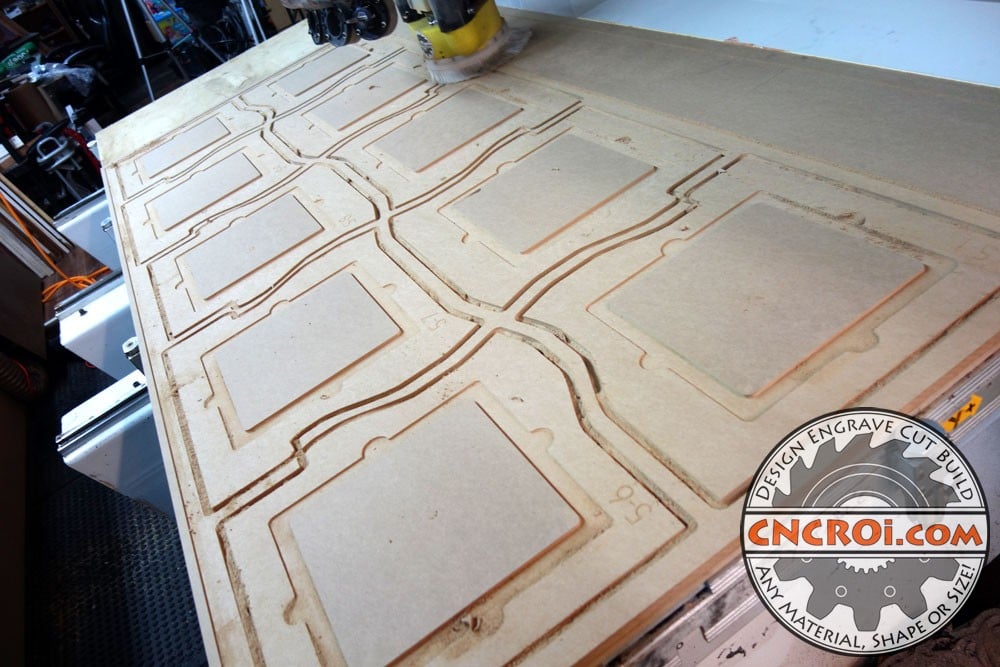

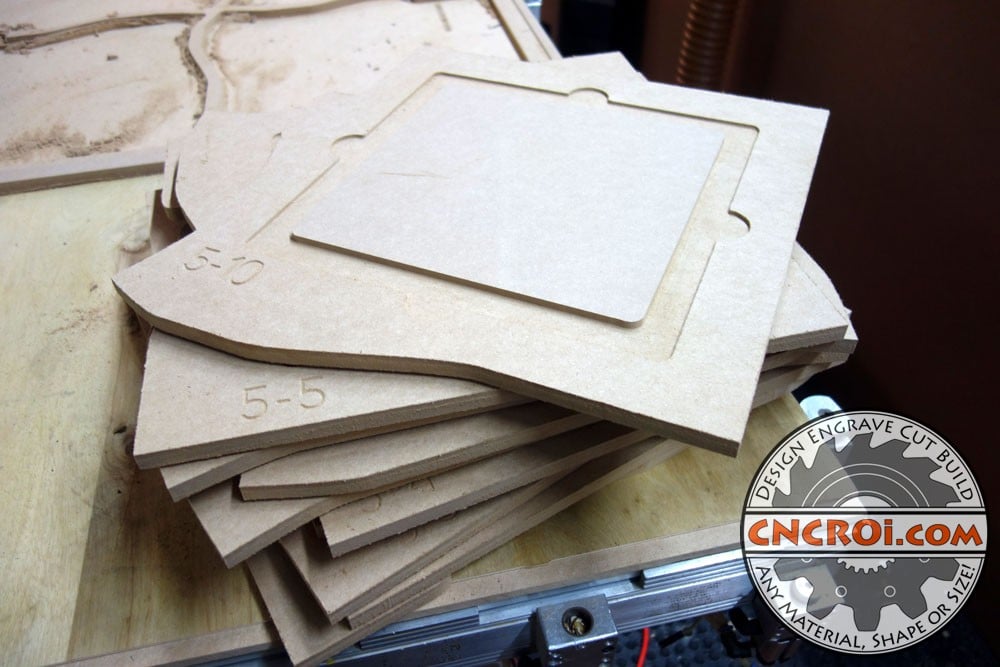

Although this is technically one solid jig, using a jigsaw puzzle type interlocking system makes a lot of sense in a production environment because it allows you to easily move and store this anywhere in the shop when ever it isn’t in use, it’s also less prone to warping and if anything gets damaged, easy enough for CNCROi.com to make that one specific jig again as a replacement at the same spec.

Two-sided jigs are also possible by CNCROi.com, a little bit more tricky depending on your product for various reasons but if that’s what you need, that’s what we make.

CNCROi.com has been making custom jigs for UV printers and other machinery for a decade now, the things my customers come-up with are always fascinating, some are definetley more challenging for a variety of reasons than others.

Each step of the routing process follows the next, meaning, you carve your way through the MDF like a layered cake rather than go plunging at full speed at random depths for this custom steel plate MDF jig.

When it comes to fabricating custom jigs, the typical process for customers is that they start with MDF, regardless of the end-material, this is a wonderful material to both prototype with and smaller production runs because it’s so easy to modify and yet, cheap enough to double-check specs before moving onto far more expensive material options such as plastics and metals.

CNCROi.com also makes jigs and templates using other materials, in this case, it’s for a woodworker who uses it as a guide for the manual router but the same idea can be applied to a UV printer jig for those extra heavy-duty parts where you need something that can widthstand a tremendous amount of abuse.

You’ll notice that what is shaved off the surface of the MDF is dead-flat and parallel, how can I tell? There are no router bit lines, and this is done with a 3″ diameter bit, any X, Y or Z deviations would immediately be visible.

The spoilboard is flattened on a regular basis, and if I have a project such as this custom steel plate MDF jig to make, flattened right before the project is to start, this assures the best possible product is made at CNCROi.com within the tolerances of the expectant customer.

I believe this projects calls on only 4 different bits, haven come from a router that had just one, and it had to be manually changed for over a decade, having access to 19 means that I don’t even bat an eye as a single digit bit requirement for anything at CNCROi.com.

After the initial layer of shaving is complete, the next step is to start carving out deeper cavities into the single sheet of MDF that will hold the lips of the metal objects that will fit on this custom steel plate MDF jig.

Light duty jigs are generally made using acrylic sheets (again, depends on volume and material) but I’ve used these jigs for YEARS at CNCROi.com with little issue.

The nice thing about MDF is that it’s easy to work with, becoming basically dust upon contact from a spinning bit but the major drawback to this is that it also produces a tremendous amount of dust, it’s like you hit a bee hive and you get an exponential increase in surface area coming right at you.

After carving out all the details in this custom steel plate MDF jig, it’s time to begin the process of cutting everything out at CNCROi.com, the reason for the spacing between the puzzle pieces is because you have to account for the bit eating the material, unlike a laser, as such, each part must be cut separated from one another so they may form a completed puzzle.

I believe the material that I made these specific custom steel plate MDF jig puzzle pieces from was 5/8″, the thickness doesn’t really matter, as long as the customer approves and designs accordingly, as they did.

Just about any material can be turned into a custom jig.

Once done, just a little visual inspection is required then this custom steel plate MDF jig can be packed and shipped from CNCROi.com straight to the customer’s front door.

Need a custom jig? Any size, shape or material, contact CNCROi.com right now!