Custom Stencils… any material!

It’s really tough to throw things away at the CNCROi.com shop, as just about anything can become a sample that we hand out or mail to a potential or existing client. These stencils are a prime example, we bought a few supplies and they came in these huge cardboard boxes, rather than recycling them whole, I decided they would be perfect for custom stencils!

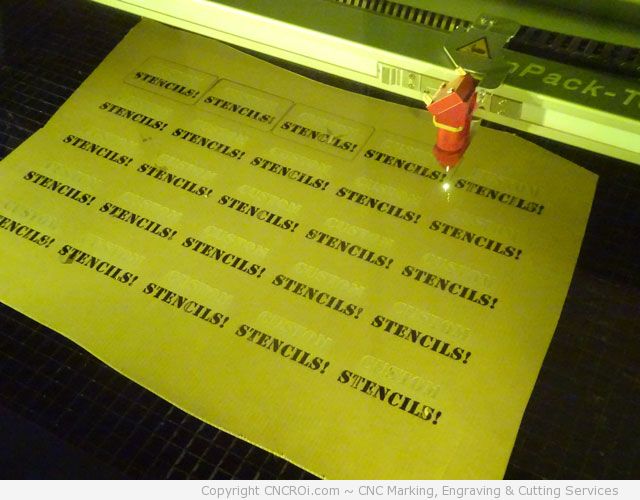

Custom is engraved using our CO2 laser source.

The first step along our custom stencil journey is to engrave things on our samples, this is regular cardboard and I thought it would be cool to show something but cut and engraved into it.

Cutting out the word stencil! using our CO2 laser source.

After the engraving is done on the cardboard, the next step is cutting out the stencil… each step of the way, we remove material without it losing it’s place. Put another way, if we cut out the outlines first then engrave and cut into them, it may allow them to move around. The longer the piece is in ONE PIECE the less prone to production errors CNC laser cutting and engraving is.

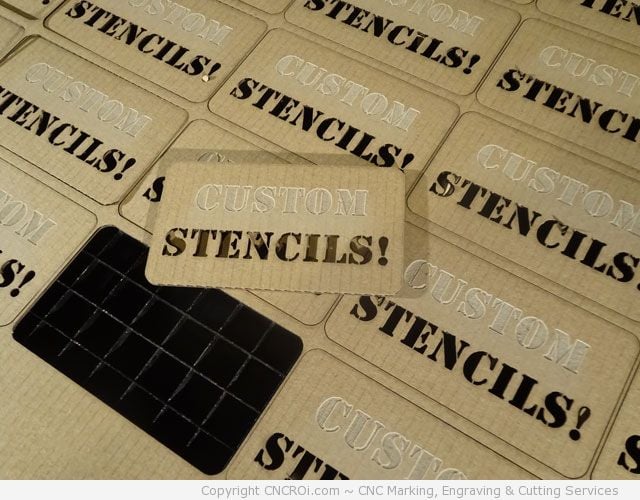

Cutting out the cards using our CO2 laser source.

Now that the engraving (custom) and cutting (stencils!) are done, it’s time to cut out the individual cards! In this case, everything was done using our CO2 laser source, not sure what our fiber would do to cardboard but that’s a blog article best written on another day.

Thin stock cardboard now with custom stencils!

The result is pretty damn cool – these are roughly the same size as a standard business card by the way. Notice the small fraction of a mm of material holding the stencil together. Awesome detail and precision thanks to our Austrian CNC Trotec Speedy 400 flexx laser!

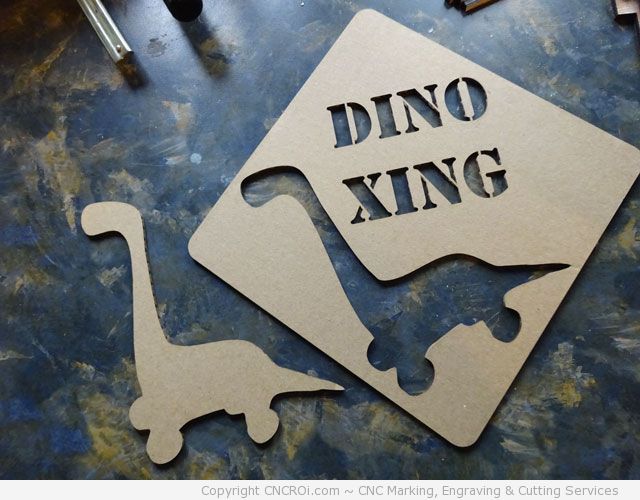

Any material for any application!

In this case, I decided to make the stencils out of cardboard that was heading for the recycle bin, but CNCROi.com could have just as easily made these out of acrylic, formica, foam, wood… even stainless steel! It all depends on the end application and budget, obviously, making these out of solid 316 stainless steel would cost exponentially more than cardboard but if the end purpose was to create a stencil to help label transport ships, you’d be hard pressed even considering using cardboard.

Stencils can come in all sizes and shapes.

Things to watch for

If you want to make stencils, make sure you are using a font that supports it, otherwise you will be stuck trying to glue or put together the insides of letters like d, p, o and so forth. Another common issue is cut lines, make sure that they are closed loops (where applicable). As for resolution, optimized your design to be a vector file and we’ll make sure you get the best result at our end.

Yep, we can make stencils out of the toughest material like formica!

Endless repeatability

The advantage of using CNCROi.com‘s services for custom stencil creation is that our CNC laser is a large format machine, meaning we can make these as huge as you need them to be. Have a design that’s a meter long and 5 meters long? Not a problem, though I wouldn’t suggest using cardboard if you want it to stay in one piece!

Using a CNC machine allows us to easily produce one or a thousand custom stencils, if you need them to be alphanumeric run off a database, again, we’ve done it before and no problem. The first stencil we cut out will be identical to the thousandth thanks to the repeatability of our technology. We also have facilities to use registration points so we can cut out your designs regardless of scale (it scaled automatically to registration points) or position of the end material.

Oh yeah, here’s the video showing the custom stencil production so you can get a feel of how it’s all done! As always, we are just a call or email away… let CNCROi.com how it can be of service to your organization!